Acrylic, being an interesting and flexible medium, has firmly established itself as the modern backbone of design across various industries. The clarity, durability, and usability of acrylic have put-making itself so-called-everything from razor-sharp furniture and architectural add-ons to odd art installations and fancy dance moves-in a whole new realm. Well, then, what is acrylic anymore? And from another standpoint, what is it that makes acrylic stand out in the world of plastics? The following write-up embarks on a journey to unravel the chemical nature of acrylic, specifically PMMA, and thereby explores the properties that make it favored in modern-day design. Whether you are in it for personal interest or are a designer by profession, you will learn something useful and worth considering about the properties of acrylic and why it remains popular.

Introduction to Acrylic and Its Composition

What is Acrylic Material?

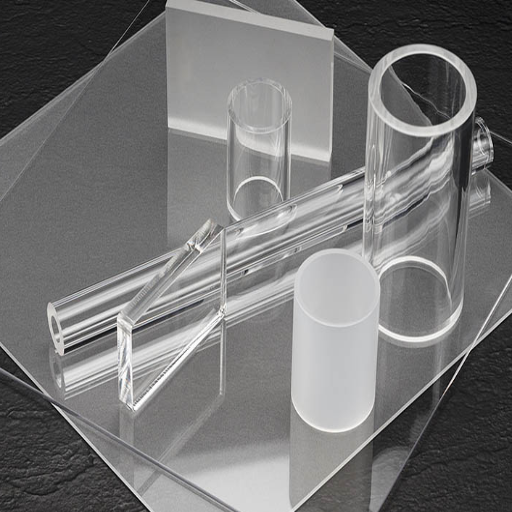

Commonly known as acrylic, polymethyl methacrylate (PMMA) is a transparent thermoplastic renowned for its versatility and durability. It is used as a lightweight and shatter-resistant alternative to glass. Chemically, acrylic consists of polymer chains from methyl methacrylate monomers turned into solid sheets, rods, tubes, or any type of shape desired.

From acrylic, there are three significant properties of important substances: visual clarity, UV resistance, and weatherability—a perfect combination for both indoor and outdoor applications. The light transmittance of acrylic is even greater, 92%, which is higher than the 89% usually transmitted by glass. This makes it an excellent choice for glazing, signboards, or showcases. Additionally, acrylic can be highly customized to suit practically any purpose through cutting, bending, or laser engraving. Its adaptability has led to wide usage in fields such as architecture, automotive, and healthcare, owing to its timeless appeal.

Acrylic Plastic Composition

It is Acrylic plastics that consist principally of PMMA, a synthetic polymer formed by polymerizing methyl methacrylate. The prime qualities being offered are optical clarity, Durability, and Weather resistance, hence its widespread application. Modifier additives, such as UV stabilizers to prevent discoloration from prolonged sun exposure, impact modifiers for enhanced toughness, and colorants for aesthetic customization, may be added to acrylic plastics to meet the property requirements of specific applications.

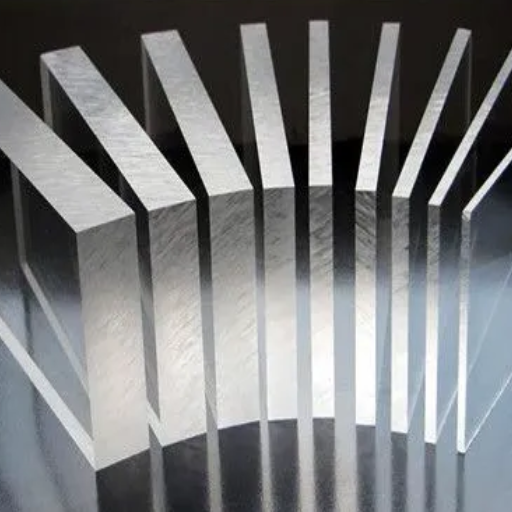

Until recent years, manufacturing technology was primarily used to develop special acrylic formulations, which included cast acrylic—with a good finish and machining qualities—and extruded acrylic, which, being less expensive and uniform in thickness, presented a preferred alternative. Either of these could be used depending on the particular application, such as for protective barriers, skylights, medical devices, and retail displays. Without a doubt, endless innovations have been carried out on acrylic plastic compositions to fulfill demands for both performance and environmental aspects.

Methyl Methacrylate in the Production of Acrylics

Methyl methacrylate, commonly abbreviated as MMA, is a crucial building block in the manufacture of acrylic plastics, thereby influencing their properties and applications. As a monomer, MMA undergoes polymerization to form polymethyl methacrylate (PMMA), the chemical name for acrylic products. This compound, being transparent and durable with ultraviolet light resistance, is equally applicable to both industrial and consumer usage.

By far, one of the best advantages of glass-like acrylics in terms of viewing is that it exhibits 92% light transmission, which is comparable to, if not better than, that of glass. It also shows better impact resistance than 17 times that of conventional glass materials when tested. This particular setting makes it very much in demand for airplane canopies, aquariums, and high-performance glazing.

Industrial activities have evolved in a manner that makes MMA production more sustainable, in light of growing environmental concerns. New methodologies, such as bio-inspired MMA synthesis and advanced catalytic methods, hold the promise of reducing emissions and dependence on petrochemicals, all while keeping production costs reasonable. Such innovations reflect the need for MMA to bring efficiency and sustainability to the production of modern acrylic products.

The History of Acrylic and Its Evolution

The Background of Acrylic Material

The educational journey with acrylic materials began in the early 20th century, during the pioneering era of synthetic polymers. The first breakthrough came much earlier: in 1901, the German chemist Otto Röhm was conducting research on polymethyl methacrylate (PMMA), discovering how it could be used to make transparent, durable plastics. However, PMMA only became industrially attractive in 1928, when Röhm and his partner, Otto Haas, filed for a patent under the trademark name “Plexiglas.”

With the outbreak of war, the growing technological demands during the 1930s and 1940s saw acrylic materials progress at a pace. Acrylic glass was used to make aircraft windshields, submarine periscopes, and gun turrets owing to its lightweight and impact-resistant properties. Its clarity and ability to resist shattering under rough conditions established it as an alternative to conventional glass.

The production of acrylics saw innovations being gradually introduced through the decades, finally rendering it cheap and versatile. Recent figures indicate a growing demand for acrylic-based products, with applications in various industries, including automotive, construction, healthcare, and consumer goods. Underlines its development through the passage of time and radical technological and environmental changes, engaging with present-day industries.

Important Landmark in Acrylic Development

Several milestones in the development of these materials have led to revolutionary changes in various industries. Discovered in the early 20th century, the commercialization of polymethyl methacrylate (PMMA) in the 1930s marked a significant milestone, known under trademark names such as Plexiglas and Lucite. The marketing of PMMA as a lightweight and resistant-to-glass material had transformed several industries, including aviation and architecture.

Mid-20th-century advances in polymer chemistry created opportunities for more customized acrylics, including tinted versions and improved weather resistance. With these changes, acrylics were then utilized in various applications, including signage, home décor, and automotive lighting. The 1980s and 1990s saw the development of newer and improved formulations of acrylic, including acrylic blends that offered enhanced strength and cost advantages, thereby catering to more high-impact applications.

Recyclable and bio-based acrylics have recently been considered in terms of sustainability and environmental performance. Responsible, bio-friendly variants contribute to global efforts in reducing carbon footprints without compromising the distinctive elements of clarity and durability that the material imparts. Acrylic remains highly relevant in various fields, including electronics, where it is utilized in LED screens and optical lenses, and in health, where it is applied in prosthetics and medical devices. These milestones, therefore, not only acknowledge the flexibility of acrylic but also highlight its contribution to technological evolution.

Modern Design and the Rise of Acrylic

Contemporary design utilizes acrylic as a fundamental element, thanks to its versatility in aesthetic appeal and solid practicality. Designers and architects admire it because it simulates real glass but is comparatively stiffer and shatter-resistant. From minimalist accent furniture to contaminated architectural features, acrylic defines new potentials for contemporary design. The flexibility of the medium allows for a wide range of uses, from home décor articles to retail displays to state-of-the-art installations, enabling the creator to push the frontiers while remaining functional.

Perhaps one of the most attractive design features of acrylic is its compatibility. With a wide assortment of colors, finishes, and thicknesses from which to choose, it allows designers to compose impromptu designs or works that are tailored to specific project requirements. The newer, advanced methods of manufacturing, such as laser cutting, UV printing, and 3-D printing, promote the use of acrylic in highly complex designs, thus allowing for detailed precision and significantly reducing material waste, the latter factor being of second priority these days with sustainability weighing so heavily in the design industry.

Think of acrylic as lightweight but sturdy. From a structural standpoint, this gives it an edge in any architectural or decorative element that data seeks longevity, along with visual impact. Additionally, due to its anti-UV and weather-resistant properties, designers rely on acrylic for both indoor environments and outdoor installations. Whether it’s a minimalist design for a clean look or more elaborate pieces that demand colors so striking they scream for attention, acrylic is an inspiration for modern design, a perfect melding of form and function.

Types of Acrylic and Their Applications

Different Forms of Acrylic Plastic

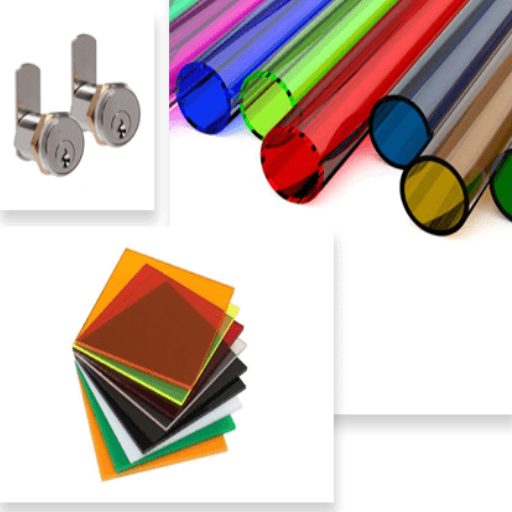

The various forms of acrylic plastic have different uses and industrial applications. Some of the main categories are:

Clear Acrylic Sheets: Transparent acrylic sheets are valued for their extraordinary transparency, with light transmittance almost equal to that of glass, being, however, much lighter and more impact-resistant. They are said to be slightly better for windows, aquariums, protective barriers, and display cases.

Colored Acrylic Sheets: These sheets, available in a broad range of colors and finishes, are designed for projects that require a strong, vibrant look. These are common for signs, interior decorating, retail displays, and artistic installations. The ability to stay true color-wise and resist fading makes them suitable for prolonged use, even outdoors.

Frosted Acrylic: Frosted acrylic features a translucent finish that diffuses light, making it ideal for use in privacy screens, room dividers, light fixtures, and decorative panels. This type of acrylic appears elegant as it diffuses and scatters light, creating a soft glow.

Acrylic Mirror Sheets: Mirror sheets can weigh less and are more shatter-proof than glass mirrors. They find applications in interior design, health and fitness studios, retail fixtures, and public spaces, wherever safety and durability rank higher without compromising reflection quality.

Textured Acrylic: These sheets feature unique surface designs that not only decorate but also function. Textured acrylic is used in cabinet doors, decorative panels, and illuminated signboards, where it manipulates light refraction to produce fabulous visual effects.

Impact acrylic is designed to enhance the general properties of acrylic with ultimate toughness; therefore, high-grade impact acrylic finds applications in fields such as safety barriers, helmet design, and machinery guards. This particular type requires direct hits, which must balance the use of a certain degree of force that might otherwise render it useless under intensive use.

Acrylic rods and acrylic tubes: Cylindrical shapes represent acrylic in general. They are predominantly utilized in architecture, scientific instrumentation, and crafts where structural elements need to be both durable and lightweight.

With advancements in manufacturing, acrylic forms can be further customized to meet changing needs, providing limitless design opportunities in terms of form and function. Each of these acrylic forms brings in its unique differences to help the designers achieve their specific needs: aesthetic, structural, or capability-based.

At some point, various industrial activities began to utilize acrylic

Acrylic is a versatile material used in numerous sectors due to its exceptional durability, appearance, and versatility. Some significant acrylic uses include:

Construction and Architecture: Being lightweight and impact-resistant, acrylic sheets are often used for windows, skylights, and partition purposes in place of glass. The material offers good clarity and UV resistance, which implies it can be used in architectural components both indoors and outdoors. Advanced fabrication techniques enable the production of textured or tinted acrylic variations, ensuring maximum design freedom.

Automotive: Acrylates are commonly used throughout the automotive industry for headlight covers, dashboards, and exterior trim. With significantly higher weathering and impact resistance, acrylic enhances safety and aesthetics while reducing vehicle weight, ultimately leading to improved fuel efficiency.

Retail and Commercial Displays: With its brilliant transparency and ease of molding, acrylic is widely used for the manufacture of display cases, signage, and point-of-purchase displays by the retail sector. Clear or colored acrylic certainly offers a polished and professional appearance for product display, while remaining sturdy enough to withstand extreme wear and tear.

Healthcare and Medical Equipment: Acrylic, being non-toxic and easy to sterilize, is preferred in the medical field. It finds its place as protective barriers, trays, and incubator enclosures. Optical clarity is crucial in the medical field, and this material provides significant visibility.

Aerospace and Defense: Due to its lightweight and shatterproof properties, acrylic finds widespread usage in the aerospace industry. The applications include cockpit canopies, helicopter windows, and instrument covers that are subjected to extreme weather conditions and noise, while ensuring safety.

Arts and Crafts: Artists and craftspeople often pick acrylic paints and sheets for their projects. The materials are essentially a trade-off between affordability, ease of customization, and a range of vivid colors to choose from, providing creators with the creative scope to experiment with new designs and techniques.

Renewable Energy: Acrylic is increasingly being used for applications in the renewable energy sector, particularly in the construction of solar panels and wind turbine structures. Being optically transparent and resistant to environmental degradation, it lends itself well to achieving higher energy efficiency.

Industry reports supporting the demand for acrylic across these sectors are on the rise, especially with the global thrust toward sustainable and efficient materials. The versatility of acrylic remains an avenue for innovation, as various industries realize the possibilities for enhancing performance and design with acrylic.

The Innovative Designs of Acrylic

Acrylic puts the foundation for a plethora of new design innovations in diverse industrial applications thanks to its versatility, strength, and aesthetics. It has been incorporated into a wide range of creative applications, spanning from the conceptualization of an object to its actual manufacture. For example, modern architecture utilizes the transparency and strength of acrylic in designing and fabricating façade panels, which serve as a splendid blend of pure functionality and visual impact. In product design, acrylic is used to create slim, ergonomic gadgets and high-performance eyewear that seamlessly blend style and utility.

Acrylic is an excellent material with wide applications in the automotive field, particularly in advanced lighting systems and aerodynamic features, which enhance performance and aesthetics. From an interior design perspective, places can be uplifted with the contemporary and minimalist appeal of acrylic furniture, which includes transparent chairs and tables that reflect light.

According to industry data, the use of acrylic for solar panels and EVs is steadily increasing, as automotive applications utilize the material for its lightweight characteristics and ability to retain energy efficiency without compromising durability. Besides, the rapid rise of 3D printing has unlocked a new paradigm for executing complex acrylic designs with unmatched accuracy, thus heralding an era of efficiency and innovation.

By demonstrating that acrylic’s properties are endowed with such uniqueness, such designs strive to mark the wilder frontier advanced by materiel-consciousness steeped in sustainability, function, and contemporary modern aesthetics.

Advantages and Disadvantages of Using Acrylic

Acrylic Materials – Benefits in Design

The benefits offered by acrylic ensure its prominence as a preferred entity in design applications across various fields. Regarding its unique qualities, acrylic offers versatility and excellent molding possibilities, presenting numerous options for creative thought. Other selling points of the acrylic include its lighter weight compared to alternative materials, yet it is robust enough to build products requiring strength. Optical clarity is another key feature, as it allows light to pass through approximately 92%, making it an ideal alternative to glass in architecture and interior design.

From a functional perspective, acrylic exhibits excellent weather resistance. It does not degrade easily under the influence of sunlight or harsh environmental conditions, allowing for a long and useful outdoor life. Additionally, it provides thermal insulation, making it an ideal choice for energy-efficient designs. With new advancements in manufacturing, it is now possible to produce acrylic in various colors, finishes, and grades to suit different project requirements. Designers also like acrylic because it is easy to work with-it can be cut, drilled, and joined with very minimal specialized equipment. This flexibility has made acrylic a key player in integrating sustainable design with innovation, aesthetics, and functionality.

Challenges and Limitations of Acrylic Plastic

The properties and advantages conferred by acrylic plastic are numerous; however, it has its considerations and limitations. One primary concern is its vulnerability to scratching, which over time compromises its clarity and further looks, particularly in high-traffic or abrasive environments. The presence of coatings can reduce concern, yet this should be an area of consideration for applications with long-term durability requirements.

Another limitation lies in the lower resistance against impacts compared with materials such as polycarbonate. While it can withstand moderate forces, cups, mugs, or heavy objects can cause it to crack or break under heavy pressure, thereby limiting its use in applications that require high resilience. Additionally, acrylic offers limited high-temperature resistance because when exposed to extreme heat, it may deform and lose strength, which poses problems in applications where thermal stability is of utmost importance.

From an environmental perspective, although it may be recyclable, acrylic is not biodegradable. This raises concerns about its long-term environmental impact if not properly disposed of through recycling systems. In addition, the manufacture of acrylic requires the use of chemicals that may pose ecological concerns if manufacturing processes are not carefully regulated.

Accommodating flexibility and economy for a wide range of projects, acrylic can become expensive at higher grades and custom specifications, thus predominantly affecting budgets for larger-scale projects. These limitations effectively highlight the importance of selecting materials based on a project’s specific needs and striking a balance between performance and practicality.

Comparative Analysis with Other Plastics

When evaluating acrylic alongside other plastics, one is bound to conclude that each material has its own set of properties that suit different applications. Acrylic, with its optical clarity and UV resistance, has always been considered distinct from polycarbonate, which offers high impact resistance. Consequently, polycarbonate has been favored in situations where weatherability and transparency are critical. Polycarbonate, with its greater impact resistance and flexibility, is preferable in physically demanding environments, such as safety equipment or automotive components. It has a propensity to get scratched easily and will often require an additional hard coat to become as durable as acrylic.

Furthermore, compared to polyethylene (generally used for packaging or piping), acrylic is stiffer and offers greater surface hardness. Given its resistance to chemicals and flexing, polyethylene is selected where the workability under diverse temperatures and exposures is necessary. The PVC (polyvinyl chloride) differentiates itself with its fire-retardant properties and chemical stability, but lacks the qualities that lead it to be perceived as brittle and with lesser optical clarity, which acrylic smoothly capitalizes on in designs.

The cost parameter also varies significantly between the varieties of plastics. Acrylic falls somewhere in the midrange in terms of price, offering a moderate level of affordability versus performance. A more specialized type, such as polycarbonate, can be more expensive to give a greater structural advantage. However, first and foremost, the recyclability of materials such as polyethylene and PVC provides sustainability advantages for industries pursuing truly eco-conscious production. Ultimately, plastic selection is a compromise among various attributes, including durability, clarity, cost, and environmental impact, depending on the specific project at hand.

Conclusion: The Future of Acrylic in Modern Design

Trends in the Use of Acrylic

From a myopic perspective, another view that highlights the most significant change is the use of acrylic, due to its inherent versatility and beauty. From what I’ve observed, one primary trend has been its applications in sustainable design. Above ground, the fact is that acrylic industries reduce environmental manipulations while offering durability and recyclable qualities. Increasingly, designers and manufacturers are incorporating recycling techniques into their product design, enabling their results to qualify as environmentally friendly while preserving the clear quality and formability inherent in acrylic.

Another trend I notice is the rise of alternative and artistic uses of acrylic in contemporary design. Furniture, signage, and even architectural accents count among the myriad applications where acrylic is used by name for ease of fabrication and coloring, endowing smooth glamour upon anything. Advancements in manufacturing methods nowadays allow for heavy customization of acrylic designs; consequently, the material has earned favour among brands and creatives wishing to propose very bold and innovative ideas.

With growing awareness of safety, especially in recent times, one of the key applications of acrylic comes into the health and safety realm. The demand for protective acrylic barriers surged during the COVID-19 pandemic in the glass industry and has since maintained its stronghold in public areas. This means acrylic meets the functional requirements as well as the aesthetic demands of today, earning it the status of an appreciated material across various industries.

Sustainability and Eco-Friendly Considerations

When considering sustainability and eco-friendly practices, acrylic offers both challenges and opportunities. From a first-person perspective, I’m aware that acrylic may not be biodegradable, but efforts are being made to mitigate its environmental impact. Recycling actions for acrylic-based products are starting to gain traction, allowing materials to be reclaimed and reused for new applications rather than being disposed of in landfills. By embracing these recycling programs, I can reduce some of the environmental impact resulting from the use of acrylic.

Again, my inclination lies with the longer life and durability of acrylic, which lends itself to its greener aspect. Some materials degrade and must be frequently replaced; acrylic will stand up to adverse conditions. Such durability implies fewer resource requirements over time, in keeping with my philosophy of responsible material consumption. Taking this into account, the reduction of energy for manufacturing and exploration of bio-based substituents are forward-thinking avenues of sustainability that I fully endorse.

Ultimately, my prime interest lies in balancing acrylic while working towards a solution for its environmental downside. I do believe one can still use the versatile material and remain eco-conscious by choosing recycled acrylic or those companies that promote green production. This draws from my belief that sustainability is about progress and inclusivity: looking for solutions that serve both nature and contemporaries.

The Lasting Impact of Acrylic on Design Aesthetics

Designs have been profoundly impacted by acrylic, providing designers with modern, sleek materials that can be applied to a diverse range of items, from functional applications that fulfill human needs to aesthetically pleasing elements. I find the adaptability of the material fascinating because it can be incorporated into practically any design context, from minimalist furniture to more complex design installations. Since it can also imitate glass and is slightly more resistant to shattering, the scope of acrylic design is much broader, as it sits between pure elegance and practical application. The sheer transparency of acrylic and its ability to tint, sculpt, and mold in infinite ways give that breadth to showmanship and boldly push the possibilities of designs ever further.

What I love about acrylic is its ability to instill a feeling of modern sophistication into any setting. Whether used in interior design, fashion, or industrial applications, its clean lines and polished finishes offer a contemporary edge that will never become dated. When acrylic lights a space with artfully designed lighting fixtures or plants, bold display cases that scream for attention, it reminds us that the material moves with current design trends while still maintaining its own identity. For me, that evolution makes the finishing material one of vital importance in design, a marriage of beauty, function, and innovation that carries the language of design across eras, for both the archaic and the avant-garde.

Reference Sources

-

What is Acrylic Fabric: Properties, How it’s Made and Where – Sewport

This source explains the composition of acrylic fabric, its properties, and the manufacturing process. -

What is Acrylic Fabric? – Revolution Fabrics

A detailed overview of acrylic as a synthetic material derived from petroleum or coal-based compounds. -

4 Clear Reasons to Embrace the Acrylic Home Decor Trend – 2Modern

Discusses the benefits of acrylic in home decor, including its suitability for small spaces and modern aesthetics. -

Enhancing Interior Spaces: The Versatility of Acrylic Products – Midton

Highlights the adaptability, elegance, and functionality of acrylic in shaping contemporary interior spaces. -

Why Acrylic Laminate Is A Popular Choice For Modern Interiors – EuroPratik

Examines the reasons behind the popularity of acrylic laminate, highlighting its versatility, durability, and aesthetic appeal. - View Plastic Pellets Manufacturers in China

Frequently Asked Questions (FAQs)

What is acrylic plastic made out of?

Acrylic plastic also falls under the category of polymethyl methacrylate, which is formed by polymerizing methyl methacrylate monomers. In a certain way, these monomers link up to form long chains that become functional materials in their own right, an advantage that makes the material very tough and versatile to work with. Acrylic manufacturing involves heating raw materials, such as acrylic acid, with several additives that serve to improve the subsequent properties. The end product is a transparent, lightweight, and shatter-resistant sheet. Acrylic is used in various applications due to its clarity and strength.

What are the types of acrylic?

Essentially, there are several types of acrylics categorized by their manufacturing process and physical properties. Cast acrylic is made by pouring a liquid mixture into molds, whereas extruded acrylic is formed by pushing the material through a die. Each offers specific advantages, such as cast acrylic having superior impact resistance and optical clarity. Acrylic-type polymers can also be compounded with other materials, such as polyester, to impart special properties. Therefore, the various types of acrylic are meant for different applications, from signage to aquariums.

What is the history of acrylic material?

The history of acrylic materials can be traced back to 1865, when chemists Rowland Hill and John Crawford were the first to synthesize the chemical compound methyl methacrylate, considered one of the most pioneering styles of synthetic materials. However, acrylics were not produced on a commercial scale until sometime in the 1930s. This multipurpose material gained prominence during World War II, when it was utilized for aircraft canopies and other applications requiring lightweight, transparent materials. Technical improvements in production methods, such as injection molding and extrusion, have enabled its further application across various domains over the years, thereby making acrylic a standard material in modern manufacturing.

What are its pros and cons?

The advantages of using acrylic are numerous: it is lightweight, shatterproof, and suitable for a wide range of applications. It is an easy-to-work-with thermoplastic that can be manufactured by methods such as thermoforming or injection molding. A disadvantage of acrylic is that it scratches easily and is permeable to certain solvents or chemicals, thereby limiting its applications in specific environments. While acrylic has a reasonably good impact resistance, it is not as impervious as some engineering plastics, such as polycarbonate. A knowledge of these pros and cons will help in choosing the right material for the given requirements.

What are the different applications of acrylic?

Due to its variety of properties, acrylic finds use in a wide range of applications. Signage, displays, and lighting fixtures are common names given to acrylic products due to their clarity and ease of fabrication. And when it comes to applications like aquariums, the aspects of transparency and impact resistance take precedence. Another set of applications is quite diverse, including automotive components, furniture, and even art supplies like acrylic paint. Due to its versatility, it is a good choice for both consumer and industrial products.

Can acrylic be recycled?

So, yes, acrylic can technically be recycled, making it perhaps the easiest to describe as a temporary misnomer for recycling compared to some other plastics. It is retrieved from scrap acrylic and refabricated into new acrylic products. However, special facilities may be needed to recycle it properly due to its unique properties. Many manufacturers are developing more efficient recycling methods for acrylic to mitigate some of the environmental burdens. Additionally, the durability inherent in acrylic means that products fabricated from it usually have longer lifespans, promoting sustainability in their design.