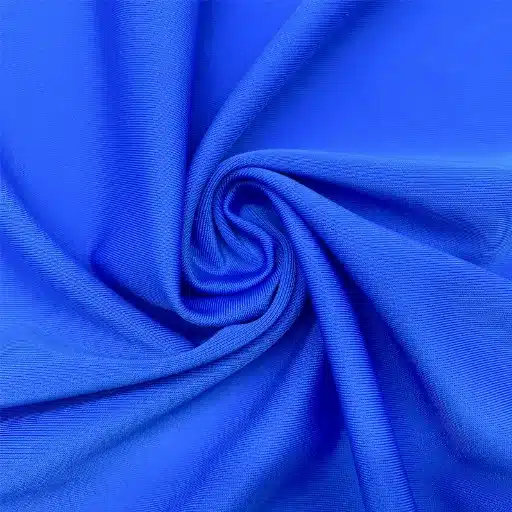

The dress of a performance material is hot in the discussion, and polyamide and polyester occasionally find themselves in the motley of the commented-upon. Both are frequently used in the textile sectors, from fashion to exteriors. They are applauded for their durability, flexibility, and versatility. Yet, a question arises: can anyone say that these synthetic fibers are interchangeable, or would they be noted for their respective advantages? This blog will delve into the in-depth comparisons between polyamide and polyester in aspects such as their strength, moisture-wicking properties, breathability, and longevity. The end of the blog should help you see how the materials behave in a particular aspect and which one works best there—selecting fabrics for sportswear, upholstery, or environmentally conscious design? The insight from this blog will assist you in making those choices.

Introduction to Polyester and Polyamide

What are Polyester and Polyamide?

Polyester and Polyamide are synthetic materials well known for their diversity and wide range of applications in various fields. With a chemical composition of polyethylene terephthalate (PET), this relatively young product is derived from petroleum, which lends it durability, resistance to wrinkling, and affordability. It is mainly used in textiles, packaging materials, and to some extent in industrial applications.

Polyamide, commonly known by the trade name Nylon, is yet another polyamide-type synthetic polymer mined from petrochemicals. These Polyamides are renowned for their superior strength, elasticity, and resistance to abrasion, making them extensively used in the apparel, industrial equipment, and automotive industries. With an active source of performance requirements, these are well-suited for applications such as activewear, ropes, and carpets.

🧵 Polyester Benefits

- Water-resistant and fast-drying

- Excellent color retention

- Wrinkle and shrinkage resistance

- Cost-effective production

💪 Polyamide Benefits

- Superior tensile strength

- Exceptional elasticity

- High abrasion resistance

- Enhanced comfort and flexibility

Both materials stand apart for their unique features from a performance perspective. Polyester is water-resistant, thus making it a fast-drying fabric suitable for activewear or outdoor products. Likewise, it retains colors wonderfully, even after successive washings and fading from plywood chips. Polyamides can have greater tensile strength and resist wear and abrasion from usage, making them suitable for heavier-use products. Additionally, due to their stretch and elasticity, Polyamides offer greater comfort, especially in garments that require stretch and flexibility.

Both materials have been developed into various forms over the years to meet the requirements of modern sustainability goals. Recycled Polyester from waste plastics, such as bottles, is probably the most accepted synonym among environmentally conscious people. In contrast, the evolution of Polyamide production has seen some bio-based variations developed that can reduce reliance on petroleum-based sources. It is clear from these innovations that the two materials are inclined toward sustainability, which in turn will keep them relevant for a long time.

Common Uses of Polyester and Polyamide Fabric

Considered highly versatile and durable, polyester and polyamide fabrics are beneficial across many industries. Polyester, being wrinkle-resistant and resistant to shrinkage and stretching, is widely used in the fashion industry for making everyday clothing, such as shirts, dresses, and activewear. Polyester is a sweat-resistant sportswear and performance gear that can be worn well and feels good. Furthermore, polyester is also used in the manufacture of home textiles, such as curtains, upholstery, and bedding, due to its durability and ability to retain bright colors over time.

Similarly, polyamide, more commonly referred to as nylon, is esteemed for its strength and abrasion resistance, two factors that make it a good choice in the manufacture of hosiery, lingerie, and outerwear. From a technical standpoint, polyamide is further utilized in parachutes, ropes, and fishing nets, where it is prized for being both lightweight and sturdy. From the perspective of biomechanical flexibility, polyamide is a major player in industrial materials, such as tire cords and conveyor belts. The increased use of recycled and bio-based alternatives for either of the fibers has not only opened up further avenues of application for the two but also ensured their relevance to the sustainability trend, thereby integrating them into contemporary industries and lifestyles.

Overview of Synthetic Fibers

Synthetic fibers are essentially man-made fibers produced through chemical processes, primarily utilizing petroleum-based raw materials such as polyesters, polyamides (nylons), and acrylics. These fibers are designed with a combination of properties, including strength, elasticity, moisture resistance, and ease of maintenance, which makes them suitable for multiple industries. Modern synthetic fiber production focuses on the sustainability and performance of modern synthetic fibers. One such example is that recycled polyester (rPET) from plastic waste has become increasingly popular, thereby helping to reduce environmental impact without compromising on quality.

📊 Global Fiber Production Statistics

Polyester comprises over 50% of the world’s fiber production, demonstrating its dominance in the market. The global production statistics for synthetic fibers reveal an uninterrupted steady growth underlying a surge in demand in the fashion, home textiles, and industrial sectors.

These synthetic fibers are further adaptable to applications that require them to perform at really high levels. For example, technical textiles such as aramid fibers are utilized in the aerospace, protective clothing, and automotive industries due to their exceptional heat resistance and strength.

Recent advancements include the development of bio-based polyamides and several other materials, essentially shifting toward greener options that are largely non-fossil-fuel-based. Industry players are also working on innovations in dyeing and recycling loops that theoretically reduce carbon footprints. As more consumers become conscious of their sustainability implications, synthetic fibers are expected to stay at the underpinning of material innovation, providing innovative solutions that promise to fulfill functionality and environmental concerns.

Differences Between Polyester and Polyamide

Chemical Structure and Properties

Polyester and polyamide, being synthetic polymers, substantially differ in their chemical structures. In contrast, a polyester is composed chiefly of ester functional groups within its polymeric chain, and these precursors may depend upon petrochemical sources, for instance, ethylene glycol and terephthalic acid. This kind of structure imparts durability, resistance to stretching and shrinking, and drying ability to a polyester substance. Polyamides, including nylon-the most popular one-make use of amide groups (-CONH-) in their backbone, derived from diamines and dicarboxylic acids or lactams as building blocks; therefore, they remain more elastic, resistant to abrasion, and heat compared to polyester.

Differences at the molecular level do influence the ultimate performance. Polyester is said to be more hydrophobic: it absorbs less water and dries faster, making it suitable for activewear. Polyamide, by contrast, has a slightly greater capacity for moisture absorption, which in some cases can increase comfort. Polyamide fibers also tend to have greater tensile strength and resist abrasion more effectively, which is why they are well-suited for heavy-duty applications such as gears and industrial products. It is the intrinsic chemical and physical differences that account for the versatility of both materials in various industries, from fashion to engineering.

Durability and Abrasion Resistance

| Property | Polyester | Polyamide |

|---|---|---|

| UV Resistance | ✓ Excellent | ⚬ Good |

| Abrasion Resistance | ⚬ Good | ✓ Superior |

| Tensile Strength | ⚬ Good | ✓ Higher |

| Environmental Resistance | ✓ Excellent (mildew resistant) | ⚬ Good |

Depending on their variants, polyester, and polyamide offer excellent durability and abrasion resistance. Which one stands better depends on the specific application. Generally, polyester has an inherent property of resisting attack from environmental agents, such as UV rays and mildew, thereby upholding its performance for long periods, even in adverse outdoor situations. That is why it’s used in items like outdoor furniture, tarps, and marine gear. Polyamide performs slightly better than polyester in terms of abrasion resistance. With greater tensile strength, it can withstand repeated abrasion and mechanical stress, making it more suitable for making ropes, parachutes, and industrial belts. This high abrasion resistance also marks its application in high-performance textiles for sportswear and protective apparel, where continuing wear is of utmost importance. All these traits complement the authentication and enhancement of both materials in many industries.

Performance in Different Conditions

The versatility of polyamides remains evident in their ability to offer diverse performances, depending on the environment, thus expanding application possibilities. Even in varying temperature ranges, these materials provide excellent mechanical characteristics, with a genus of this polymer being resistant to both heat and cold without experiencing degradation. Such high-temperature polyamides are actually employed in automotive components, as engine heat and thermal cycling require the highest level of thermal stability. Polyamides also resist moisture and chemical attack, ensuring performance in corrosive and humid environments. Technological advancements in materials engineering enable the blending of polyamides into specialized materials to meet specific industrial needs, such as reinforced polyamides with enhanced integrity under load. These properties establish polyamides as an essential class, governed by the need for industries where reliability and ruggedness are crucial.

Recycling and Environmental Impact

Benefits and Processes of Recycled Polyester

♻️ Environmental Benefits of rPET

- 30%-50% reduction in greenhouse gas emissions

- Reduced reliance on virgin petroleum resources

- Diverts plastic waste from landfills and oceans

- Lower water and energy consumption in production

Known more commonly under the abbreviation rPET, recycled polyester fabric is made from waste materials like plastic bottles, avoiding virgin polyester production and mainly benefiting the conservation of natural resources. The most significant benefit of using recycled polyester is waste reduction, as it is fabricated from used plastics that would otherwise be discarded into landfills or oceans. This helps alleviate the ever-growing problem of plastic pollution worldwide.

🔄 Recycling Process

- Collection: Gathering plastic waste materials

- Cleaning: Thorough cleaning of collected plastics

- Shredding: Breaking down into small flakes

- Melting: Converting flakes into polyester fibers

The production of recycled polyester usually starts with the collection of plastic wastes, which is then cleaned, shredded into flakes, and melted down for making polyester fibers. The production of recycled polyester requires less water and energy than the production of regular polyester, resulting in a significantly lower carbon footprint. Some studies suggest that manufacturing can reduce greenhouse gas emissions by approximately 30%-50%. Thus, it can be considered an environmentally friendly alternative in various industries, especially clothing and textiles.

Though recycled polyesters provide many environmental benefits, some challenges are posed like inconsistencies in quality and finite affects on the recycling loops because the fibers depreciate with each recycling. Nevertheless, developments in chemical recycling processes envisage overcoming these impediments by enabling unlimited recycling without compromising fiber quality. Thus, recycled polyester occupies a crucial position within sustainable manufacturing processes, promoting the development of more circular economies.

Recycled Polyamide: Challenges and Innovations

Recycled polyamide is viewed as a prime material under the sustainable manufacturing approach. There are several challenges associated with collecting and sorting recycled polyamide, as these processes are labor-intensive and require significant infrastructure for retrieving usable waste. The fact that the recycling procedure itself may degrade the polyamide material, hence affecting its strength and durability, is a limiting factor to its use in specific applications that require high engineering standards.

⚠️ Challenges

- Labor-intensive collection and sorting

- Material degradation during recycling

- Infrastructure requirements

- Quality consistency issues

💡 Innovations

- Chemical recycling technologies

- Closed-loop recycling systems

- Renewable energy integration

- Monomer breakdown processes

In the past, chemical recycling innovations were developed to overcome such limitations. Technologies now exist to break down polyamide waste back into its monomers, allowing for the production of high-quality recycled fibers with the same properties as virgin polyamide. In contrast, these in closed-loop processes employ the repurposing of nylon waste into new products so that dependency from fossil-fuel-based raw materials in the process is minimized. Scaling up recycling capacities worldwide and utilizing renewable energy in the processes reduces the carbon footprint of producing recycled polyamide. These technological developments put it into a position where it can be used to push circularity and environmental consciousness in manufacturing.

Comparative Environmental Footprint

🌍 Environmental Impact Reduction

Studies show recycled polyamide offers almost 50% reduction in greenhouse gas emissions and more than 25% lower energy requirement compared to virgin polyamide processing.

Compared to virgin polyamide, recycled polyamide offers considerable benefits in terms of greenhouse gas emissions and energy usage. Studies have, in fact, established an almost 50% reduction in emissions, along with a more than 25% lower energy requirement, for recycled polyamide processing compared to virgin polyamide. Besides, preventing nylon scraps from dominating landfills and oceans into recycling renders it with less environmental pollution and improves resource efficiency. These reductions are, thus, vital in industries such as textile and automotive manufacturing, which demand significant quantities of polyamides, highlighting the shift towards more sustainable production methods. The increased use of recycled raw materials helps alleviate final pollution and brings industries into alignment with global climate and sustainability agendas.

Polyester vs. Polyamide in Textile Applications

Comparative Performance Analysis of Fabrics

| Performance Aspect | Polyester | Polyamide |

|---|---|---|

| Moisture Resistance | Superior water resistance, quick-drying | Moderate moisture absorption |

| Tensile Strength | Good durability | Superior strength and resilience |

| UV Resistance | Excellent UV protection | Moderate UV resistance |

| Chemical Stability | Excellent resistance to oils and chemicals | Good chemical resistance |

| Thermal Performance | Higher melting point | Better heat resistance in applications |

| Comfort & Feel | Functional but less soft | Superior softness and comfort |

Polyester and polyamide are two of the most common textile fibers, each possessing different properties that make it suitable for different functions. Polyester is chosen for its greater durability, resistance to UV light, and absorption of little moisture, making it ideal for outdoor apparel, activewear, and home furnishings. Conversely, polyamide, especially nylon, is highly resistant to elastic-type abrasion and has a soft feel; hence, it is most popular in high-performance garments, such as hosiery, sportswear, and luxury fabrics.

Regarding tensile strength, polyamide easily surpasses other materials in resilience, especially where conditions demand both flexibility and durability. Conversely, polyester has superior water resistance and quick-drying properties compared to polyamide, which are fundamental features for a garment exposed to weather. Another advantage of polyester is its exceptional chemical stability, as it tends to resist degradation from oils and common chemicals, allowing it to last longer in hostile environments.

There are also evident differences in terms of thermal performance. Polyester has a higher melting point than polyamide, which can be beneficial in applications involving high heat or where the product undergoes significant heat stress, such as in industrial textiles. Meanwhile, polyamide has a certain softness and comfort that lend themselves to designs inclined towards wearability and user experience.

Adopting a recycling perspective, polyester recycling may be considered more advanced, with rPET being widely adopted in general product applications as an alternative to virgin materials. Polyamide recycling is still evolving, with a limited infrastructure set up to recover at a post-consumer scale. Further differences in post-consumer applications based on recyclability will inform material selection in sectors aiming to reduce their environmental footprint.

Pricing, availability, and end-use requirements ultimately determine the choice between polyester and polyamide, enabling textiles to be optimized for both performance and sustainability. In this somewhat dichotomous comparison of these two fibers, material innovation assumes importance in addressing the changing demands of the industry.

Choosing the Right Material for Your Needs

Sometimes, you might need to keep in mind functionality and sustainability issues when choosing specific inputs for the textile chain. Polyester is preferred for activewear and outdoor gear because it is strong, wear-resistant, and wrinkle-resistant. In contrast, polyamide offers better elasticity and abrasion resistance, but provides a softer touch; hence, it is chosen for intimate apparel and performance wear.

The two fibers have been further improved with several technical innovations. Waste plastics have been converted into recycled polyester, serving as an ecological alternative with reduced dependence on virgin resources. On the other hand, polyamide production has been enhanced by introducing bio-based varieties with a lower carbon footprint. Factors considered include purpose, environmental impact, and lifespan of materials, in order to make a decision that respects both practicality and sustainability.

Market Trends in Polyester and Polyamide Usage

📈 Polyester Trends

- Dominates activewear and fast fashion

- Growing adoption of recycled rPET

- Enhanced moisture-wicking properties

- Cost-efficient production methods

🚀 Polyamide Trends

- Expanding in sportswear and intimates

- Bio-based alternatives development

- Enhanced durability for technical gear

- Growing automotive applications

The company polyester and polyamide materials are in much demand due to their wide range of applications and ongoing innovations. Polyester is the preferred And Of The Textile Industry Because Of Cost-Efficiency, Strength, and Adaptability-That Is So Activewear, Fast Fashion. Polyamide, on the other hand, is basically referred to as nylon. It is used extensively in sportswear, intimate apparel, and technical applications such as automotive and industrial goods due to its strength and elasticity.

Another remarkable trend is the becoming fashionable of sustainable alternatives for polyester and polyamide production processes. On one side, recycled polyesters, mostly made from PET bottles and other post-consumer waste, have been widely adopted, while brands are prioritizing measures to reduce their environmental footprint. Similarly, bio-based polyamides are made from renewable resources, such as castor oil, and are gaining popularity as companies seek to integrate such measures into their sustainability initiatives.

The industry, conversely, is capitalizing on the latest manufacturing technologies to enhance material performance. Polyesters with moisture-wicking properties and polyamides offering extreme durability are increasingly being adopted for technical and performance gear. These trends demonstrate a surging consumer preference for functionality coupled with environmentally friendly products, which position polyester and polyamide on the cusp of the future sustainable versions of material innovation.

Conclusion and Future Perspectives

Synopsis of Findings

🔑 Key Takeaways

- Polyester excels in cost-effectiveness, durability, and maintenance ease

- Polyamide leads in strength, elasticity, and abrasion resistance

- Both materials are evolving toward sustainable alternatives

- Recycled versions are becoming industry standards

Our investigation has provided ample evidence of the increasing role of polyester and polyamide as materials used in various industries, notably textiles and high-performance applications. Polyester is known to be less costly to manufacture, to last longer, and to be easy to maintain. Therefore, it offers excellent versatility and is employed in all manner of consumer goods, from industrial goods. Polyamide, on the other hand, is relatively unknown for its hi-tech strength and its resistance to wear, has become essential in any application where it must give durability during demanding use conditions, say, in the manufacture of technical and outdoor equipment. Material science advancements of the highest level have therefore contributed to further enhance their functionality, giving rise to moisture-wicking polyesters and ultra-strong polyamides depending on the ever-evolving needs of consumers.

The increasing global emphasis on sustainability has influenced the development and perception of these materials. Polyester and polyamide are increasingly being produced from recycled inputs, which mitigates environmental impacts and strengthens the push toward circular economies. With respect to this arena, companies have chosen to go further by establishing closed-loop recycling systems overseas, where post-consumer wastes are converted into useful fibers so that sustainabilities and performances can perfectly coexist without compromise. Allowing trends to lead the way would indicate a highly hopeful future where functionality, innovation, and environmental consciousness converge, thus making polyester and polyamide the frontrunners in sustainable material design.

Combining these factors, it becomes clear that not only does the future of polyester and polyamide lie in their continued adaptability, but also in the need for them to fulfill some critical environmental needs. The ability to offer high-performance capabilities and incorporate sustainable practices points towards a probable course that will help reduce the gap between scientific development and ecological concerns.

Future Developments in Polyester and Polyamide Fabrics

According to me, the future of polyester and polyamide textiles lies undoubtedly in the innovation that sustainability will bring. Recycling technology is evolving fast and the main emphasis on this development is on closed-loop systems. Such systems enable post-consumer polyester and polyamide goods to be reformed into materials, thereby minimizing waste and the need for virgin raw materials. Companies are largely investing in chemical recycling, which breaks down materials into their original building blocks and rebuilds them to their full quality, without compromising performance. This very step is crucial in cutting down the environmental impact that synthetic fabrics create.

🌱 Bio-Based Innovation

Bio-polyesters and bio-polyamides derived from plants and renewable sources are gaining popularity to reduce reliance on fossil fuels.

🔬 Nanotechnology

Advanced technologies introduce improved functionalities like water repellency, odor resistance, and temperature adaptation.

Additionally, such bio-based materials are gaining popularity, viewed as a renewable path to these materials. Bio-polyesters and bio-polyamides derived from plants and other renewable sources are gaining popularity to help reduce reliance on fossil fuels. Researchers also aim to advance with advanced technologies, such as nanotechnology, to introduce improved functionalities to the fabric. These advancements can include water repellency, odor resistance, and, in some cases, fabric adaptation to temperature changes, making them ready for high performance while not compromising on sustainable factors.

In conclusion, industrial collaboration looks to be the way of future development for these fabrics. Textile producers, fashion companies, and environmental organizations are collaborating to develop a standardized set of procedures for their sustainability initiatives. Certification and transparency in fabric manufacturing are becoming the most essential forces in achieving accountability in the supply chain. With the marriage of incubation technology and a shared will for sustainability, these polyester and polyamide fabrics will evolve even further due to the responsible and innovative materials in the years to come.

Final Thoughts on Polyester vs. Polyamide

💭 Making the Right Choice

The choice between polyester and polyamide ultimately depends on specific application requirements, balancing performance needs with environmental considerations and cost factors.

Choosing between polyester and polyamide, in my opinion, is highly contingent on the actual requirements of the end use. Both types wear brilliantly, are highly versatile, and have always been at the core of the textiles and fashion industries. Polyester is very affordable and resistant to wrinkles. The colors tend to remain beautiful for a very long time. Good moisture management would mean that polyesters are well-suited for outdoor and sports applications. Polyamide, better known as nylon, earns its reputation as the stronger, stretchier, and hence more luxurious counterpart. It is used where softness and abrasion resistance are paramount—whether in performance or premium clothing.

Sustainability is also a significant factor that influences fabric selection today. Although both materials are petrochemically based, evolutions in recycling technology are paving the way for greener variants. Discounting virgin resources is the name of the game for recycled polyester; hence, it has garnered much attention as a sustainable substitute. Meanwhile, attempts to develop bio-based and recyclable polyamides are gaining momentum, bringing the fabric closer to the concept of a circular economy. So, if I know what’s going into the environment from whichever fabric I choose, it helps me make a decision, especially now that there are increasing certifications and clarity in production processes.

When putting the two fibers into perspective, it all comes down to understanding their applications and strengths. For activities where intensity is in demand or if the outerwear must be durable against rough use, polyamide wins. For casual and everyday outfits, machine washability is a key benefit of polyester. In brief, weighing the pros and cons together with functionality, style, and environmental considerations will help me make better decisions for either option.

Reference Sources

- Polyamide vs. polyester: differences and applications – Fulgar

- Polyester vs Polyamide: Expert-Level Guide – Szoneier Fabrics

- Polyester vs Polyamide – Activewear Productions

- The Ultimate Guide: Polyester vs. Polyamide for Clothing – Szoneier Fabrics

- Recycled and Biodegradable Polyester and Polyamide – FabricSight

- Find more info now.

Frequently Asked Questions (FAQs)

❓ Are polyamide and polyester different?

Polyamide and polyester are synthetic polymers widely used in the textile industry. Polyamide, commonly referred to as nylon, offers superior strength and elasticity, making it well-suited for use in sportswear and garments that require durability. Conversely, polyester, being a hydrophobic fiber, repels water and dries rapidly. Though these two are among the most preferred fabrics for apparel, the use of a particular fiber is often dictated by garment requirements such as breathability and moisture absorbency.

❓ Are polyamide and polyester the same fiber?

No, polyamide and polyester are not the same fiber. Polyamide fibers, commonly referred to as nylon, differ in their molecular structure, making them distinct from polyesters. Both are synthetic fibers of petrochemical origin; their properties vary significantly. Polyester will be firmer against wrinkles and hold its form, while polyamide withstands any abrasions and is soft. These peculiarities will weigh heavily in deciding whether to use the particular fiber for clothing or textiles.

❓ Is polyester clothing more breathable than polyamide?

Considered by many to be highly breathable, polyamide fabrics are perceived as having the ability to breathe more freely than polyester garments. This aspect of breathability due to moisture transfer attracts polyamide to activewear, both general and specific. Polyester is hydrophobic and dries quickly, but it retains more moisture than a polyamide fabric. Hence, it would generally be more comfortable to wear polyamide garments when performing strenuous activities, as polyamide can absorb moisture and keep the body dry.

❓ What is the environmental impact of polyester vis-a-vis polyamide?

The environmental impacts of polyester and polyamide vary depending on the production processes and end-of-life scenarios involved. Polyester is usually made from plastic bottles, thus adding to the stockpile of plastic waste, but some form of recycled polyester does exist, which causes less harm to the environment. Polyamide, equivalent to any cast-on synthetic polymer, can be produced from recycled polyamide materials. Regardless of fabric, however, these two types tend to be heavy contributors to microplastics in the environment when washed. Hence, opting for recycled versions and simply reducing usage may help mitigate these impacts.

❓ What is the aspect of polyester trying to compete with polyamide, in terms of durability?

Polyamide tends to be more durable than polyester. Polyamide fibers offer the best abrasion resistance and are the logical choice for heavy-duty and outdoor gear. Polyester, while still fairly durable, is not quite as resistant to wear and tear as nylon. Polyester will, however, resist UV rays better, a factor in increasing the life of garments exposed to sunlight. It is often the case that the choice depends on the use case and the kind of durability needed.

❓ Can polyester and polyamide be blended?

In other words, polyester and polyamide are capable of combining to make fabrics that enjoy the favorable properties of both substances. Polyester blends continue to gain interest in moisture-wicking properties in clothing as a counterbalance to the soft feeling of wearing clothes. This way, the mixture forms a textile that is durable in nature, suitable for everyday use, such as casual wear, or special purposes, like sportswear. Such blends are highly sought after by the fashion industry, where a balance between softness and performance is of great importance.