When it comes to choosing the right material for your esteemed project, TPE and PVC stand out as among the most versatile materials used across industries. Each material offers a set of unique attributes allowing them to accommodate various uses from manufacturing to construction, consumer goods, and medical equipment. Yet, their difference must be well understood to make sure the choice offers the best value in performance, efficiency, and costs in a given application. This project will take you through the disparities between TPE and PVC concerning their compositions, advantages, disadvantages, and good-worthy applications. If you are a product designer, engineer, or someone in decision-making, this article will provide guidance in making the best-laying decision for you.

Introduction to TPE and PVC

What are TPE and PVC?

Thermoplastics (TPE) and Polyvinyl Chloride (PVC) stand as two of the most common manufacturing materials today. They give a distinct set of properties suited for a variety of applications.

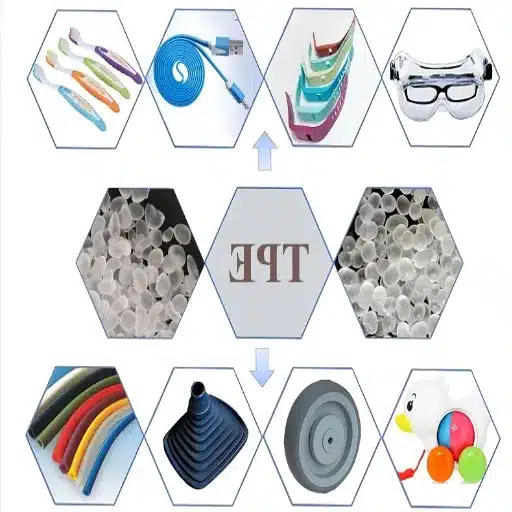

In general, TPE designates polymers that possess the elasticity of rubbers compatible with plastic processing behavior. TPEs are structurally composed of hard and soft segments, thanks to which, they behave as elastomers without undergoing vulcanization as per vulcanized rubbers. The TPEs are flexible, chemically resistant, and resilient, making them suitable for applications like sealing, grips, medical devices, and automotive parts. They are highly recyclable because they can be remelted and reprocessed, making them attractive to industries emphasizing sustainability.

By contrast, PVC constitutes a synthetic plastic polymer obtained through the polymerization of vinyl chloride monomers. PVC has become a household name in the construction, healthcare, and packaging industries due to its durability, flame-retardant nature, and chemical consistency. It is mainly manufactured as either rigid or flexible, with the latter often being plasticized to provide softness. PVC, being low in cost and capable of performing multiple functions with varying formulations, is the material of choice for pipes, cable insulation, flooring, medical tubing, and other high-throughput applications.

Although the two materials present significant advantages, the choice between TPE and PVC often depends on environmental factors and mechanical requirements, as well as regulatory and cost implications. Through analyses of these aspects, industries can ascertain how best to apply these materials for maximum functionality and efficiency.

Overview of Thermoplastic Materials

The thermoplastics are a class of polymers that become pliable or moldable upon heating and solidify on cooling. These materials have been widely prized for their durability, flexibility, and ease of processing, making them a valuable resource in many industries. Prominent features of thermoplastics include high impact resistance, good chemical resistance, and the ability to undergo repeated heating and cooling cycles without degradation.

The major division in thermoplastics is engineering-grade polymers, including polycarbonate (PC) and polyamide (PA), which offer high resistance to mechanical forces and temperatures. For critical applications, these polymers are used in the manufacturing of automotive parts, consumer electronics, and in aerospace for structural parts. In contrast, commodity thermoplastics are most often prepared as less expensive solutions for applications in packaging, household articles, and products for disposability, as they are lighter and easier to manufacture.

Further development in thermoplastic composites has enlarged this material base. Fiber-reinforced thermoplastics, for instance, give the strength of fibers like carbon or glass coupled with the lightweight and moldable properties of thermoplastic matrices. Such a phenomenon has led to its significant presence in high-end industries like renewable energy (e.g., wind turbine blades) and transportation, where concerns about weight and fuel efficiency come to the forefront.

The recycling potential of thermoplastics makes them a desirable option in sustainable manufacturing practice. Thermoplastics can be melted down and reused with minimal loss of integrity, unlike thermosetting plastics, which are increasingly sought after to reduce material waste and environmental pollution. Industries can, thus, utilize these peculiar properties to create applications with thermoplastics that meet both performance criteria and sustainability goals.

Uses of TPEs and PVC

Common TPEs and PVCs are employed widely across diverse industries owing to their diverse properties. An interesting property of TPEs is its rubber-like elasticity with the ease of processing typical of plastics. It is then the best option when the components require flexibility for everyday use and are going to be durable. These aspects of TPEs are easily applied in medical devices like tubing and seals, in automotive industries as gaskets and grips, and in consumer goods as toothbrush handles and mobile phone covers. It is further enhanced by its resistance to wide temperature and environmental conditions, even under demanding environments.

PVC, however, has historically been celebrated for its excellent chemical resistance and cost-effectiveness. It is used extensively in building construction for purposes such as piping, window frames, and floor finishes, with the main attractions being strength and durability. Medical-grade PVC is also used in IV bags and blood-storage systems because it is biocompatible and can be sterilized. PVC’s flame retardance, coupled with flexibility, enhances the material’s suitability as cable insulation.

Both materials are improving with advances in formulation technologies that allow the producer to modify the material properties further. For instance, a plasticizer or modifier added to PVC-a, which improves flexibility, can be optimized through innovations in TPE compound technology to ensure heat and UV resistance. As a result, these two materials continue to serve industries where performance, sustainability, and cost are a browbeat.

Properties of TPE vs PVC

Physical & Chemical Properties

Thermoplastic Elastomers (TPE):

TPEs are noted for their extraordinary flexibility and elasticity, which come from being a blend of both thermoplastic and elastomeric features. Low modulus of elasticity manifests in this very peculiar material, making it suitable for jobs requiring flexibility, stress, repeated flexing, and bending. The material offers chemical resistance to oils, solvents, and some acids, making it good in demanding situations. They will retain mechanical properties at a wide temperature range, generally between -30 °C and 120 °C, and are well processed by injection molding or extrusion. TPEs are recyclable due to the thermoplastic nature of the material, thus also contributing to sustainability.

Polyvinyl Chloride (PVC):

PVC provides an excellent level of rigidity and durability in its unplasticized form, also known as uPVC When plasticized, it is pretty flexible. Having high resistance to acids, alkalis, and organic solvents, PVC stands out for chemical processing applications. Due to its greater density, it exhibits far superior mechanical strength with thermal stability typically between -10° C and 60° C; however, modifiers can significantly alter these limits. Flame-retardant properties are inherent to PVC due to the chlorine present in its structure; hence, PVC is a preferred choice for fire exposure certifications. Moreover, the excellent compounding compatibility of PVC allows for the adjustment of additional properties required for a particular industrial purpose, such as impact resistance, UV resistance, etc.

Which one turned out to be opposite characters, each with its own specific settings for industrial presence, depending significantly on specific techno-practical compounding and ensuing use.

Durability and Flexibility Comparison

In analyzing the durability and the flexibility of materials like PVC and other polymers, their molecular structures and how these affect indicative performance measures must be considered. PVC is inherently resistant to weathering due to the stability of its polymer chain with chlorine, and it also resists attacks from chemical substances or moisture. This resistance feature serves as its mainstay when enduring wear and tear during long-term structural use or outdoor exposure.

Flexibility in PVC typically arises from the addition of plasticizers in the manufacturing process, which adjust its rigidity and allow customization for many uses ranging from rigid pipes to flexible wiring insulations. Conversely, some polymers such as polyethylene (PE) synthesize most of their flexibility from the natural characteristic of their macromolecular chains, providing elasticity without any additional additives.

Modern material engineering has enhanced the performance properties of PVC and its competitors. Reinforced PVC, for instance, has better tensile strength and can now be used in heavy-duty situations, whereas elastomeric polymers are further stretched to provide flexibility for dynamic applications. More precisely, specific grades of PVC may withstand tensile stresses up to 50 MPa. At the same time, high-performance elastomers show elongation at break values greater than 500%, thereby facilitating their use in situations where the utmost flexibility is required.

Therefore, evaluating the environment to which an application is subjected, along with the working stresses and flexibility options, should guide the final choice by aligning technically with the properties of a particular material.

Environmental impact of TPEs and PVC

The environmental profile of thermoplastic elastomers (TPE) and polyvinyl chloride (PVC) is quite distinct from each other and is shaped by their chemical composition and the life of the material. Production of PVC occurs through the polymerization of vinyl chloride monomers. Traditionally, this process has led to the generation of some very hazardous by-products, mainly including dioxins and chlorine-based compounds. Second, it is highly dependent on petroleum-derived substances and thus greatly aggrandizes its carbon footprint. At the end of the life cycle, its chlorine content further hinders the recycling process and makes the incineration process release toxins.

On the contrary, a positive environmental-centric view is often presented about TPEs due to their recyclability and reduced emissions in the production phase. Thermoplastic elastomers can be remelted and processed again with hardly any deterioration of existing mechanical properties, which presents possible applications for closed-loop recycling systems. Environmentally, though, a toxicological evaluation of all TPE formulations would be needed, including the level of additives or composite fillers in a given formulation. Another opportunity for reducing long-term geological impact is represented by the biodegradable types of TPE, which come with polymers from renewable sources.

In the environmental comparison between the two materials, TPE generally has a smaller environmental footprint because it can be reused and is less dependent on toxic chemical stabilizers. However, the total ecological impact of the two materials varies significantly according to the manufacturing processes, the product life cycle, and the waste management systems; thus, underlining the need for strict regulation and innovation in the sustainable design of materials.

Benefits of TPE and PVC Materials

Unpacking Benefits of TPE

Thermoplastic elastomers (TPE) are one wonderful balance of properties that make them highly beneficial across all industries. Primarily, TPEs have elasticity and the capacity to return to their original shape after deformation. For applications that require flexibility like seals, gaskets, and medical tubing, TPEs are perfect. They are lightweight materials that offer durability, resisting abrasive conditions like wear, heat, and chemicals, which increases the longevity of a product and reduces maintenance.

From the manufacturing point of view, TPE offers high versatility and compatibility in several methods of processing, such as injection molding and extrusion. This method of processing enables the quick manufacturing of complicated, high-precision parts. Moreover, TPE can be melted and reformed multiple times with minimal degradation, thereby discouraging material wastage during production, which is another boon for sustainable manufacturing.

In terms of production efficiency, TPE offers better cost options as it is a recyclable material. Since it’s so common in automotive parts, consumer goods, and electronics, the functions and environmental requirements can firmly assert that it meets them. All of these advantages ensure the importance of TPE as a modern material in engineering and product design.

Knowing the benefits of PVC

Polyvinyl chloride (PVC) is one of the most versatile and widely used thermoplastic polymers, known for its resistance and cost-efficiency. The resistance to environmental degradation, which commonly includes chemicals, moisture, or UV, sets PVC apart, and wherever it is suitable, it can be used for outdoor or indoor applications. Another fact that makes it a candidate for the building and electrical industry is its fire-retardant properties, even without heavy additives.

Mechanically speaking, it is highly durable and has horizontal tensile strength, allowing it to support large structures for long durations. It is used in construction for pipes, fittings, and building coverings. In the medical field, it is used for medical tubing and containers because it is biocompatible and easy to sterilize.

PVC is economically one of the prime polymers, with very efficient production processes and low raw material costs. Recycling further enhances its sustainable image, as many PVC products can be recycled into new materials, thus contributing to the circular economy framework. Further, some advances in the formulation of PVC, including the establishment of phthalate-free plasticizers, address environmental and health concerns and can, therefore, be considered to have an increased global market acceptability. Such properties cemented the position of PVC as a key industrial material in current manufacturing, providing innovative solutions for many industries.

Cost Considerations for TPE and PVC

When cost considerations are weighed for Thermoplastic Elastomers (TPE) and Polyvinyl Chloride (PVC), several considerations are in play: raw material prices, manufacturing efficiency, and life cycle costs. Generally speaking, TPE tends to carry a higher upfront cost since it is designed with very desirable characteristics, including flexibility, durability, temperature resistance, and chemical resistance. However, factors that can turn to TPE’s advantage, such as its ability for secondary use, ease of processing, and compatibility with various manufacturing processes, tend to reduce contamination and enhance efficiency, thereby balancing the scales toward a lower manufacturing cost.

The other way around, prioritize cost considerations: PVC is cost-effective, especially in larger works, because of its high availability and relatively cheap mass production. By virtue of its versatility and trading recycling options, economic considerations are weighed towards the extended lifecycle value. Moreover, advances in PVC formulations, such as the new phthalate-free grade, ensure compliance with environmental and safety standards without imposing significant extra cost on producers.

To conclude, the choice between TPE and PVC is often made based on the required application, balancing material properties with price considerations to achieve technical and economic objectives. Where the application demands more excellent performance, the job goes to the TPE, whereas in areas where cost and versatility are paramount, PVC will remain the material of choice. Understanding these viewpoints will enable industries to make more informed decisions that align with their operational and financial targets.

Choosing the Right Material for Your Needs

TPE vs PVC for Yoga Mats

When comparing TPE and PVC for yoga mats, several characteristics must be considered: performance, environmental implications, price, and durability. These factors determine their suitability for use in yoga. A synthetic polymer with qualities of elasticity and resilient cushioning, TPE is lightweight and flexible. Uncertified TPE mats became hazardous and did not biodegrade, raising environmental controversy; this prompted the development of green yoga mats made from TPE. It is also TPE-made yoga mats generally designed in a closed-cell manner, which inhibits moisture absorption and prevents bacteria from proliferating, thus maintaining hygiene.

In contrast, PVC mats are highly durable and resilient, providing long-term performance under heavy use. It is a cost-efficient material available in many textures, patterns, and colors, making it an attractive option for budget-oriented consumers. The only disadvantage associated with PVC is its environmental impact, as it is made from petroleum-based, non-renewable resources. If not properly processed or disposed of, it can release toxins.

| Property | TPE Mats | PVC Mats |

|---|---|---|

| Density | 0.9 – 1.1 g/cm³ | 1.3 – 1.4 g/cm³ |

| Weight | Lighter | Heavier |

| Portability | More convenient to carry | Less portable |

| Grip & Feel | Better grip, softer, natural texture | Can become slippery with heavy use |

| Environmental Impact | Eco-friendly, recyclable | Petroleum-based, potential toxins |

Numerically, TPE mats weigh less, with a density that usually ranges from 0.9 to 1.1 g/cm³, whereas PVC is denser, typically around 1.3-1.4 g/cm³. The lesser weight of TPE mats makes it more convenient to carry or move. On an application note, TPE mats provide a better grip and feel due to their softer, more natural texture, while PVC mats can become too slippery when subjected to heavy use.

Ultimately, it should depend on one’s priorities, whether TPE for the eco-friendly choice or PVC for the great value and lifespan. Considering all these factors will ensure the selection of a yoga mat that matches one’s requirements in both spirit and practicality.

Factors to Consider When Selecting a Material

- Durability and Longevity: When assessing materials, it is essential to evaluate them for durability over time. High-quality PVC is highly resistant to wear and tear, making it ideal for long-term use in settings with a lot of traffic. On the other hand, materials like TPE might degrade fairly fast in certain conditions, but make up for it with their eco-friendly nature. Understanding how frequently and intensively a material will be used helps predict its expected lifespan.

- Environmental Impact: The ecological footprint of a material is increasingly concerning for industries that focus on sustainable practices. TPEs often come into play as an alternative because their recyclable and biodegradable properties minimize pollution in the long term. On the contrary, PVC is of petrochemical origin, and its manufacturing process can produce toxic byproducts, hence raising environmental and ethical concerns.

- Cost Efficiency: Operational costs are a significant factor affecting material acceptance. PVC is considered inexpensive and readily available; therefore, it is an option acceptable to budget-conscious decisions. In contrast, TPE could cost more, usually because of its supposedly green credentials and the extra costs for processing and eco-integration.

- Performance Characteristics: The technical performance of a material ought to correspond with the way it shall be put to use. Whereas TPE would usually display superior elasticity and grip properties and thus would be suitable for products favoring a degree of comfort and flexibility (ergonomic yoga mats, for example), PVC, with its sturdy structural integrity, would be more appropriate for applications requiring rigidity and strength.

- Health Implications: Safety considerations for material composition become imperative when of notable concern for items coming into nearly direct contact with the skin. TPE is typically praised for being devoid of allergens and toxic chemicals, making it worthy of consideration for sensitive users. PVC, though durable, may sometimes emit volatile organic compounds (VOCs), posing a concern in settings that value air quality and health standards.

Each of these are to be scrutinized to make sure that the material chosen fulfills not only practical requirements but also other priorities like being environmentally responsible in the long run.

Recommendations Based on Usage

For home applications, it is highly recommended to use polythene materials like HDPE or MDF due to their durability, low cost, and ease of maintenance. These materials can adequately support usage where wear and tear and longevity are necessary, as is the case with floors and furnishings. HDPE is resistant to moisture and may be used in locations that have high humidity levels, whereas MDF provides a suitable surface for finishes and paints.

When it comes to commercial or industrial applications, more advanced materials such as anodized aluminum or stainless steel are favored because of their greater strength, corrosion resistance, and professional look. Stainless steel, for example, finds broad application in food-grade environments or in areas where specific hygiene standards are imposed on surfaces for easy cleaning and non-reactiveness. Anodized aluminum, on the other hand, is very light yet highly strong, making it perfect for both structural and aesthetic applications.

Any green project likely includes a list of renewable materials: bamboo, cork, and recycled glass. Growing rapidly and strongly, bamboo is an excellent green alternative for flooring and furniture. Recycled glass provides a fantastic option for countertops and decorative applications, combining its beauty with environmental friendliness.

Systems involved in the construction phases, such as environmental conditions and technical specifications, may interfere with the selection of materials and components throughout the process of site erection. Therefore, the choice of materials and components is determined by the operational environment, design considerations, and long-term operational goals. There ought to be an examination of various material properties for the purposes of appropriate performance. These include thermal conductivity, tensile strength, thermal expansion, corrosion resistance, ease of fabrication, ductility, and environmental adaptability, among others.

Future Trends in TPE and PVC Usage

Innovations in Thermoplastic Elastomers

From my analysis, it appears that contemporary developments in TPEs have focused heavily on enhancing their adaptability, sustainability, and functionality for different applications. One significant enhancement has been in the development of bio-based TPEs that aim to reduce dependence on fossil fuels. These materials incorporate renewable resources such as plant-based oils and natural polymers to provide a lower carbon footprint without compromising performance. It seems manufacturers are working with advanced processing methods, such as precision molecular tailoring, to improve the mechanical properties of TPE, including better elasticity, durability, and thermal stability.

Another trend is incorporating innovative functionalities for TPE formulations. Conductive and self-healing materials are creating a trend that draws various industries into accepting the concept: electronics, medical instrumentation, and automotive components, to name just a few. For example, thermo-responsive TPEs are made to respond to temperature changes for adaptive behavior such as self-sealing or shape-memory applications. 3D-printing technology presents a fertile ground for applying these materials in design with custom geometries that were once considered too complex for realization.

Furthermore, industries are striving to promote the recycling of TPEs in line with circular economy schemes. Chemical recycling methods have been developed to disintegrate and reformulate TPEs, extending their life while reducing their contribution to landfills. Together, these constitute an evolving profile of TPEs capable of meeting the higher demands modern engineering imposes, thus allowing for a more sustainable evaluation of engineering problems across industries.

Sustainability in PVC Production

When sustainability in PVC production is discussed, it is clear that essential steps are being taken to address environmental issues affecting this standard material. Considered durable and versatile, polyvinyl chloride (PVC) has faced scrutiny in recent years because its production methods rely on fossil fuels, which involve chlorine, and raise concerns about disposal. Technology and process development, however, are telling an inspiring story in favor of sustainability. Thus, more attention is being paid to renewable feedstocks like bio-based ethylene to lessen the demand for traditional petrochemicals. Also, methods are being developed that will enable further energy conservation, for instance, through better use of the oxychlorination process while reducing greenhouse gas emissions.

The recycling activities also boost PVC sustainability. In fact, mechanical recycling methods are standard in the current industry scenario, where waste PVC is reprocessed into various new products, such as pipes, flooring, and window profiles. Then there are other, more promising ones related to chemical recycling. These methods chemically break PVC into its basic constituents, allowing almost complete recovery while assuring that recycled material will have the same quality as virgin PVC. Industry ventures, such as VinylPlus in Europe, are working to establish closed-loop recycling systems and have set targets for the manufacturing and recycling of PVC materials into PVC products.

Therefore, research and development activities are aimed at phasing out or replacing harmful additives, such as lead stabilizers, with safer alternatives. This conversion aims to minimize the environmental and health risks associated with the manufacture and use of PVC. The focus on sustainability and stringent environmental regulations at the global level forces companies to innovate and adopt green practices. These, taken together, mark the latest changes toward a more sustainable and circular future, though much still needs to be done in the present time in the production of PVC.

Market Trends for TPE and PVC

According to my findings, the trends in the TPE and PVC markets demonstrate significant shifts influenced by the needs of sustainability, technological development, and industry-oriented uses. The TPE industries of automotive, medical, and consumer goods are increasingly preferred due to the greater emphasis on environmentally friendly materials and recyclability. The material’s flexibility, durability, and recyclability complement the growing population and the focus on reducing carbon footprints through regulation. New developments in bio-based TPEs are further enabling the material to infiltrate new markets, satisfying strict environmental compliance criteria.

Another trend is the transformation of PVC into a sustainable material for innovation. Slowly but surely, a shift toward non-phthalate plasticizers and bio-PVC formulations is evident as companies try to reconcile issues of health and environment. Construction and health care sectors continue as the largest user groups for PVC because it is cost-effective, strong, and versatile. However, embracing circular economy practices has promoted the development of innovative recycling methods, including chemical recycling for waste reduction and the life extension of materials.

The TPE and PVC markets are adapting together to changing consumer expectations, regulatory mandates, and environmental issues. Both materials have the highest growth potential in the automotive, medical, and infrastructure sectors, where they can adapt to innovation to meet sustainable manufacturing goals. These trends highlight the need for continued research and development to bridge performance with cost-efficiency and sustainability in material science.

Reference Sources

Timco Rubber – Material Comparison: TPE vs. PVC: This text explains the fundamental differences between TPE and PVC, including their properties and applications.

EuroPlas – TPE vs PVC: What’s the Difference?: Highlights the unique properties of TPE and PVC and their common uses in various industries.

Kent Elastomer – TPE vs PVC & Their Applications: Discusses the nonallergenic nature, flexibility, and sterilization benefits of both materials.

Rapala – PVC or Super TPE: Which Is The Better Soft Plastic Fishing Material? Compares TPE and PVC in terms of durability, stretchiness, and specific applications like fishing baits.

Disrupt Sports – Yoga Mat Showdown: TPE vs. PVC vs. Rubber: This text focuses on environmental impact and material properties, particularly in the context of yoga mats.

Frequently Asked Questions (FAQs)

What are the differences between TPE and PVC?

The main difference lies in their composition and properties. TPEs, or thermoplastic elastomers, are polymer blends with greater elasticity and flexibility, and hence, they find various applications. PVCs or polyvinyl chlorides are plastics; they are harder and less flexible than TPEs. PVCs are therefore not used in applications that expect deformation and return to its original shape, as opposed to TPEs, which find applications in such areas. PVCs contain phthalates that can be harmful, while TPEs are comparatively non-toxic and environmentally friendly.

Are TPE mats better than PVC mats?

There are many reasons to prefer TPE mats over PVC mats for yoga. TPE yoga mats provide excellent grip, are easy to wash, and use eco-friendly raw materials. On the other hand, PVC mats are sometimes difficult to clean and may present hazards owing to the chemicals used in their manufacture. In addition to being non-allergenic, these mats are highly elastic and stretchable, thus providing comfort to the user. Hence, health and environmentally-conscious yogis love TPE mats.

Is TPE recyclable, while PVC is not?

TPEs can be recycled, a huge advantage over an otherwise difficult-to-recycle material, PVC. Therefore, TPEs remain the green materials to be used in any situation where sustainability is a factor. PVC does have recycling options; however, these are quite complicated owing to the presence of additives such as phthalates. TPE and PVC are two materials serving different purposes, but in the environmental context, TPEs are usually considered the greener alternative.

So, where do applications diverge requiring the use of TPE and PVC?

Being materials with very unique properties, TPE and PVC have applications that are pretty different from each other. Since TPE exhibits high flexibility and good durability, it is used in automotive parts, electrical insulations, and consumer products. PVC will find more applications in construction, plumbing, and flooring because it is a rigid material and resists abrasion well. On the other hand, TPE is the preferred material for yoga mats because it is non-toxic and comfortable, whereas PVC mats are commonly used commercially. Ultimately, the choice between one material and the other depends on the application’s requirements.

Are there differences between TPE and PVC in elasticity?

In theory, TPE is far more elastic than PVC. One hundred percent stretched, TPE will deform without any loss of structural integrity. Generally speaking, PVC possesses some kind of elasticity as well, although it cannot be as elastic as TPE. The elasticity and flexibility of PVC would diminish as the temperature climbs, making it somewhat unreliable. Hence, TPE is selected for applications involving excellent elasticity and stretchability.

Are TPE and PVC safe for consumer products?

TPE and PVC are being used in innumerable consumer products, but their safety profiles differ. TPE is a somewhat safer option because it is usually non-toxic and does not contain harmful additives. On the flipside, PVC contains phthalates, which have been linked to several health risks. Hence, PVC products are not favored when it comes to toys and kitchenware. Consumers prefer TPE over PVC for safety and environmental friendliness in products that come into direct contact with the body.