Acrylic is an amazing, adaptable material, which is one of the reasons it is among the most widely used products. Overall, it is necessary not only in everyday products but also in specialized designs because of its unique properties. However, people often wonder about the composition of acrylic. This article breaks down the elemental scientific features of acrylic, revealing its composite structure and characteristics that make it a preferred component for designers, engineers, and manufacturers. If you want to know more about its toughness, transparency, or ease of use, acrylic is the key. It remains the preferred material in the most creative and innovative design processes globally.

Understanding Acrylic and Its Composition

What Does Acrylic Essentially Mean?

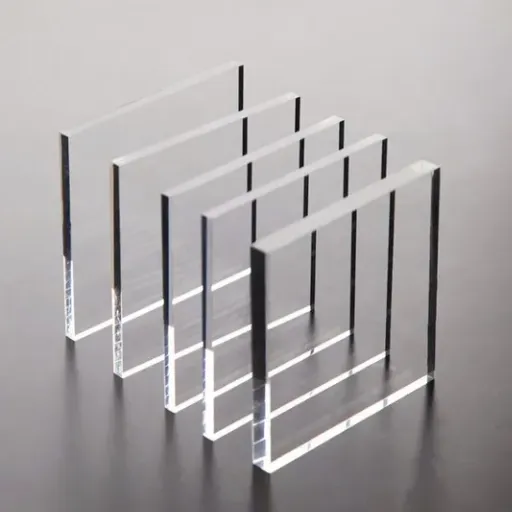

Acrylic, or polymethyl methacrylate (PMMA), is a resilient, lightweight, and easily manipulated thermoplastic widely known for its high clarity and durability, among other properties. The resin is produced by the polymerization of methyl methacrylate (MMA), yielding a tough, easily modifiable material. It is not only more impact-resistant than glass but also much lighter, making it the best choice for many industries. Moreover, its versatility in applications is limitless, as it can be easily formed into various designs and thus used to produce display cases, windows, optical lenses, and medical devices. This triple nature—transparent, strong, and flexible — makes acrylic materials highly distinctive and preferable for every high-tech design or engineering project.

Acrylic: Methyl Methacrylate’s Chemistry Behind

Methyl methacrylate (MMA) is the most critical monomer used in acrylic production. Its molecular formula is C5H8O2, and it is a clear and colorless liquid with a characteristic pungent smell. The acrylic chain is formed when MMA molecules are joined through a process called polymerization. Acrylic, a durable and transparent material, is a significant application of this substance. Polymerization usually happens via free-radical initiation, a process that guarantees the end product is strong, light, and versatile. Methyl methacrylate, in particular, is valued for its ability to produce a high-quality, weather-resistant material that remains clear over time without turning yellow. The plasticity and versatility of MMA are essential in fields such as construction, automotive, and medical applications, underscoring its significance in the present-day materials science landscape.

Types of Acrylic Materials

Acrylic materials are available in cast, extruded, and impact-modified forms; each type is uniquely suited to specific applications across different industries.

Cast Acrylic

It is a fact that cast acrylic is the king of its fellows when it comes to clarity, versatility, and durability. Thanks to its liquid acrylic formulation and casting method, it exhibits excellent optical properties. It is not easily scratched, making it the best choice for the production of display cases, aquariums, and signage.

Extruded Acrylic

Unlike the materials mentioned above, extruded acrylic is easier to produce; hence, it is a bit inferior but cheaper. Softer than cast acrylic, this type of acrylic allows easier cutting and shaping. It is frequently used for non-lighting but eye-catching applications, such as point-of-sale displays, advertisements, restaurant menus, and furniture.

Impact-Modified Acrylic

It is tough to break impact-modified acrylic, as it is made from a resin and a chemical that together increase its impact resistance and toughness. However, the product is not widely available. Such material is often used in constructing the windshield of a car and other products in that segment, such as protective barriers, and heavy equipment; however, this material is part of the heavy equipment sector only.

Textured or Patterned Acrylic

The unique patterns of the textured acrylic make it a one-of-a-kind material. And the frosted, matte, and prismatic surfaces are all light-diffusing and highly aesthetic. This material is a common choice for interior design, decorative panels, and privacy screens.

UV-Resistant Acrylic

Even in the harshest sunlight, UV-resistant acrylic can’t be ruined, which is why many outdoor applications, like greenhouses, skylights, and outdoor signage, favor this material.

The different types of plastic coatings have distinct features that meet their own needs and demonstrate the flexibility and new approach underlying contemporary acrylic technology.

The Properties of Acrylic Plastic

Durability and Strength of Acrylic

The sturdiness and durability of acrylic materials are among the most sought-after due to their outstanding performance and strength. Hence, they are the main component in many varied applications, both in the commercial and domestic sectors, for various reasons. Approximately 10 times more tough than glass, this plastic can take one hell of a beating without breaking. Besides its toughness, it is still very light, which eases the entire transportation and installation process. Furthermore, its excellent resistance to the weather and UV light ensures a long life, even in the most unfavorable environmental conditions. The material is still capable of maintaining its transparency and strength over the long term, which is why it is one of the first options for many applications that require the toughness of nature and need to look beautiful as well, such as protective barriers, outdoor furniture, and architectural elements. All the above also indicate its adaptability and durability when applied to many different jobs on a large scale, e.g., the Barrier for rootkits in which it is being used.

Transparency and Light Transmission

Acrylic is one of the materials that has a unique feature of being almost as clear as glass and similar to it in terms of light transmission. When we talk about a life of light transmission, acrylic’s rate is around 92%, making it a perfect choice for applications that require the product’s supreme optical clarity. This, together with the even light diffusion that acrylic is capable of brings better lighting and lighting fixtures, display cases, and other illumination-based designs. One more significant benefit of acrylic is that it is free of one disadvantage of traditional materials – it won’t turn yellow over time; thus, it will look good and do its job. These points are simply why acrylic has been adopted as an indispensable material in sectors where clarity and light management are the main concerns.

Weather Resistance and UV Stability

The weather resistance and stability of acrylic are very outstanding when used for a long time under the ultraviolet (UV) light. It is one of the materials that does not get brittle, discolored, or significantly degraded when exposed to sunlight for a long time, unlike many others. This toughness, tested again and again, makes it the best fit for outdoor use in applications such as signs, architectural glazing, and greenhouse panels. Moreover, due to advances in manufacturing and material coatings that enhance the substances’ compatibility, the durability of acrylic has been further boosted, so that the material can still be used without fear of losing clarity under harsh environmental conditions. Besides, it is pertinent to note that its widest installations are in places where the climate, in terms of temperature, can change drastically from very hot to very cold.

Common Uses of Acrylic in Various Industries

Acrylic in Automobile Applications

Acrylic stands out as a very important material in the automotive industry because of its strong features such as lightness and optical clarity. Communication between departments in the automotive industry has become faster, thereby making acrylic more compatible. Usage of acrylic for car windows, sunroofs, and wind deflectors is a perfect example because their energy absorption can withstand the energy of a 100 km/h impact and their translucent character makes it the best material among all the other glazing materials. Cars and windows become one, with safety coming first. Additionally, acrylic is often used in interior components, such as dashboards and display panels, for its stunning aesthetics, especially in cars and other vehicles where cabin design is a key selling point. Its scratch resistance and ability to maintain transparency over time make it an ideal material for headlights and taillights, improving visibility and vehicle aesthetics. Innovations in acrylic formulations continue to deliver enhanced UV protection and improved thermal stability, ensuring reliable performance across varying conditions in automotive applications.

Acrylic in Construction and Architecture

The acrylic, with its great versatility, toughness, and beauty, hold a special place in construction and architectural projects. It is a strong, very light material, so it is a superb substitute for glass in windows, skylights, and facades. Acrylic variations provide the user brightness and very high light transmittance rates while also removing the harm that UV rays can cause. As a bonus, its shatter resistance is far beyond that of traditional glass, making it a more reliable choice for both public and residential projects. On the other hand, manufacturers are continually introducing product developments that further improve the material features. For instance, they have managed to enhance acrylic’s resistance to weathering and its thermal properties. This way, the material is becoming more reliable for use in both interior and exterior architectural designs.

Use of Acrylic in Art and Design

Acrylic has earned a spot as the most preferred in both the art and design world thanks to its lightness, toughness, and pleasing appearance. Artists typically go with acrylic because it dries very quickly and is highly versatile, allowing them to work with bright colors, create various textures, and apply multiple layers. The material can be mixed with several different surfaces, such as canvas, wood, and metal, making it a sought-after material for experimental and mixed-media projects.

Moreover, when it comes to the design industry, acrylic’s feature of being light in weight and at the same time being easy to shape, makes it the perfect choice for the crafting of modern furniture, lighting fixtures, and intricate decorative pieces. The availability of transparent and colored acrylic sheets opens the door to limitless options for designers to achieve chic, innovative appearances while maintaining the material’s use. Lastly, both its long-lasting and non-fading properties indicate that not only the imaginative but also the technical side of the designs will remain unchanged in terms of their look or support throughout the years – thus, acrylic is a must-have for the modern creative businesses.

Comparing Acrylic with Other Plastics

Acrylic vs. Polycarbonate: Which is Better?

Both materials have advantages that make them well-suited to certain applications. Acrylic is predominantly transparent, with a glossy finish that is very attractive for displays, signage, and artistic projects, making it an obvious choice. Moreover, it is more scratch-resistant than polycarbonate. It is likely to be cheaper in most cases, both of which are appealing features for budget-conscious projects that require a visually appealing outcome.

On the other side, polycarbonate material is globally recognized for its ability to withstand shock, being 250 times stronger than glass and significantly tougher than acrylic. This makes polycarbonate a more suitable candidate for security purposes such as bulletproof windows and protective barriers. Besides that, Polycarbonate is more heat- and temperature-resistant than acrylic and is not brittle, which makes it more physically robust and sustainable in the long run.

In all honesty, the friendliness between acrylic and polycarbonate comes down to the project objectives. If transparency, the near absence of scratches, and costs are the most significant for a client, acrylic is hands-down the best choice. Instead, in the case of requiremеnts of such as durability, high impact resistance, and high heat tolerаnсe, polycarbonate would rather be the first choice. Yet since both materials are highly adaptive to nature, they are a boon to modern design and manufacturing through their suitability for specific needs.

| Property | Acrylic | Polycarbonate |

|---|---|---|

| Transparency | Excellent (92% light transmission) | Good |

| Scratch Resistance | High | Low to Moderate |

| Impact Resistance | 10x stronger than glass | 250x stronger than glass |

| Heat Resistance | Moderate | High |

| Cost | Lower | Higher |

| Best For | Displays, signage, artistic projects | Security applications, protective barriers |

Advantages Over Traditional Plastics

Acrylic and polycarbonate are the best substitutes for ordinary plastics across many industries because they offer unique benefits. Their incredibly high strength and unmatchable durability ensure complete resistance to many impacts and pressures that would typically destroy ordinary plastics. Moreover, the brightness through them is superior to that through many other materials; where acrylic shows transparency like glass, polycarbonate can transmit light remarkably well while remaining almost unbreakable. Thus, they are so understood and selected for industries that demand both beauty and function, such as architectural assemblies, car parts, and protective screens. Moreover, they are light, which eases transportation and installation, thereby lowering total costs and environmental impact. Being very sophisticated, these materials have emerged to address the difficulty of storing and using them in all environmental conditions, where the advanced applications of traditional plastics are not up to the mark.

Environmental Concerns Related to Acrylic Utilization

The eco-friendliness of using acrylic materials is a matter of utmost concern. They are essentially made from the earth’s resources, and the process of creating them may produce greenhouse gases. Additionally, acrylic is an inert material, so it can stay in a landfill for many years if it is not recycled. Nevertheless, the technical progress of converting waste acrylic to the new material has—secondly—diminished the need for the use of oil., The cons, particularly, outweigh the pros when it comes to the disposal of synthetic polymer materials which are responsible for the most significant part of the global non-biodegradable waste. Thus, the choice of low-maintenance, high-performance acrylics will merely add to the gradual depletion of the environment. This total depletion, to a certain level, will be caused by the accelerating usage of the wide-spectrum material.

How to Care for and Maintain Acrylic Products

Cleaning Of Acrylic Sheets

A recommendation for cleaning acrylic sheets effectively is to avoid using harmful chemicals or abrasive substances that may damage their surface. Instead, start with a soft microfiber cloth and lukewarm water mixed with a mild, non-abrasive soap, and ideally, in a warm and dust-free room. Wipe the cloth in a circular motion to remove dirt and grime without applying any pressure to the surface. You may use a gentle scratch-resistant scrubber if stubborn spots don’t come off. The easier thing to do is just let the soapy water stay on the acrylic surface for a little while before thoroughly wiping. Then you need to wash the sheet with clean water several times and dry it with a fresh, soft cloth —the same one you used to wash it —with to avoid water spots. Also, it is better not to use any ammonia-based cleaners, because they can make the acrylic appear cloudy over time. Regular, gentle cleaning with these methods will maintain the clarity and service life of the acrylic.

Common Mistakes to Avoid When Handling Acrylic

To avoid harsh chemicals and other products causing discoloration, my advice is when handling acrylic, avoid using anything sharp and rough for cleaning. Rough scrubbing pads, steel wool, and other tools with a too-hard texture can spoil the polished look of acrylic, leaving permanent markings. Meditate on this and then introduce microfiber cloths and a gentle soap solution that can be used daily alongside regular cleaning routines, if possible.

Another big problem I noticed is the improper way of storing and carrying acrylic sheets. Acrylic is very sensitive to bend or crack unless it is supported uniformly, hence putting heavy objects on top or keeping it in insufficient support may cause warping or damage. I am now watchful when it comes to storing the acrylic sheets as they are to be placed flat on a clean, soft surface without any heavy-laden stuff on top of them. When transporting, I use protective covers like bubble wrap to avoid any scratches or break-through accidents.

At last, I understand that the use of excessive force during drilling or cutting acrylic can cause cracks or breakage in the material. For this reason, I have to apply the best skills and tools, including acrylic-specific drill bits, to achieve the final results. Apart from this, overheating while cutting or machining acrylic can cause it to melt or deform, which is why I always use slow, smooth cutting operations and keep the workpiece cooled with airflow. The above measurements have greatly helped my work with and preservation of the acrylic pieces.

Repairing Scratches and Damage on Acrylic

When it comes to removing scratches from acrylic surfaces, I follow a three-step process. Firstly, I need to examine the scratch and its depth so that I can treat it properly. Minor ones will be treated with a microfiber cloth, plastic polish, or an acrylic scratch remover I have on hand. I usually put a small amount of polish on the cloth, then gently rub it in circles over the scratch. This also not only smooths the material’s surface but also restores the acrylic’s original clarity. Afterward, I clean off any leftover residue from the abrasive process and at the same time, buff the acrylic with a non-abrasive cleaner that has the benefit of adding extra shine.

When the damage is more serious, it is often necessary to implement a complete approach to eliminate the scratches. I start with wet sanding, using 600-800 grit sandpaper, systematically and always applying equal pressure, so no uneven spots are left. After the first sanding session, I move on to finer grits —1200 or 1500 —to remove sanding marks and further refine the surface. The next procedure is to apply a polishing compound with a soft cloth or a polishing wheel, done very slowly and without overheating the acrylic. The result of this step is a completely restored material that is shiny and smooth. Finally, I do a thorough cleaning and examination of the article for the purpose of checking the efficiency of the repair and that the acrylic looks as good as new.

It has been my experience that using the correct tools and procedures can effectively repair even extensive acrylic damage. One needs to be patient, as rushing the process might lead to accidental additional damage. Properly maintained pieces, however, can maintain their “like-new” appearance and continue to function properly over time.

Reference Sources

What is Acrylic Fabric: Properties, How it’s Made and Where – Sewport

What is Acrylic Fabric? – Revolution Fabrics

A Comprehensive Analysis of Acrylic Sheet – Piedmont Plastics

Frequently Asked Questions (FAQs)

Among many other things, what is acrylic composed of?

Acrylic is composed of a polymer called polymethyl methacrylate (PMMA), which is a resin that is synthetically synthesized. The presence of this substance is owed to the polymerization method of methyl methacrylate monomers. The outcome is a versatile, nearly colorless thermoplastic commonly used in many applications. Acrylic can be made in different forms, but the market is mostly dominated by two types — cast acrylic and extruded acrylic — due to their varied applications. It is very light, making it a good substitute for use in various places and forms, such as displays, signage, and more.

Is it correct to say that there are several different types of acrylic materials?

Acrylic materials come in several varieties, with cast and extruded acrylic being the most common. Cast acrylic is the most transparent and highest quality type. As such, it is the perfect choice for all applications that rely on light passages. The extruded acrylic, on the contrary, is considered the most cost-effective and is therefore more often seen in sheet form. Still, the two can be used in various ways such as making acrylic panels, signs, or even furniture. Furthermore, acrylic can be easily modified or compounded with other materials to enhance its properties, making it an all-purpose material for most industries.

In what ways can acrylic be found in our daily lives?

Acrylic is the point of everyday life that needs both strength and clarity in its material. The main application of its hard structure is believed to be in construction. Glass used for that purpose is another example, but the fragility of the latter always speaks against it. And this is where acrylic becomes a great, shatterproof alternative to glass. Especially in areas where safety is a major concern, it is of utmost importance to use only the safest materials. In many cases, acrylic is the most budget-friendly and user-friendly material a person who spends only a few hours on an art project at home would use to make a select crown. When thicker sheets are available, the choice of thickness may become an issue. On the other hand, being the most common thickness on the market, it can be easily cut and shaped for various purposes.

What are the advantages of using acrylic over glass?

One of the strengths of acrylic compared to glass is its weight: it is very light, does not shatter, and can be used in a variety of ways. It is a material that is often used as a transparent thermoplastic, offering clarity similar to that of glass but it is much lighter, hence making it easier to work and install. Apart from this, the impact resistance of acrylic against crack initiation is higher than that of glass; therefore, the risk of breakage is reduced. It can also be done by molding and forming into different shapes, which is very suitable for custom applications. Due to these properties, we find that acrylic is the material of choice in many applications, from home decorations to the industrial sector.

Is exterior application an acceptable use of acrylic?

Certainly, the weather resistance and UV stability of acrylic make it one of the best materials for outdoor use. It is a ubiquitous material for canopies, signs, and windows when they are likely to be exposed to outdoor conditions. The most important aspect is that it allows light to pass through efficiently while preventing harmful UV rays, which can cause color fading in the substrates. Further to this, the material is not affected by impacts, hence suitable for outdoor use where the item may be exposed to high winds and other accidental impacts. Because acrylic is so versatile, both residential and commercial sectors love using it as a significant part of their outdoor projects.

Discuss the production and processing of acrylic?

The manufacturing of Acrylic involves various methods, which include extrusion and casting. In extrusion, acrylic pellets are heated and forced through a die to form sheets of varying thickness. Casting is done by pouring liquid acrylic resin into a mould and leaving it to solidify. Both methods result in robust products, but the choice of method might change the final product sheet, particularly in terms of clarity and strength. Moreover, a variety of techniques, such as laser cutting, can be used to create extremely detailed designs and shapes from acrylic sheets, which makes it ideal for different applications.