Understanding PEI and Its Applications

What is PEI?

Polyetherimide is known as a high-performance thermoplastic. It finds preference for nearly all demanding applications resulting from its excellent mechanical and thermal properties. It is an amorphous polymer having excellent dimensional stability and resistance against heat and chemicals so that it can endure adverse environments. PEI can withstand temperatures above 200°C (or 392°F) and is therefore suited for industries where materials require high durability and reliability, such as aerospace, automotive, and electronics.

The high strength-to-weight ratio is a specialization of PEI that gives it a unique mark by enabling the production of lightweight yet durable components. Its characteristic flame-retardancy and low toxicity also make PEI a safe choice for critical applications, especially in avionics and public transportation. UV resistance and transparency further allow for its consideration in optical and outdoor applications.

Apart from the well-known injection molding processes, PEI has gained significant traction as a filament-based 3D print material, owing to its high print precision and the ability to engineer designs with minimal warping. This rare combination of properties makes PEI a crucial building material for innovative processes and further optimization of products across various sectors.

Properties of PEI Sheets

Being the perfect balance of mechanothermal and chemical properties, PEI sheets become a flexible option in demanding applications. PEI is most well-known for its high-temperature resistance, with heat deflection temperature going up to 217°C (422°F). This feature helps PEI sheets deform minimally in high-temperature environments and ensures the overall longevity of the product.

PEI sheets are not only strong mechanically but also durable, able to withstand rough handling and high impacts, even at elevated temperatures, when materials like glass or thin metals bend and crack. PEI’s natural resistance to UV rays is another valuable feature, providing protection when used outdoors or in situations with high UV exposure.

From a chemical standpoint, PEI offers robust resistance to a wide array of solvents, acids, and hydrocarbons, expanding its usability in environments with harsh chemicals. The sheets are classified as flame-retardant with low smoke generation, meeting stringent safety standards required in aerospace, transportation, and electronics.

With these properties, coupled with dimensional stability and electrical insulation, the sheets are widely used in medical devices, automotive parts, and electronic housings. Another reason why PEI is considered a modern material solution for manufacturers is its machinability and compatibility with advanced manufacturing techniques.

Applications of PEI-S in 3D Printing

Due to its high flexibility and performance features, polyetherimide, also known as PEI, is a familiar name in 3D printing. Among other uses, it is a very popular building surface for FDM printers. Applying a sheet of PEI to the print bed allows for strong printing adhesion, ensuring that parts will not warp or detach during printing, thereby preventing print failures. Therefore, PEI surfaces are handy for producing exact parts with materials such as ABS, which is frequently problematic in terms of adhesion, alongside PETG.

Additionally, PEI is utilized for the manufacture of functional components and prototypes that require chemical resistance, thermal stability, and mechanical strength. Resisting high temperature without distortion also ensures its compatibility with industrial- and engineering-grade print jobs. Hence, industries such as aerospace, automotive, and healthcare find it useful. For instance, engine parts or housings for medical devices are created using an advanced 3D printer with the assistance of PEI due to its heat resistance and insulating qualities.

Additionally, the recyclability of PEI aligns with the paradigm shift toward sustainable manufacturing practices in 3D printing workflows. Balancing performance reliability, energy-efficient production, and varied applicability of projects, this material is, therefore, a resource that cannot be left out of modern 3D printing settings.

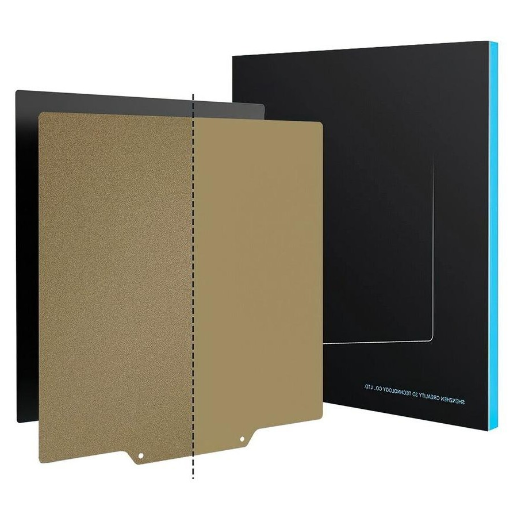

PEI Sheets and Build Plates

Advantages of Utilizing PEI Sheets for Build Plates

Key Advantages

PEI sheets hold significant value for 3D printing applications, mainly when used as build plates. While the primary advantage includes adhesion properties, PEI offers much more. PEI forms a standstill surface on which printed parts can sufficiently hold before and during the printing process, thereby restricting their movements that would otherwise cause warping and shifting, which can compromise subsequent print precision and consistency. Owing to cooling, prints can be released with ease without damage to them or the build plate.

Additionally, PEI sheets are very durable and can withstand numerous repeated heating and cooling cycles during a 3D print. They resist wear and deformation over time, greatly extending their lifespan with minimal maintenance; hence, they end up being a very affordable option for those who intend to fine-tune their production workflow.

PEI sheets are compatible with a wide range of materials, from PLA, ABS, PETG, and nylon. Such versatility caters to a wide variety of project needs, allowing the end user to work with different filaments without having to adjust or constantly change the build plate. Such an uninterrupted surface ensures consistency in quality across various prints.

PEI can also support sustainable processes if one considers the environmental angle. The last thing to do would be to churn out very often, so PEI is put into waste. PEI dual-wields by direct heat conduction energy efficiency with a clad of eco-worker in the 3D realm, thus paying homage to these perks, proving why PEI sheets are the trusted choice for professionals and hobbyists alike.

Considerations

While PEI sheets offer numerous benefits, there are some considerations to keep in mind when using them for 3D printing applications. Understanding these aspects helps users make informed decisions and optimize their printing experience.

How to Apply a PEI Sheet to a Print Bed

Beyond helping adhesion, the PEI sheet makes for an excellent surface for your 3D prints. Application of said PEI sheet requires the following precise steps:

Completing these chores establishes a firmly placed PEI sheet, allowing the print to adhere better and finish with a smooth surface without being frustrating during printing. Further maintenance added to the sheet will provide an extended lifetime.

What Is the Tile PEI Rating?

The PEI rating, or Porcelain Enamel Institute rating, is an international system that evaluates the durability and resistance of ceramic or porcelain tiles to abrasion. This system categorizes tiles into five main categories, ranging from the least to the most wear-resistant, to help consumers make an informed choice of tiles suited to their environment and application.

| PEI Rating | Traffic Level | Applications | Description |

|---|---|---|---|

| PEI 1 | No to Very Light Traffic | Residential bathroom walls | The tiles are suitable for walls or areas with minimal foot traffic, such as residential bathroom walls. They should, however, never be used on floors. |

| PEI 2 | Light Traffic | Residential bathrooms, guest bedrooms | These tiles are best suited for interiors that experience light foot traffic, like residential bathrooms or occasionally used guest bedrooms. |

| PEI 3 | Medium Traffic | Kitchens, living rooms, standard residential | With manufacturing designed to handle medium traffic, these tiles are suitable for use in kitchens, living rooms, and other standard residential areas under regular usage. |

| PEI 4 | Heavy Traffic | Entryways, restaurants, boutiques | These tiles offer increased durability and are, therefore, suitable for residential and light commercial applications, such as entryways, restaurants, or boutiques. |

| PEI 5 | Heavy to Extra Heavy Traffic | Malls, airports, and industrial areas | At the highest level of hardness, PEI 5 tiles are suitable choices for heavy-traffic commercial areas, such as malls, airports, and industrial areas that require utmost durability. |

Knowing the PEI ratings enables a homeowner or professional to choose the types of tiles that fit their aesthetic requirements as well as functional needs for a longer-lasting performance without compromising on style. Other factors to consider include the type of foot traffic expected, the abrasive materials to which the floor might be exposed, and the cleaning processes in place when selecting the right PEI-rated tile for the project.

3D Printing with PEI: Advantages and Disadvantages

Advantages of Using PEI for 3D Printing

Polyetherimide has made its way into various sectors of the 3D printing world due to its unique properties. Perhaps one of the most noteworthy advantages of PEI is its exceptionally high thermal stability, as it can tolerate extremely high printing temperatures without undergoing dimensional change. This ensures very consistent results and performance, especially in professional or industrial 3D printing systems, which require high precision.

The polymer must simultaneously exhibit good mechanical strength and resist wear to be effective for making prototypes and functional parts with durability. Chemical resistance ensures that it is compatible with any substance or medium it comes into contact with, thereby limiting the possibility of degradation over time. The other essential advantage is its minimal outgassing; thus, it is preferably chosen for industries such as aerospace and electronics, where purity and reliability are paramount.

PEI is also famous for its inherent adhesion property. Its stronger adhesion to many filaments eliminates the need for additional adhesives or surface treatments, simplifying the printing process and reducing setup time. The dimensional stability of the material ensures that it maintains high tolerances, enabling intricate and accurate design.

However, its application versatility extends from PEI platforms to supports and casings, and even medical-grade devices, further showcasing its adaptability across diverse industries. In any case, although it possesses many benefits, operational considerations like cost and equipment should be taken into consideration for an optimized 3D printing process.

Disadvantages of PEI Sheets and How to Overcome Them

Common Challenges

Wear and Tear: PEI sheets do have certain limitations despite their major benefits in 3D printing. One of the issues is that these sheets wear down with time. With repeated cycles of printing and scraping to remove the prints, the surface must eventually degrade.

Initial Cost: Another disadvantage is the initial cost. These sheets are generally costlier relative to the other types of print bed materials and that initial higher price may deter some price-conscious users.

Adhesion Difficulties: Adhesion difficulties may occur depending on the filament type used. For instance, nylon or polypropylene may not adhere well to PEI sheets without some assistance.

Maintenance Requirements: Maintaining consistent care for PEI sheets ensures their continued functionality. A lack of regular cleaning on the surface or improper handling diminishes adhesion and print quality.

Solutions & Workarounds

Combat Wear: To fix this, maintenance becomes essential, such as cleaning the print bed with isopropyl alcohol and replacing it if it starts showing signs of excessive wear like scratches and poor print bed adhesion.

Cost-Effectiveness: However, in actual use, the cost pays off in terms of durability and ease of use, which reduces the need for frequent replacement or additional adhesives. Thus, handling, cleaning, and care will add to the value.

Improve Adhesion: To solve this issue, users might apply a skinny layer of some kind of glue-like substance, for example, a glue stick or painter’s tape, to help the adhesion for these particular materials.

Maintenance Schedule: Setting a schedule for cleaning and handling the sheet delicately will retain its long-term performance without any adverse effects on printing. Tackling these issues head-on will enable users to fully enjoy the benefits that PEI sheets have to offer and help alleviate any potential issues.

A Comparison of PEI with Other 3D Printing Adhesives

From the perspective of the adhesive option, it is hard to beat PEI because it is very durable, reusable, and exhibits excellent adhesion properties for 3D printing purposes. PEI offers a consistent printing surface, unlike glue sticks or painter’s tape, as it retains its adhesive properties between numerous prints and requires no reapplication or replacement. Accordingly, glue sticks should be applied manually before every print, which can sometimes lead to uneven adhesion. On the other hand, the tape may become less effective after a few uses, primarily due to warping or tearing.

PEI sheets have the advantage of maintaining their integrity at higher temperatures and are therefore well-suited for filaments like ABS or PETG that require heated beds. On the contrary, adhesives such as hairspray and Kapton tape tend to lose some of their strength over time with prolonged exposure. They would provide less adhesion while subjected to heat. Additionally, PEI sheets are less demanding compared to those alternatives, and the only maintenance required is occasionally cleaning them with isopropyl alcohol to maintain their adhesive performance, whereas alternatives typically need to be reapplied or replaced when they wear away.

In terms of cost, PEI sheets have a higher upfront price compared to disposable adhesives, but their long life and consistent application provide better value over time. Conversely, depending on how high the consumable adhesive is replenished, the cost can spiral to become significant, typically for high-volume printers. On the contrary, PEI can be reused, withstanding tough print sessions, providing a bit of balance in terms of wastage, and allowing a print session to be stopped in midstream.

Overall, PEI sheets provide a dependable, worry-free, and heat-resistant work surface for professional 3D printing shops. For the maker community interested in achieving higher productivity, reduced downtime, and consistent print output, PEI sheets signify an easy winner over traditional adhesives.

Maintenance and Care for PEI Sheets

How to Clean a PEI Sheet Effectively

Essential Cleaning Guide

Keeping the PEI sheet clean is a crucial factor in achieving good adhesion on a print bed and obtaining adequate 3D printed results. Potential accumulation of oil from fingerprints and filament debris or other impurities can impede the proper application of this surface over time. Kindly find the entire guide below on cleaning the PEI sheet:

By integrating these processes into your routine maintenance, you will prolong the life of the PEI sheet and aid in the permanent bonding of every print. Proper care ensures an impeccable setup and may even curtail instances of print failures that arise out of contamination or wear of the surface.

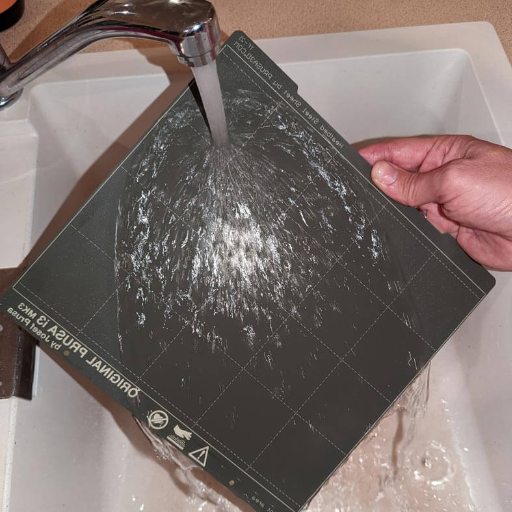

How to Get the Residue off PEI Sheets

Please ensure that the residue removal methods applied to PEI sheets should effectively work to get the job done while being gentle enough not to inflict any damage to the surface. Typically, one starts by washing the sheet with warm water and mild soap, using a soft, non-abrasive fabric to lift the grime off. If residue remains, clean the surface with a 70% or greater concentration of Isopropyl alcohol. Apply the IPA with a lint-free cloth or paper towel by gently rubbing the areas concerned. IPA dissolves oil and residue effectively without harming the sheet.

When dealing with stubborn baked-on filaments or adhesive residues, a plastic scraper is typically used to gently lift off the debris without scratching the PEI surface. Metal tools are not recommended, as they can cause permanent damage to the sheet. From here, one could use an appropriate adhesive remover or 3D-printing-related cleaning agent safe for PEI to contend with harder residues; these cleaners usually dissolve adhesives or other tough deposits without compromising the surface texture.

Finally, to curb residue from forming, light cleaning is recommended after every print session. Wipe the PEI sheet down with an IPA-dampened cloth after every few prints to minimize buildup and maintain optimal printing conditions. Forward-looking maintenance will reduce the need for heavy-duty cleaning, thereby allowing more time for your PEI sheet while maintaining consistent adhesive quality.

Best Practices for Maintaining Your PEI Build Plate

Professional Maintenance Tips

Routine Cleaning: Regular maintenance is essential to maintain adhesion performance. After generally every three or four prints, wipe the surface down with a lint-free cloth dampened with isopropyl alcohol of at least 70% concentration. Dust, skin oils, and powdery residue all accumulate on the print surface, which can cause poor builds if left unaddressed.

Never Use Abrasive Agents: Harsh cleaners can damage the surface of the PEI sheet, rendering it less effective for printing. Gentle cleaning agents, such as diluted dish soap or specialized cleaners designed for use on 3D printers, should be considered if a deeper cleaning is necessary.

Temperature Management: Higher bed temperatures are occasionally sought for printing PETG or ABS. Please ensure that your printer’s settings are suitable for the materials in use, as prolonged exposure to such high temperatures will eventually compromise the surface of PEI.

Removing Prints Carefully: For removing prints, it is best to use a soft plastic scraper or a calibrated removal tool to avoid scratching or gouging. Always avoid sharp metal tools, as they can cause permanent damage to the build plate.

Periodic Surface Reconditioning: If the PEI sheet starts showing signs of diminished performance (poor adhesion, uneven prints, etc.), one can lightly sand the surface using fine-grit sandpaper (with finer grains than 2000) to restore some of its texture. After sanding, clean up the surface with isopropyl alcohol.

Rotation or Replacement When Needed: For removable build plates, the sheet can be rotated periodically to ensure even wear. If there are still adhesion problems in spite of your best efforts to maintain it, then that’s when the PEI sheet deserves replacing so you can get consistent print quality.

Thus, by embracing these best practices in your printing routine, you can extend the lifespan of your PEI sheet while ensuring its reliable performance. Therefore, a well-maintained build plate will enable superior quality execution for every subsequent print, thereby reducing unnecessary downtime, the need for replacements, and making the 3D printing process smoother and less stressful.

Future Trends in PEI Usage for 3D Printing

Innovations in PEI Materials

When we consider innovations in PEI materials, I see a tremendous promise for the future in terms of durability, compatibility, and sustainability. Consistent with this concept, manufacturers continue to work on improved forms of PEI that will exhibit enhanced thermal stability and strength. New forms of PEI are designed to tolerate higher temperatures, allowing them to be used for more advanced types of printing. This would imply that PEI sheets will stand in for a wide variety of filament materials in the near future, including high-performance engineering-grade plastics, without compromising print quality.

Another trend I have noticed is a shift toward sustainable manufacturing. The innovations lean toward sustainable processes and recyclable PEI alternatives that fulfill broad environmental objectives. Not only does this create value for eco-conscious companies and individuals, but it also ensures that the materialis lifecycle aligns with industry demand for eco-friendly solutions. Also evolving in tandem is the surface technology of PEI sheets, which includes coatings or treatments practiced to enhance adhesion and reduce wear with time.

The fourth big area for future advances in PEI printing tech lies in the integration of innovative materials into PEI sheets. Just imagine PEI surfaces with built-in sensors that can monitor print bed conditions or provide real-time feedback as printing progresses. It’s all relatively new, but it does highlight the possibility of PEI materials transitioning from a dormant to an active, intelligent element in the printing setup. These examples demonstrate how innovations in PEI materials could shape the next generation of 3D printing technologies.

Potential New Applications of PEI in Various Industries

I see PEI (polyetherimide) as the ultimate innovation driver for many industries. The first application that I see in the aerospace domain is the engineering of lightweight yet durable components that can benefit from PEI. PEI parts are lightweight alternatives to metal due to their ability to withstand extremes of heat and chemicals, thereby reducing weight and consequently increasing the fuel efficiency of the aircraft. Another use could be in cabin interiors, where the flame-retardant qualities of PEI ensure safety without compromising the performance of the parts implemented.

The medical field is yet another area where PEI could make an impact. Due to its biocompatibility and resistance to sterilization, PEI can be utilized to produce highly specialized medical devices and surgical instruments, as well as reusable components within healthcare establishments. Resistance to repeated sterilization through steam, radiation, or chemicals is what makes PEI an ideal material in any high-demand environment striving for high standards of hygiene and durability.

Finally, I feel that consumer electronics is yet another field to be explored. Being so thin and durable really leverages the strength-to-weight ratio of PEI and its good thermal properties for creating housings, connectors, and other elements that can handle heat dissipation in their composite designs. These potential applications offer avenues that could transform the application of PEI in more than one industry in the coming years, in conjunction with advancements in 3D printing and material intelligence discussed earlier.

Evolution of the PEI Performance Standards

I recall seeing various examples of how PEI performance specifications evolved to meet the demands of newer industries and technological developments. Initially, the standards existed to maintain, if you like, a minimum standard for properties in terms of impact behavior, thermal behavior, and mechanical strength for polyetherimide materials. Hence, as new uses began to emerge, particularly in the aerospace, automotive, and electronics fields, the criteria for analyzing performance became increasingly complex. There was a dire need to examine parameters that are far more representative of real-world applications, such as extended exposure to high temperatures or the annoyance of chemical erosion.

One of the important changes I have observed in testing is the consideration of sophisticated testing methodologies relevant to current manufacturing processes, such as 3D printing and injection molding. PEI rating standards now consider how the material would behave not only in traditional applications but also in the elaborate production of custom parts allowed by additive manufacturing. This is an evolution to keep the standards aligned with the forward-thinking engineers and designers.

Sustainability and efficiency are very focused areas for the industries, and so has been the rise in eco-friendly metrics considered in PEI ratings. These focus on recyclability, energy usage in processing, and lifecycle performance of the material. At large, therefore, the evolution of PEI rating standards presents a dynamic mix of foundational testing principles and the modern-day advanced concept to solve intricate industrial problems.

Reference Sources

-

PEI plastic – TECAPEI

Provides detailed material properties, specifications, and applications of PEI. -

Polyetherimide (PEI): How to select the right grade?

Explains PEI grades, their mechanical properties, and performance characteristics. -

Polyetherimide (PEI) Material Properties & Uses

Discusses PEI’s versatility and its applications in industries like aerospace, automotive, and electronics. -

Supplier Data – Polyetherimide (PEI)

Offers a comprehensive overview of PEI’s mechanical, physical, thermal, and electrical properties. -

Moldflow Insight Help | PEI materials

Highlights PEI’s stiffness, strength, and thermal stability for high-temperature applications. - Top Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

What is the PEI sheet used for in 3D printing environments?

How do you clean a PEI build plate?

Cleaning a PEI build plate is essential to maintain its adhesive properties and ensure the prints are successful. You can clean with isopropyl alcohol (IPA) or use an alternative method, such as dish soap and warm water. The solution should be applied with a soft cloth or sponge to avoid scratching the sheet’s surface. Scrub gently, rinse with water, and wait for the plate to dry thoroughly before attempting to print with a new filament. Regular cleaning helps prevent the buildup of residue, which reduces the susceptibility to adhesion. After every few prints, it is recommended to clean the PEI surface to maintain optimal operation.