In product manufacturing, your choice of material may fall between PVC (Polyvinyl Chloride) and TPE (Thermoplastic Elastomer). PVC (Polyvinyl Chloride) and TPE (Thermoplastic Elastomer) are two materials that most often come up in your decision-making process. But how do you distinguish between them and choose the one that best fits your specific application? Designing and developing consumer goods, medical appliances, or industrial parts take these materials’, with their unique properties, benefits, and limitations, into consideration and thereby allow the respective choice of the smartest side of the decision-making process. The article goes into detail about the main differences between PVC and TPE and provides the knowledge to choose the right material. A follow-up on the very factors that determine the materials, in terms of durability, flexibility, environment, and also costs, will be outlined giving the way forward on the choice to make! Let us take a tour of these two big materials and we compare which one is better than the other.

Introduction to PVC and TPE

What does PVC stand for?

PVC, or polyvinyl chloride, is a well-known synthetic polymer appreciated for its durability and multi-functionality. It occupies the top spot among the most globally produced plastics and is highly praised for being strong, long-lasting, and cost-effective. PVC is most commonly used in the building sector as it boasts good material properties and is resistant to moisture. Furthermore, it can become either flexible or rigid through the introduction of plasticizers that alter its chemical structure, thus, broadening the product spectrum to cables, medical instruments, and even artificial leather. Despite the wide acceptance of PVC due to its cost-effectiveness and suitability for end-use versatility, the damages posed to the environment through its production and disposal have brought about serious attention and initiated the search for more eco-friendly solutions.

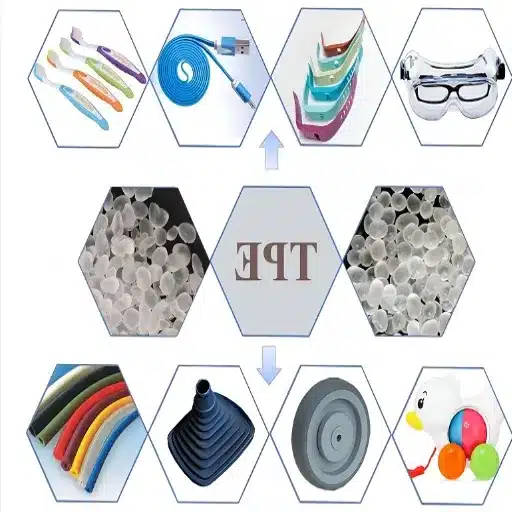

What is TPE?

Thermoplastic elastomers (TPE) are great materials, which combine the properties of the two materials into one, the rubber and the plastic. Therefore, TPE shows all three major features at the same time: rubbery elasticity and plastics flexibility at the same time. They are the materials that been through a long development process, having a level of compatibility in the materials to the extent that they can be safely used together in a single device without any issues. PostMapping in other words, though TPE is soft and bouncy like elastomers, it is still processable just like thermoplastics are; that is, it can be molded, formed, and even melted down to make another product.

Additionally, TPE has a soft feel and offers good protection against impacts, and can maintain its properties in harsh environments like high temperature, UV, and the presence of chemicals. Moreover, as the world is getting more conscious about the ‘save-the-world’ focus, a greater demand is being placed on TPEs as they are the only ones amongst the others (polymers) that can be repeatedly used.

Advantages of PVC and TPE

PVC (Polyvinyl Chloride) and TPE (Thermoplastic Elastomers) are two of the very common adapted materials in the current manufacturing industries because of their specific features. No matter if they are taken separately or in combination, they have got applications in different industries and that has a great contribution to the economy.

🚗 Automotive Industry

When it comes to making cars, PVC and TPE have been the most used materials in the production and are still the most versatile ones that could be found. Especially the automotive industry has made a very great share of it. The use of TPE has been the most common way for car manufacturers to incorporate the soft touch (uveati; chaise) dashboard idea, and the reasons for this are that its elasticity and resistance to shocks. However, PVC is equally the best for the job and still very-very widely mixed-in-in the . The main reason that it is the best one is that it is the most durable polymer and therefore it is mainly used for door trims, interior parts like upholstery and underbody protection due to its resistance to wear and exposure to all types of chemicals.

🏥 Healthcare Devices

Among the materials which are very common in the manufacturing of medical devices are PVC and TPE. For the items such as blood bags, IV tubes, and oxygen masks, the biocompatibility, transparency, and sterilization capabilities of medical PVC grade make it the most chosen. As well, TPE is being replaced by PVC in several applications that are environmentally install and friendly and is considered the most valuable and versatile polymer for medical tubing and syringes.

🏠 Consumer Electronics

The materials conspicuous among the household products are PVC and TPE where they are found in almost everything in the house from a shower curtain and a carpet. There are also more technological items made with TPE one of the most recognized is a cord, as this material helps to put less strain on wrists and hands repetitively at work.

🔌 Electronics and Cabling

PVC is utilized to a great extent for insulating wires and cables just because of its electrical non-conductivity and fire-resistant nature. TPE is another material used in electronic components that need a little bit of flexibility and are also resistant to constant motion such as the case of charging cables and headphone wires. This material provides a great alternative and adds a soft and smooth feeling to the products.

♻️ Sustainability Applications

Being sustainable is the new wave in manufacturing, and in keeping with this trend, manufacturers are taking full advantage of the characteristics of PVC and TPE materials together with the added advantage of recyclability. When PVC is used together with TPE, the materials’ being flexible and the ability to be melted and formed again gives manufacturers the possibility to generate their different models in an eco-friendly way and hence the output will be safe for the environment and at the same time meeting the current performance and safety criteria.

Key Insight: The synergy between PVC and TPE is truly leading to great things in the industry, making materials available not only to be used for a wide range of applications but also as the mix of innovation and the response of the customers who look forward to high-tech solutions and a reduced environmental impact.

Material Comparison: TPE vs PVC

What is PVC?

PVC, which stands for polyvinyl chloride, is a synthetic substance containing repeated units with a vinyl group (ethenyl). It is widely known for its very useful and durable properties. Vinyl plastic, as such it is also called, is actually the most common of all plastics in the world and is well known for its great tensile strength, weather resistance, and the ultra-low cost of it. Apart from all these advantages, one still muses about what things PVC might be of the same material as. Firstly, in building materials, PVC finds its way through life again although it is a different PVC still, its physical strength and the impermeability to moisture are still the main factors. Furthermore, with the help of plasticizers added, it can be turned into a product which is either jet black and very hard or something as light and soft as rubber, without losing the usage as a cable or even a synthetic leather, for example. The industry approves PVC for it to be very efficient as well as very quick to change the shape of which is a rather weak point of other plastics. However, the disposal problem and the risks in production provided enough for all the scientists to start looking for other but environmentally friendly alternatives in the case of PVC.

What is TPE?

The thermoplastic elastomers are the materials that can be found in many different formations. The materials have rubber and plastic characteristics into one- giving them the flexibility, durability, and recyclability that are unique. If these were to be transformed, bulk materials or fibers would be the various forms of implementation. This material has some of the characteristics of the oldest and most traditional materials and some advantages of the brand new material. They are, in fact, the processability, renewability along with the recyclability of the thermoplastic at the same time. A hotel guest, who is having a wash, also in the open air has his wet towel hung on…

The Elastomer materials are the ones that can be found in very many different forms. The materials have the flexibility, durability, and recyclability characteristics, all at the same time, so that the indipendent-minded type can see them as at least a potential solution to the ongoing global warming. Traditional elastomers have the properties of strength and resilience under various conditions for their applications. As for now, TPE is just one of the many terminologies adopted for this particular group of elastomers. Epr, Esm or Engage is the name for this compound or copolymer.

PVC and TPE applications

PVC (Polyvinyl Chloride) and TPE (Thermoplastic Elastomers) are very adaptable materials that are found in a large number of the latest developments in the manufacturing sector due to their unique qualities. Whether used separately or together, the two materials still provide useful applications to different industries with the help of Who’s that woman – fashion photographer.

| Industry | Applications | Key Benefits |

|---|---|---|

| Automotive Industry |

|

Elasticity, shock resistance, durability, chemical resistance |

| Medical Devices |

|

Biocompatibility, transparency, sterilization, recyclability |

| Consumer Goods |

|

Ergonomic design, soft feel, durability, comfort |

| Electronics and Cabling |

|

Electrical non-conductivity, flame retardant, flexibility |

| Sustainability Applications | Recyclable products, eco-friendly alternatives | Recyclability, environmental friendliness, performance |

Industry Impact: It would be difficult for one to overstate the degree to which the cooperative development of TPE and PVC is creating a continuum from the raw materials end up to high-quality, able-to-be-used-in-a-wide-variety-of-applications, easily-produced, recyclable or even biodegradable, environmentally friendly materials.

Advantages and Disadvantages of TPE and PVC

Pros and Cons of Using PVC

PVC is a material that is admired a lot because of its versatility and toughness, which make it a real asset in many sectors. Let’s face it, like every other material, PVC also has its own significant advantages and disadvantages that the user should weigh carefully.

✅ The PVC Material’s Advantages

- Cost-Effective: PVC is pretty cheap to manufacture, thus it is also an excellent alternative for consumer goods and construction.

- Durability: Being able to withstand wear and tear, impact resistance, and weathering, PVC is best deployed for long-term exposure under extreme conditions, for instance, outdoor cladding and piping.

- Chemical resistance: The performance of PVC can be significantly affected by the concentration of acids, bases, and salts, as well as the environment’s temperature.

- Versatility: It not only is a soft and flexible raw material but is also a constituent with certain characteristics. It can be manufactured in the form of rigid, flexible, foamy or jellylike and hence, the number of applications is unlimited.

- Recyclability: New advances in recycling technology have made PVC a sustainable option by enabling reprocessing into secondary products while reducing waste much more than before.

❌ Cons of PVC Material

- Environmental Concerns: The production, and disposal of PVC, emits toxic chemicals that include dioxins, which in turn may be a source of pollution and health problems.

- Brittleness at Low Temperatures: PVC, while generally very tough, can easily turn to powder and be very weak if stock in very low temperatures which greatly limits the applicability in very cold-weather environments.

- Limited UV Resistance: With time, continued exposure to direct sunlight can harm PVC which in turn will lead to discoloration and decreased performance, especially when not protected.

- Plasticizer Dependency: For PVC to be flexible, it might need plasticizers, which can thus migrate and exit the material gradually, hence, affecting material conditioning and possible environmental threats.

- Health Concerns: The health worry was started by Phthalates, which are some sort of additives in PVC, has caused enforcement of stricter regulations in certain areas.

Decision Point: By balancing the positive and negative aspects, manufacturers and designers would be able to consider whether the PVC is the prime material and TPE would be the best choice in cases where the flexibility or environmental impact is of concern.

Advantages and Disadvantages of TPE Material

Thermoplastic Elastomers (TPE) are materials that are very flexible in nature and are popular in almost all the sections of the industry since their properties combine the best of the two worlds, i.e., the rubber and the plastic. Following is an evaluation of the main features of the TPE:

✅ Pros of TPE Material

- Flexibility and Elasticity: The TPE materials are composed in a way that they show a fairly high level of flexibility and elasticity so that they can be used in the applications where stretching and recovering is needed. This characteristic is particularly advantageous in the case of consumer goods, medical devices, and automotive components.

- Recyclability: TPE is recyclable unlike thermoset rubbers as TPE can be recycled and re-infused several times without any substantial loss in product characteristics. This in turns helps in limiting waste from manufacturing and promotes the reuse of the material.

- Customizability: TPE allows the possibility of developing materials so that they can target diverse sectors with their varying degrees of hardness, UV resistance, or even grippy features, thereby, making the requirements precise.

- Lightweight and Durable: The TPE falls between the line of lightness and tough making it withstand wear and abrasion as well as the environment, thus, prolonging the life of the product.

- Wide Temperature Range: It could be applied to different industries and these parts would be safe as they would most likely be exposed to temperature extremes but the material’s flexibility or design would not be affected.

❌ Cons of TPE Material

- Cost: Price is the main problem with using TPE instead of PVC, the traditional thermoplastic material. Expensive TPE might not allow its use in industries with low cost or large-scale production.

- Limited Rigidity: By saying that the flexibility of TPE is a plus point in some cases, they also highlighted the circumstance that it is less rigid compared to conventional plastics and which at the same time could shut it out from applications where the load or the construction is the main purpose because the material used might not be up to the task.

- Chemical Resistance Variability: The chemical resistance of TPE varies depending on the formulation of the compound from which it is made. For that reason, careful material selection is imperative when the application is directly exposed to harsh chemicals or solvents.

- Processing Challenges: TPE is alleged to be difficult to handle and to bring to the final product with the help of processing techniques that are not only hard but also time-consuming, and when used by manufacturers who have just started, the cost for material may exceed that of conventional compared materials.

- Environmental Considerations: Should be TPE successfully recycled; however, the irresponsible disposal of TPE materials can still do harm to the environment, as it is not biodegradable and should fully depend on the recycling infrastructure for the benefits of sustainability.

Material Selection: Manufacturers and designers can determine whether TPE meets their performance, cost, and sustainability requirements by thoroughly examining its advantages and disadvantages. The material’s different processing methods make it as adaptable as similar materials, such as PVC or traditional rubber. This is done by creating a subcategory of it as a special case primarily in terms of use.

Which Material is Better for Your Needs?

Selecting the best-suited material is a critical exercise, as it may reflect the outcome of a project. Analysts point out the use of recyclability in the case of the most flexible and at the same time, the application-specific rubber component is manifested in recyclability. The former is generally true for Thermoplastic Elastomer (TPE).

In order to be very sure about the materials you want to make with, it is very important to decide, and the kind of usage you have will be a good starting point. As an illustration, sectors such as automobile and consumer goods usually rank TPE high due to its lightness and flexibility, hence upon the best choice for performance and environmental advantages. Moreover, industries and products that require a more resistant and durable material, like in the case of industrial machinery and outdoor equipment, could do very well with rubber as the main material. This is why it is necessary for all the companies to compare regarding purity and this the matching of the characteristics of the material and the customer’s needs is pivotal in the manufacturing process.

Environmental Impact of TPE and PVC

Recyclability of PVC

Polyvinyl chloride, also known as PVC, is one material whose recyclability involves many challenges and, at the same time, favorable conditions. It is one of the most difficult materials to recycle because it is formulated with additives and stabilizers that the material often needs to maintain its physical properties. The most popular way of recycling PVC is the mechanical one, which requires cleaning, shredding, and reprocessing of PVC to produce new items. Yet, the quality of the recycled PVC may decrease with each process, thus having a limited usage range.

The recent progress in the use of the chemical recycling technologies that the industry makes is quite promising towards overcoming the constraints of the past. The chemical recycling process goes further by breaking the PVC down to its main constituents which are then made ready for recovery and re-use; with the materials like chlorine and hydrocarbons being the core of the recycling process. By using these technologies, the PVC waste will be reduced, thereby contributing to the PVC based products to being more part of a circular economy.

Moreover, the industry has focused on PVC formulations without harmful additives. As technologies for production and recycling continue to develop, PVC can be both an environmental challenge and a recyclable material. A good ecological approach will be associated with a smaller land and resources, where a significant reduction of PVC ecological footprints and the propagation of environmentally sustainable industrial practices are the main points of argument.

Recyclability of TPE

Thermoplastic elastomers are such versatile things, that when they are being examined from the perspective of rubber’s properties, combined with the plastics’ recyclability, they are found to be more environmentally friendly in comparison with the rubbers that are thermosets. The recyclability of TPE is based on its remoldability; thus, remelting, reshaping, and reuse without appreciable loss in quality are the main processes. Polishing up the recycling system further has not only brought up the rate of TPE recovery but also has made possible the inclusion of more significant proportion of post-consumer and post-industrial TPE waste in new products.

There are various inventive mechanisms which are at present in use being utilized to get the maximum use of materials and, especially at the same time, they have been kept the performance very high by the use of chemical recycling and mechanical recycling. The chemical recycling process is being utilized to handle the polymers and they are decomposed into their respective basic chemical components. On the other hand, mechanical recycling grinds and subsequently up processes of TPE into small pellets, which are then reused again. Besides these highly sophisticated and efficient systems, the pharmaceutical, automobile, and electronics, as well as several other industries, have started to apply closed-loop recycling systems which are showing the results in turning away from using virgin materials and waste minimization. Through a continuous improvement of those technologies, TPE companies facilitate a circular economy thereafter which they already contribute to manufacturing the products that are basically re-used, thus little environmental impact being made and that of sustainable development being promoted at the same time.

Sustainability Considerations

The commitment to sustainability in the manufacturing of thermoplastic elastomers (TPE) goes far beyond recycling and additionally includes the efficiency of energy, reduction of carbon emissions, and the optimization of resources. The current manufacturing procedures put efforts into work and energy usage reductions through the use of recent technologies which are very efficient for instance in the case of extrusion and and molding. Moreover, the initiatives that involved companies in making the selection of the right types of raw materials for sustainable collection have been a rising trend through; it is one example renewability of the bio-based alternatives. These undertakings parallel the international targets for the zeroing of carbon emissions and the preservation of the environment’s ecological status and at the same time the strict sustainability needs of the sectors mentioned like the automotive, medical, and consumer goods. On the other hand, the game-changer of these objectives comes from the progressive material science that not only opens up the way for powerful TPEs to be developed but also puts stress on ecological concerns so as to ensure the customers.

TPE vs PVC in Specific Applications

Comparison in Yoga Mats: PVC vs TPE

When comparing PVC and TPE yoga mats, I notice that the decision mainly comes down to environmental impact, strength, and overall satisfaction. PVC (polyvinyl chloride) has been the most sought-after material in yoga mats due to its lower price and lastingness. This is because these mats can withstand heavy use, maintain their shape, and provide a consistent surface for various practices. But in return, PVC is extremely bad for the environment. Its production uses chemicals that are poisonous and it is also non-biodegradable, in essence, contributing to waste in landfills for a long time.

Conversely, thermoplastic elastomers (TPE) mats are typically perceived as a greener alternative. They are made from a mixture of plastic and rubber, resulting in a lighter, more pliable mat. TPE mats are nontoxic, as they lack phthalates and metals such as lead, elements usually found in PVC, and can also be reprocessed to a certain extent. Moreover, I am convinced that TPE mats are more elastic and offer better cushioning, which goes a long way to make our yoga sessions more comfortable. Still, they may not be as durable as PVC mats under very heavy, long-term use.

Conclusion: After all I think TPE is the better choice for the people who are more into being green and lighter yoga, and PVC is still the best solution for the long-lasting yoga mats at a good price. The TPE yoga mats follow the current market that requires healthier products and at the same time they are in unison with my personal and global aims of sustainability, so definitely great option for yoga lovers who truly seek the harmony between their practice and nature.

Wire and Cable Applications: TPE vs PVC

When it comes to wire and cable applications, choosing between TPE (Thermoplastic Elastomers) and PVC (Polyvinyl Chloride) depends largely on the specific requirements of the project. According to my inquiry, TPE offers several features that align with the demands of modern engineering and the environment. It is more than just highly flexible; TPE is also lightweight and resistant to UV rays, chemicals, and extreme temperatures, making it an outstanding choice for outdoor or challenging industrial environments. Moreover, TPE is recyclable, thus contributing to the ongoing development of sustainable manufacturing practices. This among many other criteria, including environmental factors and the performance characteristics, will make TPE the material of choice for most of the projects.

PVC, however, has been, and still is, extensively used in cable and wire applications owing to its cheap price and toughness. Its reliability is quite impressive, as it even offers a decent level of resistance against attrition, bruising, and humidity. Though PVC is not as eco-friendly as TPE, and it is hazardous to the environment, it is still in high demand mainly because of its cost and its widespread availability. Nevertheless, PVC has its darker side as it is made up of refined oil, which is non-degradable, and emits obnoxious sulfur during incineration.

Final Assessment: Just after battling through the pros and cons of both materials, TPE seemed to be the more adaptable and eco-friendly option for the majority of the modern wiring and cabling projects. The fact that it functions under the most severe conditions and helps the environment at the same time is what makes it an attractive option. Nevertheless, PVC must not be excluded for projects operating on a strict budget or having lower performance standards, as it is still a dependable and inexpensive alternation.

Usage in Medical Devices

The use of TPE (thermoplastic elastomers) has gained momentum in the medical field as a highly adaptable material. Its plasticity, strength, and resistance to the human body make it suitable for many applications, such as tubing, IV bags, seals, and medical gaskets. Quite the opposite of PVC (polyvinyl chloride), TPE does not contain any toxic plasticizers like phthalates. For patient safety, it’s a significant win not to have those harmful substances. This is where the medical industry’s interest in the use of non-toxic, environmentally-friendly materials that meet the requirements of regulations including ISO 10993 and USP Class VI is derived from.

The medical sector is divided into two material groups in the classification system. The classification of TPE depends directly on the sterilization method. TPE can be kept sterile by being subjected to a gas treatment, an aging one such as steam autoclaving, and a stimulant one like the gamma ray.

Besides being customized to what materials and applications it may be blended with, TPE can also be used to create new products out of old materials, thus rendering the whole process quite environmentally friendly. Husky employees recently were informed that a new health and safety policy is being implemented, starting on the 1st of next month. Also, TPE is easier to process as compared to other PVC-related silvices, which would make it the preferred product for coatings%, coverings, and other protection devices.

Reference Sources

- INFILL MADE FROM THERMOPLASTIC ELASTOMER (TPE) – A detailed document discussing TPE’s properties and applications, including its chemical composition and environmental impact.

- Thermal Changes in Polymers – This source provides insights into the thermal properties and degradation of materials like PVC, which is crucial for understanding its behavior.

- Effect of Nitrile Butadiene Rubber and Graphene Oxide on PVC – An academic paper exploring the mechanical and chemical properties of PVC and its modifications.

Frequently Asked Questions (FAQs)

❓ Comparing TPE to pvc: TPE and pvc material differences finally?

TPE differs from PVC; they are not pure materials, as TPE is a thermoplastic rubber (an elastomeric plastic) with rubber-like behavior, whereas PVC (Polyvinyl chloride or vinyl chloride-based polymer) is a thermoplastic that can be rigid or flexible. Rubber’s elasticity is best duplicated in TPE, thus TPE has the greater flexibility and softness compared to the other one and is, therefore, best for cushioning or tactile feel products. PVC gives good chemical resistance and durability in many applications while the flexible pvc grades are often chosen in the case of cost-effective, workable solutions that are widely used. Impact strength and abrasion resistance can vary depending on the formulation. Therefore, the comparison of tpe vs pvc is primarily determined by the specific requirements of the final use. If you are unsure of the right material to use, do not hesitate to take advice from our experts for a thorough, application-specific comparison.

❓ Thermoplastic elastomer: why is the TPE material considered?

TPE is the thermoplastic elastomer that is created by blending the attributes of plastics, such as the economy of conversion with rubber’s stretchability, hence becoming the best choice for such a product that demands a feel of rubber yet without vulcanization. TPE is a material that is often linked to tpe yoga mats, wire and cable insulation, soft-touch grips, and seals, and it is commonly pricier than some pvc grades but it gives the user the opportunity of choice and recycling in many cases. TPE is very much known for its good resistance to wear and tear and can stand on par with PVC as far as being elastic is concerned, thus making it a very good choice for flexing applications. The tpe being a thermoplastic material is very easy to mold as well as thermoforming, as a result, a huge number of applications are supported. When tpe or pvc is taken into consideration by the manufacturers, UV stability, chemical resistance, and cost-effectiveness should be the prime limitedchoices that will help them in deciding the value of these materials.

❓ Polyvinyl chloride: what has made PVC one of the most widely used materials in industry?

PVC is largely employed owing to its ability to be a thermoplastic which is capable to be developed in the form of rigid pvc for the construction profiles or flexible pvc for cables, tubing, and yoga mats, thus, giving a cheaper and thus a more economical solution to several industries. Polyvinyl chloride is considered a big-time chemical resistance and durability candidate, while the same time having the flexibility in offering formulations that are really good in flame retardance; this, in turn, makes it perfect as an insulator and the very basic compound in wire and cable insulation applications. The quality of PVC granted the specific plasticizers and stabilizers being used; some flexible formulations may gain the behavior of such soft materials but PVC cannot be as elastic as TPE or natural rubber. Though/conversely, PVC that comprises two broad categories (rigid and flexible) has proved to be the best choice and its advantages are reliability and durability in the presence of a very small budget and a lot of work to be done. You can opt for a complex analysis of the proper use by understanding the requirements of for TPE and PVC obtaining a rubber zootechnics and industry-wise approach to the two materials in question.

❓ Chloride concerns: how does vinyl chloride affect safety and regulation?

Polyvinyl chloride is the substance of which vinyl chloride is the monomer and its usage is considered to be a matter of certain safety, regulatory approval, and public perception of PVC-products. By employing proper production control, stabilization, and the use of additives, some PVC manufacturers take the steps to comply with safety and environmental standards, hence, making PVC one of the most regulated plastics. On the other hand, the utilization of thermoplastic elastomer formulations like tpe can be a selling point that endows the product with a reputation of being environmentally friendly or, at least, with no specific plasticizers used, which can have a certain impact on the choice of consumer products such as tpe yoga mats or pvc yoga mats. The final decision in the selection of the material is based on the clear need for health, recycling, and disposal. If you need help with assessing the regulatory issues for your product, please get in touch with us for guidance on compliance and material choice.

❓ tpe yoga mats vs pvc yoga mats: what are the factors that make tpe yoga mats a better alternative?

The marketing of typical TPE yoga mats is often about being less harmful to the environment than using pvc mats, but being equally ambitious in terms of elasticity and cushioning, as cost is a very critical factor in favour of pvc mats, particularly for the majority of novice users needing the durable material. It has been noted that TPE will be the first choice for those who are health-conscious and at the same time, want to have a recyclable product, and tpe offers more of rubber-like elasticity which makes it more comfortable and supportive to many users. PVC and TPE are two of the common choices thus people are clearly divided – undoubtedly, the latter can be said to be the leading one. PVC is one of the best in terms of adhesion and long-term resistance to wear in most of its formulations, but PVC is not any way near being eco-friendly as some of the TPE blends. Depending on your needs, the right material would be different; if you are conscious about the environment and want to get a softer feeling, TPE is your choice; if you are looking for a mat that is tough, low-priced then PVC gives the best value. If you are having difficulty in selecting the perfect material for the product category, please reach out to us for an in-depth comparison.

❓ TPV and alternatives: are there materials better than PVC for specific uses?

Thermoplastic vulcanizate (TPV) is said to analogous to TPE and old rubber, but with a twist – the TPV has a much better high-temperature and chemical resistance, and with such characteristic it can still be stretched and will not break. These are only some factors that make TPV a first choice of material for people opt for a durable and flexible material. For the wire and cable insulation material or the ones that have demand for the highest impact resistance, the materials used can make TPV and specific TPE entirely surpass PVC because in relation to the environment and the mechanical side, there happen to be better choices. Rubber despite having unmatched elasticity, can not be processed and does not have the same chemical resistance features as those of thermoplastics. Hence, deciding whether to go for rubber or plastic usually comes down to very specific requirements like UV stability and abrasion resistance among others. By a detailed comparison of performance, cost, and recyclability, the majority of manufacturers choose the material based on these aspects; TPE is most of the time more expensive than PVC, yet it can provide the consumer with enhanced comfort and environmental-friendly characteristics. If you are in the process of evaluating materials for a new product, it will be a good idea to discuss the similarities and differences between TPE, PVC, and TPV with our team in order to pick the right material for your application.