A material selection process has to be considered to provide durability in the performance and efficiency of engineering applications. Among an almost innumerable list of choices, consisting of polymers and metallic materials, Delrin Acetal is one of the best contenders due to its respect for its mechanical properties and versatility. But is it good enough for your needs? This article explores the key features of Delrin Acetal, highlighting alternative choices, and examines why this thermoplastic is frequently selected by engineers and manufacturers across various industries. By the end of this article, you will have a clear understanding of whether Delrin Acetal is the right material for your next project or if another material might better suit your performance requirements.

Understanding Acetal and Delrin

What is Acetal?

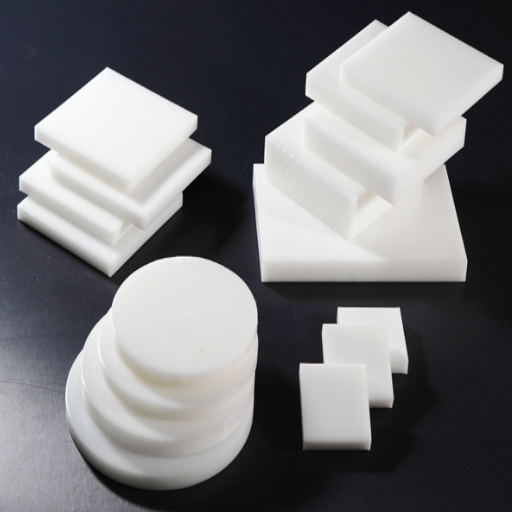

Acetal, also known as polyoxymethylene (POM), is a highly versatile engineering thermoplastic characterized by excellent mechanical strength and dimensional stability. It is used in precision components where strength, durability, and low friction are required. Acetal is highly resistant to moisture, chemicals, and wear; therefore, industries that utilize it include automotive, consumer goods, and electronics.

Acetal has several key features—from lightweight properties to strength—that enable manufacturers to achieve considerable weight savings in their manufactured parts without compromising performance. Gears, bearings, and sliding components, where smooth motion and minimal wear are paramount, are a favorite choice in Acetal due to its low coefficient of friction and self-lubrication characteristics. Acetal is also rigid over a wide temperature range, thereby providing stable performance under various environmental conditions. Such features make it a favorite amongst engineering and manufacturing environments.

What Is Delrin?

Delrin, a premium-grade acetal resin, is recognized for its excellent mechanical properties, making it suitable for a wide range of industrial applications. The high tensile strength and stiffness ensure precise and dependable performance, particularly in applications involving demanding engineering tasks. Since Delrin is resistant to moisture and certain solvents and chemicals, it is suitable for use in environments where exposure to harsh substances is routine. Its dimensional stability also allows parts to maintain their shape and function when subjected to stress or adverse climatic conditions for extended periods.

Recent advances in material science have further improved Delrin’s characteristics. For example, its impact resistance has been enhanced to provide higher durability, making it suitable for use in automotive bushings and industrial machinery parts. In addition to vibration damping from noise, this is considered a standard for use in quieter mechanical structures. With established data points confirming longevity compared to other polymers, Delrin remains the go-to polymer for manufacturers looking to ensure performance and cost efficiency over the long term.

Key Properties of Acetal Plastics

Acetal plastics, also known as polyoxymethylene (POM), have a well-established reputation due to their high mechanical properties and wide range of applications across various industries. Perhaps the number one feature is that acetal plastics can present both strength and rigidity in adverse environments. Quite simply, they are capable of withstanding significant mechanical stresses without distortion, and hence can be used in high-performance applications.

They perform well in terms of coefficient of friction and wear resistance. Acetal plastics are ideal for components such as gears, bearings, or conveyor systems where smooth operation and low wear are crucial. The acetal plastic compounds are moisture-resistant and resist a variety of chemicals, including fuels, solvents, and oils, thus ensuring optimal performance in such chemical environments.

Besides the high-dimensional stability that keeps a shape firmly intact under thermal and mechanical stresses, acetal plastics perform well across a wide temperature range, thereby increasing their potential in various industries and applications. Another self-lubricating attribute of the product lessens maintenance requirements; therefore, it tends to be more cost-efficient in the long term.

Lastly, given that the material is well-suited for machining, manufacturers can readily produce precise and intricate parts. Being strong, durable, and adaptable, acetal plastics are therefore the material of choice for applications requiring utmost reliability and long-term performance.

Comparing Acetal and Delrin

Delrin vs Acetal: A Detailed Comparison

Delrin and acetal plastics are unmistakably noted for their special nature in molding applications; however, there indeed are slight differences that affect their suitability for certain uses. Delrin stands as a brand-name acetal resin manufactured by DuPont; the unfilled homopolymer boasts higher levels of mechanical properties, such as tensile strength, rigidity, and resistance to impact, thereby granting it applications subjected to heavy loads or stress-induced repetition, such as gears, bushes, and automotive parts. It has a uniform molecular structure providing the required dimensional stability and low friction needed in precision parts.

Generally speaking, acetal plastics are referred to as polyoxymethylene (POM) and encompass both homopolymer and copolymer forms. Acetal copolymers offer slightly lower strength and stiffness compared to Delrin, but at a higher reward in terms of chemical resistance and thermal stability. Acetal copolymers are best suited for use in environments with prolonged exposure to moisture or harsh chemicals, as they impermeably resist degradation. On the contrary, copolymers better resist centerline porosity, as they are preferred materials for making thick or intricate parts.

Factors such as environmental conditions, mechanical requirements, and price must be considered when choosing between Delrin and generic acetal plastics. Delrin stands unsurpassed in strength and toughness, making it best suited for applications where mechanical strength is required. Meanwhile, acetal copolymers are considered more flexible in terms of both chemical resistance and thermal resistance. This fine distinction highlights the importance of matching the material’s properties with the specific needs of the application for optimal outcomes.

Differences Between Acetal Homopolymer and Copolymer

Very often, engineering-grade plastics are used for their strength and rigidity, as well as for materials that require high machinability. Being the closest relatives, with their great similarities, their chemical compositional differences create variations in physical properties that make them suitable for distinct applications.

Acetal Homopolymer Advantages

- Higher rigidity and mechanical strength

- Excellent dimensional stability under load

- Lower coefficient of friction

- Perfect for precision parts and gears

- Superior wear resistance

Acetal Homopolymer Limitations

- Inferior chemical resistance, especially to acids

- More susceptible to degradation over time

- Higher coefficient of thermal expansion

- Risk of centerline porosity in thick sections

An acetal homopolymer, also known as polyoxymethylene (POM), is a thermoplastic polymer based on acrylonitrile that is widely recognized for its high rigidity, mechanical strength, and excellent dimensional stability under load. It also possesses a slightly lower coefficient of friction, which makes it perfectly suited for applications exposed to wear and requiring precise dimensions, including those of gears, bearings, and precision parts. However, its chemical resistance is somewhat inferior, especially in the presence of acid media, which tend to reject it slowly over time.

Conversely, acetal copolymer offers resistance to a broader range of chemicals, including hot water, alkaline solutions, and solvents. This advantage has rendered this form of material the top choice for chemically challenging work environments or high-moisture settings, such as those found in medical devices, food processing equipment, and plumbing components. It is less rigid compared to its homopolymer counterpart, but on the other hand, it has a significantly stronger resistance to thermal degradation, making it more suitable for long-term exposure to fluctuating temperatures.

Thermal expansion and processing behaviors are another crucial key to separation. Difficult to process with tight tolerances, acetals have a smaller coefficient of thermal expansion due to their high crystallinity. On the other hand, with reduced crystallinity, the copolymer introduces less risk of centerline porosity during processing, thus resulting in a more uniform material structure through thicker sections.

For selecting the proper material, an evaluation of environmental exposure, temperature considerations, and mechanical requirements must be performed. By appropriately matching the material’s properties with the requirements of the particular application, manufacturers can ensure optimal performance, reliability, and service life of their products.

Physical Properties of Acetal and Delrin

Acetal and Delrin possess a coveted combination of material properties that endow them with superior mechanical strength, thermal stability, and chemical resistance, enabling a host of industrial and commercial applications. They have been reported to have a fairly low coefficient of friction and a high rate of wear resistance that renders trouble-free and uninterrupted performance in high-precision components such as gears, bearings, and bushings.

Density

Acetal generally stands at around 1.41 g/cm³, while Delrin, an acetal homopolymer, exhibits nearly the same density. This consistency enables the creation of lightweight designs that can be enhanced for improved mechanical performance.

Tensile Strength

Delrin takes the lead in tensile strength, with results ranging from 8,800 to 11,000 psi, depending on the particular type and formulation. This property renders Delrin fit for the applications that require mechanical stability under load. Acetal copolymers exhibit slightly lower tensile strengths but are still up to the job in harsh environments.

Flexural Modulus

The flexural modulus of both Acetals and Delrin ranges from 350,000 to 450,000 psi; this value is a clear indication of their rigidity and ability to resist deformation under stress. This property will be crucial for load-bearing parts and structures.

Thermal Properties

Both materials operate within a wide temperature range (-40°F to 180°F; -40°C to 82°C) under normal conditions, which encompasses the entire possible range. Generally speaking, Delrin is known to be thermally stable. In rare cases, however, Delrin may experience intermittent high-temperature exposure.

| Property | Acetal | Delrin | Units |

|---|---|---|---|

| Density | ~1.41 | ~1.41 | g/cm³ |

| Tensile Strength | 7,000 – 9,500 | 8,800 – 11,000 | psi |

| Flexural Modulus | 350,000 – 450,000 | 350,000 – 450,000 | psi |

| Operating Temperature | -40°F to 180°F | -40°F to 180°F | °F |

| Moisture Absorption | <0.22% | <0.22% | % at saturation |

Moisture Absorption: Acetal and Delrin have a moisture absorption rate lower than 0.22% at saturation. The property assures great dimensional performance in watery and humid conditions, which becomes critical when precision parts face variable operating conditions.

Chemical Resistance: Both materials exhibit resistance to a wide variety of chemicals, including hydrocarbons, solvents, and weak acids, ensuring they are durable enough for use across multiple industries. However, concentrated acids and strong oxidants should be avoided since they will degrade the material over time.

Hence, an engineer or manufacturer can always use these physical properties to decide what essentially makes a good-performing material best suited to a specific application.

Applications of Acetal and Delrin

High-Performance Engineering Applications

Given their excellent mechanical properties, dimensional stability, and resistance to wear and chemicals, Acetal and Delrin find widespread applications in the field of high-performance engineering. These materials have applications in industries where precision and reliability are of utmost importance, like the automotive, aerospace, electronics, and medical device industries.

For instance, in automobiles, the materials used are for joints, gears, bushings, and other fuel system components, which must be able to withstand high temperatures while maintaining their structural integrity under load. Consequently, aerospace applications utilize these materials, taking advantage of their lightweight properties and ability to withstand harsher conditions without compromising performance.

Additionally, in electronic devices, the insulation properties enable the material to perform reliably in circuits and components that require sensitivity. The industry also benefits from the medical field, as Acetal is biocompatible and can be easily sterilized, making it very often utilized in the manufacture of surgical instruments and prosthetic devices. Leveraging these unique properties, Acetal and Delrin can continue to innovate in high-performance engineering fields under stringent industry standards, offering reliable solutions to present-day challenges.

Industries Using Acetal Plastics

Key Industries and Applications:

- Automotive: Gears, bushings, fuel system components

- Consumer Electronics: Keyboard parts, housings, snap-fit connectors

- Food & Beverage: Conveyor belts, bearings, slide guides

- Medical: Surgical instruments, prosthetic devices

- Industrial: Machinery components, precision parts

Regarding different sectors, Acetal plastics play a crucial role in industries, as they are characterized by their mechanical performance, chemical resistance, and durability. One major industry that benefits from Acetal’s qualities is the automotive sector. Acetal parts, including gears, bushings, and fuel system components, find a comprehensive application with respect to their strength-to-weight ratio, low friction property, and ability to work under extreme temperatures and harsh chemical environments. Such properties help enhance vehicle performance and reduce weight, thereby enabling vehicles to better meet stringent regulatory requirements and improve fuel efficiency.

Yet another essential application for Acetal in the production of consumer goods and electronics. Their high-dimensional stability and very low moisture absorption make all Acetal materials perfect for the production of precision parts such as keyboard parts, housings, and snap-fit connectors. From an electrical point of view, they offer assurance to electronic devices regarding safety and prolonged working life. Its versatility allows for another dimension of innovations in consumer electronics, specifying compactness, ruggedness, and functionality.

Another field where Acetal plastics are used quite often is the food and beverage industry. Due to its excellent resistance to moisture, chemicals, and wear, Acetal finds extensive use in food processing machinery for applications such as conveyor belts, bearings, and slide guides. Moreover, Acetal grades compliant with the FDA are certified safe for direct food contact. This use promotes hygiene and safety, and it also preserves the product’s utility over time in an industrial environment where it is exposed to moisture and cleaning agents daily. These wide applications hence establish Acetal as one of the basic materials in any industry that runs on HPC worldwide.

Success Stories with Delrin

Food Processing Industry Success

A leading food processing company used to install stainless steel conveyor components. Switching to Delrin-based components reduced maintenance and operational costs and somewhat enhanced the operation of the conveyors due to their wear resistance and FDA compliance. Thus, the company could comply with stringent sanitation standards while significantly reducing downtime.

Automotive Industry Achievement

In the automotive industry, similarly, Delrin’s high tensile strength and low friction permitted manufacturers to extend the life of essential components, such as gears and bushings. This modification reduced warranty claims to a minimum and extended product life, resulting in cost savings and increased customer satisfaction.

Medical Device Innovation

By taking advantage of its dimensional stability and biocompatibility, the producers of medical devices have elected Delrin for the manufacture of precision instruments. Precise and dependable operation in testing environments such as the surgical theater ensures compliance with rigorous regulatory standards.

Success in the examples given highlights the flexibility and efficiency of Delrin in a host of demanding applications, making it a reliable and cost-effective solution. By enabling sustainable solutions and product enhancement, Delrin has been carving its place as a critical material in innovation-driven industries.

Choosing Between Acetal and Delrin

Factors to Consider in Material Selection

Choosing the right material, whether Acetal or Delrin, depends on several vital considerations tailored to the specific task at hand. These include mechanical considerations such as tensile strength, impact resistance, and dimensional stability. Delrin is chosen more often due to its higher crystallinity, which endows it with greater fatigue resistance and durability for use in high-load, repetitive applications, such as gears or conveyor systems.

Key Selection Criteria:

- Mechanical Requirements: Load capacity, stress resistance, dimensional stability

- Environmental Conditions: Temperature range, chemical exposure, moisture

- Thermal Considerations: Operating temperature range and thermal stability

- Chemical Resistance: Exposure to solvents, fuels, and aggressive chemicals

- Cost Efficiency: Material cost vs. performance requirements

- Regulatory Compliance: FDA, NSF, or industry-specific standards

- Sustainability: Recyclability and environmental impact

The given example is an essential thermal consideration. Delrin offers good thermal stability, allowing it to perform well in environments subject to fluctuating temperatures. Being able to maintain performance under harsher conditions is a selling point and can be the deciding factor in any application.

Chemical resistance is an important consideration. Both Acetal and Delrin can resist most solvents, fuels, and chemicals. However, Delrin can usually resist prolonged attacks in more aggressive environments; hence, it is frequently used in automotive or industrial applications.

When cost efficiency must be considered, pricing must also come into the equation. Acetal can be a more cost-effective choice for applications requiring minimal strength, while Delrin can justify its higher price for projects that require better mechanical and thermal properties.

Another consideration is the regulatory framework. In both cases, the materials can meet FDA, NSF, or other industry-specific standards, but whether they do will depend on the precise requirements for the application, specifically those related to food contact and medical use.

Lastly, sustainability is gaining due attention on the choice of materials. Manufacturers can compare the green attributes of each material, such as recyclability and energy usage during production, to ensure they align with corporate sustainability objectives.

By studying these factors more thoroughly in concrete terms, engineers and designers will have sufficient information to make informed decisions about how to optimize efficiency, performance, and cost-effectiveness in their programs.

Cost vs Performance: Acetal vs Delrin

If we bear Acetal and Delrin in mind, the cost-performance relation becomes an essential consideration in choosing the material relevant to your application. Both are types of polyoxymethylene (POM) thermoplastics, prized for their outstanding mechanical properties, yet they differ in crucial aspects that affect pricing and performance.

| Aspect | Acetal Copolymer | Delrin (Homopolymer) |

|---|---|---|

| Cost | Lower material cost | Higher premium pricing |

| Tensile Strength | Good performance | Superior strength |

| Creep Resistance | Adequate for most uses | Excellent long-term stability |

| Chemical Resistance | Superior moisture/chemical resistance | Good overall resistance |

| Best Applications | Consumer goods, cost-sensitive projects | High-stress, precision applications |

Cost Analysis: Acetal, usually sold in copolymer forms, is often less expensive than Delrin, a homopolymer POM produced exclusively by Du Pont. The relatively expensive pricing implemented by Delrin is due to its enhanced mechanical performance and manufacturing precision. For projects with a tighter budget or those requiring only general-purpose properties, Acetal copolymer provides a competitive advantage due to its lower material cost.

Performance Evaluation: While Delrin can meet superior performance requirements, its homopolymer structure provides it with higher tensile strength, better creep resistance, and greater stiffness compared to Acetal copolymer. Delrin is therefore highly recommended for gears, bearings, and precision parts, all of which are subjected to significant stresses. The Acetal, on the other hand, is highly resistant to moisture, chemicals, and fatigue, making it suitable for applications where dimensional stability and durability are paramount.

Case Study Applications: For industries requiring heavy mechanical loads, such as the automotive and aerospace sectors, Delrin justifies its higher cost due to its strength and durability. On the other hand, where economic factors are of prime concern—for example, in consumer goods or industrial use—Acetal is just about as good, without compromising key performance demands.

Establishing such trade-offs between cost and performance enables the engineer and procurement team to make a conscious decision to choose either Acetal or Delrin, optimally planning the project’s result into a balanced mix of functionality and economic efficiency.

Recommendations for Specific Applications

Specific application considerations for Acetal and Delrin require evaluating the unique demands of the intended use case. Examples would be:

Automotive Industry

Delrin: Advanced gear production, fuel system components, and bearings due to exceptional stiffness and mechanical stress compatibility. Good dimensional stability ensures longevity in environments with temperature variations and exposure to fuels or lubricants.

Acetal: Interior mechanisms and trim clips for cost-effective solutions while maintaining reliable baseline performance.

Consumer Goods

Acetal: Production of zippers, fasteners, and various small parts for appliances where cost is a significant concern.

Delrin: High-grade or precision-like products such as sports goods where higher strength and wear resistance are crucial.

Industrial Applications

Delrin: Heavy industries requiring wear-resistant parts for conveyor belts, pulleys, and valve housings, extending working life through tough and resilient nature.

Acetal: General-purpose parts where price and reliability rank equally important.

Medical Equipment

Delrin: Preferred for superior mechanical properties and resistance to sterilization processes. Applications include surgical instrument handles and orthopedic tools.

Acetal: Disposable options for mechanical parts and equipment where single-use would be more practical.

For example, both Acetal and Delrin can be carefully cross-utilized to meet the project’s performance objectives at the lowest possible cost through a critical assessment of application requirements, considering factors such as stress load, environmental exposure, and budget. In this manner, the material selection process will be entirely appropriate from both a technical and economic viewpoint.

Conclusion: Is Delrin Acetal Right for You?

Summary of Key Takeaways

Ultimately, when deciding whether Delrin Acetal is the right choice for you, it comes down to understanding your specific needs. In my opinion, Delrin Acetal strikes a perfect balance between strength, pliability, and durability, offering a wide range of applications for which it can be used. Should you require a material that is capable of withstanding high mechanical stress while remaining stable under varying conditions, Delrin Acetal would rank at the very top of the search list. It is wear-resistant, exhibits very low friction, and in terms of demanding attributes, it probably outperforms many materials.

In short, Acetal is the more flexible and cost-effective alternative, one that may be suitable when applications require similar properties but don’t require the maximum performance standards that Delrin Acetal offers. Once you have considered factors such as environmental exposure, load stresses, and budgeting, Acetal is often the material that fills the need without requiring a significant investment in either your plans or your budget.

Ultimately, the choice between Delrin and other Acetal grades largely depends on prioritizing either long-term durability or an affordable price. For projects with technically demanding requirements or materials that deliver consistent results in challenging conditions, I believe Delrin Acetal is an excellent investment. Otherwise, the cheaper, marginally performing Acetal alternatives would likely be better choices. Thus, a thoroughly analyzed application will ensure a more informed and economically sound choice.

Future Trends in Acetal and Delrin Usage

Looking ahead, I expect industries to continue pushing the use of Acetal and Delrin materials, which offer outstanding performance and adaptability. First on the sustainability agenda is the environmentally conscious trend. Manufacturers are exploring possibilities to manufacture Acetal and Delrin at lower environmental costs, including the development of biosustainable or recyclable options. This is all the more significant as industries strive to meet tighter environmental regulations and consumer expectations for eco-friendly business practices.

Another key trend I foresee is the increased integration of these materials into advanced manufacturing technologies such as additive manufacturing and precision machining. Acetal and Delrin are highly machinable and dimensionally stable, which is very important in the manufacture of custom parts and complex designs in cutting-edge fields such as aerospace, robotics, and medical devices. More companies will look to these materials for higher-performing applications where tight tolerances and reliability are necessary.

Additionally, given the next wave of industry trends in the automotive and electronics spheres, mass production of Acetal- and Delrin-based materials may be initiated due to their best strength-to-weight performance. Hence, innovations in weight reduction while maintaining the structural integrity of electric vehicles and small-sized, high-performance electronics may need to focus on these areas. For me, these trends indicate the need to stay well-informed and flexible, so that I can remain on track with the use of these materials as they evolve and as market needs change along with them.

Final Thoughts on Material Selection

From my point of view, I consider materials selection to remain among the most critical factors for the success of any innovation, more so nowadays when technology and market demands are evolving. A material is chosen not just to satisfy the basic requirements of a particular application; the designer needs to be able to make trade-off decisions that, along with others, optimize performance, sustainability, and cost effectiveness. The process of prioritizing can be challenging, but it ultimately determines whether the end product is viable and competitive. For example, the choice of lightweight composite materials for EVs indirectly affects consumer acceptance through impacts on driving range and performance.

In developing strategies for solving these problems, I consider it essential to stay at the forefront, thinking about the ‘stealing their pulse’ notion of industry advancements and new materials. These things fall into the category of tools and resources that help keep us aware of tech advances and how they’re being applied in practice. Collaborate with relevant experts, test them in real-life situations, and continue learning—these are all essential steps in choosing materials wisely. The ability to adapt your strategy in response to a shift in priorities, reflecting the sustainability behind laws or any other agreed-upon criteria, is what defines long-term success in the decision-making process surrounding materials.

Reference Sources

-

Acetal vs. Delrin®: Their Differences – Xometry

Explains the molding properties of Delrin Acetal resin and its advantages in injection molding. -

Acetal vs Delrin: The Differences Between These Engineering Plastics – Europlas

Highlights Delrin’s durability, flexibility, and suitability for demanding applications. -

Delrin vs Acetal: Compare Performance & Uses – Biopolymer Materials

Discusses Delrin’s superior mechanical properties, making it ideal for high-strength and stiffness requirements. -

Delrin vs Nylon: What Sets Them Apart? – Jiga

Compares Delrin’s strength, stiffness, and stability to those of other materials, such as nylon. -

PEEK vs Delrin: Properties and Applications – Jaco Products

Explores Delrin’s affordability, strength, and wear resistance for industrial applications. - View Plastic Pellets Manufacturers in China

Frequently Asked Questions (FAQs)

What is Delrin, and what is its relation to acetal?

Delrin is a trademark for a particular type of acetal homopolymer manufactured by DuPont. It is commonly referred to as acetal plastic and exhibits excellent mechanical properties. Delrin has an even crystalline structure, which renders it strong and durable. All Delrin is acetal, but not all acetal is Delrin. This distinction becomes particularly important when choosing applications for automotive or consumer goods, where a specific performance is required.

What are the primary distinctions between Delrin and other acetal types?

The primary distinction between Delrin and other types of acetal, such as acetal copolymers, lies in molecular structure. Delrin is a homopolymer, consisting of a single type of polymer chain, which provides higher stiffness and fatigue resistance. On the other hand, acetal copolymers contain two or more subunits, which may confer greater flexibility and impact resistance. Such differences can influence the choice of materials for applications demanding specific plastic properties, such as low friction and dimensional stability.

What would be the different physical properties between acetals and Delrin?

When comparing acetal and Delrin, it’s essential to consider the physical properties. With a somewhat lower coefficient of friction, it is used for applications where a reduction in friction is crucial at some point, e.g., gears and bearings. Furthermore, it exhibits excellent dimensional stability across varying temperature ranges, whereas certain acetal copolymers might possess better resistance to hot water. From the perspective of mechanical strength and chemical resistance, sometimes it is an either-or situation between these two materials.

What are some applications best suited for Delrin® plastic?

Delrin® is perfectly filled for automotive, food processing, and general consumer industries. Its strength and low friction coefficient make it suited for gears, bearings, and sliding parts. Wear and creep resistance further enhance its performance in harsh environments. Industries choose Delrin for the ability to resist chemical attacks and temperature changes, while still maintaining high performance.

What features set acetal apart from other plastics?

Here are some advantages that acetal plastics, including Delrin, enjoy: dimensional stability, a low coefficient of friction, and high mechanical strength. Hence, they are extensively used in fine machining and high-performance applications. Usually, acetal has a lower coefficient of friction compared to other thermoplastics, which helps reduce wear on moving parts. Additionally, acetal with greater chemical resistance can be utilized for food and medical applications, which require safe and very hygienic conditions.

What are the benefits of using acetal copolymer?

There are several unique properties offered by copolymer acetal that distinguish it from its homopolymer counterpart, such as Delrin. Being the more impact-resistant and less porous option, the copolymer is employed where flexing and toughness are required. The copolymer design yields qualitatively better performance when subjected to varying temperatures or chemical exposures. Although it is not as stiff as Delrin, in many applications, particularly those in dynamic environments, it is preferred with its lower friction coefficient and greater machinability.