Being a rigid yet flexible material, acrylic is seen as an integral component across various industries that dictate the manner in which items are designed and manufactured. Appreciated for its transmission of light, lightweight nature, and resistance against environmental factors, this material is known for its high performance and versatility. This makes acrylic a highly viable option for meeting various needs, from building applications and ultramodern interior design to automotive components and advanced medical technologies. This write-up will delve into the diverse applications and benefits of acrylic, describing how its distinctive features serve as an engine for innovation and provide sustainable alternatives in today’s highly competitive industries. Prepare yourself to be enlightened on the vast possibilities of acrylic and why it remains the material of choice among designers, engineers, and manufacturers globally.

Understanding Acrylic Material

What Is Acrylic and Its Composition?

Acrylic, also known technically as polymethyl methacrylate, is a versatile thermoplastic recognized for its clarity, strength, and durability. Chemically, it is formed by the polymerization of methyl methacrylate (MMA), resulting in a lightweight polymer with remarkable optical properties. PMMA has a high refractive index and excellent weather resistance, making it perfect for creating contrasts in applications ranging from automotive parts to architectural glazing. Its amorphous structure lends it the property of clear transparency and easy fabricability.

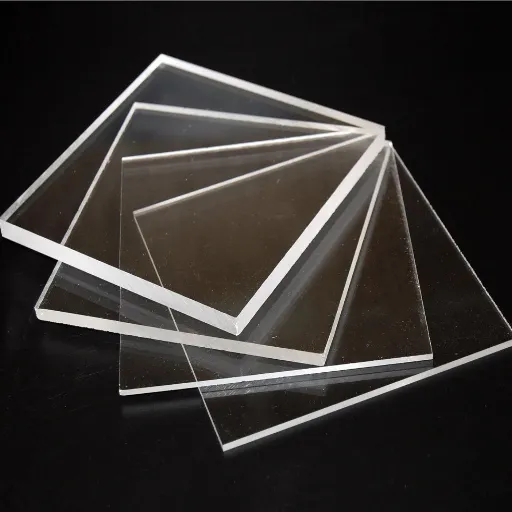

Acrylic is available in various forms, including cast and extruded sheets, which have distinct properties suited for different uses. Cast acrylic exhibits higher optical quality and greater resistance to chemicals, while extruded acrylic offers the advantage of more uniform thickness and is more cost-effective for mass production. With a tensile strength of 70 to 100 MPa, which is the industry standard, and a density of approximately 1.18 g/cm³, it is recyclable and can be reprocessed through depolymerization. This, therefore, makes it an environmentally friendly alternative to many standard ones, while bearing high-performance standards across several industries.

Types of Acrylic: Sheets, Films, etc.

The acrylic industry has a range of products in its arsenal to serve the various needs of manufacturing and consumers, though sheets and films rank first and are frequently used.

Acrylic sheets are available in various thicknesses, depending on the specific requirements. Thicknesses typically range from 1 mm to over 25 mm. It has an optical clarity of 92% light transmission. Said to be lightweight and resistant to striking away from impact, acrylic is widely used for glazing, signage, and display cases. Standard glass has approximately 17 times less impact strength than acrylic sheets. Other varieties are also available, such as UV-resistant or anti-reflective options, which are used in outdoor and optical applications to enhance durability and visibility.

Acrylic Films are thin and flexible, ranging in thickness by microns. They are used in protective coatings, display screens, and laminates due to their transparency, stiffness, and thermal stability. Advanced-level anti-scratch coatings can be given to these films to make them suitable for environments with heavy scratching or electronic displays.

Cast blocks, rods, and tubes, in addition to sheets and films, have extensive engineering applications for both structural and decorative purposes. Acrylic rods are used for precise dimensioning and machining applications, whereas seamless tubes are utilized for fluid visualization and various custom fabrications.

This ability of acrylic to take on any form aligns well with the concept of its universality, enabling it to provide flexible and customized solutions to the contemporary issues confronting humanity.

Properties of Acrylic – An Entire Overview

Polymethyl methacrylate (PMMA), commonly referred to as acrylic, is a thermoplastic characterized by distinct physical, optical, and mechanical properties. Being optically transparent (>92% light transmission), it is slightly lighter than glass; however, this very property is often exploited when it must be used in places that require visibility and structural efficiency. Acrylic features a high refractive index that enables it to retain and magnify light flow in optical devices. Being of low density, approximately 1.18 g/cm³, this plastic material reduces weight while maintaining structural properties, making it indispensable in the automotive, aerospace, and architectural industries.

Mechanically, acrylic exhibits excellent resistance to impact, approximately 15-20 times that of glass, although it is less resistant than polycarbonate. Acrylic exhibits excellent weather resistance, maintaining its transparency and integrity even under prolonged exposure to UV radiation, temperature fluctuations, or moisture. Environmental durability is enhanced by its ability to remain within a temperature range of -40°F to 194°F for extended periods without significant distortion, provided it is not used near the melting point of 320°F. The properties serve to promote it as an excellent material for outdoor installations, such as signs, windows, and protective screens.

Acrylic is a chemically inert material when it comes to several substances, including prolonged exposure to diluted acids, alkalis, and oils; thus, it is the most suitable for laboratory equipment and the storage of chemicals. On the contrary, certain solvents such as acetone or alcohol could prove detrimental by causing surface crazing or softening if mishandled. Another remarkable quality is its machinability, which allows for cuts to be made with utmost precision, as well as drilling, routing, and thermoforming to generate quite complex shapes while respecting dimensional tolerances. These characteristics, in addition to being recyclable and environmentally friendly compared to other plastics, certainly enhance its potential to stand as a highly sustainable and versatile material in many industrial, commercial, and creative applications.

Applications of Acrylic Across Industries

Acrylic in the Construction Industry

Acrylic is becoming a vital building material due to its unique combination of strength, lightness, and optical clarity. Its first major applications were as cheap windows and skylights, as well as noise barriers in the absence of glass. Environmentally, it performs very well, with its impact resistance typically rated over 10 times stronger than glass. Specific uses would be suitable in locations with severe anti-breakage concerns, such as heavy cities or industrial sites.

Additionally, the UV resistance and weatherability of acrylic will maintain its transparency and structural integrity even after prolonged exposure to sunlight and adverse atmospheric conditions. Therefore, it is primarily used as an exterior application material, such as external facades and decorative glazing. Inside, acrylic is highly versatile, often used in creative designs for partitions, displays, and lighting fixtures, where both aesthetics and durability are equally emphasized.

The latest advanced acrylic formulations have increased the material’s performance capabilities. Thermally insulating acrylic panels, for example, would support energy-efficient building design, lowering heating and cooling costs while still allowing for maximum natural light transmission. It is worth noting that various fabrication methods will produce custom shapes, thus allowing architects to pursue design innovations and their precise application in construction projects.

Acrylic not only reduces material weight, thereby implying lower transportation costs and time, but it also has a long lifespan. These attributes tout modern construction methods’ philosophy of being sustainable and cost-efficient.

Role of Acrylic in the Automotive Industry

In the automotive industry, acrylic materials are utilized due to their unique combination of high durability, lightweight properties, and design flexibility. Auto manufacturers use acrylic for windows, sunroofs, and interior components in various applications, as well as for lighting systems. Acrylic has higher impact resistance than ordinary glass, and with very little weight, it is a contributing factor to enhancing fuel efficiency in modern vehicles.

Perfect light transmission is another property that contributes to the optical clarity of acrylic, making it a suitable material for headlight and taillight covers. In fact, this acrylic is highly resistant to ultraviolet radiation and weathering; hence, exterior components have greater longevity with lower maintenance costs to be borne by the layman throughout the vehicle’s working lifetime. That being said, with the new advances in acrylic technology, there is better scratch resistance and intelligent coating methods applied that guarantee it remains durable under harsh conditions.

In terms of sustainability, this feat means that manageable manufacturing aligns well with recycling opportunities for acrylic. Vehicles are often being improved for efficiency; hence, materials like acrylic are increasingly crucial as candidates for cutting-edge design, performance, and environmental compliance in the automotive industry.

Acrylic in New Art and Design Applications

Acrylics have revolutionized modern art and design, thanks to their versatility, durability, and ability to replicate a wide range of textures and finishes. Artists often choose acrylic colors for their quick drying to add layers, intricate details, and blending techniques. Apart from traditional canvas applications, acrylic sheets are widely cast and fabricated into sculptures and installations, serving as a lightweight and shatter-resistant alternative to glass.

In interior design, the transparent acrylic material is widely used in furniture and lighting. Consider stylish coffee tables or bespoke fixtures that demand transparency and aesthetic integrity. Experimenting unexpectedly with complex forms, acrylic has also yielded some truly special and attention-grabbing architectural features, such as the kind of partitions and decorative facades that allow for artistic license. Its optical qualities, such as high light transmittance, have been analyzed further for application in design contexts, encompassing both contemporary and functional aspects, embodying the epitome of unprecedented innovation and aesthetic glory.

Advantages and Disadvantages of Acrylic Plastic

Benefits of Using Acrylic Material

There are numerous benefits of acrylic plastic due to its unique blend of physical, chemical, and aesthetic properties. Among these benefits is the fact that acrylic possesses an unprecedented strength-to-weight ratio, making it lighter in weight than glass while being at least 17 times more resistant to impact. This factor makes it more suitable for some applications where its weight would be an impediment to its consideration for use. Additionally, acrylic exhibits incredible weather resistance properties, resisting extreme UV radiation, high temperatures, and moisture while maintaining clarity and retaining its structural integrity.

✓ Key Benefits Highlighted

- ✓ Exceptional strength-to-weight ratio – 17x more impact resistant than glass

- ✓ Outstanding optical clarity – 92% light transmission

- ✓ Weather resistant – withstands UV radiation, temperature, and moisture

- ✓ Easy fabrication – can be cut, molded, and thermoformed

- ✓ Chemical resistance – withstands most cleaners, acids, and alkalis

- ✓ Recyclable and eco-friendly – sustainable material choice

Another advantage of this product is its optical feature: acrylic sheets are 92% permeable to light, bestowing upon it perfect clarity and whitish brilliance. The permanence of this property makes acrylic the choice material for glazing, signage, and optical lenses. Furthermore, this material is compatible with all fabrication processes, making it easy to cut, mold, and thermoform into intricate designs and shapes across various industries. With chemicals against them, it would add a further check as far as acrylic properties are concerned: it withstands most of the cleaners, acids, and alkalis.

Apart from its functional advantages, acrylic plastic is cheaper due to its durable nature and the ability to be recycled. The fully recyclable option enables manufacturers to minimize waste throughout their production cycle and demonstrate environmental responsibility. Advances in the formulation of acrylics continue to augment the material’s scope of application, further festering its position as a linchpin in contemporary industrial and design solutions.

Potential Drawbacks of Acrylic Plastic

⚠ Important Limitations to Consider

- ⚠ Scratch susceptibility – less resistant than tempered glass or polycarbonate

- ⚠ Lower impact resistance – compared to polycarbonate alternatives

- ⚠ Temperature sensitivity – softens at ~320°F (160°C)

- ⚠ Recycling challenges – processes not yet mainstream

Any material, even one that suits applications requiring good weather resistance, has its limitations. First of all, in comparison with tempered glasses or polycarbonates, it is less resistant to scratches; hence, in specific applications, it requires protective coatings to maintain its clarity and surface integrity. Secondly, acrylic plastic has less impact resistance compared to alternatives such as polycarbonate; it can be cracked if subjected to much stress or force. The temperature issue comes next; acrylic has a low melting point and begins to soften at about 320°F (160°C), so it should be handled carefully in a high-temperature environment. In addition, while being recyclable, acrylic recycling processes have not yet gone mainstream and are still not an efficient avenue for repurposing acrylic material, which poses a challenge in the long run at the waste management stage. These drawbacks highlight an important consideration for any application involving the use of acrylic plastic: Is it good enough?

Comparing Acrylic with Other Plastics Like Polycarbonate

In comparing acrylic with polycarbonate, one must consider the mechanical properties, optical clarity, cost-effectiveness, and environmental impact. Acrylic, chemically known as polymethyl methacrylate, is usually considered the best option whenever superior optical clarity is desired. It transmits 90-92% of light and is mainly used in signs, display cases, and aquariums. Polycarbonate, conversely, allows for slightly less light transmission, around 88-90%, but is far more impact-resistant. This material is about 250 times more impact-resistant than glass and several times more than acrylic. It is therefore used in protective barriers, eyewear lenses, and bullet-resistant glazing.

| Property | Acrylic (PMMA) | Polycarbonate |

|---|---|---|

| Light Transmission | 90-92% | 88-90% |

| Impact Resistance | 17x stronger than glass | 250x stronger than glass |

| Cost | Lower cost | Higher cost |

| Thermal Resistance | Up to 176°F (80°C) | Up to 240°F (116°C) |

| Chemical Resistance | Better resistance | Lower resistance |

| Common Applications | Signs, display cases, aquariums | Protective barriers, eyewear, bullet-resistant glazing |

Since acrylic is less costly to manufacture and purchase, from a cost perspective, acrylic ordinarily has an advantage. However, this can also lead to damage and losses, as acrylic tends to crack and shatter under high-stress conditions. Yet, its yield strength and flexibility render polycarbonate suitable for more demanding applications; however, polycarbonate’s high cost may arise as a burden, translating into a constraint on project budgets.

The other significant difference is in thermal resistance and chemical compatibility. Polycarbonate is more thermally stable, withstanding heat up to around 240°F (116°C), compared to acrylic’s maximum of 176°F (80°C), thus highlighting its suitability for use in high-heat environments. On the other hand, acrylic is better in terms of chemical resistance, meaning it is less likely to degrade when exposed to certain types of solvents or cleaning agents. These features may make them suitable for various industrial, commercial, or consumer applications, thereby necessitating a conscientious material selection in accordance with the project requirements.

Impact and Chemical Resistance of Acrylic

Knowing Acrylic Impact Strength

Acrylic is generally known to have a moderate impact strength compared to polycarbonate, thus finding applications only when somewhat strength is needed but resistance to extremely high traumas is secondary. Acrylic can withstand impact at least before it fractures, but it is more rigid and brittle than polycarbonate, which is comparatively flexible and shatter-resistant. One would say that the polycarbonate’s impact resistance is about 250 times that of glass, whereas an acrylic sheet’s impact strength is merely 17 times that of glass.

The resistance to impact that acrylic shows is more than sufficient for applications such as display cases, signage, and architectural features, as the material is not subjected to demanding mechanical stresses. However, the possible places where high-impact forces are to be expected must be ruled out because acrylic, unlike polycarbonate, is prone to cracking or shattering when confronted with sudden stress. The decision to use acrylic in impact-critical applications needs a meticulous analysis of the levels of force the material will be subjected to in its environment.

Chemical Resistance: How Acrylic Stands Up

An acrylic can provide moderate chemical resistance, making it suitable for use in many environments. The problem with acrylics is that their chemical resistance performance largely depends on the specific chemical with which they come into contact and the concentration of that chemical. Acrylics are resistant to most dilute acids and alkalis, aqueous chemical solutions, and any number of other substances, especially non-polar hydrocarbons, such as oil and grease. On the other hand, if acrylic is exposed to strong acids, chlorinated solvents, or alcohols such as ethanol and isopropanol, surface crazing, softening, or even deformation may occur over time. Additionally, resistance can be affected by temperature to some degree; chemical reactions are generally accelerated at elevated temperatures. This, in turn, makes acrylic suitable for cosmetics applications when subjected to mild or medium-grade chemicals, but not for heavy-duty commercial applications that interact with aggressive substances. A high-performance application must include exhaustive compatibility testing to render the acrylic resistant under a given set of chemical/environmental conditions.

Safety Considerations When Using Acrylic

🔥 Fire Safety Notice

Flashpoint Range: 82°C (180°F) to 96°C (205°F)

Warning: Keep away from open flames, heat sources, and sparks

When handling and using acrylic, various safety considerations must be taken into account to utilize the product effectively and circumvent hazards. Acrylic, being a flammable substance, has a flashpoint usually between 82°C (180°F) and 96°C (205°F). This property requires attention to be paid when working near open flames, heat sources, or sparks. Ventilation is always necessary in cases of cutting, machining, or thermally treating acrylic to prevent fumes from accumulating. Methyl methacrylate vapors are also a concern, as they become hazardous when present in high concentrations, especially after extended periods in the area.

When working with acrylic, it is essential to take certain precautions. The handling of acrylic sheets or components requires injury-free personal protective equipment (PPE), such as safety glasses and gloves, to protect oneself against sharp edges or splinters. The use of dull cutting tools, for instance, may cause stress fractures or microcracks in the material, which can affect its structural integrity. Acrylic should be stored under temperature-controlled conditions and low humidity to prevent warping or surface deterioration due to prolonged exposure to UV light or heat. These safety guidelines must be strictly adhered to ensure the useris protection and that acrylic remains durable in its application and efficient in performing any task.

Common Questions About Acrylic Material

Clarifying Myths About Acrylic Plastic

Myth #1: Acrylic is weaker than glass

Reality: Acrylic is actually 17 times more impact-resistant than glass and half the weight, making it stronger and easier to handle.

One of many mistaken beliefs about acrylic plastic is that it is, by nature, weaker than glass. While glass may have a higher density and feel more sturdy under certain circumstances, acrylic plastic is, in reality, much stronger and can withstand much heavier impacts — up to 17 times heavier. This means acrylic is one of the primary materials for applications requiring strength, such as safety barriers, aquariums, and skylights. Apart from that, acrylic, being only half as heavy as glass, provides easier handling and installation of oversized sheets without compromising structural performance.

Myth #2: Acrylic scratches easily and degrades quickly

Reality: Modern scratch-resistant coatings have substantially improved acrylic’s durability. With UV stabilizers, acrylic maintains its clarity even in outdoor applications.

A few more myths glamorize acrylic scratches and quick degradation. Acrylic is indeed more prone to surface scratches than polycarbonate or glass; however, the introduction of modern scratch-resistant coatings has substantially improved its resistance. Proper maintenance can also help preserve acrylic’s clarity and condition over time, and may include procedures such as gently cleaning it with a soft cloth using a non-abrasive cleaner. Acrylics are claimed, now very recently, to yellow very quickly under UV exposure; however, in recent times, manufacturers usually add UV stabilizers, thereby prolonging their life even outdoors.

These facts demonstrate that acrylic is a highly versatile, resilient, and adaptable material well-suited for various industrial and domestic applications. Dispelling these myths will allow acrylic plastics to be seen for what they are truly capable of.

Tips for Maintaining and Caring for Acrylic Products

🧹 Essential Maintenance Tips

- Use soft, non-abrasive microfiber cloths to prevent surface scratches during cleaning

- Clean with mild soap or detergent combined with lukewarm water, wiping in circular patterns

- Avoid harsh chemicals – especially ammonia-based cleaners that cause clouding

- Use acrylic-specific cleaning products to maintain clarity and prevent stress

- Protect from high temperatures and prolonged direct sunlight exposure

- Store separately from sharp objects and use protective covers when not in use

- Treat minor scratches with plastic polishing compound or specialized polishing kits

- Use compatible adhesives to prevent chemical reactions that weaken the material

- Store in dry conditions away from high humidity and temperature fluctuations

Proper acrylic product maintenance involves cleaning with a soft, non-abrasive microfiber cloth to prevent surface scratches. For general cleaning, I employ a mild soap or detergent combined with lukewarm water, gently wiping the surface in a circular pattern. Harsh chemicals should never be used, especially ammonia-based cleaners, as they can cause clouding or degradation of the material over time. Instead, I use an acrylic-specific cleaning product to ensure the clear product remains stress-free and maintains its clarity.

I always make sure to never subject acrylic to high temperatures or prolonged exposure to direct sunlight, for max heat may hinder its warping or fading. To prevent acrylic items from scratching, I keep them separate from anything sharp or abrasive, and, whenever possible, use protective covers when not in use. Should minor surface scratches appear, I treat them with a suitable plastic polishing compound or polishing kit recommended for acrylic materials, depending on the desired smooth finish.

I also ensure that I use glue or sealants compatible with acrylic, so that chemical reactions do not occur and weaken the product. Storing is equally essential: acrylic sheets or objects should be stored in dry conditions, away from places with high humidity or subject to temperature fluctuations. By practising this, I shall greatly add to the life of my acrylic items, alongside keeping the aesthetic appeal and functionality.

Reference Sources

- UV Plastic – 17 Of The Best Uses Of Acrylic Products: Highlights diverse applications of acrylic, including mirrors, aquariums, windows, and sales displays.

- Xometry – Everything You Need to Know About Acrylic and Its Uses: Explores acrylic’s uses in automotive lights, eyeglass lenses, skylights, and more.

- Curbell Plastics – Compare Plastics & View Acrylic Material Properties: Discusses acrylic’s role in signage, architectural glazing, LED lighting panels, and exhibits.

- Acme Plastics – The Advantages of Acrylic Plastic: Details acrylic’s ease of fabrication, cost-effectiveness, and adaptability for various designs.

- Plastic Sheets Shop – Acrylic Advantages and Disadvantages: Explains acrylic’s durability, weather resistance, and maintenance requirements.

- Find more info now.

Frequently Asked Questions (FAQs)

What is acrylic, and what are its properties?

Acrylic is a versatile plastic with superior optical properties and low shattering characteristics. It is a type of thermoplastic prepared from methyl methacrylate and therefore finds various applications. Acrylic is manufactured in different forms, including cast acrylic sheets and extruded acrylic sheets, with differing thicknesses and properties. Since it is slightly lighter than glass, it finds wider applications in steel cases and outdoor settings. Chemically, it resists most substances and various climatic conditions.

What are some uses of acrylic sheets in projects?

Acrylic sheets can, for sure, be involved in myriad projects, right from creative ones to serious professional applications. They can be cut to various shapes and sizes, depending on what is needed for custom display cases, signs, or even furniture. Since use and fabrication methods vary between the two, it is essential to decide from the beginning whether to use cast or extruded acrylic. For example, cast acrylic is generally preferred for intricate designs, while extruded acrylic sheets are easier to handle in large projects. Furthermore, acrylic is available in an array of colors and finishes, such as clear or colored acrylic, thereby providing avenues for creative expression.

What are the different types of acrylic available?

There are several types of acrylics: namely, cast acrylic, extruded acrylic, and impact-modified acrylic. Cast acrylic maintains the best optical properties and is thus preferred in applications where clarity is essential. Extruded acrylic sheets are relatively inexpensive and easy to work with for building purposes. The impact-modified acrylic is endowed with properties that enhance its resistance to shattering, making it ideal for situations where safety is paramount. Other variants included fluorescent acrylic, which glows under UV light, and opaque acrylic, which can be used for privacy screens or decorative pieces.

How does glass differ from acrylic?

Some consider acrylic to be lighter and more shatter-resistant than glass. Since it can easily break and shatter, glass is less durable compared to an acrylic panel, which can withstand more impact. Additionally, acrylic insulates better than glass, making it an ideal choice for outdoor use. While glass typically offers greater resistance to scratches, acrylic can be treated to enhance this resistance. The optical clarity of acrylic equals that of glass; that is why it is used in all applications where transparency is required, such as windows and display cases.

Where does acrylic find its most common use?

Being highly versatile, acrylic material finds applications in a vast array of things. Acrylic is primarily used for display cases, signage, and lighting equipment due to its high optical clarity and permanent durability. In addition to creating protective barriers, acrylic sheets can be used to make aquariums and various types of furniture. The fact that acrylic sheets are lightweight makes them very useful for outdoor installations, such as canopies and patio furniture. It is also used in the manufacturing of acrylic rods and tubes, which are utilized in both industry and art.

How do you take care of and clean acrylic products?

Actually, there are maintenance considerations to keep in mind when cleaning acrylic products, most of which are specific to prevent scratches. Wipe your acrylic object with a soft, lint-free cloth that has been dampened with soapy water or an acrylic cleaner. Avoid cleaners that contain ammonia, as these will almost certainly cause damage to the surface. For stubborn stains, apply light polishing to restore the shine. Plausibly, abrasive materials, such as scouring pads, should also be avoided as they may easily cause scratches. A regular cleaning schedule would go a long way to maintaining the optical clarity and general aesthetics of your acrylic items.