For sectors such as dentistry, construction, and even nail care, a fundamental understanding of material properties and their compounds, particularly chemical compounds, is essential. Methyl Methacrylate (MMA) and Polymethyl Methacrylate (PMMA) are two substances commonly discussed in this context. MMA and PMMA are acronyms that resemble each other, but their differences can be crucial for various applications, particularly in terms of safety, usability, and performance. This article uncovers the science, the myths, and the truths surrounding MMA and PMMA and their distinctions, which percent the most impact. This exploration is for both prospective experts in the field and curious learners making informed decisions.

What is PMMA, and how is it used?

Polymethyl methacrylate (PMMA) is a thermoplastic of glass-like optical clarity and reasonable strength. The common name is acrylic, and it is supplied under the brand names Plexiglass and Lucite. PMMA is popular in the construction industry for use in windows and skylights, as well as protective barriers. In the automobile industry, it is used for lenses and light covers. Moreover, the use of PMMA in medical appliances, signboards, as well as various forms of art is growing because of its clarity and versatility. The strength and flexibility of PMMA –particularly its optical properties- make it appropriate for a wide range of everyday and specialized applications.

The Nature of PMMA and Its Properties

Acrylic glass, or Polymethyl methacrylate (PMMA), is widely known to be a lightweight and durable substitute for glass. It boasts a near density of 1.18g/cm barb, making it relatively half the weight of glass. PMMA has a strong impact resistance and optical clarity which means it can serve for protection while still allowing light transmittance of up to 92% so that important visuals can be see without hinderance.

With advancements being made to the manufacturing techniques of PMMA, there has been a notable reduction in the negative environmental impact. Such developments, including bio-based PMMA sourced from renewable materials, greatly lessen the carbon footprint in comparison to petroleum counterparts. PMMA is also 100% recyclable because it can always be converted back to its monomer methyl methacrylate (MMA) through thermal or chemical means, allowing for performance devoid of reuse.

Weathering elements such as unfiltered sunlight tend to be destructive, however, PMMA embraces them with open arms. Its yellowing-resistant strength, coupled with unmatched UV relentless exposure, prolongs its performance, making PMMA components essential in durable, demanding industries needing lasting clarity.

Recent research shows that PMMA is increasingly used in high-tech applications like optical fiber, OLED screens, and lightweight composites in the automotive and aerospace industries. For instance, PMMA is used in OLED lighting because it enhances aesthetics by diffusively and evenly radiating light, but more importantly, energy is saved. Also, its medical applications have widened, notably with intraocular lenses for cataract surgeries and bone cement, where PMMA is used because of its biocompatibility and moldable qualities.

These developments illustrate the continuing ingenuity with which PMMA responds to new challenges in different fields, reinforcing its claim to being one of the most adaptable and essential materials of our time.

Common Applications and PMMA Products

PMMA, or acrylic and acrylic glass, is used in numerous applications owing to its superb characteristics like weather resistance, clarity, and durability. A detailed summary of its common applications and products is given below:

- Optical Applications

-

-

- Lenses for glasses

- Contact lenses

- Optical fibers used for telecommunication

- Light diffusion panels in LED lighting

-

- Automotive Industry

-

-

- Headlight and taillight covers

- Windshields for motorcycles and aviation

- Interior decorative trims

-

- Construction Materials

-

-

- Windows and skylights

- Noise barriers along highways

- Shower doors and partitions

-

- Medical Applications

-

-

- Intraocular lenses for cataract surgery

- Bone cement for orthopedic procedures

- Dental prosthetics and retainers

-

- Retail and Advertising

-

-

- Storefront displays

- Signage and illuminated panels

- Point-of-sale displays and product holders

-

- Consumer Goods

-

-

- Aquariums and terrariums

- Picture frames and display cases

- Furniture elements like tabletops and chairs

-

- Industrial Use

-

-

- Protective covers and enclosures

- Equipment guards and shields

- Molded components for machinery

-

These many uses illustrate the importance of PMMA for various industries as it combines utility and beauty, hence always remaining in global demand.

How is PMMA Used in Medical Devices?

The technological advancements in healthcare have been made possible by the use of newer materials. One such material is PMMA, which is widely known as polymethyl methacrylate. Moreover, its optical clarity and durability make it biocompatible. For these reasons, it is commonly used in the medical field. One of its main uses includes the production of bone cement, where it is utilized to secure prosthetic implants like hips and knees. It provides stability and lowers the possibility of implant migration. Studies show that PMMA-based bone cements possess remarkable mechanical characteristics, enabling aid in load distribution with long-term success of the implant.

Also, PMMA is used in the manufacturing of intraocular lenses (IOLs) required for cataract surgeries. PMMA enhances the vision quality of millions of patients every year, owing to its optical clarity and high refractive index, which makes it a suitable material for the lens. Apart from that, it is widely used in cranial and facial reconstruction surgery, where it is molded into the desired shape and fixed to the patient as an implant. Data shows that PMMA implants possess low infection rates while providing high customization, improving surgical precision and outcomes.

Moreover, the material is used in dental works such as dentures and orthodontic appliances as they are lightweight and can be fabricated easily. In addition, the ability of PMMA to be sterilized without degradation means it meets strict medical safety guidelines. These various applications serve as an indicator of PMMA’s important role in the progress of medical technology and global patient care.

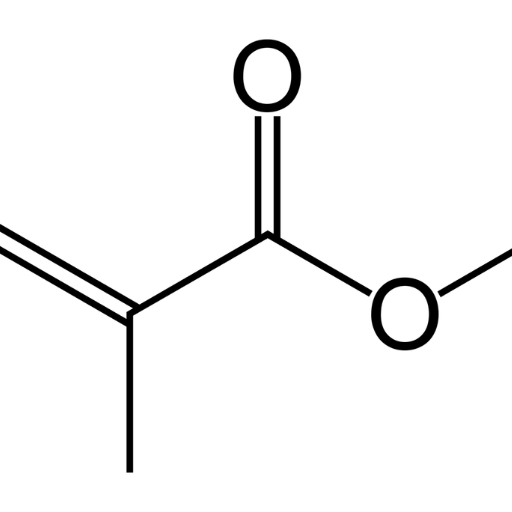

Understanding MMA: Methyl Methacrylate Explained

Methyl Methacrylate (MMA) is a clear, flammable liquid mainly utilized in the production of polymethyl methacrylate (PMMA) and other acrylic materials. MMA earns its worth due to the capacity of forming strong, transparent, and long-lasting plastics. Methods like acetone cyanohydrin or ethylene processes produce MMA and guarantee economy and productivity. Current uses include shatter-proof glass, auto parts, medical prostheses, and coating elements. Although MMA has many applications, it must be dealt with cautiously due to being highly flammable and volatile.

What is the MMA Monomer?

Methyl Methacrylate (MMA) is a multifaceted monomer with remarkable characteristics and numerous industrial uses. It is best known for being a precursor to Polymethyl Methacrylate (PMMA), a glass-like, lightweight, and shatterproof material found in display screens, skylights, aquariums, and even airline windows. MMA’s chemical structure ensures high-solubility optical clarity for transparent materials.

Furthermore, MMA is significant in the automotive and building industries. It is used in the manufacturing of automotive lenses and panels, as well as in high-performance coatings due to its scratch resistance, durability, and ultraviolet light tolerance. This increases the life span of products, thereby decreasing maintenance expenditures.

The global MMA production illustrates growing demand for various industries. Recent statistics indicate that the MMA market is anticipated to obtain a total worth of around 15 billion dollars by the year 2030 because of the increasing use of PMMA, innovation in adhesives, paints, and medical technologies, and new advancements. MMA-based resins are also modernizing dental and orthopedic devices because of their biocompatible mechanical structure and high strength.

It’s distinguished by high hardness, long-term stability, and resistance to chemicals and environmental degradation. However, because of its volatile nature, MMA facilities must follow rigorous safety procedures, as mismanagement poses health or fire hazards. Conducted research expands the application scopes of MMA, designating it as essential in contemporary manufacturing and technology.

Characteristics and Uses of Methyl Methacrylate

Methyl Methacrylate (MMA) is a quite popular compound that caters to the needs of several industries. Methyl isomer’s polymer exhibits a refractive index of approximately 1.49, is optically clear and weather resistant. Because of these beneficial properties it is able to produce Polymethyl Methacrylate (PMMA), acrylic or plexiglass is frequently known as this. PMMA is strong, lightweight, and highly durable which leads it to be used widely in protective barriers, optical lenses, glazing and many more.

The impact resistance and aesthetic properties of MMA make it an ideal substance to use in the automotive industry too. Polyacrylate derived materials are widely used for car interior components, headlight covers and several other lightweight parts. Similarly, MMA is used in construction for noise barriers, skylights and signage due to clarity and strength requirements.

MMA is useful in Prosthodontics. It can be used for dental prosthesis, bone cement and implants because of the biocompatibility. Manufacturing solutions benefit from the adaptability of the compound. The invention of 3D printing technology allows for precise and durable custom solutions.

Analysts from outside expect the global size of the MMA market will surpass 9 billion by the year 2027. This is due to the emerging economies and innovating technology. With these estimates, it shows the booming is declining to pay attention to eco-friendly sustainable materials.

The Polymerization Process of MMA

The MMA (methyl methacrylate) polymerization process of MMA monomers is done through the free radical polymerization technique, which creates long-chain polymers. I know this procedure undergoes the three steps of initiation, propagation, and termination, all of which take place after a catalyst or initiator is used to start the reaction. PMMA (polymethyl methacrylate) is produced as the primary product, which is a universal and tough material with numerous uses owing to its transparency, robustness, and ability to resist exposure to the elements.

Is PMMA Plastic Safe to Use?

Yes, PMMA plastic is considered safe to use. PMMA is non-toxic, does not emit harmful chemicals under normal conditions, and is widely employed in the medical field as well as for food-related purposes, such as in dental prosthetics and containers for displaying food. Its safety, non-shattering food display windows, and lens security ensure safety for scenarios where Hygiene is paramount. Albeit, like most other plastics, it should not be subjected to very high temperatures or exposed to open flames, as this could cause the PMMA to break down or give off fumes.

PMMA and Human Health: Is it Safe for Use?

Polymethyl methacrylate (PMMA) is considered safe for use in medical and food-related applications because of its non-toxic nature, hence, methyl methacrylate polymerization does not harm the host. PMMA is biocompatible because it does not leach any detrimental substances or additives into its surrounding environment. Therefore, owing to its non-leaching nature, it is trusted for use in dental implants, intraocular lenses, and even food display cases.

PMMA has been proven to have low microbial growth and is exceptionally durable, contributing to the sanitation requirements in hospitals and even food storage facilities. However, PMMA still poses some health threats. Abrupt and uncontrolled exposure to high levels of latent heat may lead to melting which releases irritating vapors and low concentrations of volatile organic compounds (VOCs). However, these fumes are said to irritate the lungs when inhaled. These risks can be minimized, when the suggested handling methods and usage guidelines are precisely followed.

All in all, PMMA proves to be a long-lasting and reliable choice for industrial use or personal utilization due to its temperature sensitivity, provided these boundaries are respected.

Safety Standards and PMMA’s Biocompatibility

Polymethacrylate, or PMMA as it’s known in short, is famous globally for its use in medical devices like intraocular lenses and bone cement as it passes tests for strict surgical safety and quality norms in medicine, construction, and automobiles, not forgetting engineering on the whole. Its services are accepted in various countries, including the US (FDA), Europe (REACH), and ISO, as to why subject them to boring guarantees, when in reality, it is multifunctional as a means.

Having profound results from biocompatibility tests and showing little to no cell damage, PMMA is non-allergenic to the majority of the general most population. This allows it to be widely used as a choice in implants and prosthetics. Further, further documentation states that over 90% observed in regions like orthopedic applications are proving the greatness of PMMA implants in long-term stability, integration to the body, and overall patient acceptance ratio standard. Following this, the hydrostatic tension resistance PMMA holds proves its superiority in low tension environments, safeguarding its position as an eco-safe material while international standards of safety rely on it. Therefore, proving how adaptive yet diverse materials can act in construction.

These characteristics strategize PMMA as a multi-functional material, the more diverse range it performs in.

Comparing PMMA and MMA: Which is Safer?

As both materials have their pros and cons, PMMA offers a better option in terms of safety than MMA due to the structural stability and biocompatibility of PMMA. MMA undergoes polymerization into PMMA. In addition, MMA is a dangerously flammable monomer that tends to emit strong fumes and irritate during use. On the other hand, PMMA is a polymerized stable compound that carries none of these dangers. Furthermore, the durability of PMMA, coupled with its nonreactivity, in addition to its trusted performance in the medical industry, amplifies the safety of PMMA over MMA.

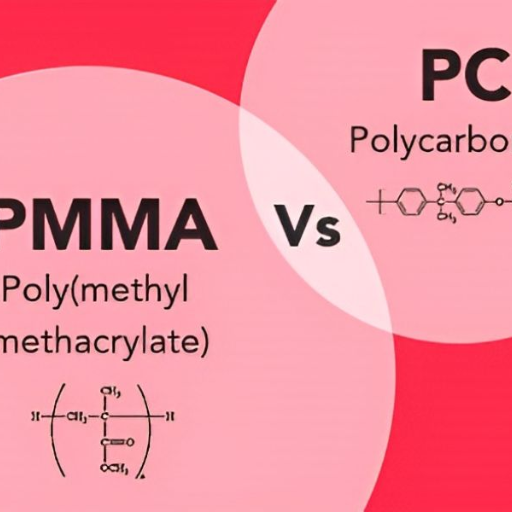

Impact Resistance and Durability

In comparison to traditional glass, PMMA provides superior impact resistance, albeit being lighter and more versatile. Protective barriers, automotive components, and moderate impact forces are example applications studied, which illustrate PMMA’s popularity for withstanding shattering forces. Although PMMA’s impact resistance is somewhat less than other plastics such as polycarbonate (PC). Used in the same context, polycarbonate materials are approximately 250 times more resistant to impact than glass, whereas PMMA’s resistance is only ten times that of glass. Such comparisons emphasize the requirement for material-based decision making depending on the intended use.

Moreover, PMMA boasts excellent durability. It is well known for having high resistance to the sun’s UV rays as well as the weather, delivering construction grade efficacy for outdoors. As a reliable and adaptable industrial PMMA’s performance is withstanding many acids and alkalis, reinforcing its reputation. Also, its surface hardness surpasses other plastics, providing increased resistance to scratching while retaining transparency and visual appeal.

Environmental Factors: Recycling and Sustainability

In my observation, PMMA takes the lead for being recyclable and the most useful in sustainable development. It can be converted into many new products which lowers waste and its carbon footprint. If we start practicing recycling, we can sustain the life of PMMA products and shift to a greener economy.

Human Health and Safety Standards

For PMMA (Polymethyl Methacrylate), there is no known risk to human health pertaining to safety and its applications. Medical devices as well as food storage containers, and furniture pieces can be manufactured using PMMA as it does not emit toxic by-products during its use. The latest studies show, PMMA passes rigorous tests like those conducted by the FDA and the EU for materials intended for food contact. Additionally, the shatter resistance property of PMMA minimizes the chances of injury in sensitive areas like hospitals and other public places. This indicates how the focus of an industry can improve the quality of life through the proper use of regulated PMMA.

How Does Polymerization Affect PMMA and MMA?

The process which changes methyl methacrylate (MMA) monomers into polymethyl methacrylate (PMMA) polymers is called polymerization. The chemical reaction links MMA molecules into extensive chains which gives PMMA its tough and inflexible structure. The material gains important attributes such as high resistance to weather and impacts, transparancy, and strength which increasses its value in a wide array of industries.

The Process of Polymerizing Methyl Methacrylate

The innovation of polymerizing methyl methacrylate(MMA) in recent years is due to the effectiveness of the process and the quality of the output. Modern techniques, such as bulk and solution polymerization, have streamlined the process of growth to have better control over energy consumption as well as the molecular weight distribution. For instance, bulk polymerization is becoming popular as a green methodology for PMMA production due to its high purity, and so the solvent-free process is being adopted widely.

According to recent statistics, the demand in the global PMMA market is expected to rise with a compound growth rate of 6% through 2030, catalyzed by the construction, electronics, and automotive sectors. Further boosting the application of PMMA in high-tech domains such as solar panels and LED light guides is the material’s having exceptional optical clarity, low weight, and chemical resistance. Such technology emphasizes the need to enhance the polymerization processes to cope with the fast-rising demands of the market while ensuring eco-friendly practices.

The Role of Polymers in Enhancing Safety

Polymers provide innovative solutions to modern challenges, especially for industry-specific needs. Their benefits are seen in the airbag and seat belt technology, as well as in the production of shatterproof windows and fire-resistant materials in the automotive sector. Preliminary reports show around 6% annual growth for polymer composite usage in vehicle safety systems and project a rise in global fire-retardant polymer use to $8 billion by 2025. Increasing global safety and autonomy regulations are expected to drive efficiency in these sectors as well.

Polymer materials, like thermoplastics, are heavily utilized to manufacture personal protective equipment (PPE) such as protective shields and helmets. This promotes improved workplace safety. They also play an important role in the medical field, with biocompatible polymers like polyethylene and silicone being used for prosthetics and advanced surgical tools. Such features highlight the versatility of these materials, reducing the chance of critical medical equipment failure, thus promoting safety and reliability in essential procedures.

This shows that industry regulations dealt with safety consider injury risks and protection hazards. Meeting safety standards increases the estimated value of polymers and elevates industry reliance on such materials. The beneficial features of polymers emphasize their fundamental place in the global mission to provide safer settings, reiterating the global burden sharing directly reduces their availability, thus making every effort count.

Polymers play a pivotal role in advancing safety across various industries by delivering innovative solutions tailored to meet modern challenges. For instance, in the automotive industry, highly engineered polymers contribute to the production of airbags, seat belts, and impact-resistant bumpers, significantly reducing injury risks during accidents. According to recent market insights, the use of polymer composites in vehicle safety systems has grown by approximately 6% annually, driven by increasing regulatory standards for safety and efficiency.

Similarly, in construction, polymers like polycarbonate and PVC are vital in manufacturing shatterproof windows, fire resistant materials, and protective coatings. Statistics indicate that the global use of fire retardant polymer materials is projected to reach $8 billion by 2025, illustrating their crucial role in mitigating fire-related hazards. Additionally, thermoplastics are widely utilized in personal protective equipment (PPE), such as helmets and protective shields, further bolstering workplace safety.

The healthcare industry also benefits immensely from polymers, with biocompatible materials used in advanced surgical tools, prosthetics, and other medical devices. For example, polyethylene and silicone-based polymers have improved safety compliance, durability, and adaptability in critical medical applications. Such widespread utilization highlights the indispensable role of polymers in fostering safer environments worldwide.

What are the Advantages of Using PMMA?

Polymethyl methacrylate (PMMA) or acrylic is a polymer that has its advantages:

- Transparency: PMMA weighs lighter than other glasses while retaining comparable glass-level clarity.

- Lightweight: PMMA is easily shaped, adapted, and molded for use in applications such as skylights, vehicle windows, and medical devices.

- Durability: Weathering, UV light, and impact do not deteriorate PMMA, ensuring long-lasting performance.

- Versatility: PMMA allows up to 92% light transmission, ensuring high transparency which is required in displays and optics.

- Cost-effectiveness: PMMA outperforms glass and other functional materials, making it the more affordable alternative.

The properties listed above make PMMA widely used in various industries of construction, automotive, healthcare, and design.

Optical Clarity and Refractive Index

Polymethyl methacrylate or PMMA is well-known for its fabulous optical clarity, surpassing glass with a light transmittance rate of 92%. PMMA is a preferred material for lenses, display screens, and LED diffusers that require extreme light transmission. Moreover, it has a refractive index of roughly 1.49, showcasing a perfect balance between clarity and light manipulation.

Its resistance to UV radiation is even more appealing as PMMA can be used for high illumination or outdoor applications. It doesn’t degrade or become discolored over time which enhances its reliability for long term use. Its PMMA’s blend of stability and clarity make it essential for industries spanning optics to advanced display technologies.

Applications as a Substitute for Glass

The listing usages of PMMA is paralelly matched with the history as an excellent glass substitute because of its lightweight, clarig and simple construction with effortless moldability.

- Automotive Industry

-

-

- Employed in the manufacturing of vehicle headlights and taillights owing to its impact resistance and high light transmission.

- Used in the manufacturing of sunroof panels which are lightweight and durable which reduces the overall weight of the vehicle.

-

- Construction and Architecture

-

-

- Commonly used for skylights, windows, and partitions because they do not shatter easily and can withstand the test of time.

- Often used in the making of greenhouses as an economical and lighter alternative to standard glass panels.

-

- Electronics Display Panels

-

-

- Used in the manufacturing of screens and covers for electronic gadgets as it does not scratch easily and has good optical properties.

-

Used in LED screens, control panels, and instrument clusters out of light-diffusing material.

-

- Medical Industry

-

-

- Best suited for the creation of incubators and protective shields in clean room settings due to its transparency and cleanliness.

- Applicable in medical devices like dental prosthetics and optical lenses because of its biocompatible properties.

-

- Advertising and Retail

-

-

- Indispensable for the production of illuminated signs and display cases as well as protective barriers, due to its optical clarity.

- Applicable in POP (point of purchase) displays and as decorative panels for enhanced aesthetic value.

-

- Aerospace

-

-

- Very useful for aircraft windows and cockpit canopy construction because of its lightweight, strength, and resistance to harsh conditions.

-

Useful in cthe onstruction of covers for drones to shield delicate instruments without significantly increasing overall weight.

-

- Aquariums and Water Features

-

-

- Usually regarded as posting material for fish tanks due to its clarity and strength against water pressure.

- Perfect for fountains and water decorations where transparency is important.

-

- Optical and Lighting Applications

-

-

- Important in the manufacturing of lenses, prisms, and other optical elements for microscopy-grade applications.

-

Commercials for light sets used in cars, streetlights, and even fancy places make use of this material.

-

The adaptability of PMMA in such cases demonstrates its ever-increasing importance as a replacement for conventional glass in achieving sustainability, reduced cost, and performance optimization.

The Glass Transition Temperature and Stability

The glass transition temperature (Tg) of PMMA is around 105°C (221°F) which indicates the point where the material moves from a stiff, glassy state into more of a rubbery or flexible state. This property is why PMMA can be used in applications that need precision and high functioning in controlled and uncontrolled environments.

The stability of PMMA stems from its thick polymer chains which are not prone to degradation from UV light and remain clear and strong with aging. It is known that PMMA has the best resistance outperforming other polymers to cracking due to thermal stress with thermal expansion coefficients usually 70–90 x 10⁻⁶/K. Besides, PMMA withstands moist conditions and most acids and alkalis which makes it dependable in exposed and sheltered conditions.

A well-defined Tg together with chemical stability makes PMMA wanted in aerospace, automotive, and construction industry where materials undergo physical and thermal abuse. With no or minimal structural change and degradation, PMMA provides excellent performance and minimizes the products used in its construction throughout its lifespan.

Reference Sources

- Surgical Applications of Methyl Methacrylate1:

- Focus: This review examines the toxicity of MMA in surgical settings, comparing it to PMMA.

- Key Findings: PMMA is less toxic than MMA monomers. The study highlights PMMA’s reduced biological reactivity and its safer profile in medical applications.

- Methodology: A comprehensive review of existing literature on MMA toxicity and PMMA’s role in mitigating risks.

- Methyl Methacrylate and Respiratory Sensitization2:

- Focus: This study investigates respiratory sensitization caused by MMA and PMMA dust exposure.

- Key Findings: MMA is identified as a significant respiratory sensitizer, while PMMA shows minimal sensitization effects.

- Methodology: Analysis of case studies and safety data sheets to evaluate sensitization risks.

- Updated Review on PMMA Modifications and Applications3:

- Focus: This review explores advancements in PMMA’s polymerization, recycling, and applications.

- Key Findings: Cross-linked PMMA demonstrates superior mechanical and thermal properties, making it ideal for diverse industries, including healthcare and construction.

- Methodology: A detailed review of polymerization techniques and the impact of additives on PMMA’s properties.

- Top PMMA Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What is the difference between PMMA and MMA?

A: PMMA, or polymethyl methacrylate, is a type of acrylic plastic that is made from the polymerization of MMA, or methyl methacrylate monomer. While MMA is a liquid monomer, PMMA is a solid material known for its high resistance and impact strength.

Q: Is PMMA safe for use in products that come into contact with food?

A: Yes, PMMA is generally considered safe for applications that require contact with food, as it meets food safety standards set by regulatory bodies like the Food and Drug Administration. However, it’s essential to ensure that the specific PMMA product is certified for food safety.

Q: What are the characteristics of PMMA that make it a versatile material?

A: PMMA is known for its optical clarity, high impact strength, and resistance to UV light and weathering. These properties of PMMA make it an ideal choice for various applications, including acrylic sheets and lucite products.

Q: Can PMMA cause allergic reactions or skin irritation?

A: PMMA is generally safe for humans and does not typically cause allergic reactions. However, during the production of PMMA, good ventilation is necessary to avoid inhaling any fumes from the liquid monomer. Skin contact with the monomer MMA should be minimized to prevent irritation.

Q: Why is PMMA considered a better option than MMA in terms of safety?

A: PMMA is considered safer than MMA because it is a stable polymer, whereas MMA is a reactive liquid monomer. The process that breaks down PMMA, known as polymerization, chemically stabilizes the material, reducing the risk of health issues associated with volatile organic compounds.

Q: How is PMMA used in different industries?

A: PMMA is used in a wide range of applications due to its advantageous properties. It is commonly found in products like acrylic sheets, optical lenses, and medical devices. Its high resistance and clarity make it suitable for both industrial and consumer products.

Q: What type of acrylic is PMMA, and what are its advantages?

A: PMMA is a type of acrylic plastic known for its clarity, durability, and versatility. The advantage of PMMA over other plastics includes its excellent optical properties and high impact strength, making it ideal for applications that require transparency and durability.

Q: How does the polymerization of MMA contribute to the safety of PMMA?

A: The polymerization of MMA into PMMA involves a chemical reaction that converts the liquid monomer into a stable, solid polymer. This process enhances the safety of PMMA by eliminating the volatile and potentially hazardous nature of the monomer MMA.

Q: Are there any environmental concerns associated with PMMA?

A: PMMA is considered to have a relatively low impact on health and the environment when used and disposed of properly. However, like any plastic, responsible production, use, and recycling practices are important to minimize environmental impact.