Acrylic is, truly, one of the most dynamic and versatile materials used by many industries today. Stylish artistic creations, construction works, automotive design, and modern technology rely on the special combination of strength, clarity, and versatility that acrylic offers. Whether you are a designer, an engineer, an artist, or just a comfort seeker interested in cutting-edge materials, it is significant to comprehend acrylic-flavored properties and applications to figure out what attracts this material to such a broad field. The paper is going to discuss how acrylic is brought into play as a pioneer both in industry and the arts, thereby stressing the importance of acrylic in mundane as well as exceptional uses.

Understanding Acrylic: A Comprehensive Overview

What is Acrylic and Its History

Acrylic, often termed polymethyl methacrylate or simply PMMA, is a thermoplastic of many virtues: transparency, durability, and light weight. Developed during the first half of the 20th century, it is said to have been discovered by a German chemist named Otto Röhm, who paved the way for its commercial production in the 1930s. The use of acrylics was heavily encouraged as a safe, light substitute for glass under trade names like Plexiglas and Perspex. This material possesses extraordinary optical properties, nearly as transparent as glass but up to 17 times more resistant to impact.

This versatility of acrylic results from being able to mold, extrude, and shape it into various forms without compromising the integrity and beauty of the resultant product. Being born out of innovation and through its myriad uses, from aircraft canopies during WWII to present-day innovations like display screens and 3D printing, acrylic is cementing its position as a material through which function meets creativity.

The Types: Cast Acrylic vs. Extruded Acrylic

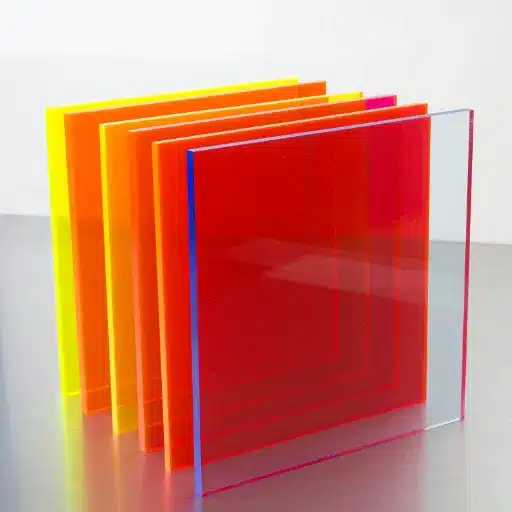

Acrylic divides as cast and extruded. These two main divisions differ very much, so usually one type will be welcome in one kind of work, while the other will be better in another. Cast acrylic is made by pouring liquid acrylic into molds, making control of thickness and optical clarity much greater. This, in turn, results in somewhat more resistant material that does not open very well to scratches and chemical attacks. Such materials are used particularly for top-quality signage, optical lenses, and display cases. Because of this manufacturing method, they will have fewer impurities, improving the general transparency and aesthetic appeal.

Alternatively known as extruded acrylic, or simply extruded, this type of acrylic is made by forcing the liquid acrylic resin into a mold composed of two rollers, between which the resin is held. It cures in a thin sheet, achieving a uniform thickness. It is cheaper by nature to make. Although extruded acrylic does not have the scratch resistance of cast acrylic, it has excellent workability and is ideal for cutting, routing, or forming into intricate shapes. Thus, it is put into POP displays, protective barriers, and construction projects where cost-effectiveness and versatility take precedence.

In deciding between cast and extruded acrylic, optical clarity, durability, cost, and use all need to be carefully weighed to see how the material fits the functional and aesthetic landscape. Both cast and extruded acrylic demonstrate the versatility that places acrylic into the class of essentials in industries.

| Feature | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Manufacturing Process | Poured into molds | Forced through rollers |

| Optical Clarity | Superior, fewer impurities | Good quality |

| Scratch Resistance | Higher resistance | Lower resistance |

| Cost | More expensive | More affordable |

| Workability | Good for precision work | Excellent for intricate shapes |

| Best Applications | Signage, optical lenses, display cases | POP displays, protective barriers, construction |

Physical Properties of Acrylic Material

With nearly 92% light transmission, acrylic is known for its phenomenal transparency, making it a widely accepted replacement for glass in several applications. It is half the weight of glass but pretty strong and has a good impact resistance, which is resistant to impact up to 17 times when compared to ordinary glass. Aside from that, it provided a weathering character to resist yellowing or aggravation arising from extended UV exposure-ideal for outdoor work.

Being thermoplastic, acrylic melts and gets soft at around 320°F (160°C) and therefore is easily molded or shaped into any desired form without jeopardizing its structural integrity. It has strong dimensional stability so that the material maintains its shape and functional performance despite temperature changes in its surrounding environment. Further, based on its chemical resistance, acrylic resists dilute acids and alkalis, but it may succumb to some solvents such as acetone. These properties render acrylic a very versatile and dependable material used in almost all industries, from construction and automotive to retail display and signage.

Key Physical Properties at a Glance

- Light Transmission: 92%

- Impact Resistance: 17x stronger than glass

- Weight: 50% lighter than glass

- Melting Point: 320°F (160°C)

- UV Resistance: Excellent (resists yellowing)

Applications of Acrylic Across Different Industries

Acrylic in the Art World: Uses of Acrylic Paint

Acrylic paint changes the art world with its distinctive ingredients and versatility. An artist retains the ability to work with the colors and effects that require quick drying through the implementation of rapid drying time, unlike oil paints. This fast-drying process allows for textures ranging from satin smooth gradients to impasto brush marks to glories in courage. Acrylic paints provide a broad spectrum of options for textures ranging from satin to bold levels or impasto marks. These paints, being somewhat similar to mediums, will stick to anything–canvas, wood, metal, or glass. This makes acrylic paints an excellent candidate for mixed media works. Also, the intense, fade-proof colors guarantee that the artwork can shine for ages. Anything from acrylic lovers, gels, and pastes makes the paint soupy, thick, glossy, matte, or anything else one can conjure with all the endless possibilities offered to the artists. Respective properties have made acrylic a preferred choice amongst art connoisseurs, while hobbyists love the freedom and infinite possibilities the medium offers.

Working With Acrylic Sheets in Construction and Design

Acrylic sheets, also known as plexiglass, have acquired a definitive place in contemporary construction and design over the years for their versatility, durability, and aesthetic prowess. Transparent and lightweight, these materials demand strength-they can withstand shocks up to 17 times stronger than ordinary glass, while they are also considerably less prone to shattering. Acrylic sheets come in a wide variety of colors, finishes, and thicknesses, which architects and designers exploit to give functional and decorative aspects to their projects. About their light-transmitting capabilities, they find the best use in skylights, windows, and signage, where both clarity and durability are of paramount importance.

Apart from your et ceraista, acrylic sheets offer extraordinary advantages during the construction stages. They possess an extreme weather resistance quality, being applicable in the interior and outdoor environment application owing to their ability to stand high temperatures under direct sunlight exposure for hours without yellowing or becoming brittle. This means performance-wise, they have long-term viability in various environments. They can be sculpted, cut, and molded with designing machinery in a great deal of complexity through laser cutting or thermoforming. Their versatility has recently led to electrostatic partitions, canopies, furniture, display cases, and even protective acrylic barriers in the public domain while giving a modern flair to all their designs.

Another factor in acrylic sheets’ problems with being increasingly popular is their environmental benefits. Many producers nowadays make acrylic sheets from recyclable materials or by more sustainable means, thus following the green construction trend. The other factor is their longevity; with a longer life span, renewal rarely happens, which in turn makes construction costs go down and waste goes down. With utility, flexibility in design, and green characteristics, acrylic sheets have built their reputation as the premier choice for architects and interior designers.

Innovative Uses of Acrylic Fiber in Textiles

Acrylic fiber may very well be a good choice with good performance and good adaptability offered in the textile. Light yet strong acrylic fiber serves mostly as an alternative to wool in cold-weather apparel, albeit in some fleece sweaters, scarves, and blankets. Emerging in the forefront of the dyeing industry, designers went wild with expressing colorful, bright hues that can be laid on acrylic with acceptance by the millinery technical jargon of enduring permanence, giving rise to a rich diversity of patterns.

From that consideration, acrylic fiber was being used to a great extent for moisture-wicking activewear. With the fiber being hydrophobic, it is functional in exercising by preventing all sweat from sticking to the skin and offering the wearer a sense of pleasant dryness.

To a lesser extent, acrylic blends are conquering their way into some really impressive outfits for outdoor use: they maintain weather resistance for tents, awnings, and upholstery fabrics, and provide comfort.

Acrylic fiber, now from the world of fashion, finds newer applications in technical textiles. These include filtration materials and medical fabrics, given their strength and easy maintenance from a layman’s perspective. The advent and progress in recyclable or sustainably sourced acrylic fibers now open vistas for ecological applications at various levels. All this, and more, ensures the display of acrylic fiber as an essential fiber to respond to ever-changing situations in modern textiles.

Advantages and Disadvantages of Using Acrylic Plastic

Benefits of Acrylic Over Other Plastics

Acrylic provides much more flexibility and strength than other plastics. Its lightweight nature enables the product to be easily transported and installed with structural integrity. It has the best optical clarity, sometimes better than your glass, with a transparent surface that resists yellowing over time. Also, acrylic is very weather-resistant and UV-resistant; hence, applications are numerous for both indoor and outdoor usage, from signage, displays, to protective barriers.

Another notable advantage of acrylic is its ease of fabrication. It can be cut, drilled, molded, or shaped to fit exact specifications, thus cutting down on production time and costs. Compared to other plastics, acrylic is less prone to scratching and cracking under ordinary environmental conditions, which increases the lifespan of the fabricated item and also ensures its cost-efficiency. Furthermore, being an environmentally friendly, recyclable material, its production demands have strongly favoured sustainability over the years. With its able-armed versatility, the choice acrylic is the go-to in industries such as construction, automotive, and even healthcare.

Some Limitations and Drawbacks of Acrylic Material

While acrylic offers a plethora of good advantages, it has a whole host of limitations that must be kept in consideration. Probably the most significant disadvantage of acrylic may be its inability to withstand high heat. Acrylic materials, when exposed to elevated temperatures, may warp, bend, or, better still, in rare cases, melt and hence are not suitable for applications demanding resistance to extreme heat. On the other hand, though, in some respects, it may be considered to be more durable than glass, the significant disadvantage of acrylic would be that it still gets scratches on the surface and eventually abrasions with the course of time, which may affect the beauty or the clarity of the material. The other demerit is that of UV degradation, for some types of acrylic may be UV resistant.

In contrast, the others may be subjected to discoloration or loss of integrity when unprotected acrylic is exposed for a very long duration to the sunlight. Finally, acrylic tends to accumulate static charge more than glass, which invites dust and particles and therefore demands proper regular maintenance in specific environments. Knowing these limitations will help in evaluating the adequacy of its application in various fields.

| ✓ Advantages | ✗ Disadvantages |

|---|---|

| Lightweight and easy to transport | Poor heat resistance (warps at high temperatures) |

| Exceptional optical clarity (92% light transmission) | Prone to scratches and surface abrasions |

| 17x more impact resistant than glass | Some types susceptible to UV degradation |

| Weather and UV resistant (with treatment) | Accumulates static charge (attracts dust) |

| Easy to fabricate (cut, drill, mold) | Vulnerable to certain solvents (acetone) |

| Recyclable and environmentally friendly | Requires regular maintenance in dusty environments |

Acrylic and Polycarbonate: Important Differences

Both acrylic and polycarbonate are very versatile and durable materials; however, due to their distinct physical properties, each is considered more suitable in specific applications. One significant difference is that of impact resistance. Polycarbonate stands out as being extremely strong and highly impact-resistant; heavy impacts may not cause it to shatter. This high impact resistance is severely required for safety equipment, bulletproof windows, and guards of industrial machinery. Contrarily, acrylic is less impact resistant, yet it is clearer and more likely not to yellow, making it the most chosen for spectacular optical products, display cases, and decorative panels.

The resistance to temperature variations, perhaps, is one of the main differences. If environmental exposure to heat needs to be considered, polycarbonate, which does not warp or lose strength at higher temperatures, will definitely be preferred. On the flipside, acrylic competes well from the UV-resistance perspective, often lasting longer in outdoor environments with suitable UV treatments. Next, coming to malleability, polycarbonate is vastly easier to shape and mold during manufacturing because of its flexibility, which benefits designs that polycarbonate can stress acrylic under.

Polycarbonate tends to be on the upper side of cost, but that durability often justifies the required expense in highly technical arenas. Then, acrylic is the inexpensive alternative for putting on style and weather resistance. Hence, knowing the question of differences plays an essential role in identifying which type of material can deliver on performance, durability, and the environmental angle.

| Property | Acrylic | Polycarbonate |

|---|---|---|

| Impact Resistance | 17x stronger than glass | Extremely high (virtually unbreakable) |

| Optical Clarity | Superior (92% light transmission) | Good (but less clear than acrylic) |

| Heat Resistance | Poor (warps at high temperatures) | Excellent (maintains strength) |

| UV Resistance | Excellent (resists yellowing) | Moderate (may yellow over time) |

| Flexibility | Less flexible (can crack under stress) | Highly flexible (easier to mold) |

| Cost | More affordable | More expensive |

| Best Applications | Display cases, signage, decorative panels | Safety equipment, bulletproof windows, machinery guards |

Frequently Asked Questions About Acrylic

What Should You Know About Acrylic Products?

Acrylic is a versatile material that finds many applications across different industries because it is endowed with unusual combinations of properties. It is a thermoplastic with excellent transparency; it transmits up to 92 percent of all visible light. An alternative to glass, acrylic weighs less and breaks less easily. It gives excellent weather resistance, making it a perfect choice for the outside use of signage, skylights, and protective barriers.

One of the primary reasons for marketing acrylic is how easily it can be fabricated. It may be cut, shaped, and polished with fine precision in the custom applications that find its use from home décor to industrial settings. Being available in a wide range of colors, appearances, and in many thicknesses-one can freely experiment creatively and still be assured of its durability. It can maintain its clarity and appearance over time due to its resistance to yellowing and degradation by UV.

Although if anything, one can say that it is more prone to scratching than polycarbonate, acrylic can be protected by coatings or simply by careful handling. Acrylic sits midway in the middle, anywhere between cost, looks, and performance, which makes it the very first choice in projects that require a combination of elegance and functionality.

Taking Care of and Maintenance for Acrylic Items

If acrylic products are correctly maintained, their lifespan can be extended and their clarity preserved. Clean acrylic surfaces with a soft microfiber cloth using some mild, non-abrasive soap with water. Dust, smudges, and fingerprints are all gently wiped off, never using very harsh chemicals that include ammonia or acetone because they can cause damage or clouding of the surface.

In case you put the item on a hard surface, do take care to place some protective pads or a piece of fabric between the item and the surface to prevent scratching. If scratches have made it to the acrylic, some polishing compounds or kits meant for acrylic may work fine to restore the smooth finish to the surface. Always store acrylic items in a temperature-controlled environment so that they do not get warped or discolored with prolonged exposure to heat or sunlight.

Not only will rough scrubbers or abrasive tools eventually wear away and etch the surface, but professional-grade coatings exist to safeguard against scratching and UV protection so you may want to consider having this coating applied to your acrylic items at some point in the future to keep them in optimum condition that much longer.

Quick Maintenance Tips

- ✓ Use soft microfiber cloths for cleaning

- ✓ Apply mild, non-abrasive soap with water

- ✗ Avoid ammonia or acetone-based cleaners

- ✗ Never use rough scrubbers or abrasive tools

- ✓ Use protective pads on hard surfaces

- ✓ Store in temperature-controlled environments

Common Mistakes: Differentiating Between Acrylic and Plexiglass

One common misconception is that the two materials are entirely different, when indeed the Plexiglass is just a trade name for acrylic. Acrylic, scientifically known as polymethyl methacrylate (PMMA), is a versatile plastic that can be cast in a variety of molds and shapes. Plexiglass, together with other brands such as Lucite and Acrylite, is made from the same PMMA raw material but may differ slightly in manufacturing techniques or proprietary formulations.

Another misconception has been that Plexiglass is more durable or more commonly used than generic acrylic. Usually, branded versions may undergo some additional quality checks for a false assurance of superiority; actually, these little differences cease to matter depending on the project requirements: thickness, coatings, etc. For instance, UV protection may be one of them. Have people know these subtleties so that they can decide without brand influence.

Lastly, many give the impression that Plexiglass is more resistant to the effects of scratching than ordinary acrylic. The scratch-resistance of any acrylic-backed material is almost always a function of the treatment of the surface. Suppose any investment into protective coatings is to be made. In that case, one will make Plexiglass coatings or standard acrylic coatings, which are all the same in providing the best finish in protection coating for durability and longevity, and later clarity and hardness.

The Future of Acrylic: Trends and Innovations

Advancements in Acrylic Technology

With the evolution of acrylic materials, the boundaries have continued to be pushed by technological innovations at the forefront of the field. The latest developments have sought to augment the clarity, strength, and environmental attributes of acrylic. For example, manufacturers are developing new formulations of acrylic that reduce haze and distortion, thereby making the acrylic suitable for high-precision applications such as optical lenses and cutting-edge display technologies. Furthermore, enhancements in the design of polymer composites have yielded a more impact-resistant acrylic that is as durable as traditional glass yet weighs less.

Sustainability has come far into focus, stimulating the research to create more eco-friendly routes for acrylic synthesis. To reduce the dependence on petrochemicals and the environmental impact from acrylic, recyclable and bio-based acrylics are being investigated. These are the greener alternatives being demanded by other mainstream industries, ranging from building and construction to consumer goods. Hence, with the development in acrylic, it is yet to meet its growing demand for versatile, futuristic materials-on-demand that are environmentally friendly and long-lasting.

Conventional Acrylic vs. Environmentally Friendly Alternative

Through my research, I have come across numerous eco-friendly solutions to conventional acrylic that emphasize sustainability and lowering environmental impact. An encouraging choice would be bio-based acrylic that is produced from renewable sources such as plant oils, cellulose, and sugars instead of petrochemicals. These bio-based alternatives have properties similar to those of conventional acrylic, such as being durable and precise; however, in producing them, fewer greenhouse gases are released and fewer finite fossil resources are used. These materials are now being investigated by companies and researchers alike to prove to be as good as traditional materials while being far more sustainable.

Other innovations also worthy of note include recycled acrylic. Post-industrial or post-consumer waste acrylic is collected, processed, and then reformed into new products. Apart from preventing waste, it also stops further extraction of raw materials and energy-intensive production. Due to advances in recycling technologies, the technical properties of recycled acrylic could be retained, meaning recycled acrylic is almost the same as virgin acrylic but with a much lower environmental impact.

Beyond these, materials such as polycarbonate and biodegradable or compostable polymers are growing more in demand for uses where acrylic would have traditionally been utilized. While they cannot always copy all the characteristics of acrylic, they offer somewhat more realistic options for very particular usages. There is no doubt about the industry’s focus on greener methods for production and materials, and I feel confident that with a bit of advancement in technology, green alternatives to a wide array of applications will be made viable and readily available for general use.

Sustainable Acrylic Innovations

Bio-Based Acrylic

Made from renewable sources like plant oils, cellulose, and sugars with lower greenhouse gas emissions.

Recycled Acrylic

Processed from post-industrial and post-consumer waste, retaining properties similar to virgin acrylic.

Biodegradable Polymers

Alternative materials offering compostable options for specific applications.

Potential New Application of Acrylic Materials

From my experience, there can only be further evolution with acrylic materials, with technology and manufacturing being leveled upwards alongside. One promising area for development is calcifying components for renewable energy systems that are lightweight and durable. For example, acrylic is getting more popular as a material for solar panel covers due to its excellent clarity, UV resistance, and weather durability. These properties enhance not only solar panel efficiency but also their long-term performance under harsh environmental conditions. Acrylic, in the same way, is considered for innovations in wind turbine design, where strong materials and light are considered.

Another promising area for application lies in medicine. Acrylic materials are being designed to produce quality medical devices, such as diagnostic equipment and prostheses. Because of the biocompatibility requirement for acrylic and its ease of sterilization, it is important for products requiring precision and safety. In addition, I foresee acrylic variants having the potential to take up a greater portion in the optics technology arena, i.e., lenses for AR devices or high-powered imaging systems. These advanced applications illustrate how the clarity and versatility of acrylic can aid industries that place much importance on visual clarity and endurance.

Looking ahead, it surely appears acrylics will begin to find further integration in smart-home technologies and sustainable urban designs, wherein the practical aspects integrated with aesthetics could give way to endless creative new possibilities. The momentum going towards innovation suggests that acrylic is still very much an untapped material of potential in a wide range of contemporary applications.

🔋 Renewable Energy

Solar panel covers and wind turbine components leveraging acrylic’s clarity and durability.

🏥 Medical Devices

Diagnostic equipment and prostheses utilizing biocompatibility and sterilization ease.

👓 Advanced Optics

AR device lenses and high-powered imaging systems requiring exceptional clarity.

🏡 Smart Technologies

Integration in smart-home systems and sustainable urban design applications.

Reference Sources

- Acrylic Fiber – Wikipedia: Provides an overview of acrylic fibers, their composition, and properties.

- What Is Acrylic Fabric? – Swavelle: Explains acrylic as a synthetic fabric, its development, and its widespread use as a wool alternative.

- 17 Of The Best Uses Of Acrylic Products – UV Plastic: Highlights diverse applications of acrylic, including mirrors, windows, aquariums, and more.

- Acrylic Polymers: A Clear Focus – MDDI Online: Discusses the use of acrylic in the medical industry, such as for syringes, test kits, and tubing connectors.

- Uses of Acrylic Sheets: 10 Surprising Applications You’ll Love – FL Acrylic: Covers various applications of acrylic sheets in signs, construction, protective barriers, and more.

Frequently Asked Questions (FAQs)

What is the history of acrylic?

The history of acrylic dates back to the early 1900s when German chemist Otto Röhm developed polymethyl methacrylate (PMMA) in the 1930s. This material grew fast in prominence due to its unmatched clarity and versatility. In the beginning, acrylic was used as a substitute for glass in applications from outdoor signage to display cases. The acrylic-making polymerization process can produce many forms, such as extruded and cast acrylic, making it highly useful. With time and better ways of production, a variety of acrylic products have made their way into the marketplace.

What are the properties of acrylic?

There are multiple advantages that acrylic has as a material, and it is very well regarded across industries due to its versatile applications. It has excellent optical properties, especially when light transmission is concerned, as it is better than glass in resisting impact and scratches. It’s also a lightweight acrylic when weighed against the heaviness of glass, which makes it simple to install or carry. As well as being offered in multiple thicknesses and colors, acrylic has a plethora of possibilities for use. Being able to bend it with heat makes it an ideal material for extrusion and injection molding.

How does cast acrylic differentiate from extruded acrylic?

The casting of acrylic entails pouring liquid monomers into a mold to undergo the polymerization reaction, thereby producing thicker and thus sturdier stock. In comparison, extruding acrylic involves forcing the material through a die that creates a continuous sheet, thinner and more uniform by nature. Hence, cast acrylic has better optical clarity and surface finish, whereas extruded acrylic is generally cheaper and simpler to work with on larger scales.

What are the advantages and disadvantages of acrylic?

Since it is a lightweight material that is shatterproof with excellent optical clarity, the applications of acrylic are many, ranging from display cases to outdoor signage. It comes in various colors and can be fabricated readily by any tool designed for plastics. One drawback of acrylic is that it is very prone to scratches and UV light degradation. With proper maintenance, though, it will have a very long life. Acrylic should be wiped with a soft cloth. However, harsh chemicals should be avoided as they might damage the surface. While these are disadvantages, the advantages of acrylic tie it all up; thus, it tends to be the preferred choice for many applications.

How to properly use acrylic paint?

Because acrylic paint is versatile, it has a variety of applications-from classic canvas painting to crafting and decorating. One of the perks of using dye is the swift drying time, allowing application of successive colors in a layering manner without any waiting period for drying time. However, acrylic tends to dry extremely fast; therefore, brushes should be kept moist to allow the paint to flow and should be cleaned immediately with a soft cloth. Another option with acrylics for thinning or changing the finish is water or acrylic mediums. Various techniques of applying acrylics, such as glazing or layering, make the artwork more vivid.

What are the common uses for acrylic?

Acrylic is used in a broad variety of materials, from signage, display cases, and furniture to even medical devices. With its optical clarity and durability, it can be installed indoors and outdoors, being a shatter-resistant replacement for glass. Other uses include manufacturing synthetic fibers, like acrylic yarn, that find favor within the textile industry. The numerous applications of acrylic make it suitable for special requests that need particular shapes and sizes, thus allowing for free creative expression. The ability to color and mold acrylic with relative ease further makes it a good proposition in many industry sectors.