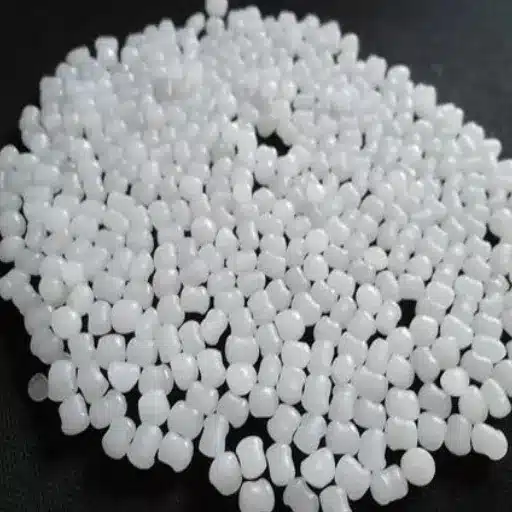

High-density polyethylene (HDPE) plastic resin pellets have become a crucial component in production and recycling, popularity for their tremendous flexibility, long life, and environmentally friendly properties. Often regarded as one of the most secure and extended-warranty materials to make high-performance plastic products, large volumes of HDPE pellets are used in a wide range of applications from packaging solutions to construction materials. This article goes deep into the plastic resin pellets of HDPE with a lot of use and show how they are involved in the process of making the manufacturing and recycling of things more sustainable. If you are a manufacturer looking for new material technologies or an environmentalist who wishes to do so, this material will light you up on the topic of HDPE as a necessity in both fields of industry and ecology.

Understanding HDPE and Its Properties

Definition and Composition of HDPE

The polymeric material known as High-Density Polyethylene (HDPE) consists mainly of ethylene monomers. The cat-a-lyst-assisted poly-mer-i-za-tion pro-cess causes the ethylene molecules to be con-nected using the bonds in order to form a tight and very crys-tal-line structure, hence mak-ing a very light and still very strong material. For that reason, HDPE is characterized by the ratio of its high strength-to-density, high impact resistance, as well as exceptional chemical stability which all together makes it feasible for a wide variety of applications. Its molecular structure, being minimally branched chains, gives it rigidity and tensile strength, thus setting it apart from other forms of polyethylene. Also, its non-porousness and resistance to moisture and corrosion enhance the virtues of HDPE in a variety of industries that stretch from packaging and construction to automotive and medical sectors. The processing of HDPE raw materials has rapidly changed over the years; the purity of the material, its recyclability, and the environmental performance have all been greatly improved by the use of advanced catalysts resulting in the material keeping its position in latest manufacturing trends-on one hand, and, on the other, also extending its area of application.

Physical and Chemical Properties of HDPE

HDPE is characterized by a distinctive set of body features and chemical properties that enable it to be suitable for multiple applications. The material has a high strength-to-density ratio, usually between 0.93 and 0.97 g/cm³, which means that it is both durable and lightweight as well as structurally transparent. This type of plastic exhibits superior tensile strength that can even surpass 31.4 MPa, thus making it a good choice for the load-bearing applications. As for the melting point of HDPE, it varies between 120°C and 140°C, depending on the grade, which allows the thermoplastic to work efficiently under the majority of thermal environmental conditions.

HDPE’s chemical nature is such that it is the least affected by destructive agents such as solvents, acids, bases, and environmental stresses, thus becoming the material of choice in extremely aggressive chemical environments. This is mainly due to the linear polymer chain of the polymer with little or no branching, which makes the polyethylene high in crystallinity and therefore raises both its physical and chemical stability.

Besides that, HDPE shows very good toughness against impacts and does not absorb much water, with the standard water vapor transmission being less than 0.5 g/m²/day, hence the excellent barrier properties. As of today, through the use of catalysts based on metallocenes, one can say that the current advancements in the field of polymerization have made it possible to tailor the molecular weight distribution and crystallinity and, thus, the properties for certain industrial applications. These technical advantages once again prove HDPE to be a primary building block of engineering and manufacturing processes.

Differences Between HDPE and Other Polyethylene Types

In contrast to other polyethylene varieties like low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE), distinctive characteristics can be observed in the case of high-density polyethylene (HDPE). One important feature that makes HDPE different from other polyethylenes is its high degree of crystallinity and dense molecular structure, which give it remarkable tensile strength, rigidity, and resistance to environmental stress cracking. On the other hand, LDPE with polymer chains that are highly branched is better suited for flexibility and impact resistance but lags behind in terms of mechanical strength and temperature resistance.

Linear Low-Density Polyethylene (LLDPE) with its linear structure and short side branches is preferred over LDPE because it has less of a balance of the properties of both the latter and HDPE. Referring to the characteristics of tensile strength and puncture resistance LLDPE would be the option to choose over LDPE, however, it is not to be mentioned matching the performance of HDPE with respect to either very high load conditions or the impermeability to gases and liquids. Blending and copolymerisation of polymers are the techniques, which have enabled the manufacturers to produce the above-mentioned polymers, thus, providing the possibility to get materials that are significantly advanced in their properties and that are for a specific application. This has set a clear distinction, but HDPE is still in the application with the highest structure and environment resistance needs, as far as, product choice is concerned.

Applications of HDPE Plastic Resin Pellets

Use in Injection Molding Processes

The use of HDPE plastic resin pellets is very common in injection molding as they have a perfect blend of physical properties, processing ease, and lower cost. The plastic is commonly used and can be heated and shaped under pressure. It is known for its high melt strength and good flow ability which makes it the most suitable material for manufacturing complex shapes with high precision. And due to the injection of molten HDPE material into a closed cavity with a mold, an article is created having the same shape as the cavity.

This resin is characterized by a great deal of resistance to chemicals to the point that it is very fitting for those areas where regular exposure to detrimental materials take places such as in the case of corrosive or high-humidity environments The whole journey from automobile parts to goods for the everyday individual turns a lot better due to HDPE’s skill to uphold the strength of the structure under the constant application of force to the material. In addition, the fact that it can be recycled makes HDPE match the efforts being made in the industry for ecological manufacturing practices, by the reduction of material dumps and the consequent environmental damage. The plastic resin used in the manufacture of modern day injection molding applications looks as though it is the HDPE material.

HDPE in Packaging Solutions

High-density polyethylene (HDPE) is widely used in packaging because of the incredible strength to density ratio, chemical resistance, and the fact that it is a very light material. The applications of this material go from food and beverages to pharmaceuticals and consumer goods, giving the consumer the best of both worlds when it comes to quality and the price. Precisely, HDPE is the material of choice for the making of containers for milk, washing liquids, as well as for various medicaments where the reactivity of the container poses a safety and preserving properties context. The very recent improvements in the quality of the HDPE material have made it unbeatable as a moisture, oxygen, and other uninvited materials protective barrier and the packaging contents of a product can be safely ensured being protected at the same time. Moreover, HDPE is very convenient for recycling by advanced technologies which reasonably reinforces the principles of the circular economy and moreover leaves just a trace to the environment by complying with the standards of the industry. The combination of technology and compatibility has kept high-density polyethylene as the main reference for the packaging industry regarding sustainability and performance.

The important role of HDPE in Consumer Products

HDPE is very important in the consumer product development process, as it offers very unique properties like toughness, lightness of weight, and being resistant to both moisture and chemicals. In the making of such household items as the above-mentioned as detergent bottles, milk jugs, toys, HDPE is among the most common. The protective characteristic it provides to these items keeps them in good condition for a long time. Also, the agreement of HDPE with the food safety and hygiene rules makes it a great choice when it comes to the packaging and storing of food. The possibility of molding the polymer very easily and cheaply places it among the top five plastics which, combining functional and aesthetic requirements, can cater to a multitude of consumer markets, thus creating more space for product design innovation. HDPE, along with other polymer sciences, is offering the production of consumer goods with a continuous, stable, and high performance variety of materials that are sustainable.

Benefits of Using Bulk HDPE Resin

Cost-Effectiveness and Availability

High-Density Polyethylene (HDPE) resin is a material that is in very high demand because of its exceptional cost-effectiveness and its widespread availability. It is also an active material across various manufacturing sectors. In general, the use of HDPE results in the reduction of the costs of the products’ transportation. The low manufacturing costs of HDPE are mostly due to very effective polymerization techniques and the availability of huge amounts of raw materials. This also empowers them to keep the prices of the products competitive in large-scale production. Moreover, the durability of HDPE together with its low weight-nature reduces the costs of transportation which in turn adds to the economic appeal of the material. The low price of HDPE resin, together with the cheap and easy access to it, is the reason why it is seen as an economic plastic. As HDPE resin is known, it is the least heavy among its competitive products.

Environmental Impact and Recyclability

HDPE resin is highly appreciated because of its minor impact on the environment as compared to other plastic materials. Generally, its production process is not only less energy-consuming but also less pollution-causing, thereby being the most coveted solution in sectors that are into sustainable materials. Moreover, HDPE is recycler-friendly and has a place among the plastics with the highest recyclability rate. Recycled HDPE is usually made into pipes, plastic lumber, and bottles, which greatly help in preventing the waste that could have ended up in the landfills.

To make HDPE even more sustainable, the advanced recycling technologies like closed-loop recycling can efficiently collect, process, and re-manufacture post-consumer HDPE products into new applications, therefore, journeying the virgin resin production dependency, saving resources, and fitting in with the global trend of circular economy.

Nevertheless, the upholding of the maximum level of recyclability is subject to the appropriate and efficient waste management systems and active involvement of the general public in the recycling programs, highlighting that there needs to be a continuous influx of innovation and cooperation amongst the industries to up the material’s environmental performance.

Virgin vs. Recycled HDPE: Pros and Cons

Virgin HDPE and recycled HDPE are two materials that showcase different characteristics and advantages and rather being completely different entities. Instead, they have emerged as vital elements in the different industries according to their strengths and weaknesses. First, virgin HDPE, the material that comes from petrochemical resources, is the one that is strongest, most consistent and purest among all three. That is why it should be used where very high-quality standards are required e.g., the food packaging or medical industry where the risk of contamination must be the lowest. However, on the other side of the coin, the extraction process for the material is resource-heavy, and thus it causes the release of more harmful emissions and the use of fossil fuels, the major culprit of global warming.

Recycled HDPE, however, epitomizes eco-friendliness by reusing post-consumer and post-industrial plastics, first of all. The loss of the material’s mechanical properties a little bit is very likely to occur as a result of the heat exposure during the process and the fact that it gets mixed with other materials. Nevertheless, improvements in the recycling technologies, for example, the development of extrusion systems and the introduction of purification steps, have shown a marked-up in the quality of recycled HDPE. Recycled types of HDPE often present themselves as a good fit for applications that don’t require the same strict quality standards as in food packaging like construction materials, piping, and non-food-grade containers. Besides, the recycled HDPE even has a smaller carbon footprint than the virgin resin, thus it also has a place in the list as a part of the “green” team.

Virgin and recycled HDPE are the options that are often chosen based on the requirements of a certain application, performance needs, and environmental goals. However, a good mix of both recycled and virgin HDPE with recycled HDPE being extensively used and virgin HDPE strategically selected for the most crucial applications can make a win-win situation in terms of functionality and environmental impact. Moreover, it is required that industries go through life-cycle evaluation, incremental innovative solutions, and also integrate recycling of HDPE materials to enhance the circularity.

Choosing the Right Supplier for HDPE Pellets

Criteria to be Kept in Mind during the Choice of HDPE Supplier

Every time you assess the performance of HDPE suppliers, you should monitor a vast number of technical and logistical factors that are crucial for the realization of your operation and the environmental objectives. The most important things to be considered are:

- 1Quality and Specifications of the Material: One of the points to check is that the supplier is able to give the correct HDPE pellets material which should fulfill the requirements of the density, the melt flow rate, and the strength for your product. Demand full material datasheets and samples for real-world testing to be sure that the given products meet the targeted very high performance levels.

- 2Standards and Regulatory Approvals: Look for suppliers that have professional organizations’ approval for the quality management or the environmental management systems like ISO 9001 and ISO 14001, respectively. Also, make sure to check that the components of the product meet the safety and health requirements that are applicable to your region and your specific area of application, e.g., FDA or RoHS standards.

- 3Sustainable Practices: Examine the supplier’s commitment to sustainable manufacturing. This involves using recycled HDPE as the raw material, cutting down waste in the production processes, and incorporating sources of renewable energy. If you collaborate with suppliers who feel rather about the environment, then your product can even have a higher standing in terms of sustainability.

- 4Production and Supply Chain Capabilities: Get to know the supplier’s production output, lead time, and upscale capacity according to your demand. Those with well-established inventory management systems and distribution networks that are well connected will prevent any changes in supply as the reason why their products are always delivered on time.

- 5Technical Support and Expertise: Always go for the suppliers that provide complete technical support, which should include assistance in the selection of materials and issues with the products after purchase. A supplier that is extremely knowledgeable about the different applications of HDPE can make a serious difference in terms of your processes and the resulting products.

- 6Cost and Long-term Value: All in all, a cost-effective supplier is a must, but the comparison must be made between the cost and the value he can offer to the business in the long run. The concurrent use of top-quality HDPE materials and responsive customer service is able to minimize operational disturbances thus making it a cost-effective partnership over time.

A comprehensive evaluation of these aspects would help to choose exactly that HDPE supplier who is aligned with your business but is also a promotor of operational efficiency and sustainability.

Quality Standards for HDPE Resin Pellets

The evaluation of HDPE (High-Density Polyethylene) resin pellets quality standards should consider specific performance metrics that have a direct influence on their fit for use. Those metrics could include the MFR (melt flow rate), density, and tensile strength, and they in sum imply the material’s processing features and mechanical properties. MFR is the first of the most common test in plastic testing and does not represent the polymer’s significant properties like the engineering modulus and the tensile strength, tensile stress at the yield point, elongation, and other mechanical properties, it still can be the most vital property for the mode of employment.

Moreover, tensile strength can also be thought of as a durability benchmark, and higher values indicate stronger resistance to mechanical stress and deformation under a load. Suppliers who follow the international standards such as ISO 9001 and ASTM specifications are showing that they have a clear understanding of and the intention to deliver HDPE resin pellets that are uniform in quality and performance. Suppliers’ compliance is a must when industrial piping systems and also consumer packaging applications are at stake, the latter one being directly related to customers and therefore demanding high reliability and safety features. The material testing to be done in a very strict and precise manner should also lead to the conformity of such standards and thus support the product durability within a very wide range of applications.

Assessing Supplier Performance and Service

Measuring the dependability and quality of service a vendor provides is connected with a thorough system based on quantifiable standards. The first and most important factor is the supplier’s performance consistency. If the deliveries are made on time, they help to reduce the interruptions in the supply chain, which is the key to keeping the production plans in place. The supplier’s compliance with agreed-upon delivery times and order accuracy is the way the company’s operational reliability is typically rated. Second, communication transparency is a must; vendors should furnish comprehensive information, including the documentation of materials, inspection reports, and traceability records, to confirm their compliance with the mandatory norms of the industry and the contractual requirements of the customer.

Moreover, the customer service is a key factor in service quality. The supplier should be able to answer the questions quickly and at the same time be preventing the problems by being proactive. Among after-sales services that support the best customer service are being a partner who helps in the areas of integration of the product and the fault-finding, etc. And, lastly, a supplier with a strong financial situation and long-time collaboration with the elite in the industry acts as a pointer to the ability of the supplier to keep the operations going and to invest in the process of continuous improvement, thus, as a very reliable partner in the supply chain.

Future Trends in HDPE and Plastic Resin Materials

The innovation in the HDPE manufacturing process

The results of my research show that the innovation of the manufacturing process of high-density polyethylene (HDPE) is rooted in the increasing demand for eco-friendly and cost-effective materials. The most important innovation is the higher and higher use of the advanced catalyst and polymerization technologies. These innovations give better control of the molecular structure of the polymer and, as a result, the material properties are also improved, e.g. tensile strength, durability, and stress crack resistance. Metallocene is a family of catalysts that allows the firms to make HDPE that matches the requirements of specific applications like excellent packaging, pipes, and containers.

On the other hand, a very important trend is the combination of the circular economy with HDPE production. The producers are currently giving all of their attention to the chemical recycling of the technology in order to collect reusable monomers. This step will not only get rid of the need for virgin fossil-based resources but also fostering the development of high-quality recycled HDPE with such similar primary material properties. Moreover, they are using energy-efficient production techniques that involve the use of automation and artificial intelligence systems to optimize resource consumption, minimize waste, and consequently minimize carbon footprints.

In conclusion, the introduction of bio-based HDPE, made out of renewable feedstocks just like sugarcane, causes a great change. The performance of bio-based HDPE is on par with that of the petroleum-based product but the former creates a lower environmental impact. These developments are the way by which the industry signals its acceptance of both performance requirements and environmental goals, thus initiating the paradigm shift of HDPE materials in a wide range of applications.

Emerging Applications in Various Industries

The incorporation of high-density polyethylene (HDPE) in diverse emerging industries beforehand by material engineering and eco-friendliness innovations and the plastic’s adaptability and versatility are the reasons for its prevalence in the market. One area where this polymer finds its use extensively is the construction sector, the material being the major element when it comes to the production of geomembranes and plastic lumber. These materials are the best alternatives to the old ones as they are sturdy, wear-resistant, and have long lives, which makes them very suitable for the big-scale infrastructural work like setting up landfills, digging canals, and putting up retaining walls. Furthermore, the HDPE piping systems have been widely accepted because of their strength and corroding resistance which has made them very crucial assets in the gas pipeline network and even water supply lines.

HDPE is also a rising star in the energy industry, especially in the renewable energy field. What is also happening is that HDPE is turning to be a sturdy and useful material for solar panel support system components, which are environmentally friendly. The material is very light and at the same time strong, providing an extra layer of structural integrity. In addition, it is a vital material in the offshore wind energy field, at the same time it is used in floating platforms, cabling systems, and maintenance infrastructures. Its resistance to saltwater and UV radiation makes it the preferred material for the geographical and environmental conditions that are very harsh in marine environments.

To conclude, the packaging sector is still the leading one when it comes to the new applications of HDPE, whereby the trend is for the stricter recycling and circular economy process. Among the various positive commercial features of the plastic, its capacity to recycle back to its polymer (polyethylene) and even to its monomer (ethylene) has been the most advantageous for the network which has developed numerous post-consumer HDPE items. The new packaging goes a long way to add to the progress the industry has already made in combating environmental pollution, as well as saving energy. On the whole, elephantine steps have been made in this industry, highlighted by the emergence of HDPE as a big player in the global resource efficiency, infrastructure resilience, and environmental protection.

Impact of Legislation on HDPE Usage

According to my research, the usage of High-Density Polyethylene (HDPE) in different industries is influenced by a number of legislative trends. Governments all over the world are more and more adopting policies that are supposed to minimize plastic waste and, what the ultimate effect of this is, the production and the recycling of HDPE materials. One of to illustrate, over the packaging of goods several countries now have a recycled content requirement which is obligatory and this is one manner the governments are forcing the manufacturers to use a certain percentage of the post-consumer recycled (PCR) material creation of new HDPE products. This measure not only leads but at the same time making the use of technology in recycling develop and thereby leading to the higher compatibility with the principles of the circular economy. Even so, these measures demand that the manufacturers pay for their sourcing and thus need stronger recycling alliances as the process of making the product is concerned.

Moreover, there is a lobbying for the implementation of the extended producer responsibility (EPR) regulations, where the manufacturers are obliged to be responsible for all of their plastic products’ life cycle, including HDPE bottles. Businesses, under EPR, will have the obligation to finance the waste collection and recycling or disposal of HDPE materials, which in turn will bring the way for more and better plastic material recovery and re-use technologies. As a result, the closure of the circle will be made where the HDPE materials will be reused or converted sparingly and our planet will be less affected by achieving a lesser dependence on the new plastic products.

Indeed, the prohibition or levy of one-time-use plastics in lots of places are driving the shift to long-lasting and recyclable materials such as HDPE. Therefore, the very same policies indirectly have become the force behind higher demand for HDPE in certain sectors. They have, in fact, made it more necessary for quality and strength reasons and less so for the secondary market need. Yet, in line with these rules, the procedure of the interstate trading of recyclables might be subject to various interpretations leading to non-compliance or even fraud. This situation is especially true when we observe copper scrap, which is in conflict with the trade codes of BIR, while the no-men area is nameless zinc. Even the preceding widely used practice of buying on the spot market could violate the law of the previous owner to receive an upgrade and other features hinder the way of appraising the scrap material. On the grand scale, these regulations are forming a highly dynamic market in which using HDPE is the only option creating a ripple effect that reaches recycling breakthroughs and plastic waste minimization fortifying the society as a whole.

Reference Sources

- Additive Manufacturing with High Density Polyethylene – South Dakota State University – Explores the use of HDPE as a recyclable material in additive manufacturing and construction.

- Mechanical, Thermal, Flammability Analyses of Composites – University of Alabama at Birmingham – Discusses the suitability of recycled HDPE for various applications, including its limitations in high-performance uses.

- Preparation of Pinewood Residues/Recycled HDPE Composites – North Carolina State University – Examines the creation of HDPE composites for potential use as substitutes for medium-density fiberboards.

- State Water Resources Control Board – California – Provides insights into the production and environmental considerations of HDPE resin pellets, also known as “nurdles.”

Frequently Asked Questions (FAQs)

The definition of hdpe resin and its comparison with other types of already raw plastic material what is it?

HDPE resin is a high-density polyethylene polymer that is generally used as a strong plastic material for injection molding and extrusion. It offers more stiffness and strength than low-density polyethylene and is often selected for applications requiring high impact resistance and long-term durability. Being a typical thermoplastic resin in packaging and piping, it is better than some copolymers and nylon when it comes to chemical resistance and moisture barrier properties. HDPE can be processed either as a virgin material or as a recycled resin depending on the costs and environmental marks that need to be met. Besides, it facilitates the use of master batch coloration and additives for the products to meet the food grade and regulatory needs while remaining a cost-effective plastic resin for injection-molded applications.

Plastic pellets and polyethylene granules are packed and sent in bulk?

The most common packaging for plastic pellets and polyethylene granules is 25 kg bags, bulk rail or truck containers, and super sacks for big shipments. Suppliers are very specific about the condition of plastic granules before they are packed. The majority of the time, granules are dry and uncontaminated, especially for food grade shipments where sealed bags and moisture barrier liners are used. It is essential that the bulk packaging would be designed in a way that it could also take the master batch blends or specific additive-loaded plastic resin pellets to achieve desired consistency. Shipping documents will specify whether the product is coming from virgin material or recycled resin and will include instructions for handling in the case of environment-sensitive or high-impact formulations. A number of the vendors provide samples and certificates of analysis pertinent to the polymer grade and density polyethylene resin specifications.

Do food grade and environmentally-friendly options exist for the hdpe pellet grades?

Yes, a lot of producers are actively engaged in giving food grade HDPE resin that is made for direct as well as indirect food packaging. Production of food grade HDPE resin made under controlled conditions is frequent as well as from virgin material, and it is tested to be in accordance with the prevalent rule and regulation. Green options are also on-site for the customers like the ones that produce post-consumer recycled HDPE or use energy-saving measures leading to less amount of gases being put out and less waste. The parties that want to get the materials for their business should demand the recycling data, polymer grade, and usage of any master batch additives even for the places of pure food and the eco-friendly environment. These materials are still a popular type of thermoplastic resins that are mainly used in making containers, bottles, and other packaging where safety and environmental friendliness are significant both.

What is the difference between polyethylene resin, ldpe, and lldpe in terms of performance?

Polyethylene resins embrace a collection of materials including LDPE, LLDPE, and HDPE, each having its own measure of weight and qualities when in use. LDPE (low-density polyethylene) is a more flexible material compared to HDPE and is also less stiff, thus, it is suitable for making films and packaging that can flex, while LLDPE is an improved version to LDPE, giving a higher tensile strength and puncture resistance in film applications. HDPE provides the highest stiffness, the best chemical resistance, and the longest lasting rigid parts and will be the favorite plastic in demanding structural areas. A selection among these popular thermoplastic resins needs the needed flexibility, impact resistance, and process while taking into account the fact of the application of either injection molding applications or blown film extrusion. Possibility arises for an incorporation of an additive like a polyolefin elastomer as a means to tune impact properties according to specific needs.

Can one use plastic resin pellets in bulk for the injection molding process, and are there specific resin pellets that are preferred for this process?

Certainly, the bulk plastic resin pellets are the number one raw material for the injection molding process, and the highly demanded materials, such as HDPE, PP, and some copolymers, are usually used according to the application. In cases where injection molding requires high impact, durability, and dimensional stability, either polypropylene or HDPE resin pellets are the most likely choice of the two, but copolymer materials can also be selected to enhance the impact and flow properties. The manufacturers typically opt for the plastic resin that has a very uniform melt flow index and minimum moisture content to ensure the absence of defects. Another point is that there is no need to add master batch colorants and performance additives separately as they are usually inserted into the pellets for uniformity purposes.

What is the difference between recycled HDPE resin pellets and virgin material in terms of characteristics and environmental advantages?

The functional properties of recycled HDPE resin pellets can differ slightly from those of virgin material but, essentially, they are very similar. However, when it comes to stiffness or consistency, the former may be a little lower than the latter due to the various products and handling. Just imagine recycled resin pellets are already one step ahead from virgin material since they will then be used as a virgin. The second-best advantage of using recycled resin pellets is the elevation of the environmental state-earth’s health. It happens because the plastics are not thrown in a landfill and also the energy needed in the polymer production process becomes lesser. When special applications need to be dealt with, processors can still use their usual virgin material or they can also engage in the use of a master batch which serves as the color and performance restorer. There are, however, only a few sources of recycled pellets which are good enough for food grade use. The said pellets must comply with the strict contamination and traceability standards which might also limit the sources of pellets. Yet, recycled HDPE is an excellent choice for those who want a sustainable and high-performing product option, especially for the packaging and durable goods industries.

Are there any additives or copolymer options that can be used to increase the strength, lifetime, or flexibility of plastic material pellets?

Stiffness and other properties of the pellets can be changed by a vast array of additives and copolymer types: the glass fiber or mineral fillers will have an impact on the stiffness and the dimensional stability of the product, while injections & extrusions and thermoplastic rubbers or TPE/TPO additives will improve the impact resistance and the flexibility. Using master batch concentrates, the final product can be obtained in many colors, and the obtained colors will be stable under fluorescent and UV lighting; the materials will also be protected against oxidation, therefore the processing heating stability will be ensured. Welding and stress crack resistance can be improved using copolymers also. Are you looking for a broom handle to be less brittle, the chances it would have higher toughness are more at hand? Suppliers are here to help you with their range of plastic granules or blends out of which they can then target the balance that is the closest to your targeted specifications.