PP&A plastic is now the most valued product due to this material’s flexibility. Its incorporation into the most difficult sectors from its manufacturing technology to its various forms is what makes it so special. The polymer science and engineering fields have indeed reached a new peak with the development of this material. This article will provide a detailed analysis of the production of PP&A plastic, through the description of the manufacturing and technological steps that make it an efficient and long-lasting material. Moreover, we will examine the industries where it is being used most, such as auto, medical, and consumer products, and the reasons for which it has been adopted as a key component in the current manufacturing. If you are a professional looking for a technical side of the story or just a person who is curious about the inside of the industrial materials, this tour will give you a full understanding of the pivotal role played by PP&A plastic in today’s world

Understanding PP&A Plastic: Composition and Properties

What does PPA Plastic stand for?

PPA (Polyphthalamide) plastic is one of the high-performance thermoplastics that are a part of the nylon family and it is very well known for its excellent thermal, mechanical, and chemical resistance properties, which are its unique features. The most common and widely used types of aromatic dicarboxylic acids for the production of PPA are Terephthalic Acid and Isophthalic Acid combined with aliphatic diamines. Due to the presence of those acids, PPA brings not only additional stability but also better performance and quality at high temperatures. It can be applied not only as a metal replacement but also as a very good reinforcement material in the automotive and electronics fields. In addition, the polymer’s resistance to moisture is another remarkable advantage over the more common nylon grades, which suffer from changes or losses of mechanical strength in humid environments. Furthermore, PPA’s very hot and very moisture physical properties make it the right plastic material for very harsh environmental conditions like automotive, airplanes, and industrial process airgrafts, where it has the high-performance thermal and/or chemical resistance and prevents moisture from being the major cause of failure.

Characteristics of Polyphthalamide

Polyphthalamide (PPA) is best known for its outstanding mechanical properties and its ability to resist either thermal or chemical degradation and is considered one of the top thermoplastics for engineering purposes. PPA parts can withstand temperatures up to 200°C without any problems thus, they can be used in point of high temperatures like engine systems and ultra-high electrically conductive parts. Its super chemical resistance includes automotive coolant, even solvents used in the industry, and harsh cleaning agents, thus it promotes both the longevity and the operation time to the horizon.

In addition, the reason why PPA is so stable through dimensional means is that it doesn’t take in much moisture and its thermal expansion is very little. The very quality that makes it so good for extremely tight tolerance parts that have to be held on to under temperatures and humidity that go up and down is high-tech stability. The other feature that is precisely its very high increased stiffness and strength, and the some quite remarkable, because ones are now available with glass-fiber or mineral filer, grades, exceeding by far the mechanical robustness of the common nylons.

Moreover, PPA’s adaptability is further manifested by its alloying with flame-retardant agents, thus it can be applied for safety-critical cases like electrically conductive parts and enclosures. Due to its far-reaching light solution and on top the ability to endure the long-term heat and wear stresses the material’s outstanding position in the performance-, efficiency-, and sustainability-oriented sectors is safe forever.

Comparison of Polyamide and PPA Plastic

Polyamide (also known as Nylon commonly) and Polyphthalamide (PPA) belong to the same family of thermoplastics but differ significantly in terms of performance and application. Polyamide is mainly appreciated for its ductility, resistance to impact, and chemical resistance, which makes it suitable for products like fabrics, car parts, and consumer goods, among others. Yet withstanding extreme heat and humidity for extended periods could cause Polyamide to lose some of its mechanical strength and thermal resistance.

PPA, on the other hand, not only surpasses but excellently showcases its abilities under tough conditions. It is less affected by humidity compared to regular polyamides, leading to more reliable mechanical and dimensional properties and, thus, being able to remain stable also in humid environments. Besides, PPA gives a fantastic resistance to heat, thus, its ability to hold up to 130°C continued temperatures and also because of its good creep resistance when put through loads of high mechanical. The features of the PPA material, make it sought after for use in not less than the rough environments like those of automotive under-the-hood parts, electrical systems, and industrial machinery.

With the use of nylon in an unlimited range of applications, one can never go wrong in terms of performance and cost, but for high-performance applications that demand better stability, fire resistance, and load-carrying capacity PPA material is unbeatable in the industry.

The Manufacturing Process of PPA Plastic

Introduction to Injection Molding Techniques

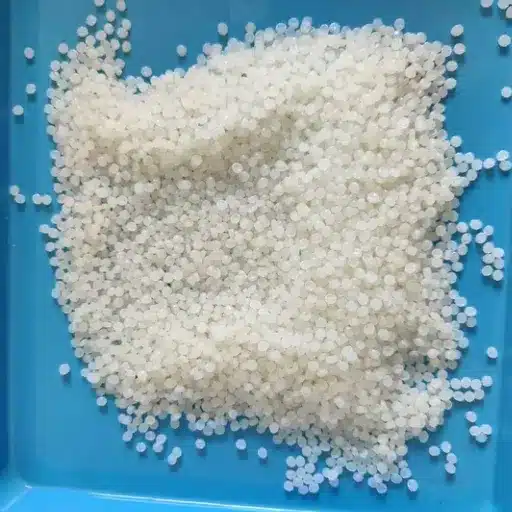

Injection molding is the primary process in the production of PPA plastic parts as a result of its precision, speed, and excellent results in geometrical complexities. The main steps of this process include resin pellets made of PPA heated up and pushed into a barrel, where the pellets melt with one another and form a relatively uniform melt. Then, under a pressure of a significant amount, the slurry-like mass is squeezed into a mold that was precisely made for its filling through a gate. This is a way of getting the mold filled as packed as possible and as quickly as possible and of getting the material to yield to the shape of the mold rightly and thus being able to obtain the detailed parts consistently.

The key features of the injection molding sector are the adaptive temperature control systems that alter the energy requirements and related settings over the entire process to minimize material degradation and maintain a consistent rate of crystallization. On top of that, usage of the pressure monitoring technology alongside multiple-point clamping systems has been reported to significantly improve the specs, increase the lifetime of the part, and reduce the time of the cycle by allowing for the molds to be released at the same instant over the precisely determined areas. The companys efforts in the area of alternative materials are paying off as they are mostly using gas-assisted and co-injection molding and obtaining various advantages from suppliers, one of which is the capability to deliver light-weight multi-material PPA items. These operations, through the integration of new technologies, will enable the industry to improve overall production processes while not compromising the strength of PPA.

Steps in the PPA production process

To the best of my knowledge, the process of making Polyphthalamide (PPA) products involves a great deal of high quality production requirements, where experts in each step use advanced production methods for the best possible results and characteristics of the material. Initially, the process starts with the polymer synthesis period by conducting the reaction of aromatic dicarboxylic acids, for example, terephthalic acid with aliphatic diamines under regulated conditions. The polymerization process at present uses very high temperatures and pressures, hence, creating the high-strength, heat-resistant and PPA polymers. Getting the right molecular weight and viscosity is the most important requirement for achieving the desired mechanical and thermal properties at this stage that will be shown in the final product.

Next, the polymer is added with different substances to modify it depending on its usage, which is then the first step of the process of assimilating the polymer into the system. The class of additives can be plasticizers, fillers, mixtures of ingredients etc. Reinforcements such as glass fibers or carbon fibers are also utilized to improve mechanical strength and stability in the plane of the force applied. Moreover, stabilizers may be compounds for preventing degradation of the polymer as well as lubricants to make the processing of the polymer easier. During this manufacturing process, precision mixing and homogenization methods are employed to make sure that the material has good properties throughout the whole length. Technologies like the use of a combined extrusion system to achieve the best distribution of additives are very popular and they help in turning out the product that has been designed to meet the high product quality demands.

The transformation of PPA into end products basically undergoes injection molding, extrusion, or other thermoplastic manufacturing methods. The use of modern processing techniques, including gas-assisted molding, overmolding, and others, makes it possible to work with the most complex geometries without warping, shrinkage, or other defects. By means of completely automated real-time monitoring, which is the function of the latest sensors, the entire temperature, pressure, and cooling cycle is constantly checked, hence key parameters are kept within very narrow tolerances and very tight precisions. The postproduction stage involves procedures for maintaining top-notch quality and for testing the parts to ensure that they are structurally perfect, but also match the industry and application requirements in every tiny point. The evolving market demands for the applications of PPA and other different products are creating a comprehensive production-friendly market and are producing a set of quality products.

Quality Control in PPA Manufacturing

Quality control of Polyphthalamide (PPA) products need considerable investment in various advanced methodologies in different production stages. Today’s quality control systems that are available use automated inspection technologies like machine vision systems and non-destructive testing (NDT) to find out production defects during and even after the manufacturing process. Very often high-resolution imaging and laser-based measurements are the means of choice in terms of the detection of dimensions, surface finish, and material uniformity irregularities with the use of very high precision.

In the same way, it is a common practice to carry out thermal and mechanical performance testing to prove that the PPA materials are up to the required standards concerning heat resistance, load-bearing capacity, and long-term durability. In addition, these tests are accompanied by the analysis of chemical composition by spectroscopic and chromatographic methods to ensure the stability and the uniformity of the polymer.

The continuos monitorization of the operation parameters of a process is done with the help of Statistical Process Control (SPC). Early deviations can be detected and the necessary corrective actions implemented by analysing real-time data, thus maintaining a high level of quality. Furthermore, these strict quality protocols, in combination with the cutting-edge predictive technologies of maintenance, lead to the full compliance with the specific requirements of the industry and the application, thereby considerably reducing waste and increasing the overall production efficiency.

Applications of PPA Plastic in Various Industries

Automotive Industry Uses of PP&A Plastic

Polyphthalamide (PPA) plastic, with its remarkable thermal, mechanical, and chemical properties is getting more and more common in the automotive industry. The superb heat and dimensional stability in the material make it a perfect choice for applications that suffer from harsh environmental conditions, like the engine compartments and under-the-hood. PPA plastics are frequently utilized for the manufacturing of fuel system parts that are for instance fuel pump housings and line connectors mostly due to the material’s resistance to even most aggressive fuels and high temperatures.

Moreover, PP&A materials are fundamental to light weight automobiles designed by motor vehicle makers. Their greater-than-the-materials-itself strength turns possible the cutting down of the weight of the vital components for the sake of better fuel economy per pointer and without losing the structure integrity. The fatigue resistance of PPA plastics, on the other side, is so good that it can accommodate parts that are always in stress like gears, bearing cages, and power train components. These features along with others appoint PPA plastic as a core material in the promotion of up to date automobile technologies, especially in electric and hybrid vehicle systems, where the key requirements are thermal control and durability.

Electronics and Electrical Applications

PPA plastics are one of the main players in the electronics and electrical industry, particularly because they possess superior insulating properties, high dielectric strength, and the ability to endure extended periods of high temperature exposure. Generally, they are the primary materials for the used in the the manufacturing of connectors, switch housings, and electronic control units since they can still perform very well under punishing environmental conditions. Moreover, the in most cases flame retardant feature of PPA, often promoted with certain types of additives, the material is the best choice for very safe components. PPA plastics give healthy disruption to the electronics industry just like traditional plastics and, the best part is that it happens silently.

PP&A Plastics in the Aerospace Industry

Polyphthalamide (PPA) plastics have a crucial function in the field of new aerospace engineering due to their perfect combination of lightness, toughness, and thermal resistance. These materials are specifically designed to perform under very harsh conditions; thus, they are suitable for the most demanding aerospace applications where other materials would fail, such as structural components, brackets, and housings. The use of PPA plastics instead of metal parts allows the creation of structures with a weight that is 50% less, thus leading directly to lower fuel and CO2 emissions.

Moreover, PPA plastics are the best performers in terms of the composite material resistance to chemicals and wear out, only second to ceramic ones which have the maximum resistance in these properties. This resistance of PPA plastics to chemicals and wear guarantees them a long life and excellent performance specifically in harsh working conditions. On the other hand, the fact that they can be injection-molded with precision brings the advantage where complex component designs can be produced which will further improve the performance of participating parts and not compromise the strength of the whole product. The aerospace industry, on the other hand, has always been on the lookout for ways to use fuel more effectively and be more friendly to the environment, and hence, by the adoption of PPA plastics, these are forecasted to be over exactly a critical step forward in the establishment of the next-generation aircraft and spacecraft systems.

Advantages of Using PPA Plastic

Durability and Thermal Resistance

Polyphthalamide (PPA) plastics are known to have an impressive combination of durability and thermal resistance, hence, they are widely used in high-performance applications. The material’s semi-crystalline structure guarantees the material will have excellent mechanical properties, even in temperatures that are extremely high for a long duration; they can even handle up to 266°C (510°F) in some grades. This characteristic of PPA plastics makes it possible to maintain the structural integrity by preventing thermal deformation and resisting the mechanical stress in tough environments. Moreover, the plastics are almost unaffected by chemicals, oils, and grease, which is further helpful in lengthening the product’s lifecycle. Hence, the PPA plastics have become a necessity when it comes to components that are constantly exposed to thermal changes, like engine systems, electrical housings, and heat shields in both the automotive and aviation industries.

Cost-Effectiveness in Production

Cost savings in the material production of PPA plastics are mainly due to their effectiveness in mass manufacturing and less need for finishing work. The up-to-date polymerization methods provide high yields with little waste, and hence, the usage of material is maximized. Not only that, but their inherent strength and wear resistance lower the amount of parts that need to be replaced, hence, they are more cost-effective for industries throughout their lifecycle. On top of that, improvements in the compounding and processing sectors mean that the manufacturers are reaching the highest possible performance for their tailored formulations, and thus, very little need for extra additives. This, along with the fact that they can take the place of costly materials like metals in several applications, leads to the fact that PPA plastics are a cost-efficient solution for a multitude of high-performance requirements in different sectors.

Environmental Impact and Sustainability Considerations

One of the major aspects to consider in the process of determining the feasibility of PPA (Polyphthalamide) plastics for environmentally friendly production is their environmental impact. As a rule, these plastics show extended lifetimes for their products owing to their toughness and wear resistance, which in turn leads to a decrease in the number of replacements and thus contributes in the decrease of the total material consumption. Furthermore, the development of recycling technologies for polymer materials has made the recovery and reuse of PPA materials more efficient, hence leading to the reduction of the waste pile-up as well as limiting their share in the landfill.

On the grounds of sustainability, it is possible to use PPAs as a replacement for conventional materials such as metals which, aside from that, draws energy and power during production. The mining and refining of metals are already very energy-consuming processes, more so than making plastics out of PPA. Additionally, using PPA rather than metals in the automotive industry leads to less weight and, accordingly, improved fuel efficiency which eventually supports the reduction of greenhouse gas (GHG) emissions.

New research brings up the probability of having biobased PPA polymers made from renewable feedstocks, showing a way to cut down a lot on oil dependence. The world is becoming more and more devoted to the use of renewable materials and more automated manufacturing processes that would also help companies meet the more environmentally benign but stricter regulations and, at the same time, keep up with the ever-rising need for eco-friendly solutions.

Future Trends in PPA Plastic Development

Advances in the PPA Grades and Formulations

The recent advances in PPA (Polyphthalamide) grades and formulations are directly related to the continuous need for better material performance and ecological friendliness of industrial applications, as it is shown by my research. The manufacturers have acknowledged the need for more sustainable and better performing materials, which is the main reason why they are now creating completely new PPA versions that not only provide various thermal stability, chemical resistance, and mechanical strength features but also allow the material to be used in the fiercest applications like the automotive, electronics, and oil and gas fields. One significant instance is that the development of glass-filled PPA grades has made it possible to create materials that can take higher operational temperatures and a longer time of exposure to severe chemicals without having a negative effect on their structure. These technological breakthroughs allow PPA to substitute for components made of metal and, hence, this leads to the more efficient replacement of metal, which, as a result, helps the customers to not only decrease their overall operational costs but also to increase the energy efficiency in their products.

Another important point of progress involves the production of fire-resistant and low water-absorbing PPA compositions. The fire-resistant PPA types, equipped with a variety of special additives, are fulfilling the demanding safety standards of modern uses of electronics and electricals without using the very toxic halogenated chemicals—so it is an environmentally friendly way. At the same time, the moisture-sensitive PPA kinds that are going with less humidity sensitivity are dealing with a big issue of maintaining their dimensional stability and mechanical properties when it comes to varying humidities. This makes them perfect for applications requiring very precise dimensions like those found in many different industrial sectors.

Moreover, as industries continue to invest in healthier ecosystems, we are seeing the introduction of various bio-based and recycled PPA formulations. These innovations absorb renewable resources and that is definitely the case of carbohydrates derived from castor oil that helps in lowering the dependence on petroleum resources besides being the reason behind the retention of the rigid performance criteria of PPA. Lately, the formulations have been directed to the circular economy and so they have become more recyclable. The progress being made in these areas mainly to make PPA one of the materials of the future that not only more than meets the technical needs of the time but also has a less negative impact on the environment.

New Digital Manufacturing Trends

I am indeed amazed by the role of new technologies like smart sensors and IoT-enabled gadgets that are replacing inefficient, inaccurate, and unsustainable practices within the injection molding sector. It’s particularly magnificent that the Fourth Industrial Revolution principles are being put into such good use especially that this has been all about the topic of the month so far! One of the ways this is happening is through the adoption of Industry 4.0 principles, which means the injection molding process can now be monitored and analyzed in real time by making use of smart sensors and IoT-enabled devices. These production systems have lately been responsible for a decrease in equipment downtime through predictive maintenance and the increase in production efficiency by analyzing the material flow, the temperature, and the pressure data. A vivid illustration would be the machine learning algorithms that are now able to detect and signal defects in a product at the very same time it is being manufactured thus improving on reprocess rates and cost of production through the reduction of the volume of the material used and the lesser number of products being scrapped.

A significant additional factor is the increase in the usage of 3D printing that accompanies modern molding injection techniques. At present, several systems are meant to act as a support for the speed and manufacturability of the injection molding process on the one hand, and as an additive flex- ibility tool, on the other, while making it easier to produce complex molds and low-volume prototypes. Similarly, the introduction of bio-based polymers and high-performance thermoplastics, materials that have been deemed as one of the most dramatic developments of the 21st century, is predicted to push the applications of traditional molding to new heights in achieving sustainability targets.

In conclusion, the advent of eco-friendly electric injection molding machines is showing how committed the world is to decreasing the carbon footprint of manufacture. They are more energy-efficient and cause much less waste heat than hydraulic machines, so they are in line with the global campaign to cut carbon emissions. The other side of the coin is that the heat-dissipating conformal cooling brought by a brand-new, very detailed cooling channel design made by building up the material one layer after another, via 3D-printing, procedure, and majorly decrease the cycle time and increase the part quality. These two technologies are therefore seen as the meeting point of the utmost engineering precision and the uttermost attention to the environment, which is so important in the manufacturing of today, in which quite high demands have to be met.

Market Growth and Estimated Applications

It is apparent, from the comprehensive analysis of the most recent market patterns and data trends, that additive manufacturing is ready for an upturn, and, with the help of such technological advancements and renewals as conformal cooling and power-saving technologies, will be one of the eventual and major contributors to the growth. The globe’s additive manufacturing market, as per the new outlooks, has the chance to shoot ahead with an approx. 20% rate in terms of compound annual growth over the next five years. The classified advertisement verification by the connection of more control in the spheres of aerospace, automotive, medical/health and consumer goods remains the number one force behind the growth. The call for pieces to be individually made, light in weight and long-lasting with a parallel interest in environmental friendliness, are the principal drivers of this massive sector boom.

Various parts of the economy are being affected by the transformative nature of technology. In the case of aerospace, 3D printing has made possible the manufacture of parts with complex geometries that need low material and are at the same time greener in terms of fuel consumption. On the other hand, the automotive sector has been putting into practice these kinds of technologies for their positive effect on part weight, which in turn is part of the main contributing factors to improved vehicle performance and lesser emissions. It is the case that conformal cooling is vital when it comes to injection molding that is made mostly by medical device companies. It has become simpler and quicker to produce high-precision medical devices and the product is of higher quality on the whole. The main advantage of this new technology is that it is not only easily adaptable but also widely usable.

Reference Sources

- Scaling the Polymerization of Polyaldehydes – LSU Repository

Discusses advancements in the scalability of PPA synthesis for industrial manufacturing. - Study of High-Performance Engineering Polymers – Purdue University

Explores injection molding as a cost-efficient method for producing structural plastic parts. - Plastics Collection – Syracuse University

Offers insights into various plastics, including manufacturers, materials, and processes. - Production, Use, and Fate of All Plastics – PubMed Central

Provides a global account of plastic production, usage, and end-of-life management. - Strategy for Plastics Innovation – U.S. Department of Energy

Covers the entire plastic lifecycle, including innovations in manufacturing and recycling.

Frequently Asked Questions (FAQs)

❓ What is the difference in the composition of PPA plastic material as compared to the other nylons?

The significance of PPA is a strong point of the versatility of nylons with a high performance level, and it is an aromatic polyamide that has a high melting point and an amazing thermal stability when matched with nylon 66. The acid component and the polymer chain in PPA resins provide the material with toughness and heat resistance beyond the glass transition temperature as well as super high strength. Skeletal compounds added to the PPA usually via the partly polymerization process, reduce the possibility of the material thus enhancing the performance in some specific applications. Their properties create a very big niche for these PPA-based parts, and they have been identified to be the best for parts in engines and pumps as compared to the more traditional ones. Primarily because the material along with the low water absorption and rather good electrical properties exhibits exceptional behavior that is contrary to what is generally seen in nylons, PPA is a completely different case.

❓ How do the PPA plastic material physical properties behave at high temperatures?

PPA has an outstanding combination of thermal and electrical properties and it remains a strong material in a mechanical sense at high temperatures where standard nylons would turn soft. PPA’s high melting point allows the components to go through high processing temperatures and still serve in high-temperature environments. The high heat resistance and low moisture behavior of PPA together with the material being less sensitive to moisture allow the retention of stiffness and mechanical properties. The use of PPA in applications, such as thermostat housings, coolant pumps, and air coolers, is justified by a set of its thermal management advantages, among others. It is quite common that PPA is the choice for high-temperature applications based on the reason of thermal and mechanical reliability.

❓ What are the reasons why less moisture should be absorbed by PPA polymer material in electric parts?

The feature of low moisture absorption of PPA resins ensures the preservation and improvement of the electrical properties and the dimensional stability which makes them indispensable for motor bobbin parts and many other electrical components. The humidity level can cause the resistance of the insulation to decrease and the mechanical properties to change beyond the glass transition temperature; therefore, the lower moisture absorption of the majority of PPA grades is one of the reasons for their long-term performance reliability. The material’s semicrystalline character and specific properties lead to the consistent behavior of the compound even in a humid environment. This is why PPA is often used in applications that need stable thermal and electrical properties for a long time. To keep the performance drift in sensitive assemblies to a minimum, product designers frequently go for PPA as their material of choice.

❓ What is the impact on processing and assembling of PPA plastic material with its high melting point?

PPA has a high melting point, hence allowing high processing temperature molding with no or minimal degradation, and thus, can efficiently make parts with more precision and better crystallinity. In general, high processing temperatures are necessary for total polymer chain melting and achievement of particular mechanical properties and heat resistance. PPA becomes a good option to meet the high processing requirements of polymer material especially in such areas as the aircraft, automotive, electrical, and electronic industries. PPA’s melting temperature also makes it possible to use thermal and mechanical joining methods as well as operating in high-temperature areas like bearings pads in aircraft engines. At the same time, the equipment will need to withstand the increased temperatures, and in some cases, the formulations may contain glass fibers aimed at enhancing the stiffness of the material. In its transformed state, PPA plastic material will most probably show a very good performance over the long term when used in the most severe forms of environmental conditions.

❓ What are the cases in which the use of PPA plastic material is more common?

PPA is mostly used in technologies which stipulate the urgent need for thermal and chemical resistance that is top quality. This happens in the case of coolant pumps, pump wear rings, fuel line connectors, thermostat housings, and air coolers to name a few. The high-performance nature and resin-specific features improve the use of this material in places that require resistance to fuels, oils, or any harsh chemicals and high temperatures. We should not forget to mention that becoming stronger plus getting less moisture makes it possible for PPA to help the designers reduce the numbers of parts and at the same time have much better reliability. The material is selected also for the electrical and mechanical parts of the motor and bobbining process because of its grades being filled and tailored. All in all, PPA is a perfect match for a wide range of applications where one is looking for high heat and chemical resistance and at the same time, stiffness.