Correct handling of resin pellets usage is another issue to ponder about in any industrial application to enhance the production process and ensure neat finish work. If you are using components made of plastic material, and/or molds, and practicing injection moulding, the kind of resin used will also determine the utility and serviceability of the finished products and their unit costs. The overcoat is intended to unravel the troublesome process of choosing resins by examining the main aspects that must be taken into account by representatives of industrial sectors, these issue will range from the material composition and strength requirements to temperature maturity and possible incorporations. At the end, you will be able to comprehend how to come up with the most effective decisions in line with the project necessities so that you obtain what is required at the end.

Understanding Resin Pellets

What are Resin Pellets?

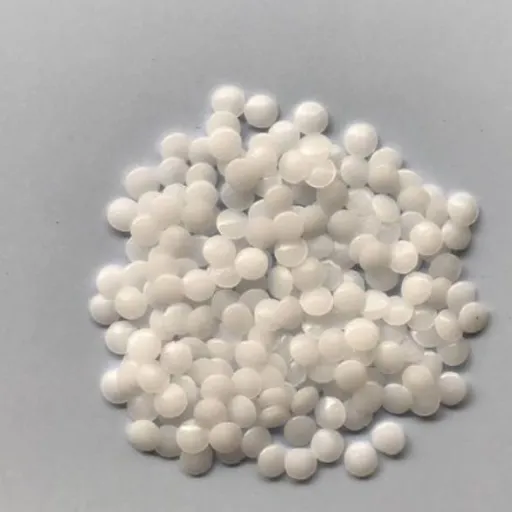

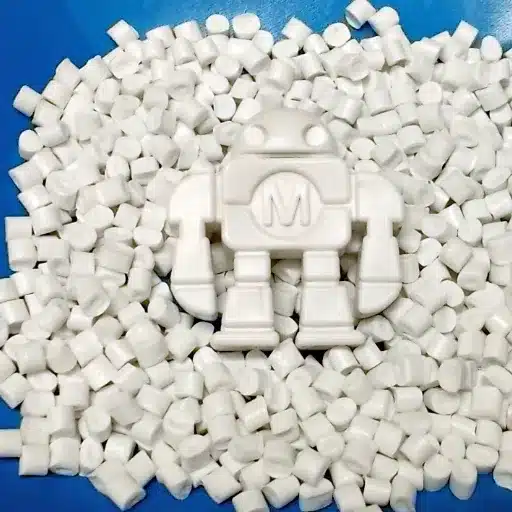

Resin pellets refer to granules made from polymers, also known as the most important raw material in the manufacture of plastic. These pellets are usually made under very controlled conditions, like polymerization or polycondensation that form them into regular shapes with the same sizes to make them easier to work with. Normally, the diameter of resin pellets shall range from 2 to 5 mm and have to be customized in quality and properties along various aspects, including tensile strength, modulus of elasticity and thermal intolerance so as to cater for the numerous industrial applications. These materials also come in different types – thermoplastics, thermosets, and elastomers – each having its own unique characteristics. Such chemical elements as pigments, fillers, plasticizers, plasticizers or pigments can be added to the materials using advanced compounding techniques as well as increasing the other sections of the chart. For example, the impact of movies, decorations, and energy sources on resin productivity, will in turn depend on the degree of UV reinforcement, flammability and resistivity of constituents, among other factors.

Types of Resin Pellets: Polypropylene and Polyethylene

Polypropylene (PP)

Employed as an all-purpose industrial material in sectors stretching from automotive trims to films within the walk ways, polypropylene fits the role to perfection. Its chemical resistant characteristics make it a bit daunting as it draws attention especially when it is applied in any packaging industries. Its ability to maintain its strength without succumbing decaying issues and being light in weight is one of its most remarkable features. The development in the synthesis of PPs has allowed for new and improved modifications to mechanical properties, like tensile strength and the ability to resist impact as per the conditions of intended use. Also, it is easy to process with molding and extrusion which also allows for cost effectiveness when engineered with mandates of large scale production.

Polyethylene (PE)

Polyethylene is a universal plastic, manufactured in wide expanses around the globe and presented mainly in three forms based on the density of the material and the level of branching – Low-density polyethylene (LDPE), High-density polyethylene (HDPE), and Linear low-density polyethylene (LLDPE). Each type has been formulated for particular purposes, where HDPE, for example, is more suitable for heavy-duty products such as storage containers due to its high rigidness and LDPE more appropriate for films and coatings due to the flexibility that it offers them. It is thanks to the developments in catalyst technology that polyethylene has become what we called it: a polymer that has some tailored molecular structures for purposes of high clarity, strength, and ESCR ratings. These improvements enhance its performance in consumer and industrial applications.

Applications of Plastic Resin Pellets in Industry

In a lot of industrial branches, plastic granulate plays a very significant role because it serves as the basis for the enormous quantity of goods. Distinctive features such as lightness, resistance to chemicals and the molding into soft or hard structures make polyethylene and polypropylene granules particularly suitable for these applications in the field of packaging – in containers, films and protective packages. These materials include polycarbonate and ABS pellets for other applications, including car-building applications where such specific materials are utilized in areas as dash boards, fuel system parts and body while mechanical components are produced comparatively lighter which subsequently helps increase the fuel economy by minimizing the overall weight of the vehicle.

It is also worth mentioning that in the electronics sector, products like PA and PBT resin granules find extensive use in the fabrication of tough and temperature-resistant casings, contact elements, and wire sheaths. High temperature polymer materials used in this industry include, for instance, PBT (Polybutylene Terephthlate). The healthcare niche also thrives on application-specific polymer granules. A perfect example are materials like medical PVC and Polyethylene which can be used for making surgical devices, IV bags, and tubing. The transition caused by new developments and the introduction of biopolymer resin pellets has greatly helped the environment, especially within industries which require performance against environmental effects.

Choosing the Right Resin Pellets

Factors to Consider: Density and Grade

Density and grade, on the other hand, are two of the most important parameters in measuring its possibility in accomplishing a specific task. This is because a resin that has a higher density will typically have better mechanical qualities, including the strength, rigidity, and impact energy characteristics. High-density resins, for example, high-density polyethylene (HDPE) hjjgh typically hdpe, are used for structural purposes as less denser materials, such as low-density polyethylene (LDPE), are very soft and are used in making packing materials that are lightweight and flexible.

Another term that is associated with resins is grade which refers to the purity and its characteristic properties. It would be appropriate to comment that for instance those resins which are industrial versus food grade resins, will offer more strength or more temperature resistance, while on the other hand food grade or medical grade resins in pellet format will have undergone additional modification to ensure that the declared parameters are achieved in compliance with set conditions. When choosing resin pellets, the overall density and grade of the said pellets will need to be weighed with the scope of anticipated tasks for purposes of achieving defined scope and requirements as observed in the respective sector.

Understanding Weight and Bulk Packaging

The gross cloud section characterizes a cloud dropping that can overflow and affect business aspects creating excessive hazards. Furthermore, the splitting of the gross cloud section into the LPS, and APS will maintain a reasonable industry megasector size that is more manageable than S0 or E0 facilities. However, in the overall market, resin packaging implies all packaging of microwave absorbers or reflectors on a structure. Furthermore, it also concerns machining that does not require the use of filling material and the packaging of the machined body with resin. These result tests allow evaluation of the coating storage modulus, phase angle, and extension factor of materials that exhibit burstiness. For the purposes of the sealing test of the gap in the piping, the test gas that shall be used is specified as compressed air at room temperature. On the other hand, high-temperature gases can be used for the testing of the heat-resistant joint.

Weight systems follow strict codes in order to guarantee that packages are not in breach of the set shipping policies. This includes the adjustment of the bulk weight systems for variances and any sensibility due to humidity or pellet settling. Furthermore, any form of bulk packaging also ensures compliance with the safe stacking criteria, allowing ease of product flow and that the nature of the commodity is sustained. Variants of weight and packaging systems techniques that work in the proposed approach will go a long way in promoting operations efficiency and cost reductions.

Custom Resin Pellets: Tailoring for Specific Applications

In the quest for high-performance engineered functional materials and components, injection molded products require a compounded resin batch that is specifically engineered to meet a desired set of requirements. The process of such customization usually involves the selection of specific polymer matrix along with suitable blending and / or oxidative thermosets and elastomeric materials in order to provide the desired mechanical, thermal and chemical properties which are necessary for a given application. Thus, carving out kinds of Resin that are typically used in the high-end production of Car and Truck bodies may need to have High-Impact Resistance and fused and stability whereas Resins for Medical devices, on the contrary, need to be Sterilizer Compatible as well as Biocompatible. As such, it is possible to withstand the effects of gamma or microwaves on these resins without heat. With the help of Latex compounding blending with other additives like colorants, UV stabilizers or flame retardants is allowed to Temperature- Resistance of the resin to be enhanced and thereby ensuring that the aesthetic and regulatory guidelines are observed. Major improvements such as including nanoparticles into blends have allowed for leather applications of custom molded resin pellets to be gained especially in the new trend fields like avionics, electronics as well as green packaging. It also means that the effective use of some guides in customizing material reduces the probability of their unnecessary consumption for other objective reasons and enhances the lifetime of the product.

Resin Pellets in Injection Molding

The Role of Resin in Injection Molding Processes

In the process of injection molding, without any doubt, resin is the most important material serving as the primary constituent from which molded parts are produced. The choice of resin can as well influence the quality of the final product, specifically mechanical, thermal and chemical properties. Among the other wide material categories, thermoplastic resins top the list since they include polyethylene (PE), polypropylene (PP), acrylonitrile butadiene styrene (ABS) among others and they may be used for a number of reasons depending on the mechanical aspects of the user. The latest in these resins with combinations of additives and modifiers have enabled many – especially development of automotive and medical products – manufacturers to use these products for even most difficult applications. Properly selected resins are important in order to avoid poor molding characteristics, warpage and shrinking during production and are also beneficial for production efficiency in terms of cycle time reduction and low scrap levels. Contemporary market trends promoting the production of sustainable options have been well-enhanced with innovative production strategies such as green resins, which signify a movement towards “green” economy, markedly different from the conventional economy. These changes reveal that raw material resin has a significant role in the design of products that are both functional and sustainable in terms of production.

Choosing the Right Plastic Pellet for Molding

Among the technical factors that influence selection, key elements relate to material properties of the molding compound, the functional purposes of the finished product, and the location of the processing. The main points are the type of the polymer (e.g. polyethylene, polypropylene, polyamide), the melt flow index, resistance to heat, which can fluctuate around 140 degrees depending on the conditions or improve technology, mechanical properties among others. All these expressions must be correlated to the State in which the product is to be used.

Besides, making decisions depends more and more on eco-friendliness and governmental laws. Taking for instance, the use of bio-sourced and recycled materials in attaining sustainability is an area that tends to that create opportunities vis a vis conformity. The efficiency of the manufacturing process may also be underscored by the examination of the moisture content tendency of the material in question, since too much moisture may cause defects or poor pellet formation.

Operators can achieve more effective production loss when there are very few scrap materials within your manufacturing process. This can be controlled through material analysis, process evaluation and control thereby all indications of production failures that will minimize production losses.

Environmental Impact of Resin Pellets

Pollution Concerns with Plastic Pellets

The risk of damage to the environment from the ubiquitous flow of plastic pellets or nurdles is significant as they are very capable of causing pollution both on the shores and on the ocean surface. These simple forms of raw materials which are small and lightweight tend to be thrown off during handling either before manufacture, while in transit or during storage, and are therefore deposited many times at the effluent of water bodies until they reach the ultimate destination; the sea. Carried even further by the currents, the plastic pellets will then be transported in the atmosphere. For instance, due to the fact that once again they are man-made, a substantial number of pellets are produced in large vats using numerous reuse cycles. These waste plastics are produced in large quantities and can avoid becoming waste by reusing them again and again with the required protection. In the ocean, plastic pellets take a long time to degrade due to their structure and hence can stay for more than several decades. Moreover, the plastic pellets are ecologically harmful when consumed by marine organisms that help in the transfer of pop contaminants.

There are a number of scientific studies that show how dangerous ingestion of plastic pellets to marine animals is and can bring about poor health, injury and death as well. What is more worrying is that since the pellets can be transferred through the food chain, such toxins will eventually pose up to a health risk not only to the water ecosystems but also to people. It is very important that the industries do their activities as per best practice which encompasses putting in places efficient containment measures and using suitable modes of transportation that are less likely to bring about pellets spillage. Specific conventional regulations against pellet incursion and this involves Operation clean Sweep, have the purpose of tackling the issue by means of raising standards in handling of plastics and their manufacture.

Eco-Friendly Alternatives to Traditional Resin Pellets

Industries all over the world have begun embracing the quest for sustainable practices. The production of ‘green’ plastic processing deals is one aspect that extremely demands this. Degradable plastic almost entirely disintegrates when in the soil due to the attack by microorganisms and hence reduces the negative environmental impacts over longer period. They are polymers synthesized from, for example, cornstarch, polylactic acid (PLA) or polyhydroxyalkanoates (PHA), which is generally better than other more general plastics for erasing the petroleum base applied earlier.

A new desegregating idea is utilized both recycled pellets of resin place, which are made when disposed of polymers are processed into secondary raw materials, pellets. Adoption of the above technique helps mitigate the build-up of environmental pollutants and also seeks to save the world’s limited resources by reducing the need for newly made plastics. Innovations that can still be mentioned are creation of ocean-bound plastic pellets, which are those that are produced from plastics that could have gotten to the sea through the rivers.

Strategies to Reduce the Environmental Impact of Plastic Manufacturing and Disposal Efforts Encourage the Adoption of More Ecologically Sound Alternatives Do Not End Here at Home Nevertheless, the existing eco-friendly solutions have certain limitations which need to be overcome in order for those solutions to be mainstreamed. Continued studies combined with government intervention and private sector involvement will be focus changes and enhance the production procedure of these materials.

Strategies to Reduce Environmental Footprint in Resin Use

The first and most important condition ultimately rests in improvement of materials. With the ever-increasing interest and attention to replace traditional synthetic polymers and resins with the ones based and grain from plants is due to two main reasons. Firstly the replacement of the petroleum based resins by bio-based resins reduces the dependence on fossil fuels and secondly it reduces the production of green house gases. It may also be necessary to improve the mechanical characteristics such as strength, fatigue and failure properties of bioresins, in order to make them suitable for critical applications such as the automotive and construction industries.

Just as important is the inclusion of emerging waste management approaches, which focus on the reuse and recovery of resources, especially toutless chemical degeneration. This is because, some of the concerned advanced customer systems within processing as well as waste management areas can cause the majority of the waste to loose their intrinsic properties as a result of the monotonous treatment. This can be witnessed in technologies like depolymerization and pyrolysis which significantly move us nearer in achieving cyclic resin producing systems.

The Authorities need to take measures which will promote theconversion of all raw materials into final products so that manufacturers are able to value addition to their products for example the use of recycled content. Sectorial epr schemes can be one of the mechanisms in place to change the value chain of industry and the way in which resin-based products are disposed such as implementation of useful life schemes to regulated waste disposal. These approaches, taken in combination, strive to reduce environmental degradation and secure eco-efficiency in the petrochemical field.

Supply and Handling of Resin Pellets

Best Practices for Storing and Handling Resin Pellets

I aim for tightly keeping the materials in good order when dealt with, particularly in the handling and storing of resin pellets to meet their performance output as efficiently as is ought to in the processing stage. Proper storage of pellets commences with the appropriate selection of a protective environment against external sources of contaminants such as condensation, floating particles, and additional matter that could damage the pellets. Pellets should be covered in airtight containers or closed bags, which may be durable with limited to no moister and further kept in a source that is limited light and free of moisture. When these pellets are exposed to moisture, especially during the summer or the rainy season, the pellets absorb moisture and become hygroscopic, leading to changes in their properties, which may result in defects after forming. Moreover, it’s worth putting a special mark on each and every stand by material so as to label resin type, batch and do some date of release as a tool to follow pathway or any specific action when situations necessitate.

While handling I make sure that the precautions against pollution are observed. This is achieved by using specialized equipment for each and every process. These provisions include clean transfer systems, vacuum loaders and even antistatic hoses to avoid particle contamination. It is also necessary to try and limit manual handling of the materials as contact can enhance the possibility of contamination or loss. Another preventive measure against material handling risk is implementing a “First-In-First-Out” inventory system, which facilitates the smooth and effective stock management, as the old pellets are exhausted prior to the new ones which is good for the company as it helps eliminate the wastage of costs on stock inventories that have been stored for long periods of time.

Moreover, I abide by the rules and regulations governing workplace safety to ensure the prevention of incidents such as leakage or invasion of static which is dangerous to encounter, especially with cranked up quantities of resin pellets. In addition, gear protection against electric currents and covering the critical body areas with personal hard vests makes the area less risky. These approaches could be used at various levels of products and modern use of it, for example, in the case of resin pellets being stored and produced into other products.

Understanding Resin Fill for Efficient Supply Chain Management

It is essential to adopt data-centric measures when concerning fill of resin into the supply chain, more specifically its management so as to make it efficiency. With this technology of tracking systems change is over expected as it use is an incredible step towards the right direction in matching the supply and demand. In the sense that it calls for the employment of solutions such as ERP software which offer a wider view of the supply chain flow. Likewise, knowledge on the characteristics of different resin types and their grades comes in handy in that it helps me to fuse the characteristics of the material into production, minimizing defects and other errors while conforming to the rules of good manufacturing practices (GMP).

Another essential element towards the filling of resin is the coordination of all interested parties for instance preparation is crucial. Using predictive analytics which will be based on the historical consumption as well as the market trends helps in predicting possible change in demand and prevent overstocking or stock out situations. It is also worth mentioning that working with reputable suppliers will make sure that pellets are availed on time hence reducing the lead times and making sure production is ongoing. This will also reduce any negative consequences of unexpected events such as delays in supply or equipment failure and the plant operations will go on without inconveniences.

Last but not least, eco-friendliness has a very important point when talking about managing resin fill in an efficient manner. I will be able to help lower the purchasing cost and mitigate the environmental impact by using raw materials from sustainable sources and recycling the excess resin. The use of closed loop production schemes makes it more feasible to manufacture products bearing optimal quality and enables recycling of the materials. Consequently, by use of technological recourse, strategic managing as well as desire to go green I am very much capable of resin fill management optimization and building of a well-functioning supply chain.

Comparing Different Packaging Options for Bulk Resin Pellets

| Packaging Type | Advantages | Best Use Cases |

|---|---|---|

| FIBC (Bulk Bags) | Efficient space utilization, lightweight, self-standing, can be rejuvenated and reused, cost-effective | Large-scale operations, automated systems, bulk storage |

| Plastic/Metal Drums & Bins | Better protection from contamination and humidity, improved moisture resistance, increased air tightness | Intermediate operations, long-term storage, sensitive materials |

| Biodegradable/Recyclable Paper Sacks | Environmentally friendly, reduced carbon footprint, recyclable or properly disposable | Short-term storage, eco-conscious operations, limited duration needs |

In order to judge the various packaging types for bulk resin pellets, I ensure to cover crucial aspects such as the tolerance of the substance, the compactness of storing, environmental concerns, and the capital efficiencies. One such alternative is the FIBC (Flexible Intermediate Bulk Containers) which are also referred to as Bulk bags. A well-liked option as it allows efficient space utilization, these bags have the capacity to contain a significantly large amount of the product. These bags are not heavy and can be used as a buffer inside an automated system because they can self-stand and are not very thick. What is more, many of the FIBC sacks can be rejuvenated and used again thus would not only contain costs but would also help the premium quality management through reducing perishing or obsolete stocks.

You may also utilize plastic drums and/or metal bins which are both smaller than FIBCs and stiffer, the advantage of which is that there is a better safety from external pollution or humidity, which is significant in the case of in-process materials. However, even if such packaging has more advantages such as improved resistance to moisture and increased air tightness, it is less functional as far as space utilization is concerned when compared to flexible intermediate bulk containers. It means that such packaging is more suitable for intermediate operations and for situations where there is a need of keeping polymer beads for a long time in a proper storage.

If a business aims at being green in their operations, some alternatives would involve the use of biodegradable or recyclable paper sacks, which are more suitable for storage for a limited duration or needs. Might be that these are the fragile kind of packaging as opposed to the plastic based brands, they help reduce the carbon influence to a large extent if trashed in a proper way or where they could be reconstructed. In the end, the packaging materials would vary depending on the purpose, size of the operation, and environmental goals, taking into consideration the associated expenses, as well as the effectiveness and environmental impact, with the additional value of prevention of over spill and or further impact beyond these limits.

Reference Sources

- Commercializing a Resin-Coated Proppant – Discusses considerations in selecting resin-coated materials for industrial use.

- Combustion Emissions from d-RDF (Densified-Refuse Derived Fuel) Pellets: Bench-Scale Studies – Explores the use of pellets in industrial applications, focusing on emissions and material properties.

- Characterization of Ceramic Waste Filled Unsaturated Polyester Resin – Examines factors influencing resin selection and the integration of waste materials in industrial processes.

Frequently Asked Questions (FAQs)

In simple terms, what are resin pellets and how does this plastic pellet material function?

To be precise, resin pellets, are also known as thermoplastic granules, are used as plastic products’ raw materials. Pellets are completely molten during the manufacturing process, either by moulding or extrusion, so as to actually manufacture parts, with stable flow properties and a standard rate of melt. These standard pellets are unvarying in size and offer better ease of operation especially in feeding automatic feeders and dosing systems which require controlled pound/lbs output. Resin pellets supply numerous molds found in the automotive and marine sectors, and in markets for consumers and can improve the environmental exposure since they can be recycled. In many cases, the so-called pellets are made from the recycling of plastic bottles, making it more sustainable than the use of raw virgin materials.

How do resin pellets differ from other forms such as granule or bead like plastic pellets?

There are instances when plastic resin pellets are considered as the most appropriate material for use in manufacturing. Pellets exhibit superior feeding consistency in fast-cycle applications. It should be noted that plastic resin pellets and granules are divisions in the same class of detacher but differ in size, form and behaviour in flow with certain size spherical pellets having ease of flow and no bridging problem while others would not facilitate flow. Other forms such as bead or powder may sometimes be used when it is necessary to provide different flow characteristics and/or thermal treatments; still pellets are generally easier to contain without making a mess. Deciding whether to specify pellet, granule or powder has implications of the quality of the plastic goods produced and the period of service of molds and screws. In specific cases slightly better chemical resistance or heat resistance might be required for automotive or industrial component and some grades are designed for this purpose. Some degrees are preferred by some simply because of the better machining capabilities they offer. It is essential for the design consideration to encompass the methods of injection molding therein, the criteria of the product design and the techniques that could be used in further treatment of the product.

Can resin pellets be used as cornhole bag or bean bag fill, and what is the most suitable grade to use?

Resin pellets are popularly marketed as cornhole/bean bag filler since they provide consistent play characteristics as a result of their weight, hardness, and physical form. High density polyethylene (HDPE) and polypropylene (PP) are the most suitable types of plastic for filling the bean bag due to the fact that they are effectively moisture resistant; this in turn helps to protect the fillings and maintains their weight in the container. Numerous firms sell fillers in bulk bags which can be purchased in pound or lbs, for both do-it-yourself (DIY) and commercial applications of the bag design. Alternatively, opt for recycled PP or HDPE used sparingly. Such materials remove plastic waste and help the environment. When used, ensure the material possesses high resistance to abrasion and know the right particle diameter, otherwise the product will deteriorate the fabric or even show through the seams.

How would weight, lbs, and density appear in the case of specifying plastic resin pellets for the injection molding process?

Delineating the requirements of a polymeric material in its granular form which is intended for further processing via injection molding particular process includes some aspects for consideration. These are the proportions of the material in terms of density and weight which are crucial for determining the mass of the part, the number of cycles the tool would take and the material cost per pound among other such like factors. The same properties of the material however also determine quickly away from the effect of mass, bond line spacing and other fitting and cutting compensations required on the tooling. In most cases, the technical data sheet to a polymer material includes information about the grade of the resin, melt flow index, recommended processing temperatures, etc. in order to reach the desired quality of the part. This is important in that accurate bulk weight measurements as well as density measurements are necessary for determining and assessing the amount of raw materials that may be used in the processes and hence avoid production losses in cases where shortfalls are expected. It is also necessary to think about resistance of the resin material to temperature increase or whether they would be compatible with any other materials or bonuses where automotive or high-performance parts are catered for.

Are polypropylene (PP) and polyethylene pellets different?

Polypropylene (PP) and polyethylene (PE) pellets differ in crystal structure, rigidity rate, and temperature range that each material possesses, aligning with the plastic product selection or usage. This is due to the fact that PP does not only handle higher temperatures better but also provides better stiffness. Conversely, HDPE material offers better tensile or impact strength and more resistance to chemicals hence has a bearing on the service life of the component, grade adoption as well as POLYETHYLENE (PE) FITTING use. The heat resistance, higher ductility, better resistance to chemicals – all require PE, infusion and, or PP and / or PC blends for the transport applications including car part designs and electronic ceramics where the materials find multiple use’. It should be noted that both kinds of plastics (polymers) can be produced from vine grained (reclaimed/Recycled) or clear (virgin) resin and formulated in such a way as to make them suitable for use in injection moulding or extrusion. You should test flow, melt index and resistance against relevant environments (ageing) in order to evaluate the selected resin consented to manufacture and use.

How is phenolic resin packed and preserved from the risk of contamination in the process of operating equipment?

Phenolic resins in the form of colored pellets can be nowadays supplied in bulk or polyethylene bags and need to be combated against moisture and heat loss effects or external ingress which might damage their freeness and product parts. There are various solutions found at the work site like storage by silos or bins, rather in the storage boxes or bags with a dessicant; it ensures that the quality of the raw material is maintained and restricted from pollution. Procedures for handling are done with the use of conveyors, strips as well as filters to separate different polymer materials or mixing of additives. Prospects for departmental inventory are recalculated at the end of every month to ensure the valid number of polymer pellets available for processing. The distribution of raw materials, including both production and non-production facilities and inventory stock respectively do not destroy instruments’ coatings and are a part of various reduction strategies such as: production waste recycling and minimum scraping.