Understanding the advantages and disadvantages of various polymers is vital for material selection for engineering applications. Among the most commonly utilized, POM and Nylon both have diverse performance characteristics. But which one is stronger? This article thoroughly compares the high-performance attributes of the two polymers, including tensile strength, durability, and wear resistance. At the end, you will understand the similarities and differences between POM and Nylon, thus enabling you to make an appropriate selection for your application.

What is the Difference Between POM and Nylon?

POM (Polyoxymethylene) and Nylon are both highly durable engineering thermoplastics, but they differ in key aspects:

- Tensile Strength: POM generally offers higher tensile strength, making it more rigid and ideal for applications requiring dimensional stability under load. Nylon, while strong, is more flexible and suited to applications where some elasticity is beneficial.

- Moisture Resistance: POM exhibits excellent moisture resistance, maintaining consistent properties in wet environments. On the other hand, nylon tends to absorb moisture, which can affect its mechanical properties over time.

- Wear Resistance: Both materials excel in wear resistance, but POM has an edge due to its low coefficient of friction, making it superior for applications involving sliding or moving parts.

- Thermal Properties: Nylon tolerates higher continuous-use temperatures than POM, making it a better choice for high-heat environments.

Choosing between POM and Nylon depends on your application’s specific demands, including load requirements, environmental conditions, and operational temperatures.

Understanding Polyoxymethylene and Nylon Plastic

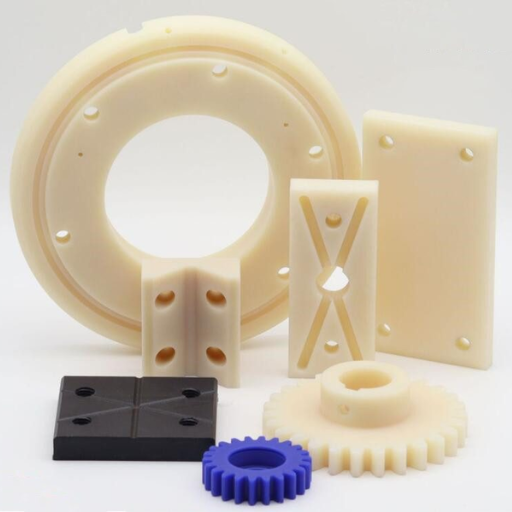

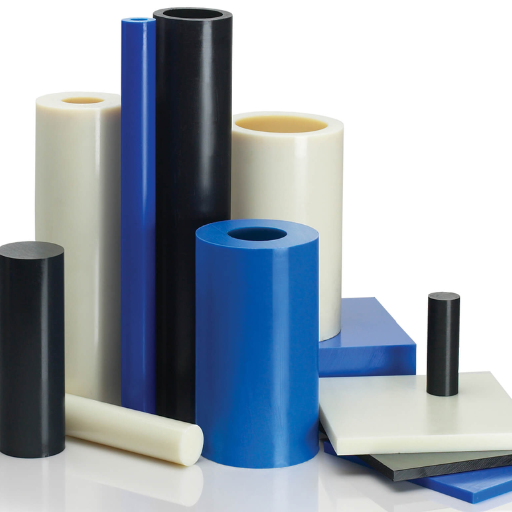

POM and Nylon are two widely used polymers in industrial and consumer products owing to their unique characteristics. Due to its high moisture resistance, POM is extensively applied in manufacturing precision components such as gears, bushings, and electrical parts with close tolerances. In addition, its superior wear resistance enables application in sliding parts of automotive and mechanical systems.

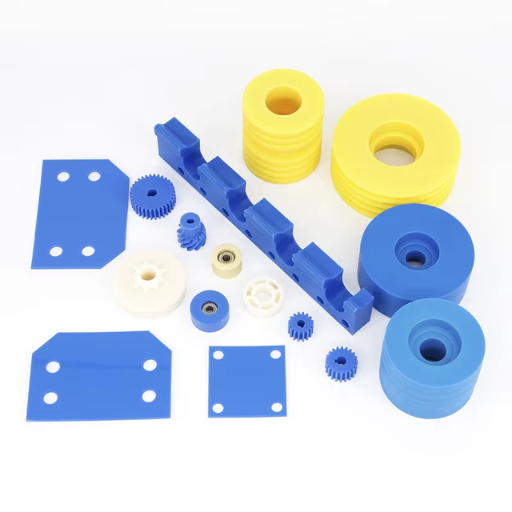

Nylon’s remarkable strength and high fatigue resistance make it one of the most valuable materials for components like bearings, pulleys, and structural fasteners that undergo repetitive stress. Due to its durability against harsh environmental conditions, such as exposure to chemicals and oils, nylon is also used alongside textiles in the automotive and aerospace industries.

Recent developments in materials engineering have further increased the functionality of these thermoplastics. For example, reinforced grades of Nylon, like those with glass fiber reinforcement, are now provided with additional mechanical strength and increased thermal stability, which makes them suitable for more demanding uses such as engine parts. Likewise, the copolymer variants of POM have been shown to perform better under low temperatures and are more resistant to impact, increasing their utility in colder environments.

Using either of these materials requires a deep examination of stress limits, thermal exposure, and other environmental interactions. Further innovation seeks to maximize the scope of their functionalities, providing engineers with tailored solutions to intricate design problems.

Key Properties of POM and Nylon

POM (Polyoxymethylene), well-known for its stiffness, low coefficient of friction, and excellent dimensional stability, is an ideal material for precision components like automotive parts, gears, and bearings. It is relatively unrivaled, guaranteeing dependable performance throughout various demanding applications due to its mechanical properties at constant stress alongside resistance to creep and wear. Coupled with POM’s strong mechanical properties, its exceptional endurance against chemically harsh fuels, solvents, and lubricants enhances its reliability across various applications.

Valued for attributes such as impressive tensile strength and the ability to absorb impacts without permanent deformation, Nylon’s toughness is arguably unrivaled. Its exceptional streak doesn’t end there; unlike most materials with similar traits, Nylon exhibits abrasion and thermal resistance. In certain conditions, nylon’s Moisture absorption properties enable enhanced flexibility and elongation, which can be beneficial when contending with dynamic loads. The specific applications might require moisture stabilization treatments to maintain mechanical integrity due to potential absorption, especially on lower-temperature nylon alloys.

Recent POM and Nylon material science, including glass-filled and fiber-reinforced variants, has resulted in reinforced grades with significantly improved mechanical and thermal performance. These bespoke polymers further enable engineers to solve more complex design challenges with precision and reliability.

Applications of Nylon and POM

Nylon and POM are highly versatile engineering plastics, finding extensive applications across various industries due to their excellent mechanical, thermal, and chemical properties. Nylon is widely used in the automotive sector for components such as gears, bearings, and cable ties, whose high tensile strength and wear resistance play a critical role. Its ability to withstand repeated stress cycles makes it suitable for textiles, industrial belts, and ropes. Furthermore, Nylon’s inherent chemical resistance allows it to perform reliably in environments exposed to oils and chemicals.

POM, on the other hand, is favored for precision applications requiring dimensional stability and low friction. It is commonly used to produce small mechanical components like bushings, fasteners, and pump parts. POM’s low moisture absorption rate suits outdoor or water-exposure applications, such as plumbing fixtures and irrigation systems.

Together, Nylon and POM are integral materials in industries aiming to enhance performance while adhering to cost-efficiency and durability standards. Their modified grades further extend their usability in advanced engineering applications, enabling manufacturers to meet evolving technological requirements with precision and reliability.

How Do the Mechanical Properties of POM Compare to Nylon?

POM (Polyoxymethylene) and Nylon have different mechanical properties and performance for various applications. Compared to Nylon, POM is distinguished by its excellent low friction, hardness, and wear resistance. These properties make POM ideal for precision parts continuously subjected to mechanical stresses. On the other hand, Nylon is more flexible and has greater impact resistance and higher tensile strength, making it useful in rigid applications that endure dynamic loads. The selection of POM and Nylon is mainly decided based on POMs rigidity and wear resistance versus the toughness and flexibility of Nylon.

Tensile Strength and Rigidity of POM vs Nylon

Polyoxymethylene (POM) also displays exceptional strength with a high modulus of elasticity from 2.5 to 3.5 GPa, depending on the grade, yielding outstanding dimensional stability. On the other hand, nylon has better average ultimate tensile strength (AUS), with common grades ranging between 65 and 85 MPa at standard conditions and significant pliability. Nylon’s elongation before breakage ensures plasticity during dynamic stresses, making it suitable for load-bearing components subjected to impact or varying forces.

However, the stiffness of Nylon tends to soften in high-humidity environments because of its relatively high moisture absorption rate, which can exceed 3% by weight at saturation. In contrast, POM’s lower hygroscopicity (usually < 0.2% at equilibrium), strength, and stiffness retention are far less in humid environments. These aspects must be thoroughly considered during material selection to guarantee absolute functionality in the intended working environment.

Wear Resistance and Impact Resistance

Engineering plastics’ wear and impact resistance is also of utmost importance, as these greatly influence applicability. For example, nylon, or polyamide (PA), has outstanding abrasion resistance due to a low friction coefficient and ability to endure cycling loads. It resists wear so effectively that it may be applied to gears and bushings. However, wear resistance may improve at higher loads or temperatures, requiring specific design strategies or reinforcement with glass or carbon fiber fillers.

Conversely, Polyoxymethylene (POM), or acetal, possesses significant resistance to wear and impact, particularly in colder temperatures. POM’s impact durability is due to its high crystallinity and toughened materials that provide dynamic endurance. POM’s deformation also enables freedom from permanent deformation during impact; hence, POM is so important in precision instruments functioning under static and dynamic loads over a long period. Changes in material formulation, or the composition of additives and fillers, have strengthened these materials’ wear and impact resistance to suit industrial needs.

Dimensional Stability and Absorption Rates

Like many polymers, Polyoxymethylene (POM) has low moisture absorption rates, with 0.2% to 0.5% at saturation. This extremely low moisture absorption prevents POM from swelling, warping, or property loss in humid environments. The low moisture absorption is also favorable for sustained structural integrity. POM’s excellent crystalline structure greatly enhances these properties by minimizing thermal or moisture exposure damage.

In addition, POM outperforms many other thermoplastics in retaining physical dimensions while continually exposed to moisture. This makes POM particularly useful for high-precision components like gears, bearings, and other tightly toleranced parts. Such reliability in varying environmental conditions ensures enduring performance and longevity in industrial and engineering applications.

Which Material Has Better Thermal Properties: POM or Nylon?

Nylon is noted to withstand elevated temperatures of up to 220°C, whereas POM has a maximum heat resistance of 150°C. This gives Nylon an edge over POM in terms of thermal stability. Furthermore, Nylon’s ability to sustain its properties under heat makes it more appropriate for prolonged high-temperature industrial usage. On the contrary, POM’s lower thermodynamic stability reduces moisture absorption, which enhances performance consistency compared to Nylon in constructions subjected to variable temperatures. The choice between the two materials lies in the application’s requirements of thermal, ever-changing circumstantial conditions.

Melting Points and High-Temperature Performance

Understanding potential Nylon applications further requires analysis of the coupled temperature sensitivity of its core materials. While increased temperatures are beneficial for specific applications, other practices rely on restricted applications above a certain threshold. These phenomena are determined while paying attention to the melting point of the utilized material. For example, Polyoxymethylene (POM) melts from 175°C to about ~180 °C. This range, coupled with its thermal features, makes it a difference maker. Knowing these differences enables these technologies to develop new designs, owing to the built-up structural strength of higher-melting-point Nylons. Depending on the specific type of Caprolactam Nylon, it can melt as follows: Nylon 6 from 220°C and Nylon 6,6 reaches up to 260°C. While POM would withstand a rigid deformed state once reaching its melting point, these Nylons would still maintain their structural integrity.

Nylon’s important role in the automotive and aerospace industries stems from its ability to withstand degradation under continuous heat exposure. While less able to withstand extreme heat, POM maintains stability at moderate temperatures and is exceptional in precision mechanical components due to its low thermal expansion and wear rate. Choosing a material involves a trade-off between thermal endurance and environmental resilience, resulting from the intended operating conditions.

Thermal Conductivity Comparisons

The selection of a material is particularly critical for transferring thermal energy for insulation, as it demands efficiency. Thermal insulation materials like PTFE benefit from much lower thermal conductivity (about 0.25 W/m·K) than metals (aluminum at 237 W/m·K and copper at 398 W/m·K), making them valuable in electronics and energy systems.

Plastics such as Polyoxymethylene (POM) and Polyethylene Terephthalate (PET) are engineering plastics with thermal conductivity values between 0.22 and 0.30 W/m·K. While they cannot compare in efficiency to metals when it comes to heat conduction, the metals’ thermal resistance, density, bearings, and gears subjected to fractionator heat make them an ideal choice for use.

Materials for low and high thermal management focus differ because the latter relies on operating temperature ranges, thermal cycling, and intervals of heat release or retention, along with requirements for their containment or dissipation. This creates a need for understanding value material-for-thermal conductivity specifics hyper-range.

UV Resistance in POM and Nylon

Despite POM and Nylon being reputable engineering thermoplastics, their performance divergence under UV exposure can affect the usability of outdoor long-term applications. Due to POM’s Chemical structure, its low UV resistance renders it more susceptible to radiation exposure, resulting in surface cracking, discoloration, and loss of mechanical strength. These changes reduce their longevity. They are usually fortified with stabilizers or UV protective coatings to enhance the usage of such POM components.

It has already been established that, depending on the particular nylon’s grade and formulation, nylon exhibits moderate resistance to UV radiation. Most nylons that are not modified suffer from surface chalking, fading, and loss of tensile strength when exposed to UV radiation for a prolonged period. Nylon grades resistant to UV radiation have additives like carbon black or UV stabilizers, which increase their ability to endure ultraviolet light while maintaining structural integrity.

These two materials are versatile, but special care must be taken regarding UV exposure, especially in outdoor applications. Engineering teams commonly conduct a detailed analysis on UV dosage estimation and apply UV-stabilized grades or protective coatings necessary to prolong the service life of these polymers.

In What Applications is POM Preferred Over Nylon?

POM is more advantageous than nylon in areas concerned about low moisture absorption, high dimensional stability, and wear resistance. This is why POM is used in precision gears, bearings, conveyor belts, and electrical components, as its materials are more humidity-tolerant than nylon. Moreover, POM’s low friction and stiffness make it worthwhile for smooth mechanical movements and tight tolerances.

Choosing the Right Plastic Material for Gears

As in the case of many gears, the best performance of a plastic depends on accurate analysis of some crucial factors. First, it seems intuitive that mechanical properties like tensile strength, hardness, and impact toughness will be essential as gears are repetitively loaded and stressed cyclically (fatigued). Furthermore, thermal stability is also necessary in specific applications, mainly when the working environment includes elevated temperatures.

An equally important factor here is the frictional component and wear resistance. POM and Nylon are two materials that stand out because of their high gear-seal life due to low friction and wear resistance. Looking at those who manufacture heavy-duty or fast-moving gear systems, reinforced plastics, like polyamide reinforced with glass fibers, offer unparalleled fatigue strength and rigidity, and better serve those requiring them.

The possibility of contact with oils, solvents, or other reactive substances necessitates considering their chemical resistance. In this regard, POM is a leading choice due to its strong resistance to degradation. Furthermore, manufacturing ease and cost considerations motivate using other materials such as ABS (Acrylonitrile Butadiene Styrene), which is easier to mold and fabricate, even though it is meant for lighter-duty applications.

As always, synthesizing gear with the machine demands the thorough study of application and operational conditions, environmental considerations, material economic factors, and the properties of the selected material. By doing so, engineers can achieve dependable and optimal gear performance in different industrial and mechanical systems.

Automotive Applications: POM vs Nylon

POM and Nylon must be evaluated for their specific characteristics for different automotive applications. POM is effective in wear resistance, low friction, and maintaining its shape, so it is used in accurate parts like gears and bushings. Nylon is better in toughness and impact resistance, making it more useful in dynamic or vibrating loads. Considering all these factors, I decide based on the prevailing conditions of an application, like the external environment, mechanical forces, and whether the device needs long-lasting durability for its expenses.

Other Common Uses of POM and Nylon

Nylon and Polyoxymethylene (POM) are gaining popularity for their low friction and wear resistance, employing different mechanics in industrial uses and consumer products. This makes POM worthwhile in manufacturing precision gear wheels, conveyor belts, and automobile parts like fuel system components and door lock mechanisms. Additionally, its resistance to wear makes it useful for high-performance appliances.

Conversely, nylon is preferred for products needing flexibility and high-elasticity impact resistance. Bearings, electrical insulators, and strong fabrics like parachute cords and industrial textiles are common nylon uses. Skis, fishing nets, and protective helmets also use Nylon, which makes it very useful for sports equipment. Both these materials are critical in the aerospace and consumer goods sector, which shows how vital they are in innovation and advanced product modification; their versatility improves innovation and functionality.

What Are the Chemical Resistance Properties of POM and Nylon?

POM (Polyoxymethylene) is very useful because it is resistant to many chemicals, such as fuels, oils, alcohols, and even dilute acids. Nevertheless, strong acids and alkalis are less of a problem since they can slowly damage its structure over time.

Nylon also has robust chemical resistance, especially in oil, grease, and almost all solvents. It is moderately resistant to weak acids and alkalis but is susceptible to strong acids, which can cause hydrolytic degradation. Both materials are quite robust, and while extreme care should be taken not to expose either to weakening chemicals or endure prolonged exposure, their permissive weaknesses complement the strengths without enhancing the overall damage.

Resistance to Solvents and Chemicals

Developments in polymer science have increased the ability of certain materials, such as nylon and polyethylene, to withstand chemical reactions. For example, the current formulations made of high-density polyethylene (HDPE) are resistant to most acids, including hydrochloric and sulfuric acids, which is why they are used in industrial storage tanks and pipelines. Nylon is also used in industrial applications, particularly when blended with reinforcements such as fiberglass, due to its enhanced resistance to oil permeation and hydrocarbon exposure. However, despite these advances, constant monitoring and maintenance are still needed to ensure the materials withstand prolonged exposure to harsh chemicals. These factors, alongside countless others, can lead to the materials losing their service lifetime.

Moisture Absorption in Nylon vs POM

Polyamide (nylon) and Polyoxymethylene (POM) exhibit differing behaviors toward moisture absorption, making nylon more susceptible than POM. Nylon’s molecular structure, which contains amide groups, makes it hygroscopic. This property enables nylon to absorb water, in turn risking dimensional alterations, loss of tensile strength, and changes in its electrical properties. Nylon is estimated to absorb 2 to 9 percent of its weight in water, depending on humidity and grade.

On the contrary, POM has far less water absorption due to its highly crystalline structure and absence of polar chemical groups that readily hydrate. Under similar conditions, POM absorbs less than 0.2% water by weight, preserving dimensional and mechanical stability even in high-humidity environments. These characteristics also render POM advantageous in making precision gears, bearings, and other components that operate in wet or humid conditions where property change is critical to operational dependability.

How Chemical Resistance Affects Material Choice

Chemical resistance is one of the most important considerations for determining the applicability of a material, especially when such materials are frequently exposed to harsh chemicals, solvents, or corrosive substances. Materials with high chemical resistance, such as Polytetrafluoroethylene (PTFE) or Fluorinated Ethylene Propylene (FEP), are frequently used in Chemical processing industries, medical equipment manufacturing, and food production industries because these materials do not undergo degradation in the presence of hostile chemicals. For instance, PTFE is extremely inert with acids, alkalis, and organic solvents, remaining unreactive even in contact with strong reagents.

Chemical concentration, temperature, and even exposure duration all play critical roles in a material’s selection for a chemically harsh environment. Polymer-based materials like Polyethylene (PE) and Polypropylene (PP) are resistant to many chemicals; however, high temperatures or prolonged exposure can lead to failure. On the other hand, metals, particularly stainless steel, while providing strong resistance to corrosive agents, can develop pitting or stress corrosion cracking from exposure to specific halogens or chlorides.

Profound care in the selection of the material guarantees dependable operations, increases service life, and minimizes maintenance expenses. The aetiology of an engineer dealing with materials having peculiar stimuli off standards entails comprehensive chemical resistance, mechanical, thermal, and environmental factors as well as performance. Material producers often aid in decisions through their tables and comparative charts.

Is POM Generally More Expensive than Nylon?

POM (Polyoxymethylene) is more costly than Nylon. POM expenses are attributed to its superior properties, suitability for precision applications, and low friction characteristics. These factors include POM’s greater resistance to moisture and harsh, chemically reactive substances. Conversely, Nylon’s lower price can be attributed to less effective moisture absorption and lower dimensional stability.

Cost Considerations in Material Selection

When comparing expenses related to POM and Nylon materials, it is crucial to examine the life cycle costs of the application. POM comes at a premium compared to other options, but the purchase price is justifiable because POM outperforms others in mechanical strength, wear resistance, and moisture absorption. POM’s durability in these demanding environments translates to reduced maintenance and replacement costs, thus offsetting the upfront investment. Nylon comes at a cheaper price, but the cost benefits are overshadowed by the need for additional coatings to reduce moisture absorption and improve dimensional stability.

Availability of raw materials and economic issues are equally important. The production of POM requires more expensive polymerization processes, which raises production costs. Nylon is frequently produced in various forms, gaining economies of scale, which lowers the market price. Moreover, global supply chain changes, feedstocks derived from petroleum, and technological advancements in materials can impact temporal cost trends for both materials.

Long-term Value: POM vs Nylon

In determining the value of POM (Polyoxymethylene) against Nylon in the long stretch, parameters like operations and those directly associated with having nylon produced in many grades, such as Nylon 6 and 6/6. Nylons are used in various applications, including but not limited to textiles, automotive parts, and other consumer goods. The tough nature of nylon, coupled with its impact-absorbing properties, makes it a sought-after material for use in parts bearing dynamic loads. POM is praised for its wear resistance and low friction tendencies, possessing exceptional dimensional stability. This makes POM vital in precision engineering, widely used in gears, bearing,s and sophisticated mechanical parts industries. Alongside these characteristics are the benefits of having the material demanded in harsh environments, such as lowered required maintenance and overall costs.

Compared to other options, POM’s increased efficiency in resisting moisture absorption and its thermal expansion characteristics enhance reliability in highly humid and heat-fluctuating areas. Despite this, nylon’s ability to be modified with glass fiber additives makes it suitable for high-strength reinforced applications. Finding the material that provides the best long-term investment depends on particular use parameters, environmental factors, and total lifecycle cost calculations linked with value-added construction, upkeep, and real-world performance.

Reference Sources

-

Wear and Contact Temperature on Steel Surface in Linear Dry Friction Contact with Polymers with SGF (2021)

- Key Findings: This study analyzed polymers, including nylon and POM, ‘s friction and wear behavior when reinforced with short glass fibers (SGF). It found that reinforcement significantly improves tensile strength and wear resistance. POM exhibited better dimensional stability and lower water absorption than nylon, making it more suitable for high-precision applications.

- Methodology: The research involved tribological tests under varying loads and speeds, using steel surfaces to evaluate wear and friction coefficients.

-

- Key Findings: This paper compared the mechanical properties of various polymers, including nylon and POM, in dental applications. It highlighted that POM offers higher rigidity and resistance to wear compared to nylon, which tends to absorb more moisture and degrade over time.

- Methodology: The study involved clinical observations and mechanical testing of reinforced polymer samples used in dental prosthetics.

-

- Key Findings: This research focused on the mechanical properties of polyamide (nylon) in medical implants. While nylon offers good biocompatibility and tensile strength, its performance under compressive loads is inferior to that of other polymers like POM. The study emphasized optimizing manufacturing parameters to enhance nylon’s mechanical properties.

- Methodology: The study used selective laser sintering (SLS) to fabricate nylon samples, followed by compression tests and finite element analysis to evaluate their mechanical behavior.

- Top POM Plastic Pellets Suppliers in China

Frequently Asked Questions

Q: What is the main difference between POM and Nylon as engineering plastics?

A: The main difference lies in their properties; POM (Polyoxymethylene) generally has superior mechanical properties, while Nylon is widely used for its high tensile strength and flexibility.

Q: Is POM stronger than Nylon?

A: POM is highly strong and stiff. While nylon is slightly stronger in some applications, POM excels in low friction and abrasion resistance, making it a better choice for specific uses.

Q: What applications are suitable for POM plastic?

A: POM is often used in applications that require low friction, high mechanical strength, and excellent abrasion resistance, such as gears, bearings, and automotive components.

Q: How does water absorption compare between POM and Nylon?

A: POM maintains a low water absorption coefficient compared to Nylon, which can absorb moisture, affecting its mechanical properties and dimensional stability.

Q: Why is Nylon often used in engineering applications?

A: Nylon is often used due to its high tensile strength, flexibility, and ability to withstand high temperatures, making it suitable for various engineering applications.

Q: Can POM be a better choice than Nylon for specific applications?

A: Yes, POM is often the better choice for applications that demand low friction, high abrasion resistance, and superior mechanical properties, particularly when moisture exposure is a factor.

Q: What are the cost implications when choosing between POM and Nylon?

A: POM is generally more expensive than nylon, which might influence the decision depending on the budget and specific requirements of the plastic engineering application.

Q: What is the structural difference between POM and Nylon?

A: POM’s structure allows for a more crystalline formation, contributing to its high strength and stiffness, whereas Nylon’s structure provides flexibility and toughness but can lead to higher water absorption.

Q: How does the coefficient of friction of POM compare to Nylon?

A: POM has a low coefficient of friction, making it suitable for applications where reduced friction is essential, while Nylon may not perform as well in this regard.

Q: Are there specific industries where POM is preferred over Nylon?

A: Yes, POM is preferred in industries such as automotive, aerospace, and manufacturing for components that require durability, low friction, and high mechanical strength. Its properties outperform Nylon.