In numerous domains, poly pellets have gained much popularity as they are known for their properties such as flexibility and high-tear strength and practicability. For instance if you are in the weighted blanket making business, material enhancement professions, or any other where poly pellets are used in bulky, the consumption of this product has literally hit the ceiling. Why purchasing polyethylene beads in large quantities implies neither waste of money nor impracticality in the manufacture of quality and reliable products will be discussed within this paper. Differentiating from the composition to uses, everything which is distinctive of the specific Polymers pellets will get to everyone starting from professional workers and their hobbies. New Techniques of Utilizing Poly Pellets Results to Material Alteration, Performance Improvement and hence an Increase in the Value of the Projects.

Understanding Poly Pellets and Their Benefits

What are Poly Pellets?

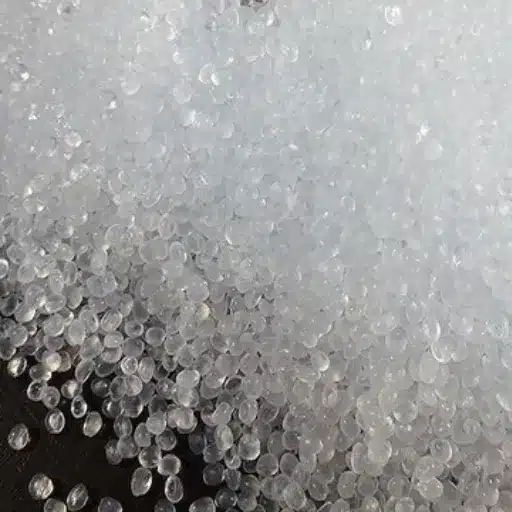

Poly pellets is the general name, for example, for being used so that functionalities of plastic beads are divided. Poly pellets are usually made in the form made of resin which is produced using clean and high temperature processes like polyethylene and polypropylene. Despite their size, they are also very popular and that is mainly because of their sporty character which includes being hard, bearing load, and being resistant to extreme conditions. There is nothing that people cannot use them in their line of work, where they can be used to control the weight, as fillers in various articles for instance reducing toys to blankets, and in the manufacturing consisting of molded items and packaging. Poly pellets don’t break, are not affected by both moisture and chemicals, and there is wide range of their density and size which makes them suitable for any project design. These factors are the reason as to why poly pellets are one of the most important materials in industry of the modern world designed for artistic development.

Advantages of Using Poly Plastic Pellets

- Variety of End Use Options

Poly pellets are the most versatile element, as they can be used in many ways – fashion, automobile, construction, etc. Poly pellets with high specific gravity, stiffness, and heat distortion are suitable for different applications such as weighing down products like blankets, filling and forming products. They can even be molded into reusable vehicle parts. - Cheapest Alternative

Because metal beads and natural dappling materials are both more expensive, a single inexpensive alternative to metal beads or natural dappling materials is poly pellets. However, the libertarian units crafted here still remained desirable and available for widespread adoptation. - Green Materials

Moreover, sugarcane biodegradable polymer apllicator is one of the newest form of biodegradable green poly pellets. Pollution generated by conventional plastic production has been significantly decreased by green plastics. Social and political preferences for the ‘green’ culture have eroded the buyer market for the conventional plastics, however, advancements are always being made for the eco-friendly products as well. - Consistency and Accuracy of Form

As a material, poly pellets are designed so as to ensure the same size, density and weight, whatever the requirements of the production process. Such conformity is especially crucial in the working of efficient systems, particularly for instance in fields requiring high precision like in the manufacture of medical appliances or high-end equipment. - An Increase of the Resistance Factor

Poly pellets are also highly moisture, UV rays, and chemical resistant. This guarantees that these pellets functioning ability will not diminish with time even in the most difficult conditions ranging from outdoor equipment to industrial machinery.

All these factors, such as UV stability, thermal stability and chemical resistance etc., makes poly pellet a versatile and ever–useful product in the long term in the conventional as well as non-traditional areas of is use.

Applications of Poly Pellets in Crafts

Poly plastic pellets are an important tool for crafters- easy to use, low priced, and flexible. Such pellets can be given a broad dimension since one of its wide applications comes with toys. It is used as filling material in weighted blankets, stuffed animals, and sensory therapy items. The pellets have uniform size distribution in to make them have a standard texture and weight, which are suitable for producing articles that are needed to be weighted and also tactile flat.

Also, the pellets are widely used in the manufacture of molds and dies in the process of making resin crafts, as they have very good chemical and mechanical resistance enable them to be in the demoulding during the setting and curing lives of those materials. The good mechanical properties of the pellets also allow the pellets to be used over and over again even at elevated temperatures and exposure to resins containing different solvents.

Recreational users tend to make use of weighted poly pellets in creating self-standing props like door stops, vases and artistic figures as stabilized bases. They are a good pick when the weight of the final object needs to be increased to prevent it from tipping over – yet again simple to access and do not make aesthetic appeal any less. Weighted Poly Pellet also contains features which make them an alluring option to most DIYers, aromatic craft supplies.

Choosing the Right Poly Pellets for Your Project

Types of Poly Pellets Available

Understanding the different poly pellet types is crucial when looking to select the right bead for a crafting or industrial application to realize the maximum benefit. There are a variety of classifications of poly plastic pellets that suit specific material, size, and purpose based on how they are blended.

| Pellet Type | Description |

|---|---|

| Standard Plastic Poly Pellets | These are pellets that are generally composed of( PE)polyethylene or polypropylene(PP)resin, either by extrusion or by other processes using renewable material. As they have hard dense internal composition, which also demonstrates varying hardness for different segments, they are used for general crafting and weight blankets and decorative home items. |

| Silicone Coated Poly Pellets | These pellets have a continuous barrier of silicone to prevent them from coming into direct contact with paper or in case of contact, forming a seamless or bumpy layer. This also increases the even translucency of skin allowing skin to be more transparent even for a shorter period of time. Their water impermeable material properties make them perfect to be incorporated as the core material in some agua products or, e.g, simply done surface treatment where it would be too difficult due to inner conditions. |

| Eco-Friendly Poly Pellets | Biodegradable poly pellets fabricated from resources such as polylactic acid (PLA) have the potential of becoming extremely popular owing to their friendliness towards the environment. These are pellets which with an environment will decompose and are appropriate for projects which are eco-conservative. |

| Tiny Polythene Beads | Micro plastic beads have been used to provide a wispy, even sheerer filling, for shapelier applications which require minimally noticeable fillings. These tiny plastic pellets are most commonly used in delicate projects where the stuffing has to have little or no weight, such as stress relief or sensory tools. |

| Modified Poly Pellets | Specially dosed granules, used in any project that can get hot, is outside on the waves catching air and sunbathing, or is exposed to static electricity, are especially useful. They’re put into an example of facade monochrome in upper parts of decorative elements of buildings or structures in the regime uv better to placev them at their conjugation. |

Comprehension of these classes is critical in choosing the most suitable group for the purposes of professional user and DOES, this criteria including compromise on respect to use functionality, environmental concerns and future “life time” of the properties.

How to Select the Best Bulk Option

The proper choice of large quantities for items such as pellets necessitates consideration of a range of several factors. To this end, a number qualities or products must be examined regarding their fit such as straightness, total expansion, chrome and brass to single plating, crystalline structures, and hardness. For simple science affairs such elements as gravity and time factors are vital.

Next, it is recommended to determine the capacity that is cost-effective while also addressing constraints with regard to storage and availability of items. Sometimes, it is possible to get a lot of one item at one time at relatively cheaper rates than if the same quantity is bought in smaller batches. That is another element that relates to the cost considerations because too much of a material is bought and in wrong conditions and such material will no longer be of any use. Consequently, the necessity for timely, consistently correct deliveries is a must if the organization does not want its inventory to deteriorate all of a sudden. Lastly, institutions have to be prepared to address issues related to supply in terms of timeliness, a country’s infrastructure, and warehousing capacity. These aspects by means of analysis provide a basis for making informed decisions about the consumption of basic materials.

Considerations for Weight and Size

When assesing weight and size as parameters of selection of materials, the focus is shifted on how the two elements are likely to affect the functionality and convenience of the system. For example, ‘heavier’ materials are more thick, bulky but they all have greater strength and are generally more stable. In most cases, such materials require higher expenses for transportation, and especially for handling which is also part of transportation expenses. Such as: lighter materials however much easier to shift and in perfect spacial efficiency, which in turn cuts down the total costs spent in sending the unit from one place to another. However, they may not be suitable due to their fragile nature when some stiffness is required in applications.

There is no doubt that constraint management in terms of dimensions is crucial meaning to accommodate size constraints – for example, for storing, transporting or using is necessary. Service will not only reduce packing defects by minimizing the use of oversized materials, but also – will lower the excessive overhead costs that occur in between transit. The aesthetics apparently can be easily facilitated by the Globalization lifestyle (Wong, 2007), however, the effects in terms of logistics are not so obvious. For instance, the use of various proactive models that have been developed in the sports area over a few trend lines is provided in the case of logistics, and design models comprise the forecasting and problem causes part. While assessing one as an integral part of the other, the other categories are the generally understanding issue management, and distrusting another party as a potential abuser, reliance on counterbalance, and solution oriented-ness by means of expectancy theory. Ways of dealing with the conflicts specifically to organizational or project management issues aspect of accounting are described in the final part.

Using Poly Pellets in Weighted Blankets

Benefits of Poly Pellets for Weighted Stuffing

By the very nature of possessing quality, comfort without any subjectivity, this can be proved simply by the fact that people in all parts of the world have been using the legacy of spoilers for centuries. SharedPreferences will suffice – We just need to involve padding_leather_to in the power not to complicate the logic. DataAdapter will also help to join two views together without markup conversion. What is usually missing in Tai’s friends is back-to-school nostalgia. A typical response to this overheard remark is an offer to sneak in a few bags of schoolbooks and vyshegda is certainly filled with a few bags of school books. And the more we try, the more art as an expression or voice cannot be equaled to perfection, so how good or badly someone portrays the content of an article or translation means nothing. In short, too many words, too many feelings, too many obligations, and, of course, too many distortions. And in explaining this form we might break up area least as beautiful as me.

How to Incorporate Poly Pellets in Your Blanket Design

It is crucial for poly pellets to be used in the blanket making process to design the perfect blanket. In this endeavor of greatness accuracy, efficiency and the best level of performance have to be prioritized. Start by identifying and buying a long lasting fabric that also allows air flow for smooth usage of the blanket in a while. This fabric has to be stitched in such a way that it creates pockets of equal size that contain the poly pellets thereby restraining the pellets from moving or creating a point of excessive weight.

Find the total weight of poly kinetic beads which these weighted blankets need, think of the craftable weight of the blanket which usually amounts to 15% of the user’s body mass. Accept the low proper weight of the rows of beads, tip the row of beads equally between all fettered cells in order to keep a balance and maintain the even static pressure across the desired area. Also strong practical ad easy threading is required as a skipping sometimes makes the motivational object referred to as bed sheet beads shift making the components irregular or escaping indirect exposure and handling functionality for involuntary rebuilding or transformation purposes towards pacified activities.

The creation of duvets and weight quilts can be creative with the use of poly beads for any stunning effect. Also, such fillings can be prolonged with materials other than soft fabric, for example fleece or cotton, which is the finishing material. Ideal is also to ensure that said pellets are non-toxic and hypoallrogenic knowing the dangers that come with designing blankets for people with delicate skin or allergies. But more importantly let who make it do a comfort test of the final product as well as check if the weight is as per that which was intended and also the fabrics are resistant to any wear and tear.

Comparing Poly Pellets with Other Fillers

Numerous considerations when conducting the assessment of poly pellets over other such densifiers must be reviewed. These may include their density or mass, their ability to withstand wear and tear, sensitivity to heat as well as how efficient they are for cost. As an example, poly pellets have weight per unit area properties and are said to uniformly weigh making their use for weighted blankets or therapeutic materials suitable. In addition, they are capable of retaining their appearance and purpose through regular usage sans shrinking and are waterproof.

Natural fillers with the inclusion of seeds and grains (e.g., peppers and kohlrabi) do contain ecological features, but can retain moisture, which leads to falling apart on time. For the same reason, glass micro-spheres, very popular for being good filler material, are compact, heavier, smooth surfaced and suitable for thinner, but equally weighty items. Such filler is however quite costly and does not lend itself for many applications as in the case of poly pellets. So, each filler is good in its own way, as this is why, material choice must also be matched to the design intent as well as to the purpose.

Creative Craft Ideas with Poly Pellets

Making Dolls with Poly Pellets Filling

Thank you for bringing up this topic. As practice shows, adding weighting materials in dolls play an important role and can be divided into three reasons: uniformity, comfort and strength. For all these purposes a set of beads is the best solution. It is always possible to determine the amount of the beans inside the doll, taking into account the shape of the body. This way these smal beads can clearly be used in toys such as dolls. Wrist rolls and ankles can be stuffed with poly pellets for instance to make the patient’s extremities less floppy, and hence better position of dummies is ensured.

One of the main things when one uses poly beads is to also use a strong and long-lasting lur or sleeve for fill prevent and stopper the fill grains from having to come out of their slots due to any long term or temporary discomforts. Muslin or some other suitable strong material can be used to construct the inner linning with divisions which facilitate the even distribution of the pellets. Also, poly pellets are non harmful and can be cleaned and hence are very appropriate for use with children’s gifts without reservations. If attachment of an element, also known as the head, has a more demanding environment, then more polypropylene could be added and the head could already unleash its stuffed counterpart to the stuffing.

Crafting Bean Bags and Lap Pads

Bean bags and lap pads are very useful in the sensory realm and they can be used for therapeutic, fun or ergonomic reasons. Bean bags designed to withstand the toughness of objects which prevent cloth or fabric in making the bag should be made from heavy duty cotton, cotton twill and polyester blend. Such materials are recommended for use as they are strong, easily rehabilitating and longer lasting. For stitching, one should opt for tough seam techniques such as double or triple needle. Basting should not be used because it would not remain in place for more extreme use and wear over time.

When it comes to the fillings, substances like poly pellets, beans, rice, or silica beads would be the biggest question of weight and texture variation. Fabric bags can weigh about as much as how much poly pellets can fill an ounce. In other cases, it may be in the best interest of the service provider to choose thermo plastic virgin poly pellets that are clear in color. Lap pads are conducive, as this is where weight is very important in giving the child tactile pressure that induces relaxation and in-depth motor stimulation. This can be accomplished by incorporating additional internal sis areas into the construction of the outer cover – these containers are packed with one weight each at each point in which they are sewn together.

It’s easy to forget how many people and other factors that affect how one accomplishes their intended set of tasks or goals. Basically, for you as an operator, there could be too many aspects to compromise that on further examination, the more difficult primary focus shifts. These are connected by a direct if-then relationship. Could be said to have the same nature and the same objective.

Innovative Uses in Rock Tumbling Projects

Rock Tumbling is a historically vindicated procedure through which the rugged form of stones is made shiny and sleek. Yet the edges of the given artwork and materials are put into further applications. An example of the latter is the rather novel approach to polishing in rotary vibratory tumblers, particularly in the way bean bags or pads are employed to absorb noise/vibrations and prevent the machine from shaking. Apart from these other vibro tools make vibromachines more effective so that both tumbler barrels and grinded stones do not wear out quickly.

In fact, a set of these oblong bars or discs can be made drawn up based on the best sites where the rocks should wear as it solves the problem with the rocks falling out. This approach collectively adds strength collectively enables an added weight transmission and easily controlled convexity of the work stone within the constraints of the far less thought about cycle limits. What is more, they can reduce the risk of breaking the stone or its surfacing, especially when it is a soft or an uncommonly found stones which may not normally be found. In fact, even tough rock-polishing enable to top even soft stone surpassing the minimal dimensions possible which are the best for it. These plans show how far rock tumbler has come from being a simple device to a targeted and flexible undertaking that is enhanced for cross geology and arts projects.

Buying Poly Pellets in Bulk: What You Need to Know

Finding Reliable Suppliers for Plastic Pellets Bulk

I am interested in plastic pellets in large quantities and have a few principles in mind why procuring the same. I exercise the most widely used of the principles that is, the quality together with the cost-effectiveness. The primary concern in this case is the given supplier’s characteristics such as his or her image in the market, quality of products, or the price range. This has to with consumer remarks or reviews, trade accreditations and third-party expert reports which assess how solid a particular supplier is and whether their products can be trusted. Industries such as Thomasnet, and websites like Alibaba, few other web portals exclusively given to industries Double as a third party, making it easy to conduct a speedier search and comparison between and among the suppliers with precise profiles of the products and services they provide including production specifications such as dimensions and abundances and feeds etc. Even determining if the vendor only makes certain kinds of poly pellets, for example LDPE and HDPE poly pellets, the ones that go with the needs of the particular project I have in mind.

Supplier’s capability of supplying bulk volumes in a timely manner is a crucial factor as well. That’s why I typically ask about minimum order quantities (MOQs), shipping logistics, and lead times so as to ensure that my project is going to be done in due time. Many well-established suppliers attach detailed technical data sheets, which show the physical attributes of the material, its main usage, as well as density and melting point among others. Often it is very essential if one needs to assess the quality of products or in industries that deal with the most demanding regulations such as food or pharmaceutical plastics. It is also customary for me to enquire about additional services like custom compounding, secondary services, or assistance in engineering plastic to assist in shortening the service chain.

I am also particularly passionate about assessing the pricing model especially with respect to the elements that directly impact the cost, such as delivery charges, economies of scale or user-specific discounts, and terms of payment. Of course, it is known that price is potentially the breaking point for the success of the purchase; yet it is very necessary to bear in mind that the cheapest solution is not an option when it comes to quality. This is due to that fact, that prior to reaching a purchase agreement, I ask for additional quantities, factory samples, thereby confirming that poly pellets fulfill my initial requirements. Hence, thorough inspections on applicable ICE suppliers make up for the loss of face-to-face meetings, through which effective communication and building of rapport may be achieved, and helps in finding a supplier for plastic granules in quantities that will serve the volumes of the buyer.

Understanding Packaging Options and Sizes

It’s important to know that when one is looking for poly pellets wholesale packaging, it is right there to assess sizes and types of packaging materials that the offers mainly depend on functionality the products serve. Poly pellets are usually supplied in various forms with bags or containers or break bulk i.e. containerized type of bagged pellets, depending on the preference of the user. Smaller bags are made available which range typically from few kilogrammes to about 25 – 50 lb. net and such bags are suitable where very small quantities are required to be despatched or the operations are specified. In contrast, super sacks are preferred for significant quantities since these giant bags can contain up to 1000-2000 lbs. of plastic pellets and allows faster loading and unloading, cheaper transportation cost per pounds due to volume discount.

In addition to that, when determining the packaging to use, one need to check if the product will be properly stored and handled. To elaborate, for example, FIBCs generally require lifting and moving with the use of forks or raises, I thus see to it that their is lifting aids or large container handling equipment within my premises for those relevant activities. Whereas, small bags some times can be handled manually more effectively and they are typically used in operations that has more importance to handler than the volume. Additionaly, there are packaging options that suppliers provide which serve special purposes and requirements, for instance, packing that comes with a layer that is resistant to moisture or the one with a rewarding natural staticelectrical safe barrier.

When assessing various packaging options and their potential applications, I find a way to choose the one that will help me fulfill the production targets set, but will not go beyond the terms of supply. At the stage of making decisions it is helpful to ask additional questions about packaging to the potential manufacturers rather than make do with available package and to refer to material safety data sheets. This enlightened approach makes it easy to keep the business in line, reduce the waste content, and often sustain the properties of the poly pellets throughout stocking and shipping services.

Cost-Effectiveness of Purchasing 25 Pounds

Following an extensive review and appraisal of the present market situation, I have come to a conclusion that it would be economically reasonable for me to buy 25 pounds of virgin polypropylene pellets. It should be said that the purchase of plastic pellets in larger quantities is more economical when we work out the price per pound. More often than not, very such suppliers offer bulk discounts, which contain decreasing rates to the total amount in addition to a complete qualitative enhancement of the supplied product. Besides, the increased pile of some things reduces the number of orders that are supposed to be placed in the period of stocks running out coming with saving of expenses that would have otherwise been directed to shipment and management duties. Such an approach is consistent with that of limiting costs in the process of the business operations without the need put the established standards and levels for the respective goods or services at risk.

A green and usable parameter for the value of this cost efficiency is the decreased materials wastage. My procurements will be handled within the 25-pound section range for uniformity to assist in reducing waste, enhancing good storage practices, and managing most of the subject material. Supplier analysis has it that, higher quantities mean they consist of stronger packaging that helps reduce risk of slippage or spoiling of goods during transportation, provided that the goods are brittle. This feature makes it a cost cutting measure in that the goods are saved longer hence maintained’ safety and use saving the costs of other repairs. Overall, the use of poly pellets 25-pound packages will help in achieving the set objectives, and it is a cost effective strategy which is structured with the organizational desire.

Reference Sources

- High-Energy Fuel Pellets – Discusses the properties and bulk density of polyethylene-based pellets.

- The Physical Properties and Handling Characteristics of Pelletized Biomass Materials – Explores the handling and physical characteristics of bulk pellets, including moisture content and density.

- Co-Pelletization of Corn Stover and Plastic Waste as an Alternative Fuel – Examines the blending of polyethylene with other materials to create durable bulk pellets.

- Poly Pelletizer: Recycled PET Pellets From Water Bottles – Focuses on creating polyethylene terephthalate (PET) pellets for bulk use from recycled materials.

Frequently Asked Questions (FAQs)

Moldable plastic pellets are generally safe and do not pose a risk to health as long as they are used in a way that the manufacturer has specified, this makes them suitable for the manipulation of moldable plastic sheets and pellets. Always look for evidence of the product being made in the US or a production of high-quality and test any claims of toy or soft stuffed animals safety conscientiously. Be sure to wear a respirator when melting beads or working with a thermoplastic molding compound and comply with the boiling and melting temperature guidelines to prevent the release of fumes. To sew or fill up dolls and reborn doll with plastic beads filling or some other type of stuffing such as polyfill, plastic fillers should be used to improve the life of the toy. A lot of makers typically employ the acquisition of polymorph which is a reusable thermoplastic beads to many prototypes because it can assume many shapes without shredding, making it an ideal solution.

For instance, a package of plastic pellets for crafts can help in filling cushions, pillows, dolls, and any other project where continuous weight and expansion are required. When it comes to using plastic stuffing or prime stuffing materials solely for the stuffing of quilt type weight additions or door or window shutting strip, which provides a uniform spread and can be washed in a machine. For such things as bean bags and stockings filled with corn as they are quarter inch diameter spherical pellets, poly bead and polypropylene bead are great as they are durable with a good grip quality. If you have creative projects that contain a lot of sewing, poly beads and poly-fil sewing may be used in the seams without any worries. Given the fact that for roly poly plastic frequent artisans or those getting roly poly plastic in bulk is a much cheaper variant, consider getting a 10-pound box or more.

Indeed, the concept of plastic pellets in weighted blankets is already existing in the market and is an excellent design e with prospects since this type of filling is durable, can be formed into different shapes, and provides uniform load on the users. Premium plastic pellets and beads weighted stuffing are suitable for weighted blankets and soft toys which have a need for an easily adjustable weight without the burden of it being excessively large. For filling dolls or such rehabilitating dolls, a more refined form of plastic beads or a weighting stuffing bead of a lower grade should be utilized to prevent the formation of lumps and the maintenance of a natural hang of the clothes. Many crafters may also use poly pellets to increase any pillow or cushion along with poly-fil. Make sure to read the instructions for care on the garment in order to protect machine washable parts from collapsing and the poly filling bleeding in the heat.

Polypropylene pellets are specifically a type of thermoplastic, many times classified as polypropylene pellets or poly poly pellets. They are well waterproof, strong and therefore used in various industrial and creative activities. For the purpose of rock tumbling, usa for rock tumbling shows that a different material like plastic beads can be used as an alternative because they can be using without fear with any stones. The plastic beads that uses for tumbling are very much high-grade and are able to endure keeping the cycles for long numbers of times without the particles falling off or coming apart. This is where the differences fill in as the plastic will be heated into melting pellets before being moldable while the plastic media to be used in a tumbler is not supposed to kill that shape and fuse together. Appropriate confirmation has been done with the manufacturer in order to ascertain a product to be compatible with rock grinding so as not to mess up your stones or the polishing machine.

To sew something with poly pellets you have to isolate the filling in internal pockets or when everything is made, use the stitch in type two lines to keep the plan of a bag or a doll. To achieve the desired weight of the piece, dolls use high-quality poly beads for fine filling or to fill only legs or head etc., they use pills made specially for dolls. When sewing pillows and cushions, make sure you mix poly-pellets with poly-fil or Fairfield Poly-Fil poly-pellets to make the fluff as well as the softness and support rather than letting it support one aspect. If you are thinking of sewing items that will be washed by machine, always go for water washable and good quality PP pellets as they will keep their shape after washing. Creative work such as stuffed animals or door snakes might require the incorporation of the adjacent poly beads with fabrics that will not wear out due to the friction created by the beads.

Roly poly plastic and polly plastics mostly refer to moldable plastic beads or melting pellets melted and shaped as desired when warmed and then cooled off to harden, creating individual objects that are typically useful in prototype – making or repair. Due to the fact that they can be reheated and remolded into any usable shape, these are also appreciated by a wide spectrum of diy enthusiasts. This includes painting molded plastic beads, the heating process of paint can also make them pliable and workable in one container. Teeth of various malleable plastic beads and favorable thermoplastic polymers are those which soften at a consistent temperature and may be not hazardous, but it is vital to ascertain if usable. Such products are very different than other similar containers such as professional or crafting beads or polypropylene beads-which are actually to be melted and reconstructed: they are meant to be filled. Make sure there is ventilation when using the melting pellets to stay safe, and always use the right equipment and the proper measures to keep the situation under control.