Polyetherimide has established itself as a powerhouse material in various industries, being appreciated for its exceptional performance features and unique properties. From aerospace to healthcare and electronics, the combination of strength and durability with versatility has made PEI the engineering plastic of choice for demanding applications. But what exactly sets PEI apart from other engineering plastics? This guide will reveal the unique material properties of PEI, describing some aspects of its exceptional thermal stability, chemical resistance, and lightweight composition. Whether for high-performance component design or next-generation product development, the advantages of PEI may open new doors of innovation. Now, let’s explore why PEI is becoming the top material that efficiencies, perform, and rely upon.

Understanding Polyetherimide (PEI) and Its Unique Characteristics

What Is Polyetherimide (PEI)?

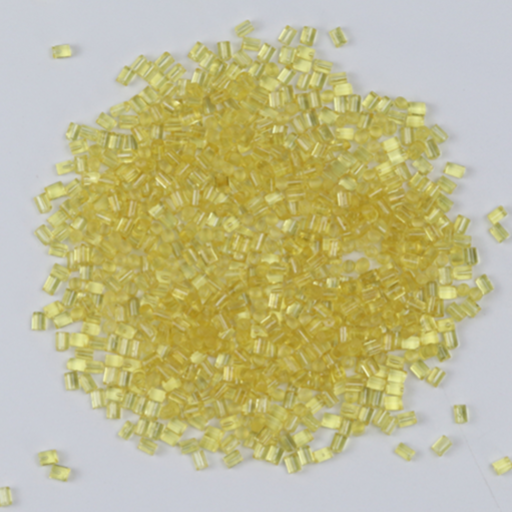

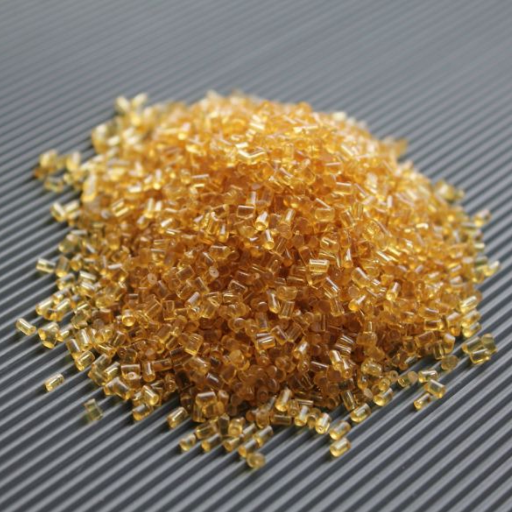

Polyetherimide (PEI), a high-performance thermoplastic polymer, is well known for its outstanding mechanical properties and versatility. The repeating imide and ether linkages in its chemical structure provide it with excellent thermal stability, enabling it to perform well at temperatures up to 218°C (424°F). It exhibits resistance to a broad spectrum of chemicals, including hydrocarbons and strong acids, which enables it to withstand the most demanding applications in the aerospace, automotive, medical, and electronic sectors.

PEI also exhibits a notable strength-to-weight ratio, high tensile strength, and satisfactory dimensional stability under stress. These features aid in selecting PEI for lightweight components where durability is crucial.

Being inherently flame-retardant, PEI self-extinguishes and meets stringent safety standards, making it an essential material for designing safe yet efficient products. Electrical insulation properties further add to its attractiveness for electronic and electrical utility, with a promise of performance over time. The synergy of thermal endurance, chemical resistance, and mechanical strength makes polyetherimide the material of choice for many cutting-edge innovations in various advanced disciplines.

Key Properties of PEI Material

Polyetherimide (PEI) has garnered attention in modern times for its exceptional attributes, including thermal resistance, among many others. It is an engineering plastic used in situations demanding very stringent requirements in engineering applications. Withstanding high temperatures, its thermal resistance remains such that PEI execution is consistent even at raised temperatures, with a glass transition temperature of above 215 °C.

- High Tensile Strength: PEI exhibits high tensile strength and stiffness, which are required to withstand stress without degradation

- Chemical Resistance: Ensures that the PEI will resist a huge array of solvents, acids, and hydrocarbons, thereby giving it reliability in harsh environments

- Excellent Electrical Properties: PEI is an excellent insulator with high dielectric strength, crucial in electronic applications

- Lightweight Design: Very lightweight while maintaining extraordinary strength, making it ideal for components requiring strength with low weight

- Flame Retardancy: UL94 V-0 rated, ensuring it meets stringent flame-retardancy standards for safety-critical applications

These properties find ample application in the aerospace, automotive, healthcare, and telecommunication sectors, continuously extending their reach into these highly technical fields.

Comparison with Other Thermoplastics

These attributes gained by PEI, as it lacks the presence of reinforcing agents and modified grades of the polymer, distinguish the plastics from other engineering thermoplastics, such as PC and PEEK, in demanding applications. For example, PEI has a distinct advantage over many other plastics in being able to resist operating temperatures continuously up to 340°F (170°C); this, in other words, puts PEI at a higher level than polycarbonate in terms of thermal performance.

| Material | Continuous Operating Temperature | Flame Retardancy | Cost Effectiveness | Chemical Resistance |

|---|---|---|---|---|

| PEI | 340°F (170°C) | Inherent (UL94 V-0) | High | Excellent |

| Polycarbonate | Lower than PEI | Requires additives | Moderate | Good |

| PEEK | Higher than PEI | Excellent | Low (expensive) | Excellent |

| ABS | Much lower | Requires additives | High | Poor |

PEEK offers somewhat higher temperature resistance and mechanical strength but is far dearer, thus giving PEI an edge as an economically viable solution where a reasonable performance is all that the budget can allow. PEI is highly resistant to chemicals and has good structural integrity compared to ABS (Acrylonitrile Butadiene Styrene), which enables it to withstand harsh chemical environments or stress.

Exploring the Material Properties of PEI

Thermal Stability and Resistance to High Temperature

With its zealous thermal stability, polyetherimide may well be considered a platinum material for any application in high-temperature environments. With a Tg of circa 217°C (423°F) coupled with continuous use temperatures of as much as 170°C (338°F), PEI finds it difficult to yield any three-dimensional mechanical force even in intense environments. These features make PEI quite attractive in high-temperature environments, such as those found in electronic components and automotive engine parts.

- Thermal Degradation Resistance: PEI attains resistance to thermal degradation and resists significant changes in structural properties upon prolonged thermal exposure

- Dimensional Stability: Can resist thermal expansion and maintain dimensional stability in thermally variable environments

- Creep Resistance: Resistance to creep under continuous mechanical loading, offering increased assurance in precision applications

- Safety Compliance: Produces minimal smoke or toxic substances during heating, making it safer than other engineering plastics

Mechanical Strength and Durability

Polyetherimide (PEI) offers excellent mechanical strength, making it a highly reliable material for demanding engineering applications. Its tensile strength, ranging from 15,000 to 22,000 psi, positions it for optimal performance under stress. Furthermore, PEI, with its high modulus of elasticity, is sturdy enough to be used for components where dimensional stability is essential.

This further categorizes it as very durable due to its physiology, which provides resistance against wear and creep under mechanical loads in prolonged or high-stress environments.

It retains its physical properties over a wide temperature range, allowing for consistent service performance in extreme conditions. PEI is, therefore, a material valued in automotive, electronics, and industrial machinery applications requiring the character of a material to be subjected to severe, demanding operational conditions-a high-strength, deformation-resistant one, and one promising in service over time.

Chemical Resistance and Environmental Stability

Due to the excellent chemical resistance of PEI, it is consequently used in chemical applications where corrosive atmospheres are present. It retains its mechanical properties when subjected to chemicals such as hydrocarbons, alcohols, and acids, which provide durability in challenging conditions.

- Hydrolysis Resistance: PEI resists hydrolysis, providing dependable performance when exposed to high humidity levels or continuous steam treatments

- UV Resistance: UV rays and other elements do not cause damage over time, enabling performance in harsh weather conditions

- Low Outgassing: Necessary for contamination reduction in aerospace and electronics industries

- Sterilization Compatibility: Essential for medical devices where autoclaving and sterilization are everyday operations

Applications of PEI Plastics in Various Industries

Aerospace and Automotive Applications

Polyetherimide plastics are critically important for aerospace and automotive applications due to their highly demanding performance requirements. Given its incredible strength-to-weight ratio, PEI lends itself well to applications requiring lightweighting, which is highly in demand in the aerospace and automotive industries for fuel efficiency and emission considerations.

- Aircraft Components: Seat frames, overhead bins, and ventilation systems requiring fire resistance and low smoke generation

- Automotive Parts: Electrical connectors, under-the-hood components, and lighting systems

- EV Technology: Sensors, autonomous vehicle technology, and EV components utilizing PEI’s dielectric properties

Electronics and Electrical Components

Polyetherimide (PEI) is a primary material used in electronics and electrical applications due to its excellent thermal stability, high electrical insulation properties, and flame retardancy. PEI demonstrates high-temperature stability and good mechanical properties, making it an ideal choice for connectors, circuit board housings, and insulators.

- High-Frequency Applications: Dielectric properties enable better performance at high frequencies for telecommunications

- Consumer Electronics: Lightweight and precision-moldable for wearable technologies and smart devices

- Safety Compliance: Components comply with stringent electrical safety and performance standards

Medical Device Manufacturing

Polyetherimide (PEI) is particularly relevant in medical device manufacturing due to its biocompatibility, resistance to sterilization, and high mechanical strength. These factors earn PEI the right to be called the material of choice in developing reliable and safe medical instruments.

- Medical Instruments: Surgical instruments, dental instruments, and diagnostic instrument housings

- Sterilization Resistance: Undergoes multiple sterilization cycles including autoclaving without compromising quality

- Life-Saving Technologies: Fluid management, instrumentation, and medical monitoring systems

Benefits of Using Ultem Plastic in Engineering

Advantages of Ultem High-Temperature Applications

Due to its high thermal stability, Ultem plastic is considered a preferred material for high-temperature applications. This high-performance engineering thermoplastic can retain its mechanical strength, dimensional stability, and electrical properties even at continuous operating temperatures of up to 340°F (170°C).

- Heat Deflection Temperature: HDT rating of approximately 392°F (200°C) for rigorous aerospace, automotive, and electronics needs

- No Deformation: Ensures Ultem components remain functional without deformation, degradation, or loss of function

- Flame Resistance: Inherent flame resistance meets stringent safety standards (UL94 V-0 rating)

- Electrical Insulation: Exceptional dielectric strength at elevated temperatures for sensitive electronic components

Cost-Effectiveness and Performance Efficiency

Ultem is a suitable choice for higher-end applications due to its excellent thermal and mechanical properties and relative affordability. By creating premium-grade high-temperature polymers, we balance the dual constraints of strength and price, enabling industries that require good performance to achieve it within their production costs.

Ultem is equipped with a long lifespan, thereby reducing the incidence of repairs and replacements, which result in significant cost savings in the long run.

They mean something in those industries that emphasize a streamlined production process, valuing the versatility of Ultem as it permits fine designs and complex geometries under injection molding and 3D printing, thereby minimizing material waste and ensuring maximum yield in manufacturing.

Environmental Considerations and Sustainability

From a performance standpoint, Ultem demonstrates sustainability in its manufacturing process. The greater durability afforded by Ultem also means that, being longer lasting, its valued products need not be replaced frequently, thus reducing overall material consumption and waste.

- Resource Efficiency: Complements 3D printing ensuring efficient resource utilization with minimal scrap

- Recyclability: Creates opportunities for industries to recover and reuse post-industrial materials

- Energy Efficiency: Manufacturing methods enhance environmental consciousness through energy-efficient processes

- Carbon Footprint Reduction: Use of renewable energy and optimized supply chains reduces environmental impact

Future Trends in PEI Material Development

Innovations in PEI Polymer Technology

Recent developments in PEI polymer technology are focused on enhancing material performance, promoting sustainability, and providing adaptability for contemporary industrial applications. A significant innovation in this regard has been the development of nanotech-enabled high-performance PEI composites, which enhance the strength-to-weight ratio, thermal stability, and electrical conductivity.

- Nanotech Composites: Enhanced strength-to-weight ratio, thermal stability, and electrical conductivity for aerospace and automotive industries

- Additive Manufacturing: 3D-printing advances enabling precise fabrication of complex geometries using PEI filaments

- Sustainable Materials: Exploration of nature-derived alternatives to replace PEI precursors while maintaining high performance

- Recycling Innovation: Transforming PEI wastes into reusable materials for secondary applications

Potential New Applications in Emerging Markets

I see a lot of potential for PEI in emerging markets where industries are quickly developing and in need of advanced solutions. In renewable energy, for instance, PEI’s excellent thermal resistance and mechanical characteristics make it an ideal candidate for applications in wind turbines and solar panels, where durability and efficiency depend on precise demand.

Renewable Energy

PEI’s thermal resistance and mechanical characteristics make it ideal for wind turbines and solar panels applications where durability and efficiency are crucial.

Electric Vehicles

As the EV industry gains momentum, PEI could play a crucial role in reducing vehicle component weight while enhancing energy efficiency and ensuring safety standards.

Telecommunications

With 5G network rollouts, PEI’s usefulness in miniaturized components operating under harsh conditions enhances network reliability and performance.

Challenges and Opportunities in PEI Manufacturing

When I think about the manufacturing procedure of Polyetherimide, some particular challenges come to mind: these arise mostly because of the particular properties of the material. Considered Diaspically, one of the key challenges arises in processing polyetherimide due to its very high melting point and viscosity, necessitating specialized installation and machinery to meet the extreme conditions required in production.

- Processing Challenges: High melting point and viscosity require specialized equipment and machinery

- Quality Consistency: Achieving practical consistency in large-scale production with stringent temperature control

- Supply Chain Issues: Special raw materials face supply or price fluctuation problems

- Technology Advancement: Improved processing methods in molding and extrusion enable more efficient PEI handling

Reference Sources

-

PEI Plastic – TECAPEI by Ensinger Plastics

Discusses PEI’s high operating temperature, mechanical strength, rigidity, and creep resistance. -

Polyetherimide (PEI): How to Select the Right Grade? – SpecialChem

Covers PEI’s tensile strength, stiffness, impact strength, and flexural modulus. -

PEI Material: Properties, Applications & Manufacturing Uses – American Additive

Highlights PEI’s thermal stability, chemical resistance, and compatibility with various solvents and fuels. -

Polyetherimide (PEI) Material Properties & Uses – TunTun Plastic

Explains PEI’s strength, rigidity, heat resistance, and electrical properties. -

Polyetherimide (PEI) – Drake Plastics

Focuses on PEI’s strength-to-weight ratio, thermal oxidation resistance, and long-term performance. - View Plastic Pellets Manufacturers in China

Frequently Asked Questions (FAQs)

What are the key characteristics of PEI materials?

Widely acclaimed mechanical properties of PEI include high strength and rigidity. This amorphous engineering thermoplastic has excellent thermal properties, suitable for high-temperature applications. Electrical properties of PEI plastics, although generally good, are necessary in specific industrial applications. Due to its good dimensional stability, PEI can retain its shape under stress and undergo glass fiber reinforcement for enhanced performance. In brief, PEI is often referred to as a versatile polymer capable of meeting modern engineering needs.

How does Ultem plastic compare with other engineering thermoplastics?

On this scale, Ultem was the working name for polyetherimine. It has better properties when compared to most other engineering-grade thermoplastics. The resistance to high temperatures categorizes this product as an ideal solution for applications in environments that experience extreme heat. Ultem, compared to other thermoplastics, exhibits greater mechanical strength and durability, resisting stress cracking more effectively. The manufacturing process proves quite economical for mass production, accounting for the maintenance of interspecies quality. Hence, Ultem finds a vast scope in industrial applications.

What are typical applications of PEI materials?

Industrial PEI materials, such as those sold under the Ultem trademark, have applications in nearly every sector, particularly in the aerospace and automotive industries. Their high mechanical strength and thermal properties underscore their suitability for operation under high temperatures. PEI is primarily used to manufacture electrical connectors, insulators, and components for microwave applications. Furthermore, its excellent mechanical and electrical properties make it suitable for medical device and tooling design applications. Therefore, PEI’s versatility is a significant reason why it finds use in industries that require applications that need strong and durable materials.

What distinguishes polyetherimide as a specialty plastic?

Polyetherimides are a relatively new group of specialty plastics characterized by a unique combination of properties. They are amorphous engineering thermoplastics known for heat resistance at elevated temperatures and superior mechanical properties. This particular class of polymers is primarily developed to address polyimide-related issues, offering higher dimensional stability and ductility. PEI materials are sometimes reinforced with glass fiber for enhanced strength and rigidity. Their adaptable nature in meeting industrial demands contributes to their position as the new specialty plastic class.

How does PEI thermal performance influence its application?

The thermal properties of PEI materials are indeed the primary grounds for their applications. These materials, being highly heat-resistant, can maintain their performance and structural integrity even in exposure to higher temperature extremes. This inclines them toward the aerospace and automotive sectors, where thermal stresses are considerable on the components. Meanwhile, the excellent thermal stability of PEI also makes it suitable for mold-making processes, where the material must retain its shape and strength in temperature-varied conditions. This property goes a long way in fully extending the range of uses where PEI can be put effectively.

Are PEI materials tailor-made for particular applications?

Yes, PEI materials can be suitably modified for specific applications, with their performance being enhanced accordingly. The strength and rigidity imparted to unfilled PEI by the addition of glass fibers enable it to be used in harsher environments. Similarly, a significant number of additives can be used to improve various properties such as fire resistance, or friction and wear performance. The modified form then becomes suitable for engineers to use in customizing PEI materials according to projects. Hence, the versatility of PEI as a polymer makes it particularly sought after in various applications, including electronics and automotive manufacturing.