These polycarbonate pellets, by all means, introduced a new dimension in the realm of current manufacturing, offering a rare combination of strength, flexibility, and versatility. These humble plastic granules essentially form the very basis of a large variety of products that sustain our daily life, from heavy-duty automotive parts, through state-of-the-art electronic devices, to green building materials. How then do these products stand out amidst polycarbonate pellets, and what innovations do they trigger in various industries? In this blog, we examine the properties of polycarbonate that give it its edge, its multiple applications, and the cutting-edge discoveries that are catapulting it into modern manufacturing. Whether an industry insider or just curious about the materials that drive present-day technology, this exhaustive report will take you through the wonderful world of polycarbonate pellets.

Understanding Polycarbonate Pellets

What Are Polycarbonate Pellets?

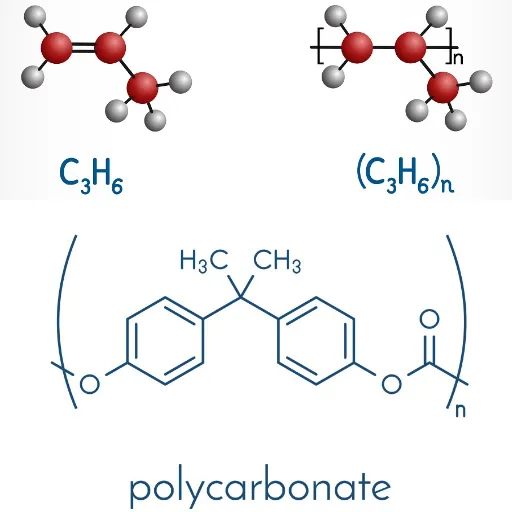

Polycarbonate pellets are small, spherical granules composed of polycarbonate resin, a high-performance thermoplastic. These beads are raw materials used in various manufacturing processes, including injection molding, extrusion, and thermoforming. Due to their excellent combination of durability, impact resistance, and optical transparency, polycarbonate pellets are widely used in the automotive, electronics, construction, and healthcare sectors. They can withstand extreme temperatures, resist UV exposure, and exhibit excellent dimensional stability; thus, they are suitable for manufacturing items and parts that require specific properties without compromising strength or requiring tight tolerances. With modern technological progress, numerous specialized containers have been made available that promote additional properties such as flame-retardance, scratch resistance, and better recyclability in order to satisfy current requirements surrounding sustainable manufacture.

Properties of Polycarbonate Resin

Polycarbonate resin is a flexible engineering material due to its unusual combination of properties. The resin is incredibly impact-resistant and can withstand extreme shocks without cracking or shattering, even in low temperatures. Considering its strength, the resin finds application in safety instruments that include bullet-resistant glasses, protective helmets, and many other products. It provides high optical clarity and transmits between 89% and 92% of light, almost precisely matching the performance of glass, thus making applications such as sunglass lenses and transparent enclosures possible.

Its thermal properties are pretty interesting. The resin in polycarbonate form has a comparatively high glass transition temperature, ranging from 140°C to 150°C (284°F to 302°F), depending on the grade, with an approximate figure of 147°C (297°F), indicating that it remains stable when exposed to high heat. The relatively low absorption of moisture has resulted in the material being dimensionally stable in high humidity, making it dependable in outdoor environments for extended periods.

Polycarbonate’s self-extinguishing flame resistance further makes it appealing for electrical and electronic components that conform to industry standards for safety. Modern formulations have also included UV-resistance technology, preventing yellowing or degradation from prolonged exposure to sunlight and extending the life cycle of polycarbonate. With enhanced recyclability, polycarbonate resins are now increasingly preferred for their sustainable production programs, which are tied to the circular economy.

Polycarbonate Granule Types

Polycarbonate granules are versatile materials that come in various types and are used in multiple industries and commercial applications. Below are the main types and what makes them different from one another:

🔹 General-Purpose Polycarbonate Granules

These granules, due to their excellent balance of transparency, impact resistance, and heat resistance, find wide application. They are used in lenses, medical appliances, and safety equipment. Being highly durable, they serve well for everyday applications.

☀️ UV-Stabilized Polycarbonate Granules

UV-stabilized granules, designed for extended outdoor use, feature sophisticated formulations that prevent yellowing and maintain mechanical properties under harsh environmental conditions. These are best suited for outdoor use, including roofing sheets, greenhouses, and automotive parts.

🔥 Flame-Retardant Polycarbonate Granules

These are fire-retardant chemical modifications designed to meet stringent safety specifications for electrical and electronic components. Polycarbonates are self-extinguishing and therefore critical in circuit boards, electronic device housings, and other high-hazard applications.

💎 Glass-Filled Polycarbonate Granules

Glass fibers incorporated for mechanical strength, dimensional stability, and heat resistance are used in structural applications that require greater rigidity. Such glass-filled polycarbonates are used for aerospace, automotive, and industrial machinery applications.

♻️ Recycled Polycarbonate Granules

The increased importance of sustainability makes recycled polycarbonate granules an option that can be used on an environmentally friendly basis to reprocess used materials. These offer an alternative in many non-critical applications that blossoms into cost efficiency while supporting the circular economy objectives.

🎨 Colored and Transparent Granules

Available in various colors and varying degrees of transparency, these granules complement applications where aesthetic appeal is essential, such as lighting, decorative panels, and consumer products. Design flexibility comes together with excellent material properties.

All types of polycarbonate granules cater to specific industry requirements, guaranteeing a delicate balance between optimum performance and adaptation to environmental and regulatory demands. The selection of one type over the other rests on what application will be served and what properties will be desired.

Applications of Polycarbonate in Manufacturing

Working with Polycarbonate in 3D Printing

Polycarbonate is gaining worldwide fame as a versatile material in 3D printing due to its high strength, durability, and heat resistance. With its tensile strength often said to exceed that of ABS and PLA filaments, polycarbonate is highly suitable for functional prototypes, engineering parts, and any other component subjected to mechanical stresses. The material can face temperatures as high as 110°C, making it suitable for producing parts subjected to heat and operations involving high impact stress.

One additional benefit worth mentioning about polycarbonate in 3D printing is its superior optical clarity, allowing components to be transparent or light-transmitting. High extrusion temperatures are required for polycarbonate, ranging from 260 to 300°C, necessitating modern-day 3D printers with heated beds and enclosed printing chambers. Despite being awesome, it stands to lose its qualities if not dried properly. In contrast, filaments need to be stored in a sealed bag with desiccants in low humidity to preserve their printability.

Polycarbonate additive manufacturing is increasingly used to produce lightweight yet strong parts in the automotive, aerospace, and medical industries. The continuous development in polycarbonate filament composition translates into easier processing and diverse applications, thereby reinforcing its significance in 3D printing.

Polycarbonate in Food Contact Materials

Due to its durability, transparency, and ability to withstand enormous temperature changes, polycarbonate finds use in food-contact materials. It commonly allows the making of reusable water bottles, food-storage containers, and baby bottles. Polycarbonate, in simple terms, is a material that remains very light yet sturdy, offering the advantage of products being easy to work with while being highly durable. Such heat resistance in materials allows for the sterilization of items or places them comfortably in heated incubation during their daily use of food or beverages.

The FDA and the EFSA have established regulatory frameworks for the use of polycarbonate in contact with food to ensure its safety. However, concerns have been raised regarding the potential leaching of bisphenol A (BPA), a chemical used in the manufacture of polycarbonate, into food or beverages under certain conditions. In response to the consumer demand for safer products, many manufacturers have issued BPA-free alternatives or introduced alternative manufacturing methods. Research and innovation in materials science are ongoing, aiming to improve the properties of polycarbonate for food applications, while maintaining functionality and addressing health and environmental factors.

Innovative Uses in Various Industries

Polycarbonate materials have revolutionized specific industries due to their unique combination of structural concepts, including strength, lightweightness, and versatility. Polycarbonate is used for components such as headlights, windows, and interior panels in the automotive industry, which in turn offers improvements in performance and energy efficiency over traditional glass. Polycarbonate significantly supports the electronics sector by enabling the manufacture of safe and reliable casings, optical discs, and LED lighting fixtures.

Polycarbonate is increasingly used in architectural glazing, roofing, and skylights. Due to its unique ability to withstand extreme weather conditions and provide sound thermal insulation, polycarbonate is preferred for energy-efficient building designs. Furthermore, it is used in the medical field for equipment such as oxygenators, dialysis machines, and incubators, owing to its biocompatibility and ability to be sterilized easily.

The worldwide adoption of polycarbonate is now accelerating in renewable energy projects, particularly in solar panels, where its high transparency and strength enhance efficiency and reduce maintenance costs. Recent developments in recycling technology have enabled the introduction of sustainable polycarbonate products, all in tandem with the growing environmental consciousness. These varied applications indicate that polycarbonate has been a spearhead in affecting innovation in a broad spectrum.

Benefits of Using Polycarbonate Resin

💪Durability and Impact Resistance

Polycarbonate resin is renowned for its exceptional durability and impact resistance; therefore, it is widely used. Upon applications that may exert immense physical stress upon the resin, it would otherwise crack into pieces, such as automotive parts. Research has demonstrated that polycarbonate can protect from an impact 250 times greater than the forces a piece of glass of equal thickness could absorb. An environment enriched with such strength somehow enhances product safety, resulting in less demand for restoration, repair, or replacement, which equates to cost-effective and environmentally friendly solutions for both manufacturers and consumers.

⚖️Lightweight Nature

Polycarbonate exhibits lightweight properties and is, therefore, a sought-after material used across many industries. It weighs about 1.2 g/cm³, which is lighter than the weight of glass. Hence, it produces lightweight and strong components. Such a feature is significant in the automotive and aerospace industries, as weight alterations improve fuel efficiency and overall vehicle performance. The lightweight nature, therefore, eases handling and installation, reducing both transportation costs and the effort required during assembly. However, despite being lightweight, polycarbonate remains strong and durable, achieving a balance between performance efficiency and practical application. Hence, polycarbonate has been widely used throughout the engineering and design industries.

🌡️Thermal Stability and Performance

Good thermal stability means that polycarbonate can be applied in situations where the polymer will be exposed to a wide range of temperatures. The polycarbonate maintains its geometry and strength during thermal stress, with a glass transition temperature of approximately 147°C (297°F). This property will resist deformation and softening under heat, allowing the material to be used in automotive or industrial machinery applications that require some resistance to high temperatures. Additionally, from an insulation perspective, these materials help keep buildings and consumer electronics energy-efficient. With the help of advanced stabilizers and sometimes advanced coating systems, their use under extreme thermophysical loads can be extended, leading to improved long-term reliability. Such features make polycarbonates the material of choice when both durability and resistance to temperature fluctuations are required.

Comparative Analysis of Polycarbonate with Other Thermoplastics

Polycarbonate vs Other Plastics

Polycarbonate is a very tough, transparent, and heat-resistant thermoplastic. Polycarbonate yields a higher impact strength than acrylic, and therefore, it should be used where mechanical durability is sought, such as in safety glazing and protective shields. Unlike polyethylene, polycarbonate retains its structural properties and performance in applications where high temperatures are a factor, typically exceeding 250°F (121°C).

Another aspect that makes polycarbonates ideal for outdoor lenses is their superior optical clarity and UV resistance compared to ABS (Acrylonitrile Butadiene Styrene), thus affording them usability as an exterior sighting system or outdoor lens. Polycarbonate also has a higher UL 94 flame rating, which facilitates its use in electrical casing and devices requiring rigorous safety certification. Such combined properties render polycarbonates significantly more versatile, giving them a distinct advantage over other plastics in harsh environments prevalent in various industries.

Advantages of PC Over Traditional Materials

The advantages that Polycarbonate (PC) can offer, when compared to traditional materials such as glass, wood, or metal, are numerous. One significant advantage is its superior impact resistance; it is almost 250 times stronger than glass and is significantly more rigid than acrylic, thereby minimizing the chances of breakage wherever safety is a concern. Additionally, it is lightweight, weighing approximately half of what glass does while retaining considerable strength. Such a feature makes it particularly suitable for any transportation or construction application, with weight reduction resulting in improved efficiency and cost management. On the other hand, polycarbonate exhibits excellent thermal stability, maintaining its consistency even at high temperatures or extreme conditions, and neither bends nor degrades. The moldability, shoppability, or fabricability into intricate designs further adds to flexibility on the manufacturer’s part, minimizing the production process and even optimizing the cost of materials. Thus, all these benefits contribute to making polycarbonate an extremely dependable and efficient material that fuels creativity and innovation across various sectors, from automotive to electronics.

Cost-Effectiveness of Polycarbonate Resin

Known for its cost-effectiveness, polycarbonate resin holds this status primarily due to its durability, lightweight nature, and production flexibility. It is a newer material with a longer lifespan, resulting in fewer replacements, which can save on costs across the industries. Furthermore, the recycling process adds value to polycarbonate by reducing material waste and recovering costs in an environmentally friendly manner. Bottom line: In automotive applications, lightweight polycarbonate parts enhance fuel economy and, thereby, reduce operational costs. In other cases, the very inexpensive per-unit price of polycarbonates and their vast adaptability provide a strong economic advantage without compromising either price or quality.

Future Trends in Polycarbonate Manufacturing

Advancements in Producing Polycarbonates

My thought is that the most significant advancement so far has been the increased awareness of sustainable practices and the importance of being environmentally friendly. There has been much encouragement to reduce carbon emissions and non-renewable energy consumption in production. In this regard, some companies are adopting a bio-based approach, which involves using renewable raw materials, such as biomass, instead of non-renewable fossil sources. This kind of innovation not only reduces adverse environmental effects but also meets the global demand for greener supply chains.

Yet another exciting development is the improvement in recycling technologies for polycarbonate. Chemically advanced recycling schemes are gaining traction in the industry, where manufacturers decompose used polycarbonate into its fundamental constituents to be reused in producing new-grade materials. This circular economy prevents waste and landfills, as well as the drifting of discarded plastics into oceans. The companies are also investing in advanced production machinery and processes to enhance production yield and minimize material wastage.

Lastly, areas in material engineering have given rise to special considerations for the making of unique polycarbonate grades, which are basically designed for high-performance applications, such as flame retardancy or UV-stabilizing compatibility. Thus, these advancements make the polymer highly adaptable, allowing for its use in various industries, including construction, electronics, and automotive. They, in fact, speak much of cutting-edge trends in support of innovation and sustainability, which also meet the ever-changing demands of modern applications.

Sustainability in Polycarbonate Use

Sustainability-wise, I believe polycarbonate presents some challenges yet offers opportunities for an environmentally conscious choice. It is a very resilient material, hence providing opportunities for interventions such as crafting reusable products or construction materials that reduce waste over time. It can be recycled into high-quality secondary materials and used to create higher levels within a circular economy. Emphasizing reclamation and recycling programs would lessen waste while lessening the environmental footprint of polycarbonate production.

Furthermore, bio-based polycarbonate technologies seem to hold good prospects. Manufacturers are exploring plant-based raw materials, such as isosorbide derived from corn, as alternatives to the fossil-fuel refineries currently in use. This significant innovation thus enables the theoretical reduction of GHG emissions from the process, contributing to the global dream of sustainability. Additionally, efficient energy manufacturing processes are currently allowing the industries to reduce their ecological impact, thereby providing steel a path to sustainability for polycarbonate usage.

More fundamental problems, such as effective waste management and the prevention of pollution from polycarbonate, need to be addressed. Initiating the collection of polycarbonate-based products for recycling at the end of their useful life is critical. I believe that if industries collaborated and invested in sustainable technologies, we would have a stronger, more responsible use of polycarbonates, ultimately leading to a healthier Earth.

Emerging Technologies in Polycarbonate Applications

The recent years have witnessed remarkable progress in technology, which has acted as a catalyst for the innovative use of polycarbonates across various industries. With great strides being made in one sector lies the cutting-edge development of coatings that enhance the durability and utility of polycarbonate materials. These coatings together provide resistance against scratches, UV rays, and chemical exposure, making it impossible for a product made from polycarbonate to achieve a Class-II finish with a long-term warranty. One such application is in the automotive industry, where polycarbonate is utilized. Applications such as headlight lenses and panoramic sunroofs are increasingly accepted due to enhanced coatings that provide long-term clarity and hardness on glass.

In the exciting field of additive manufacturing, especially 3D printing, polycarbonate is of particular interest. Polycarbonate materials offer the advantages of strength, heat resistance, and flexibility in the creation of highly customized parts for various industries, such as aerospace and healthcare. 3D printing with polycarbonate enables the rapid prototyping of lightweight designs that can withstand their own weight under load. This helps speed up product development while reducing material waste, and both are benefits for sustainability.

This shows another side of polycarbonate’s versatility in renewable energy technology. Polycarbonate is used in photovoltaic panels and LED lighting systems because of its excellent optical properties, impact resistance, and weatherability. These qualities enable it to protect delicate components and provide energy efficiency under various environmental conditions. Considering all this, if we continue to promote and explore such emerging technologies, powered by polycarbonate, I see a bright future where they can address modern challenges while fostering further innovations throughout various industries.

Reference Sources

- Polycarbonate (PC) – Properties, Uses, & Structure – Discusses the properties, eco-friendly processing, and recyclability of polycarbonate, along with its applications.

- Advantages and Applications of Polycarbonate for High-Performance Uses – Highlights its use in industries requiring durability and clarity, such as medical devices and safety-critical applications.

- Industrial Uses for Polycarbonate and Epoxy Resins – Explores applications in energy-efficient lighting, architectural features, aerospace, and more.

- Polycarbonates – Provides insights into polycarbonate uses in medical, electronic, and construction industries.

- Exploring the Innovations and Impact of Polycarbonate Extrusion – Examines advancements in polycarbonate extrusion technology and its impact on modern manufacturing.

Frequently Asked Questions (FAQs)

❓ How do polycarbonate pellets work in injection molding?

Due to their excellent mechanical properties and ease of processing, polycarbonate pellets have become widely used in injection molding applications. These thermoplastic resin pellets are accepted for applications where parts must be injection molded into complicated shapes, such as in automotive components and packaging. The high impact resistance means they can resist severe hits without cracking. Clear polycarbonate also finds use for electronic device housings and lenses due to the resin’s transparency. Polycarbonate also finds application in the medical field, where design is crucial for precision and safety.

❓ Polycarbonate resin processing: How does viscosity affect it?

Polycarbonate resin processing is always a matter of viscosity. The higher the viscosity, the more difficult it becomes to inject the resin inside molds; the lower the viscosity, the better it flows for the details in the molded parts. Hence, manufacturers often weigh viscosity against temperature to get the best processing condition. Having said that, viscosity can also affect the product properties, such as dimensional stability and mechanical strength. Understanding the implications of viscosity on processing parameters is another way to produce deluxe items.

❓ What are the optical properties of Lexan polycarbonate?

These days, polycarbonates are regarded as materials with exceptional optical properties. Like glass, applications that require clarity and light transmission rarely utilize Lexan material, as they have similar levels of transparency. Lexan can transmit UV radiation, which can then be treated with different UV protection layers, preventing degradation in the presence of sunlight. Therefore, this feature benefits outdoor applications where weathering can become an issue. Furthermore, the optical clarity coupled with high impact resistance is an ideal choice for protective eyewear and equipment.

❓ How does polycarbonate behave in humid environments?

In humid environments, polycarbonate performs well due to its low moisture absorption. It differs from several polymers that may, for instance, swell on exposure to humidity or otherwise lose strength or mechanical properties. Polycarbonate ensures that reliability is paramount during the various applications in the automotive and electronics industries. The other primary characteristic of polycarbonate is its high impact strength, which allows the product to remain durable even under severe conditions. Coatings and treatments can be applied to enhance the moisture-resistant properties of polycarbonate further.

❓ What makes polycarbonate an environmentally sustainable option for manufacturers?

Manufacturers consider polycarbonate a sustainable choice due to its longevity and recyclability. Being highly impact-resistant and durable, it does not require frequent replacement, thereby reducing waste. Additionally, with the evolution of production methods, the energy needed to manufacture polycarbonate has decreased, resulting in a smaller environmental footprint. Another avenue that manufacturers are now venturing into is bio-based polycarbonates, which hold promise as a greener alternative to polycarbonates. Polycarbonate’s versatility also allows its use practically everywhere, from automobile applications to food packaging, meeting possible sustainable criteria.

❓ Can polycarbonate pellets be used for food contact applications?

When they pass FDA regulations, polycarbonate pellets can be used in contact with food. Food-grade polycarbonate is produced for safety and in compliance with food safety regulations. Hence, it can be used for packaging, containers, and any other food-related products. Apart from this, the clarity and strength of the material maintain food quality and shelf life. Polycarbonates do not crack or absorb moisture; thus, they remain intact in different food storage environments, making polycarbonate an excellent choice for the food industry.