Plexiglass is a very versatile and highly rated material for its apparent and strong features that is used in a lot of common applications such as shields, decorations, optics, and car glasses. But what causes such a material to be so unique? It is the combined material that gives this item its distinctively unbreakable character and at the same time, the big chance of being dealt very little visual pollution. This article focuses on the scientific aspects of plexiglass, clarifying how its internal structure contributes to both its toughness and its transparency. If you are someone working in production, an architect who designs innovatively, or even someone very inquisitive about plastic use in our world, then this article will be very enlightening about the major factors that make plexiglass the no. 1 choice in today’s product design. How about concentrating on the reasons for the creation of a composition?

Plexiglass and Its Composition

Understanding Plexiglass: What Is PMMA?

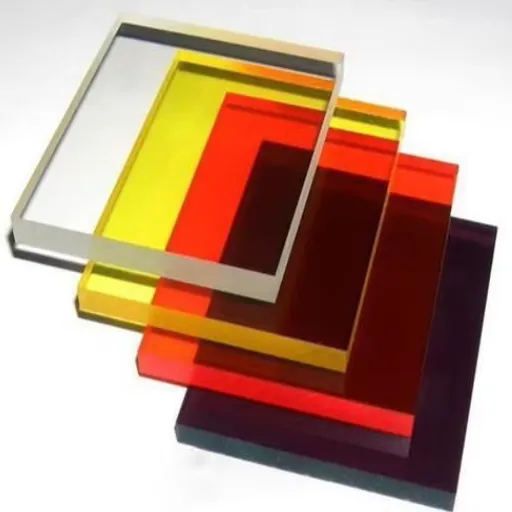

Polymethyl methacrylate (PMMA), commonly known as plexiglass, is a clear, lightweight, and shatter-resistant thermoplastic which is a versatile alternative to glass. Developed in the 20th century, it was also highly optical, a factor that helped it become a household name. PMMA is essentially a polymer consisting of methyl methacrylate units linked in a chain, a feature that underlies both toughness and clarity. Nowadays, this popular non-glass material, to no lesser extent than when it was launched long ago, is gaining a firm hold in the market because of its many advantages, including UV and weather resistance. This being the case, it is suitable for outdoor applications because it will last longer. Even though the material was, and still is, used in a multitude of industries, such as construction, automotive, and electronics, there were many constraints posed by traditional PMMA tile manufacturing up to the 1970s. Eventually the switch was to extrusion, which was the first real breakthrough in the processing and production of acrylic. A complete revolution in the industry came early this century with the invention of the Cell Cast Manufacturing Process, which was followed by other advances, ultimately paving the way to the present situation in which PMMA is indispensable in contemporary engineering.

The Role of Methyl Methacrylate in Acrylic Sheets

Methyl methacrylate (MMA) is the starting monomer for manufacturing of polymethyl methacrylate (PMMA) that has a major share in the composition of the latest acrylic/plexiglass sheets. The most important feature of MMA is its contribution to the crystal-clear, lightweight properties of acrylic sheets. Further, MMA makes the sheets more durable and resistant to environmental factors like impact and corrosion. It is, in fact, one of the best properties that MMA offers. MMA then undergoes polymerization and contributes to the formation of a super strong molecular structure, which is the building block for the material’s persistent optical transparency and mechanical resistance.

There is a new era of technology in MMA and huge progress has been made in the development of specialty acrylic sheets that suit different areas of application like, for example, UV-resistant coatings for outdoor use, anti-scratch treatments for high-traffic areas, and heat-resistant formulations for industrial settings. Also, it is universally acknowledged that acrylic sheets derived from MMA have a good environmental profile because they are recyclable and generate only minimal waste during manufacturing. Such accomplishments point up the flexibility and ever more crucial role of methyl methacrylate in the plastic universe.

Comparison of Plexiglass and Polycarbonate

Both Plexiglass (acrylic) and polycarbonate are well-known and widely-used transparent thermoplastics known for their unique features in various industries. They may be similar in that they transmit light well and provide clear visual images, yet there are a number of differentiations that make them very different with each one being the better of the two for certain applications.

Polycarbonate is widely used in applications that require high strength, such as safety barriers, bullet-resistant panels, and protective equipment, due to its exceptional impact resistance compared to plexiglass. It is even 250 times stronger than glass and approximately 30 times more impact-resistant than acrylic. Nonetheless, plexiglass is less susceptible to scratches, creating a harder surface that is quite resilient in scenarios with little or no risk of impact damage and a higher chance of abrasion.

Weight and Workability: Both Plexiglass and polycarbonate are much lighter materials than glass. The latter, nevertheless, still maintains the edge over polycarbonate in weight. Yet, the fact remains that plexiglass is superior in terms of both machinability and workability such as cutting, drilling, and polishing, all of which ultimately help, specifically, in the case of fine, intricate designs, or artistic applications. Polycarbonate, on the other hand, though one of the difficult materials to be mechanically processed with high precision, may still outshine the others in the case of the applications requiring elasticity and the ability to bend since it is capable of deformation without cracking under bending stress.

UV Resistance and Weatherability: Plexiglass is a material that naturally withstands UV light and weathering so well that it loses almost no transparency or strength even when left outdoors for a very long time. Polycarbonate is much more resistant to impacts but may be less desirable for prolonged outdoor exposure to UV light, as the material is likely to change color or become brittle unless a UV-resistant coating is applied. In situations where the projects depend on outdoor performance and weatherability, plexiglass generally requires less additional treatment than polycarbonate.

Finance and Money Considerations:In comparison to polycarbonate, pricing for plexiglass is generally lower, which has made it a favorite choice among those who are cost-conscious and yet do not need a greatly robust material. The fact that polycarbonate is more expensive is mainly due to its toughness and resistance to impact; thus, it is a good investment for applications that require safety or special structural features.

Usages in Business and Industry: The main applications of plexiglass include displays, signs, aquariums, and decorative panels. This is because plexiglass is clear and visually appealing. Polycarbonate, on the other hand, does well in applications where the surrounding medium is tough, such as construction panels, machine guards, and optical lenses, where the material has to be tough.

It is so by knowing the distinct properties of the two materials that the professionals would be able to make a selection by being fully aware of the functional and aesthetic needs of their applications and thus, picking the material that is more in line with their choice.

Physical Properties of Plexiglass

Durability: Effects of Composition on Strength

The strength of a material is a function of its molecular structure and the way it acts under stress. Plexiglass, derived from polymethyl methacrylate (PMMA), is an unleashed reminder of the plasticity of materials – it is the obvious choice for projects where they are used due to the availability of temperature stability in addition to clear strength. It is pretty much scratch-proof and is not even bothered by UV radiation, being then able to be seen through without any losses.

The material used in making polycarbonates is a polymer with a very tough molecular bond. Its prowess is mostly felt under circumstances where impact tolerance is of prime concern. It’s almost impossible to break this material and it can resist heavy blows without breaking thus providing as the best option for the industries depending on the safety and also security. Durability is the common aspect of both materials, but their areas of application are quite different owing to the structure of their molecular levels. The right material to select is a matter of comparing between the two materials in terms of external demands such as impact levels and environmental conditions thus securing a long period of the materials’ good performance.

Transparency and Clarity in Plexiglas

Acrylic glass is easily distinguishable because of the unusual quality of its optical clarity and light transmission compared to traditional glass. It is very common that acrylic glass alone can transmit 92% of the light, and it does so with a view that is very sharp; mostly, it is free of distortion. The smooth surface and the ability of the material to be thinned, just as the user desires, are the major reasons why acrylic glass is selected for making displays, signboards, and also for its use in the construction industry. Moving on, the progress in manufacturing methods has allowed the creation of acrylic sheets that not only resist UV but also remain clear even when they are exposed to the sun for a long time. The presence of this characteristic combination of qualities- clarity and endurance- puts acrylic glass in the category of materials that are really diverse and can be utilized in different sectors which would enjoy both practical and aesthetic advantages by doing so.

Impact Resistance: Why It Matters

Acrylic glass’s impact resistance is so strong that it is wielded as a definitive factor that distinguishes it from more breakable materials like conventional glass. Acrylic is, in fact, around 10 times more resistant to impacts, thus becoming a safer substitute for applications where the need is for both durability and safety. The added strength, therefore, destines the material to a situation less likely to break, where the build retains its core strength even if it is under some severe mechanical stress. The industries that depend on the material for their products include the construction, transportation, and retail industries which find it beneficial to produce products that are not only durable but also have a long life span. In addition, the materials engineering and manufacturing sectors have made it possible to produce grades of acrylic that are not only high impact strength but are also very specific to the applications such as for armor

panels or for parts of the machinery that deal with heavy wear and tear. Such a move towards varied forms, plasticity, and specific resilience gets our attention to the point that resistance to cracking is not a mere characteristic but a chief argument accounting for acrylic glass’s extensive application.

Manufacturing Process of Plexiglass

From Starting Materials to Final Products

The production process of plexiglass, also called acrylic glass, is a highly complex and accurate process that is intended to make sure its quality, transparency, and usability. The method starts with the polymerization of methyl methacrylate (MMA) monomer, which is a main raw material. Normally, this step is taken in controlled conditions in order to get a uniform, high-quality polymethyl methacrylate (PMMA) product.

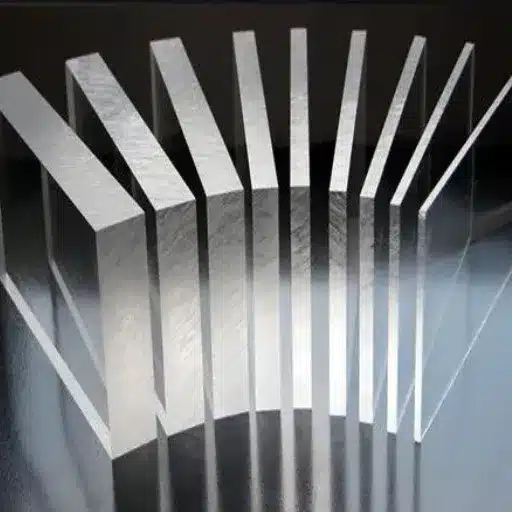

After that, the material is brought to its desired shape by using advanced production techniques like cell casting, extrusion, or continuous casting. The optical clarity and uniformity achieved with cell casting are the main reasons why it is the method of choice in certain industries that require a visual appeal in their products. In contrast, extrusion is a process that is known for the production of large amounts of cheap acrylic sheets in an easy way with the highest yield ratios.

During the production steps, the Primest quality control practices are made to guarantee the material meets the performance circumstances. Ones such as evenness of the thickness, the optical purity, and the quality of the surface are looked upon carefully. The final products, at last, are cut, polished, and treated to result in top-notched performance, no matter it is for the architectural design, the fence protecting or the material in the industrial stuff. This smooth change of the MMA raw materials into the pure and processed acrylic products shows the very tip of the manufacturing and material science innovations.

Acrylic Sheet Production Techniques

Advanced techniques have been used in the modern-day acrylic sheet production to ensure the production of high-quality results that can meet various applications. One example is the cast polymerization process, as in the case of liquid monomer, which is poured into molds and polymerized under conditions of controlled temperature and pressure. This process produces sheets that are renowned for their excellent optical clarity, uniform thickness, and structural integrity.

Extrusion, where the resins are melted and formed into sheets by passing through a series of rollers, is another majorly used technique in the production of acrylic sheets. Extrusion gives quick production speeds, quality consistency and at the same time reduces the cost, making it very suitable for the big manufacture process. Moreover, continuous casting is a process that combines the precision of casting with the efficiency of extrusion and therefore achieves a very good production of sheets with less material inconsistencies.

In order to add more benefit to acrylic sheets, the applications of special coatings and treatments are done. This includes anti-scratch and UV resistant finishes that ensure the durability and longevity of the sheets in harsh places. Coextrusion with multiple layers is also one of the breakthroughs that make it possible for the pigments or surface to be directly incorporated with the sheet getting this gives a chance to reduce the necessity of the post-production finishing ospatel.

By incorporating such exploitation with state-of-the-art automation and quality control systems, manufacturers are able to reach a level of quality and product variety that is unmatched in the market, and even example for the sectors with the most demanding requirements like air and space. Every method is selected according to the very properties and uses of a product, and thereby, the strictness and imagination that are the components of today’s acrylic sheet production will be reflected by the method used.

Uses of Plexiglass in Everyday Products

Common Applications in Home and Industry

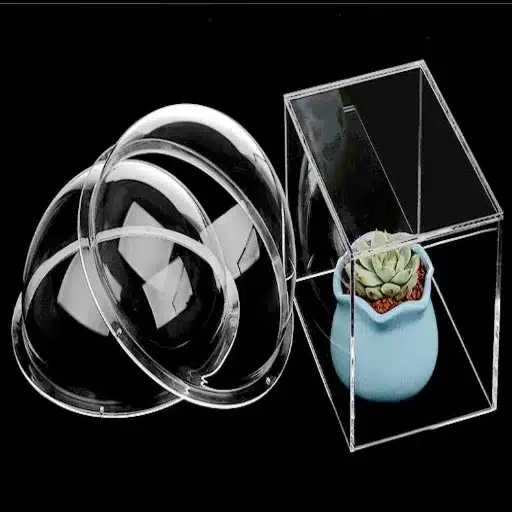

It can be seen that Plexiglas, due to its strength, low weight, and optical clarity, is a flexible material that is ideal for home and commercial projects. The material has a multitude of uses in almost all aspects of home activities. It is frequently used as the glazing material for the windows, as accents for furniture, and as a barrier to protect works of art or photographs. Apart from being shatterproof, the latter property also explains why it is increasingly employed in modern homes instead of the regular glass that is very brittle. The use of Plexiglas in home construction also leads to the swallowing up of expensive problems of creativity and lavishness that arise out of the strict adherence of home designs to standard home repetitive practices.

Plexiglass is widely used in the industry to substitute for equipment enclosures, safety shield, and control panel areas, more so in the manufacturing and health sectors, which are the key players in the glass and plastic field. For instance, the medical industries use plexiglass in incubators, protective barriers, and medical device casings because it provides a hygienic and easy-to-clean surface. Also, the automotive and aviation sectors use this material for manufacturing windshields and interior parts where the safety and clear visibility are very important driving factors. All these factors including plexiglass being an adaptable material make it indispensable across the broad spectrum of different applications.

Plexiglass in Safety and Security Solutions

In the present time, the application of Plexiglass can be seen in the core of the modern safety and security solutions. It would not be wrong to say that the medium combines some of the most wanted properties such as the combination of strength, transparency, and versatility, one of the most important characteristics of a plexiglass. It has better impact resistance than the traditional glass, which is why it is the best alternative for the protective barriers of places like schools, banks, and supermarkets. The other side of the coin is that the plexiglass is lighter and this is one of the main reasons it is getting more popular day by day and will slowly replace the providing of safety shields, partitions, and security windows. Another remarkable property of the material is its ability to withstand UV radiation so the material will not change in color and will remain as clear as it was in the beginning in open-air security setups. Plexiglass, which has seen a lot of changes involving technology, is now also a part of the latest more unique solutions such as bullet-proof windows and stronger safety panels, being capable of providing better safety while keeping the visibility and the beauty. The whole territory of safety and security will be a perfect match with the plexiglass as a reliable solution, and the union of the two — functionality and innovation — will strengthen the position of plexiglass in the safety and security industry changing the scenario.

Innovative Uses in Art and Design

Plexiglass underwent a total transformation from its roots in industrial use, in the art and design worlds it now ranks among the most preferred materials. It’s not just unmatched when it comes to its flexibility, transparency, and toughness but those three combined resulted in the innovative ideas to be carried out. Take for instance sculptors who found its softness to be the missing piece in the puzzle of creation of intricate three-dimensional structures that, in the language of light and reflection, have the power to fascinate the observer. The preference of the interior designer for the plexiglass is more and more seen through the modern furniture, room dividers, and decorative installations that the material is best known for. The very fact that it can be had in every color and finish under the sun only goes to show that the designers can do almost anything by the marriage of form and function in an awesomely innovative manner. It is one of the areas where plexiglass can be said to have significant up-and-coming lifestyle and design trend because of its flexibility.

Pros and Cons of Using Plexiglass

Advantages of Plexiglass Over Glass

It is my observation that plexiglass is much better than the regular glass in several aspects, making it the preferred type for many applications. By far, the most significant factor is its strength and impact-resistance. For places where safety and the life of the material are of prime importance, plexiglass is the perfect choice as it is not very possible to break it when there is pressure against it. One such situation is the one in which there are plenty of people or a kiddie corner; in such places, strength offers the dual advantage of a worry-free peace of mind and a glass-like look that is glossy as well.

The third benefit that I consider significant is the fact that plexiglass is very lightweight. Glass is much heavier than plexiglass, which makes the transportation, handling, and installation processes easier and with less labor especially in the case of large-scale projects. This property has a positive impact on the project cost and it allows for the saving of a considerable sum of money. The material that is used for signage, windows, and or furniture carries the added advantage that it is very light, enhancing its versatility while keeping the aesthetically pleasing side.

Moreover, plexiglass has high visual quality and very good weather resistance. The plastic will stay clear and clean for many years, not like most glasses, practically forever, even when it is exposed to sunlight continuously, among others, it is always because of its outstanding property to stop UV light. The material is extremely useful outdoors for applications that need clear visibility, such as shields, roofs, and plant nurseries. Furthermore, the fact that it can be cut, saponified, and customized, another application of plexiglass is as practical and adaptable, accordingly, the plastic counterpart of glass emerges as a very useful product fitting well with the needs of modern design and the most pragmatic approach of functionality.

Acrylic Sheets Limitations and Drawbacks

According to my own experience, while acrylic sheets provide a variety of awesome advantages, they also come with a variety of drawbacks. One of the biggest disadvantages is that they scratch easily. Glass, on the other hand, is less prone to scratching and so it can be seen as a massive disadvantage of the acrylic surface. In areas where the resistance to physical impact is of high importance, such as in the case of acrylic, this can be a real issue as the material might need to be given special treatments or might just need to be maintained frequently to remain clear.

Another drawback of acrylic sheets is their lack of heat resistance when compared to tempered glass and other such materials. Acrylic, when it is exposed to high temperatures can either be softened, bent, or it can even catch fire. Making it inappropriate for locations with varying or extreme temperatures. This limitation also goes as far as being a flammable material, the acrylic, and therefore, the concern of fire safety among people is a must-be thing when it is used in such circumstances.

In addition, even though acrylic is inexpensive and easy to handle, it may not last well in severe weather conditions for several years. When it gets extremely cold, it could become fragile and be subject to special handling in the snow regions to avoid cracking. Besides, despite being UV-resistant and not yellowing, the continuous action of harsh weather elements may cause a bit of its strength to decrease with time. These are all points to consider when deciding to use acrylic and so it is crucial for one to evaluate the project aims and needs thoroughly before commitment.

Cost Considerations for Plexiglass Products

Yeah, I have this tendency to see cost differences in plexiglass. It tends to be the case that you cannot find anything more different over the aspects like size, thickness, quality, and supplier. When considering the purchase of plexiglass, it’s good to think about smaller and thinner as more affordable solutions, starting at $5 to $10 per square foot for standard quality materials. However, for special quality and very thick sheets, the price can be as high as more than 30 dollars per square foot. Special types of plexiglass, shapes, and cuts, and additional treatments like anti-glare coatings can all raise the final cost of the plexiglass. It is therefore crucial to be prepared even without money but a clear picture of the project in your head, and this is what the industry advises before making the purchase.

Moreover, I have as well noticed that bulk purchasing of plexiglass typically lowers the cost per unit and that’s an option worth exploring for substantial projects or ongoing use. Buying from local suppliers sometimes saves more money because of less shipping costs but at the same time, online retailers may give more, including customized orders. A smart shopper compares quotations from different sellers to be assured of the lowest price. You have to keep in mind that though the less expensive alternatives might be luring, they might perform poorly in tough applications which in turn might lead to the need for regular repairs or replacements, hence, higher maintenance or replacement costs.

I always give weight to the total costs over the life of plexiglass as opposed to other materials. Even though the first sight of plexiglass may make it seem more cost-effective than glass or polycarbonate for in some cases, the fact that it is durable and does not break easily can lead to the cost of the replacement being saved in the long run. Furthermore, the fact that it is light in weight may have an impact on the installation costs of projects that demand very accurate handling. One can take all these factors into consideration and thus make a decision which is truly value-for-money and even more appropriate to the particular project. Find more info now.

Reference Sources

Guide to Plexiglass Strength and Durability – Jumei Acrylic – Highlights the impact resistance and strength of plexiglass compared to traditional glass.

A Comprehensive Analysis of Acrylic Sheet – Piedmont Plastics – Discusses the properties of acrylic sheets, including clarity and impact resistance.

What is Plexiglass? | Pros and Cons of Acrylic Glass – Rustica – Explains how the flexibility of plexiglass contributes to its durability and transparency.

Plexiglass – an overview | ScienceDirect Topics – Provides an in-depth look at plexiglass (PMMA), its composition, and its high light transmission properties.

PLEXIGLAS® General Information and Properties – Emco Plastics – Offers detailed insights into the chemical composition, impact resistance, and thermoformability of plexiglass.

Frequently Asked Questions (FAQs)

What is the composition of plexiglass?

Plexiglass, commonly referred to as acrylic, consists mainly of polymethyl methacrylate (PMMA), a man-made polymer that can be produced by the polymerization of methyl methacrylate. This specific recipe is responsible for providing plexiglass with its most valuable features, i.e. very high optical clarity and transparency of the material. PMMA is a derivative of acrylic acid, a compound known for its flexibility and thus rendered fit for a broad range of applications. The light weight and tough characteristics of the material make it a solid leader in applications of that sort as the signage industry which seeks brilliance in materials used and the protective barrier market which requires the materials to be shatterproof. The polymer’s chemical name reflects its powerful resistance to both UV light and environmental degradation, making it even more durable.

What are the physical properties of acrylic sheets?

Acrylic sheets are the product of either cast acrylic or extruded acrylic and have a few remarkable physical properties. They are clear thermoplastics, which means very high light transmission and optical clarity in the same fashion as glass, but much lighter. Moreover, they come with the added quality of being impact resistant which, in turn, makes them shatter resistant as well as involved in different and various applications. They are also recognized for their easy laser cutting and welding, which means it is possible to use them in an extremely broad set of processes. On top of that, they are UV light-resistant, which guarantees long-term clarity and color retention. Lastly, the acrylic masterpiece is the chemical resistance, which makes it survive various chemical, and hence, environmental conditions without being decomposed

What are the advantages and disadvantages of plexiglass, and what is its benefit in terms of overall costs?

The use of plexiglass has to be carefully considered, with both the good and the bad in mind. One very important advantage is its lightness when compared to glass, which in turn makes it easier to handle and install due to its lower weight. It is also, no less importantly, a shatter-proof material so it can hardly harm persons in case the glass is used in windows and enclosures. Nevertheless, hard to believe, its major disadvantage is that it can be easily scratched reducing its optical clarity over time. In addition to this and on the contrary side, while plexiglass shows good chemical resistance, some specific solvents can also attack it. It is also important here to mention that even though the price of good-quality acrylic may be higher than that of other materials, it pays off in the long run.

What is the process of plexiglass manufacturing?

The process of producing plexiglass usually has as a major step the polymerization of methyl methacrylate, which can be done by either casting or extrusion. In casting, the liquid monomer is poured and then allowed to cure in the molds, thus giving a sheet of acrylic that is both thick and clear. On the other hand, extrusion involves pushing the liquid material through a die in order to obtain continuous sheets of acrylic. The two methods result in the sheets’ thicknesses and surface finishes varying. The edition also can be given as to the production of UV-resistant acrylic with a substance that increases durability.

What about the plexiglass factories that have never opened?

Plexiglass is so popular in a huge scale of industries only for its variety of uses and its traits. You can see it mounting a sign that has to be clearly visible where its property of being optically clear is extremely useful. Also, in the case of construction, the plexiglass panels for windows and skylights can be not only extremely thin but very strong, offering the best trade-off between glass and weight. On another hand, it is becoming the first choice in the building of aquariums and displays depended upon the fact that they are transparent. In addition, still widely used for protective screens such as sneeze guards, especially in medical environments, due to the fact that they are lightweight and the range of sizes and shapes is practically unlimited. At last, one of the typical applications for the material is in lighting and designing of furniture, providing the product with an aesthetic appeal coupled with the functionality.

What makes polycarbonate different from plexiglass?

Even though they are both transparent thermoplastics, polycarbonate and plexiglass (acrylic glass) have fundamentally different compositions and tendencies. Polycarbonate is typically more durable and can stand a greater shock, hence it will less likely fracture when compared with plexiglass. However, plexiglass has better optical clarity while being more user-friendly in terms of things like laser cutting. The main reasons why people sometimes prefer the former is its price and the required level of skills due to the fact that polycarbonate has a higher melting point. On the other hand, plexiglass is less prone to scratching, unlike polycarbonate which can have its surface durability improved by means of applying coatings. To sum up, the choice between the two is determined by the demands of each particular case.