Activewear fabrics have come a long way with their balance of performance, comfort, and durability, but the polyamide versus polyester debate remains at the heart of innovation in 2025. Whether you are an athlete, a fitness enthusiast, or simply someone who likes performance clothing, this article will inform you of the pros and cons of these two materials. The article delves deep into the characteristics of polyamide and polyester, considering factors such as moisture-wicking ability, durability, environmental impact, and more. By the end of this article, you will understand which fabric best suits your activewear needs and how the latest developments in textile technology are elevating sportswear to a whole new level.

Understanding the Basics of Polyester and Polyamide

What Is Polyester?

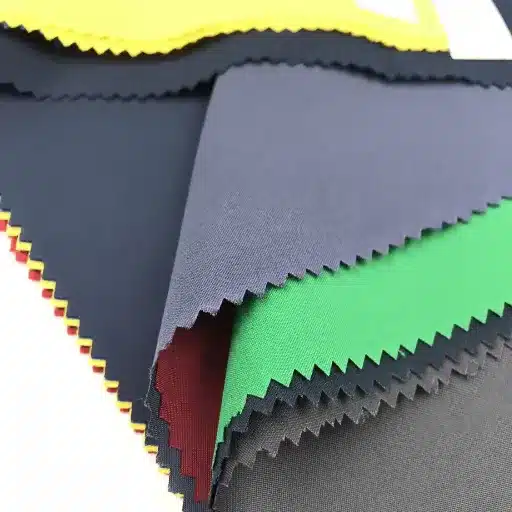

Being a synthetic fiber largely petroleum-derived, polyester stands out as perhaps the most commonly utilized textile material worldwide. Known for its strength, polyester is renowned for not stretching or shrinking and is associated with quick-dry capability. Because a polyester is hydrophobic, it repels water and moisture, making it useful in sweat-wicking. In recent developments, polyester now also comes in recycled types, reducing its environmental footprint for the green-conscious buyer. Polyester can also blend with other fibers of choice, like cotton or spandex, to give texture, elasticity, and performance attributes required to fulfill the needs of different activities and lifestyles.

What is Polyamide (Nylon)?

Polyamide, more commonly known as nylon, is a synthetic fiber that boasts durability, elasticity, and ultimate versatility. Developed as a substitute for silk in the 1930s, nylon changed the textile scenario because of its ability to withstand prolonged use and wear. Since it is lightweight yet sturdy, this fiber finds diverse uses ranging from performance sport apparel, hosiery, and outdoor gear to industrial applications such as ropes and nets. The wet resistance and fast drying properties of nylon further enhance its capabilities in performance apparel.

Besides its physical effects, technology has enabled the creation of sustainable nylon variations, such as recycled polyamides made from pre- and post-consumer waste, including fishing nets and fabric scraps. The step has been taken to adapt to an increasing demand for environmentally friendly materials in the fashion and textile industries. The chimeric fiber, under its own league, has plagued nylon, which is always recognized for its strength and versatility, to accommodate innovative processes.

Key Differences Between Polyamide and Polyester

Polyamide and polyester are perhaps the two most commonplace synthetic fibers. Still, they are vastly different in terms of their characteristics, applications, and sustainability. A polyamide fiber, which is marketed under the name nylon, is strong, flexible, and resilient. It is frequently used in situations that require the utmost durability, such as in active and outdoor wear and industrial materials. Polyester, on the other hand, resists moisture, dries quickly, and is inexpensive, making it suitable for casual apparel, home furnishings, and lightweight fabrics.

An equally basic differentiation rests in their feel. Polyamide somehow has that soft and warm feel that lends itself to textiles grown for comfort and luxury. The feel of a polyester fabric, on the other hand, is crisper and cooler, making it suitable for garments that need to be lightweight and breathable.

As technology increases its influence in sustainability, both fibers keep evolving. Recycled polyamide, for instance, has started attracting sustainability-focused interest because it uses discarded fishing nets and fabric waste as raw materials. In contrast, recycled polyester has grown prominent in the fight against plastic pollution and is predominantly produced using PET bottles. Whereas polyamides require higher energy consumption during manufacture, they give rise to considerable environmental problems owing to non-biodegradability.

Understanding these distinctions helps industries and consumers select the most appropriate textile for performance requirements, cost considerations, and environmental goals.

| Characteristic | Polyamide (Nylon) | Polyester |

|---|---|---|

| Feel & Texture | Soft and warm feel | Crisper and cooler |

| Primary Strengths | Elasticity, flexibility, resilience | Moisture resistance, quick-drying |

| Best Applications | Active wear, outdoor gear, industrial materials | Casual apparel, home furnishings, lightweight fabrics |

| Recycled Sources | Fishing nets, fabric scraps | PET bottles |

| Cost | Higher energy consumption | More inexpensive |

Physical Properties of Polyester and Polyamide Fabrics

Mechanical Properties of Polyester Versus Polyamide

Distinct mechanical properties of the two polymers allow for different uses in various industries. Polyester excels in tensile strength and durability, making it preferred for applications requiring high wear resistance, such as outdoor fabric and sportswear. It also remains dimensionally stable due to very low elongation, a feature beneficial in keeping garment shape for longer.

On the other hand, polyamide proved to deliver greater elasticity and abrasion resistance, adding a degree of flexibility and resilience for applications such as activewear and industrial uses. It also has more impact and fatigue resistance, which are the very factors making it relevant for demanding environments where mechanical stress is a daily occurrence. Although these strengths are mentioned, polyester absorbs less water than polyamide, giving it greater moisture-wicking capabilities and faster drying times in specific textile qualities.

Understanding the trade-offs between strength, elasticity, and moisture management is crucial when selecting fabrics that must meet specific functional and performance requirements. Continuous progress in textile design is putting forward solutions for sustainable and high-performance demands.

Polyester Excels At:

- Tensile strength and durability

- Dimensional stability

- Low water absorption

- Moisture-wicking capabilities

- Faster drying times

Polyamide Excels At:

- Greater elasticity

- Superior abrasion resistance

- Flexibility and resilience

- Impact resistance

- Fatigue resistance

Abrasion resistance: which is better?

The selection of the abrasion resistance method shall depend on how the fabric is going to be used. Nylon, indeed, has a reputation for excellent abrasion resistance, making it an essential property for materials used in outdoor gear, backpacks, and industrial-use fabrics. This heavy-duty possibility is provided by a very close packing of the nylon molecular chains, thus resisting wear and tear in prolonged use.

Polyester abrasion resistance is in the excellent category, although the performance characteristics are quite different. While it does not seem to match nylon for abrasion resistance under extreme conditions, polyester may compensate by offering better UV resistance and colorfastness. This set of properties makes it an excellent alternative for any application exposed to sunlight, such as outdoor wear or marine textiles.

In comparing nylon and polyester, one should be cautious of performance factors, such as exposure conditions, longevity, and functional priority. Improvements in blends and coatings have greatly enhanced abrasion resistance in both fabrics, providing tailor-made solutions for a wide range of applications. When these options are coupled with knowledge about the unique needs of the project, it is easier to make confident fabric decisions.

Checking Differences in Strength Between Polyamide and Polyester

Polyamide (more commonly referred to as nylon) and polyester are considered among the most durable synthetic materials. However, time and specific uses may cause them to wear out, depending heavily on their intrinsic properties and treatment. Polyamide is especially admired for its abrasion resistance and high elasticity; hence, it is favored wherever slight bending or repeated movements are involved. For instance, industries that require dynamically exerted tension, such as the outdoor gear or fishing net sectors, would mostly prefer polyamide.

On the contrary, polyester offers high resistance to UV radiation and water penetration, making it more preferable for prolonged outdoor exposure. It does not take in much water, thus it weakens less quickly in moist surroundings. More recently, coatings or hybrid weaves, for example, have been applied to enhance the durability of polyester further, posing intense competition in construction and marine applications.

In other words, when comparing the longevity of the two, polyamide will prioritize initial strength and elasticity, while polyester offers better resistance to environmental degradation over time. Knowing the requirements of end-use regarding exposure to sunlight, moisture, and abrasion will lead to the right selection of materials, along with advanced finishes and treatments for each scenario.

Sustainability and Environmental Impact

The Recyclability of Polyester and Polyamide

Polyester is said to be recyclable, and the same is said for nylon; yet, their recyclability differs depending on the processing method and the availability of infrastructure, end-market demand notwithstanding. It thus follows that polyester, predominantly PET, benefits from extensive recycling streams as it lies at the heart of textile and packaging applications. Polyester can be mechanically recycled into fibers or pellets, which are used in the making of new fabrics, bottles, or other products. Chemical scrubber developments are gaining momentum in polyester recycling operations Today, where fibers are depolymerized to their monomers for producing high-quality recycled materials without degradation.

While less popular, polyamide recycling is becoming more accepted owing to new technologies. Mechanical recycling of polyamide, commonly used in industrial applications like carpets or fishing nets, is typically conducted in a waste-to-lower-grade manner, resulting in industrial plastics. Closed-loop chemical recycling technologies for polyamide by depolymerization are being developed, where the process converts polyamide waste back into its original molecular structure for high-grade reuse. In the wake of tightening environmental regulations and increasingly demanding consumers, both brands and manufacturers are investing in these methods to create circular economies.

Ultimately, enhancing the recycling capabilities of raw materials relies on global cooperation to improve collection systems, develop technological advancements, and expedite the adoption of inputs that are sustainably sourced or recycled in production.

| Recycling Aspect | Polyester | Polyamide |

|---|---|---|

| Primary Method | Mechanical & Chemical recycling | Emerging chemical recycling |

| Source Materials | PET bottles, textile waste | Fishing nets, carpets, industrial waste |

| Infrastructure | Extensive recycling streams | Less developed, growing acceptance |

| Output Quality | High-quality recycled materials | Closed-loop high-grade reuse possible |

Environmental Considerations in the Making of Fabric

A shallower environmental footprint of fabric trades is still an important issue to work toward the greener movement. In the working arrangement for fabric producers, there seems to be an excellent push for eco-friendly materials such as organic cotton, hemp, and recycled polyester to lessen the dependency on virgin sources. In wet processing, the introduction of such technologies allows the least water consumption and limits the quantity of chemical waste discharged. To apply natural resources responsibly, closed-loop systems use these technologies. Progress in developing biodegradable and compostable textiles will come to the rescue, addressing concerns regarding microplastic pollution from synthetic fibers.

Textile manufacturing is also an area attempting to achieve carbon neutrality. The companies employ solar and wind energy for emission offset during production stages. To monitor and trace the supply chain, companies increasingly tie into their suppliers to ensure fair and environmentally compliant sourcing practices. Along with this, growing consumer awareness points to joint efforts to make fabric production more environmentally friendly for our future generation.

Recycled Polyester vs Recycled Polyamide

In the two major materials now at the forefront of green fashion, recycled polyester and recycled polyamide have become increasingly valuable in recent times. Both basically are made from post-consumer or post-industrial waste, thus presenting alternatives to their virgin equivalents in an eco-friendly manner. Discarded plastic bottles are primarily used in the production of recycled polyester, helping to reduce overall plastic waste and conserve resources in the textile production process. It effectively confers durability, flexibility, and moisture resistance to textiles, making it the preferred choice for active wear and outdoor activities.

Fishing nets, carpets, and industrial wastes are sources that can be recycled to form recycled polyamide. It is a celebrated fiber for its very strength, elasticity, and soft Texture; hence, it is used for making swimwear, lingerie, and performance fabrics. Both of these are important in lessening carbon footprints, but recycled polyamide is usually more complicated and energy-intensive to recycle than recycled polyester. Its importance in the realm of sustainability is gaining momentum due to its impact on oceanic plastic pollution.

Manufacturers and designers need to consider the end-use of the material, its recycling impact, and its overall sustainability lifecycle in their eco-friendly agenda. Together, they point out how circular economies can give a new vision of textile in the future.

Applications in Activewear and Textile Industries

Why Polyester for Activewear?

It is the most excellent choice for activewear because it offers unparalleled performance characteristics and adapts to modern demands for functionality and sustainability. Polyester provides exceptional strength, allowing it to resist many washings and wearings, making it suitable for intense activities and long-term use. Those special sweat-back-air features keep the wearer dry and comfortable during workouts. It can serve as a quick-drying garment as well, providing a much-appreciated convenience and minuscule downtimes for the athletic-oriented and fitness enthusiasts.

Advancements in textile technology have added to polyester’s popularity. For example, recycled polyester, primarily obtained by recycling PET plastic bottles, has gained visibility due to its reduced environmental impact. This sustainable method addresses concerns about marine plastic pollution and satisfies customers who are becoming increasingly eco-conscious. Additionally, polyester blends, especially with spandex, tend to provide extra give and stretch with a light grade of support.

From high-performance sportswear to casual athleisure wear, polyester is favored for its flexibility. It thus dominates the textile industry as a reliable and innovative choice for activewear manufacturers and environmentally conscious brands alike.

Advantages of Polyamide in Performance Fabrics

Polyamide – nylon, in other words, has always been one of the performance fabrics because of its durability, elasticity, and light weight. Polyamide fabric has an excellent strength-to-weight ratio, thus offering wearers comfort coupled with rigorous use. Polyamide can keep one dry in intense activities as it wicks away sweat from the body. Moreover, being resistant to abrasion and wear means the activewear will have a longer life, retaining its quality even after several uses.

Modern textile technology has further enhanced the properties of polyamide. Seamless knitting methods and anti-odor treatments make it a fine-pitched encore for the high-performance athlete and the everyday wearer. Polyamide offers yet another blend with other fibers to create fabrics that balance stretch and support with durability, establishing its role as an essential fiber in the creation of advanced-level performance wear.

Activewear Applications at a Glance

Polyester Best For:

- High-performance sportswear

- Casual athleisure wear

- Quick-dry garments

- Long-term durability needs

Polyamide Best For:

- Swimwear and lingerie

- Performance fabrics

- Flexibility-required garments

- High-stretch activewear

Other Textile Uses of Polyester and Polyamide

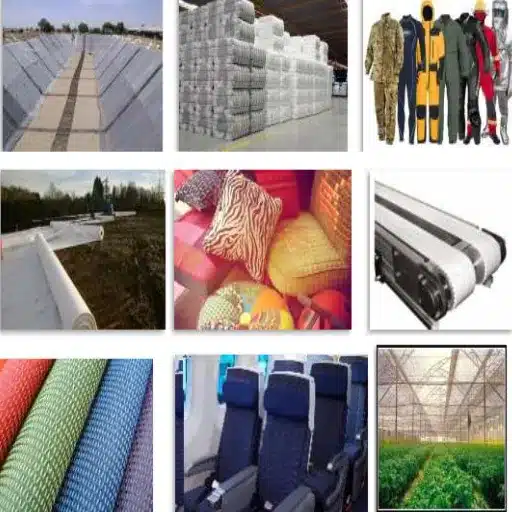

In turn, the stressing and finishing of polyester and pane stretching are key processes in performance wear. In contrast, other methods like finishing, dyeing, and printing are secondary in their application to textiles. Given their unique set of properties, they are indeed preferred by industries ranging from home furnishings to industrial ones. For example, polyester does not stretch or shrink and is resistant to wrinkling. This makes polyester an excellent cloth for upholstery, curtains, and bed linens, as it would remain spotless for a long time, requiring minimal maintenance. Polyamide, with its resistance to abrasion and strength, is used in carpets, ropes, and industrial belts where longevity is of utmost importance.

Technical textiles have been another growing market for these materials in recent times, in items like protective clothing, geotextiles, and filtration fabrics. Being compatible with advanced finishing processes such as water-repellent treatments and UV-protective coatings ensures these materials retain their versatility and functionality. These fibers are advancing textile engineering and promoting environmental consciousness, alongside other sustainable manufacturing innovations like polyester recycling and bio-based polyamide development.

Future Trends in Polyester and Polyamide Fabrics

Sustainable Textiles Innovations

Investigations into innovations in sustainable polyester and polyamide fabrics reveal that, by and large, the industry has focused more on reducing environmental impacts while improving functionality. In this case, recycled polyester from post-consumer plastic wastes, including PET bottles, appears to be a highly developed and promising concept. It avoids the filling of landfills while saving energy and reducing greenhouse gases during production compared to virgin polyester. Similarly, polyamide manufacturers are working towards bio-based alternatives produced from renewable resources, such as castor oil, which have a better environmental profile while retaining the material’s famous durability and elasticity.

Another exciting issue under constant development is the application of circular-economy principles in textile production. Industries implement a system whereby polyester and polyamide garments can be decomposed into their original monomers and reformed into new fibers without any compromise on quality. In essence, chemical recycling means recycling a material multiple times. With this, one aims to keep it out of landfill for as long as possible and conserve the raw resources needed to produce the material. For example, garment-to-garment recycling solutions are being promoted as the solution to sustainable textile production.

Beyond recycling, a finishing method should be increasingly sustainable. Waterless dyeing and bio-based finishing are fast emerging as attractive alternatives to resource-intensive conventional ways of dyeing and finishing. These technologies reduce water usage and chemical consumption and meet the growing need for fabrics to have additional attributes, such as antimicrobial properties or enhanced durability. This gives hope for a bright, sustainable future for the polyester and polyamide industry, where these two factors are no longer at odds with each other.

Key Sustainability Innovations

♻️ Circular Economy

Garment-to-garment recycling solutions

💧 Waterless Dyeing

Reduced water usage and chemical consumption

🌱 Bio-based Materials

Polyamide from castor oil and renewable sources

🔬 Chemical Recycling

Depolymerization for high-quality reuse

Measurements of Technology for Fabric Development

When I think about technology and fabric development, I see extraordinary opportunities that pair science and innovation to create textiles that change industries. From advanced manufacturing to the incorporation of innovative materials, technology has changed the entire process of fabric design, fabrication, and utilization. One of the most incredible and exciting advances is nanotechnology, which enables the creation of fabrics with added properties such as water repellency, UV protection, or self-cleaning ability. In other words, these nano-coatings enhance the durability of polyester and polyamide fabrics, allowing them to be used in more severe environments, while remaining very light and versatile.

Wearable tech and smart textiles represent prominent domains of technology development. These textiles can be embedded with sensors to monitor vital signs and track motion, or they can be connected with other devices. This is a boon to health, sports, and fashion, an industry that bases itself on making wearables that are functionally multifunctional. Sports wear, for example, is moisture-wicking and temperature-regulating, while it effectively addresses the user’s needs. It kind of ties fabric technology into a bridge linking traditional materials and interactive designs.

On top of functional improvements, sustainability has fueled fabric innovations. AI-based design control and manufacturing methods bring down waste and optimize raw materials. Recycling technologies, on the other hand, serve to convert post-consumer waste like plastic bottles into quality fibers. This set of issues supports the circular economy, making sure that performance and environmental care become intertwined. In essence, technology enables a reassessment of fabric development and the creation of more innovative, sustainable, and impactful solutions.

Shift in Consumer Demand: Going for Sustainable Options

The world today has witnessed drastic changes toward more sustainable options in recent years. Since the environment is now considered in purchasing decisions, eco-friendly products have seen growing demand. Since buying items made from organic or recycled fibers and using less wasteful packaging have become mainstream options, these are no longer niche choices. This shift in preference may primarily be due to increased awareness of climate change, plastic pollution, and unethical labor practices. These are some of the chief attributes in many purchasing decisions today.

What’s very interesting is that businesses and brands play a significant role in fulfilling this demand. Companies are using innovation to introduce products that are environmentally responsible but still meet quality and price standards. For instance, sustainable fashion is not only found in small boutique brands—across the landscape, major players are gradually adopting eco-conscious practices, whether in sourcing materials or implementing circularity in design.

It is very inspiring for me to see consumers voting with their wallets by supporting businesses that reflect their values. This goes a long way toward promoting transparency among companies and encouraging them to compete against one another to find real, sustainable solutions. Sustainability is clearly not just a buzzword anymore; it has become an irrefutable expectation of how commerce will look moving forward.

Reference Sources

Polyamide vs polyester: differences and applications

Polyamide and Polyester: What’s the Difference?

The Ultimate Guide: Polyester vs Polyamide for Clothing and Technical Gear

Polyamide vs Polyester: Which Material is Right for You?

Frequently Asked Questions (FAQs)

Polyamide and polyester: what distinguishes the two?

Deriving from different polymerization processes, we classify polyester and polyamide as synthetic fibers. Polyamide consists of amide bonds, whereas polyester is made of ester linkages, which is the main dissimilarity in chemical composition. This difference confers further fabric properties; for instance, polyamide makes for better moisture-wicking, suitable for sportswear, while polyester is more abrasion-resistant and, in turn, more durable. Polyamide has a higher melting point than polyester and is thus sometimes preferred in applications that call for high temperatures. Both of them serve different purposes in the kind of textiles used in the apparel industry.

How are polyester and polyamide made?

The polyester is produced by polymerizing polyethylene terephthalate (PET) through the condensation reaction of ethylene glycol and terephthalic acid. In contrast to polyester, a polyamide is made by the polymerization reaction of complementary monomers that contain amine and carboxylic acid groups. This makes the fabric have unique properties like high elasticity and resistance to wear. Both types of synthetic fibers can be produced from either virgin materials or recycled sources, thereby further sustaining the textile industry. An understanding of these processes makes an educated consumer aware of the environmental impact their fabric selection might have.

What are the environmental impacts of polyester and polyamide?

Both polyester and polyamide indeed affect the environment, considering that they are derived from fossil-fuel materials and plastic waste. Virgin polyester is responsible for microplastics in the ocean, while polyamide formation also causes the generation of waste. Recycled polyester and recycled polyamide, however, are becoming more accepted as sustainable alternatives to plastic waste. One thing for sure: the ability to recycle these materials is an essential factor in the reduction of their ecological footprint. Moreover, textile recycling processes geared toward closed loops are to be developed in the near future as a means to make both fabrics environmentally friendly choices for consumers.

What are the physical properties offered by polyester fabrics and polyamide?

Why are polyester fabrics used in home textiles and upholstery? Durable, wrinkle-proof, and dimensionally stable. While polyamide is more elastic and softer, it is best suited for garments that need freedom of movement. Both synthetic fibers offer moisture-regain properties, but polyester generally absorbs less moisture than polyamide. Consideration of these physical properties will help the consumer select the correct fabric for their needs, whether it is for activewear or casual wear.

Can polyamide and polyester be recycled?

Yes, both polyamide and polyester are recyclable, although the methods and processes might vary. Recycled polyester is becoming more popular and is often made from plastic bottles or other plastic waste. Similarly, recycled polyamide can be attributed to fishing nets and other textile wastes, again to reduce the presence of plastics in landfills. It is their capability to be recycled that allows these synthetic fibers to support a sustainable textile industry. As the contemporary consumer becomes more environmentally aware, the demand for recycled options will increase, compelling many more brands to adopt sustainable practices.

Which style is better for sportswear: polyamide or polyester?

Polyamide and polyester both have their appeal when it comes to sportswear, but polyamide often performs better because of its high stretch and moisture-wicking properties. Thus, it becomes advantageous where movement in activewear is key. Polyester also finds its ground in sportswear and is very resilient, making it suitable for the wear and tear of longer-lasting apparel. Choosing one or the other thus really depends on what the athlete wants from the fabric requirement factor, like breathability, comfort, and durability to sustain physical stress. Also, they can be combined to yield synthetic textiles that promote better performance.