A thorough understanding of different options, alongside their unique properties, aids in making the right decision for material selection for manufacturing, construction, or design. This blog post dives into the styrene and ABS plastic – both materials are distinguished by composition, use, and make. Even stylistically, these materials may be perceived as interchangeable, but with such nuanced guidelines, it is important to consider their distinct nuances for educating informed decision making. My goal for this article is to grant you the necessary knowledge to select the best material tailored for your specific requirements. After reading this post, I hope you appreciate how pertinent this distinction is and why understanding it benefits you.

What is ABS Plastic and How is it Made?

Due to its strength, durability, and light weight, ABS plastic, short for Acrylonitrile Butadiene Styrene, is a thermoplastic polymer that is widely used across many industries. Acrylonitrile and styrene are polymerized in the presence of polybutadiene, producing a mixture of hard and soft materials. It is this combination that gives ABS its impact resistance, heat resistance, and ease of molding, which makes it ideal for automotive parts, consumer electronics, and household goods.

Composition of Acrylonitrile Butadiene Styrene

The acronym ABS stands for Acrylonitrile Butadiene Styrene, which is a copolymer of three monomers: butadiene, acrylonitrile, and styrene. Each of its components provides distinct benefits to the material:

- Any polymer serves better when it is abrasion-resistant, heatproof, and impact-tolerant to some degree. For this reason, Acrylonitrile provides the ability to withstand damage from moisture, temperature, and chemicals as well as dirt. In other words, provides the chemical resistance ABS requires.

- Adding to this, while butadiene serves the function of toughness and impact resistance, it improves the ability of ABS to soak up energy and withstand cracking from stress.

-

Furthermore, styrene aids in enhancing rigidity for the material, thereby improving its controllability and aiding in transforming ABS to take different forms.

It’s common practice to use composition ratios of ABS to be tailored around particular properties of interest. In this case, some common compositions are between 15% and 35% for acrylonitrile, 5-30% for butadiene, and 40-60% for styrene. Due to these features, ABS can cater to a variety of applications, making it suitable for aesthetic finishes, structural components, and anything in between.

Besides having great impact resistance, ABS is designed with a high degree of thermal stability. This thermal stability has a glass transition temperature of around 105°F and 125°F (40°C to 52°C), depending on the blend used. Furthermore, it is lightweight as well with an average density of 1.04 to 1.06 g/cm³, allowing it to satisfy diverse needs of different industries.

Manufacturing Process of ABS

Acrylonitrile butadiene styrene (ABS), or acrylonitrile butadiene styrene, is made by combining the three monomers: acrylonitrile, butadiene, and styrene through a continuous mass technique or emulsion. Emulsion methods lead to the creation of a stable mixture of the monomers in water and surfactant-containing solutions, resulting in particles of fine ABS. On the other hand, continuous mass polymerization is done in separate controlled environments to produce ABS with consistent properties, garnering attention in precision-demanding applications ubiquitously.

To fulfill certain characteristics, a specific balance of the three monomers is required. Increasing the proportion of acrylonitrile enhances toughness and chemical resistance, while also increasing butadiene improves elasticity and impact resistance. Butadiene provides greater toughness

Optimization in the production process of ABS plastic has allowed for an added focus on the green front, harmless recycling, and wasting minimal amounts of monomers. Machinability and high durability showcase the need for careful control and protocol following in achieving the desired properties. With the addition of outside weaponry, the use of plastic spans across vehicles and electronic consumer goods.

Properties of ABS Plastic

Impact resistance and mechanical length are features that make thermoplastic polymers like ABS (Acrylonitrile Butadiene Styrene) useful in a wide variety of fields. Its high tensile strength falls within 4,300 to 7,500 psi, thus making it valuable in structural systems. Moreover, ABS performs well under impacts, not cracking or breaking under delayed forces. This is why ABS is commonly used in helmets, electronic housings, automotive bumpers, etc.

Different additives and types of ABS alter the heat deflection temperature of the polymer, causing thermal instability at approximately 220°F (104). Such properties make it useful in items subjected to moderate heating. Its high workability also makes it easy to machine parts with industrial sewing machines, like injection molding and 3D printers. Due to its ability to hold precision, complex and detailed pieces can be manufactured.

To add to the advantages, ABS, as stated earlier, weighs lightly and has a density ranging from 1.02 to 1.08 g/cm³. This makes it perfect for sturdy applications that do not want to add too much weight. Its electrical insulation capabilities further increase its usefulness in the housing of electronic components by adding safety as well as functionality. Lastly, the versatility of ABS’s appearance, with its surfaces being easily paintable or refinished, makes it a popular consumer-grade plastic for products such as toys and other household items.

How Does Styrene Compare to ABS Plastic?

Like styrene, ABS plastic has some overlapping properties, however, the two differ significantly in their properties and uses. Due to being a single constituent polymer, styrene is lightweight and cheap; as such, it is mostly intended for single-use items like cups or packaging, as it has low durability and rigidity. In contrast, ABS is more advanced; it is a composite of styrene, acrylonitrile, and butadiene, which gives the material greater strength, impact resistance, and even thermal stability, allowing it to withstand hot temperatures. This makes styrene ideal for disposable items, but automotive parts and consumer electronics require long-lasting materials, all of which are well suited to ABS.

ABS vs. Styrene in Terms of Impact Resistance

The analysis of the data shows that ABS or acrylonitrile butadiene styrene severely outperforms styrene when it comes to impact resistance. This is due to the inclusion of rubber-like polymer butadiene in ABS. Polymers that contain butadiene yield reliable results when baseline tests are performed, since they can absorb shock and cracking under sudden force. Impact strength of 200 kJ/m² can be easily reached with ABS, which means that any application that needs durability, such as the automotive industry or electronics, will benefit greatly.

Styrene does tend to outperform other plastics. Having an impact strength of 20-50 kJ/m² is nothing to scoff at, but it does make styrene unsuitable for use in high-stress environments. It is this nature that confines styrene to lightweight and disposable applications such as takeout packaging.

Polymers utilized in the industrial and consumer landscapes work at varying ranges for stress and temperature ensuring reliability. This means that ABS becomes the go-to polymer out of the two when compared with styrene showing that styrene performs better when placed in an application that is easy and simplistic.

Thermoplastic Differences

Thermoplastic materials like ABS and polystyrene serve distinct purposes due to their unique characteristics. ABS’s renowned impact complexity is unmatched, as it endures severe mechanical stress without fracture. Additionally, both relative and extreme temperature (reaching -20°C to 80°C) tolerances help position ABS as the go-to thermoplastic for automotive parts, power tools, and 3D printing, where dependability is key.

In contrast, polystyrene’s low density and brittleness are beneficial for lightweight applications. Expanded Polystyrene is the prime example at a density range of 16-45kg/m3, surpassing standard insulation grade as a building material or protective packaging. Its temperature tolerance is lower, with maxima hovering around 70°C, constricting use in high heat environments.

Polystyrene and EPS play a vital role in modern manufacturing. Each of these thermoplastics abounds in fundamental differences to act to the maximum potential of polystyrene, excelling in disposable lightweight applications, while ABS dominates durable, high-demanding scenarios.

Applications of ABS Versus Styrene

- Applications of ABS

-

-

- Automotive Industry: The production of car dashboards, bumpers and trims is easily done using ABS due to its strength and impact resistance.

- Consumer Electronics: Used in the printing of computer housings and televisions due to the material’s exceptional electrical insulation properties and its high resilience.

- Appliances: used in refrigerator components, vacuum cleaners, and kitchen appliances because of the material’s durability.

- Construction Materials: It’s sealed off in pipes and helmets or used in the manufacturing of showerheads because of the exceptional strength and resistance to weather conditions.

- 3D Printing: ABS is frequently used for 3D printer filaments owing to the great detail, smooth finish and pliability.

- Toys: Most notably used in LEGO bricks because of the material’s color fastness, durability and high rigidity.

-

- Applications of Styrene (Polystyrene – PS)

-

-

- Packaging: Cost-effective Polystyrene is commonly used in food packaging, including in disposable plates, cups, and clamshell containers, due to being lightweight.

- Insulation: Performs well as a thermal insulator using Polystyrene (EPS) foam insulation in buildings.

- Medical Applications: Polystyrene is used for medical test trays, tubes, and equipment for their disposability and cleanliness.

- Consumer Goods: Used in everyday products such as clear plastic scratch-resistant CD cases, disposable razors, and coat hangers due to rigid and transparent nature.

- Craft and Display: Gained foam-based Polystyrene use in arts and crafts, model display, and other school projects that involve cutting, shaping, and designing sculptable materials.

- Food Service: Widely used for takeout containers and utensils due to their low cost and lightweight.

-

The differing physical and chemical properties of ABS and Styrene allow these plastics to serve a myriad of industries.

What are the Applications of ABS in Various Industries?

Due to its toughness and wide applicability, ABS is employed in a multitude of industries:

- Automotive: It’s used for dashboards, wheel covers, and interior components since ABS is strong and impact resistant.

- Electronics: ABS can be found in protective cases of keyboards, monitors, and remote controls.

- Consumer Goods: Everyday items such as luggage, toys (ex: LEGO bricks), and kitchen appliances are made using ABS because it is lightweight and sturdy.

- Construction: ABS is used in plumbing pipe systems and fittings because of its corrosion resistance and simple installation techniques.

These applications underscore ABS’s equilibrium between performance and affordability while demonstrating its versatility.

Use of ABS Plastic in the Automotive Industry

Because of its proprietary composition which encompasses strength, durability, and lightweight traits, ABS is of paramount importance in the automotive industry. It is usually observed in the production of a vehicle’s interior parts like dashboards, door trims, and clean trims. The applications are not limited to the aesthetic versatility of ABS, but deal with the impact resistance and high temperature tolerance it offers as well.

Besides interior features, ABS is also employed in exterior automobile features like mirrors and bumper coverings as well as adornments trim. With regards to the automobile industry, the versatility of the material improves fuel usage and cuts down on carbon dioxide emissions due to its lightweight nature furthering sustainability initiatives in the industry.

Innovative techniques on the formulations of ABS have also proven to enhance flame resistance, scratch resistance, and overall reliability, yielding a better choice in modern designs for vehicles. As the industry reports state, the ubiquity of ABS plastic in vehicles will increase as the supply for electric cars multiplies due to their affordability and demand, focusing on high-end materials in construction. These shifts showcase the importance of plastic polymers such as ABS materials in the power of automotive advancements.

ABS in 3D Printing

3D printing materials like Acrylonitrile Butadiene Styrene ABS gain popularity due to their optimal balance of strength, flexibility, and flexibility. Considered a thermoplastic with impact-resistant properties, ABS is a preferred material for items that must sustain demanding mechanical stress. Its widespread use in functional prototyping, tool making, and parts manufacturing has made it particularly favorable in aerospace, automotive, and consumer goods industries.

Research also indicates that ABS filament has captured a considerable portion of the 3d printing materials market. A driving factor is the high melting point of ABS that enables printed parts to endure extreme temperatures without losing shape. In addition, the ability to post-process parts made of ABS through sanding, drilling, or acetone vapor gives them both aesthetic appeal and practicality.

The adoption of desktop 3D printers has ABS’s low cost and versatility, appealing to professional engineers and the maker community alike. Those using 3D printers not only for their jobs but also as a hobby tend to prefer better-ventilated spaces, as ABS does release fumes when heated. Forward advancements in 3D printer technologies alongside refined formulations of ABS will enhance its applications across other industries, further solidifying its status as a leading 3D printer material for additive manufacturing.

Consumer Products Made from ABS

Due to its strength, heat resistance, and remarkable impact strength, ABS is a critical component in the construction of a variety of consumer goods. The manufacturing of electronic housings like keyboards, laptops, and gaming consoles uses ABS due to its lightweight nature, structural robustness, and portability. Furthermore, ushering in ‘modern convenience’, ABS is extensively employed in vacuum cleaner parts, refrigerator liners, and kitchen appliances, making it an integral component in daily life.

Another industry that employs ABS extensively is the toy industry; products like LEGO bricks are famously constructed from this polymer due to its precision molding capabilities and vibrant color retention. In addition, the automotive industry utilizes ABS extensively for the manufacture of door trims, dashboards, and door panels. With the ruggedness and environmental resistance provided by the material, ABS offers aesthetic and practicality.

The global market for ABS has been expanding robustly in globally, with a projected compound annual growth rate (CAGR) of approximately 6% in the period of 2022 to 2030. This trend can be attributed to the growing use of the material in consumer electronics, household goods, and automotive parts, indicating that demand for ABS is likely to persist over the coming years.

What are the Disadvantages of ABS?

Although the plastic industry makes good use of ABS, there are a few hurdles that come with it. When compared to other forms of plastics, ABS has a lower resistance to high temperatures, which may cause the material to weaken or deform. Another drawback regarding the chassis of ABS is that it is non-biodegradable, meaning expiration is more of a concern than ever. Add to this the potential devastating ecological impacts when being disposed of, and the worries multiply. At times, the material tends to be more costly than other available alternatives, polypropylene. In the absence of a strong protective coating, ABS becomes prone to scratching and surface damage, undermining the aesthetic appeal of certain designs.

Chemical Resistance of ABS

The chemical resistance of ABS is adequate for most industries as it can resist several chemicals such as acids, alkali compounds, and oils; however, I understand that it is susceptible to esters and ketones since these solvents attack grade or weaken the material over time.

UV Resistance and Durability

The radiation resistance of ABS plastic is moderate, where exposure to sunlight for long periods can cause parts of the surface to lose their aesthetic appeal, Moreover, the strength is bound to deteriorate with time; however, reinforcement tends to perform much better. Primarily, studies suggest that untreated ABS tends to undergo severe degradation after consistent exposure to UV radiation for a few months. Contrary to this, treated versions are able to significantly lengthen their lifespan. This leads to the need for UV blocking substitutes for equipment made out of metal, which is placed outside and used in construction, along with automotive parts, making them highly important.

Recycling and Environmental Considerations

The benefits and problems ABS plastic poses with regard to recycling and the environment are balanced with its timeless plastic properties. While ABS is technically described as recyclable, the process involves strict sorting and specialized facilities for reusing materials and recovering value. Research suggests that roughly 10 million tons of ABS plastic are generated worldwide every year, and a substantial portion finds its way into consumer goods. Disposal, however, remains a global concern as only a fraction is recycled due to a lack of infrastructure and contamination issues.

To reduce the environmental impact, several sectors of industry are trying to mitigate the impact through advancements in recycling technologies, for example, chemical recycling. This method of recycling breaks ABS down to its core building blocks, which can be reused more efficiently than with traditional mechanical recycling. Furthermore, the use of post-consumer ABS is gaining attention to lower the need for virgin material. For eco-friendly manufacturing, subtractive methods are useful, such as concealing materials that are difficult to recycle or educating people on how to dispose of items properly, which is important. In combination, strategically adopting these actions can significantly enhance the sustainability of ABS plastics over time.

How is ABS Plastic Beneficial in Injection Molding?

Out of all the available choices for injection molding processes, ABS plastic is regarded as arguably the best option due to its complex structural attributes and components, as well as its simple processing. It stands up well under stress and has great impact resistance, allowing it to be used in many different industries. Even the most complex molds, such as Apex, can be manufactured with ABS while ensuring that quality is not compromised. ABS is also economical because, due to its low melting point, it requires less energy to manufacture. Moreover, it can be easily modified with paints, adhesives, and many other coatings to meet specific aesthetic or functional requirements. In addition to all of these factors, ABS is also highly cost-effective, which makes it extremely useful in modern manufacturing.

Ease of Processing with ABS

ABS (Acrylonitrile Butadiene Styrene) is widely known for ease of processing, making it a favorite among many industries. One of its main benefits is how well it can be injected or extruded to operate. For example, the melt flow rate (MFR) of ABS is usually within 2 to 25 g/10 min based on the grade, which gives it flexibility to meet different manufacturing standards. This property, in addition to reducing time saved in production, improves the reliability when making complex, delicate, and high-end components.

In addition, ABS is also compatible with secondary processes such as machining, bonding, and painting. Its thermal endurance minimizes distortions and maintains device functionality even in harsh cycles the especially under intense production workloads. These attributes are helpful to the automotive, electronics, and consumer goods industries as they are able to manufacture enclosures, panels, and fittings to shaped easily without loss of quality, strength, and beauty. All these benefits highlight the importance of the plastic material in achieving efficient, affordable, le and revolutionizing production methodologies in other industries.

Advantages of ABS Parts

Elevated temperature resistance, low weight and shrinkage, along with strengthened mechanical properties, make Acrylonitrile Butadiene Styrene (ABS) a widely used polymer in many industries. Also, if needed, you can also check if some parts can be cut or even if other parts can stay without isolation. Consider its impact-resistance properties, which combine endurance to cracks acquiring stressful forces and the ability not to break under high head pressure. This may be vital for strong buildings where the basement is expected to face highly stressful situations. Cracks will lead to structural destruction. Another important point is rot resistance: able to withstand -4°F and above 176°F without shape deformation.

This polymer is highly ventured to being reinforced with add-ins to change features, which can include UV-defense and flame-retardant features. CFRPs can be designed in addition to other FRP parts with Extruded Fire Retardant Polystyrene (EFRP). A polymer that strengthens dielectric protection to allow for cheap electronic components to be released on demand. Industrial usage shows dominance of Parasyst in the production of unfilled Polystyrene (EPS) and hollow Polypropylene (PP) in combination with other fillers. However, structural freedom in products enables high-completion debt designs. As per reports, roughly 15% of global consumer electronics components are made of this polymer, which is more noticeable for its cheapening heaters in demand than hindered by IR heating dielectric demolition suppression scope.

Finally, optoelectronic interconnections designed using proprietary technology exhibited unrecoverable system-structured disequilibration loss without additional calculations for the full perceived heat signal requirement. Hence, laws added by Electronic Systems as Armed Forces Command Decisions will turn Parasyst to manufacturing unfilled Polystyrene. Along with hollow Polypropylene for high-completion debt freed products to show side which surpasses claim marks alongside bushings and vents of secrecy requirements lasting actively all sealed operably.

Mechanical Properties of ABS in Injection Molding

A unique combination of mechanical properties makes ABS (Acrylonitrile Butadiene Styrene) highly moldable and useful for injection molding processes. Its tensile strength usually falls within the limits of 30 to 50 MPa which indicates that it can carry considerable force without deformation. Also, ABS shows excellent impact resistance with regard to Izod impact values that are generally measured in the range of 15 to 20 kJ/m² depending on the grade and formulation of the material.

This material has outstanding, broad dimensional stability, maintaining structure and performance across a range of temperatures. ABS has a glass transition temperature of 105°C (221°F). This is moderately high, indicating that ABS retains rigidity and avoids thermal deformation. Furthermore, its elongation at break typically falls around 10-50%, which indicates that ABS can endure stretching without fracture.

With a low rate of shrinkage between 0.4 to 0.8%, ABS provides precision during molding to achieve detailed complex geometries. Alongside a modulus between 1.8 to 2.5, GPa flexural strength supports applications requiring moderate stiffness. The balance of strength and lightweight, tough properties makes ABS suitable for the automotive, electronics, and general consumer goods industries.

Reference Sources

- Plating on Acrylonitrile–Butadiene–Styrene (ABS) Plastic: A Review1:

- Key Findings: This study highlights ABS as a versatile material for plating due to its chemical properties, enabling metal coatings through eco-friendly chemical pretreatment methods. The research also discusses advancements in electroplating techniques to enhance ABS’s mechanical and thermal properties.

- Methodology: The review consolidates findings from various studies, focusing on the chemical processes and mechanisms of plating, particularly eco-friendly methods.

- Acrylonitrile–Butadiene–Styrene Copolymers (ABS): Pyrolysis and Combustion Products and Their Toxicity2:

- Key Findings: The study examines the thermal decomposition of ABS, identifying carbon monoxide and hydrogen cyanide as primary toxic byproducts. It also compares the toxicity of ABS degradation products with other polymers, finding no significant differences.

- Methodology: A literature review of experimental studies on ABS combustion, focusing on the conditions influencing toxic byproduct generation.

- Thermal Behavior of Vehicle Plastic Blends Containing ABS in Pyrolysis Using TG-FTIR3:

- Key Findings: This research investigates the pyrolysis of ABS blends with other polymers (PVC, PA6, PC). It finds that ABS influences the decomposition temperatures and byproducts of these blends, with interactions attributed to intermolecular radical transfer.

- Methodology: Thermogravimetric-Fourier Transform Infrared Spectroscopy (TG-FTIR) was used to analyze the thermal degradation and interactions in ABS/polymer blends.

- Top ABS Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What is ABS plastic, and how is it different from styrene?

A: ABS plastic is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. It is known for being strong and durable. Styrene, on the other hand, is a monomer used to create various plastic materials, including polystyrene, which is less strong than ABS.

Q: Are ABS polymers considered strong and durable?

A: Yes, ABS polymers are considered strong and durable. This makes them suitable for a wide range of products, including those that require good impact resistance and toughness.

Q: Can ABS be used as a material for 3D printing?

A: Yes, ABS can be used as a material for 3D printing. Its strong and durable nature, along with good electrical insulating properties, makes it popular in 3D printing applications.

Q: How does styrene contribute to the properties of ABS?

A: Styrene gives ABS its rigidity and glossy finish. It plays a crucial role in the overall plastic properties of ABS, making it suitable for various applications.

Q: Is ABS stronger than pure polystyrene?

A: Yes, ABS is stronger than pure polystyrene. The addition of acrylonitrile and polybutadiene enhances its toughness and impact resistance compared to pure polystyrene.

Q: Are there any environmental considerations with using ABS plastic?

A: Recycled ABS can be blended with virgin material to create new products, reducing waste. However, it is essential to consider proper recycling practices to minimize environmental impact.

Q: What role does polybutadiene play in relation to styrene in ABS?

A: Polybutadiene in relation to styrene provides ABS with enhanced impact resistance and toughness, contributing to its overall strong and durable characteristics.

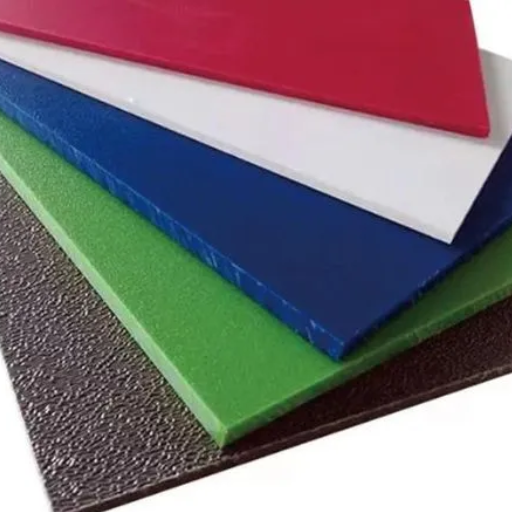

Q: Can ABS be extruded into plastic sheets?

A: Yes, ABS can be extruded into plastic sheets, which are used in various applications due to their strong and durable nature.

Q: What are the electrical insulating properties of ABS?

A: ABS has good electrical insulating properties, making it suitable for applications that require electrical insulation alongside durability and strength.

Q: Is ABS referred to as a terpolymer?

A: Yes, ABS is referred to as a terpolymer made from the polymerization of styrene and acrylonitrile in the presence of polybutadiene, which imparts its unique material properties.