While plastics are essential in industries requiring strength, durability, and precision, high-performance materials such as PEEK and PEI have become the top picks in the field. Both materials share impeccable qualities of thermal resistance, mechanical properties, and adaptability, which virtually tie them, from aerospace industries to medical and automotive applications. But, how do the two engineering wonders stand against each other, and which one fits your application best? This guide goes through the essential differences between PEEK and PEI and their strengths, weaknesses, and applications to give you a clearer picture of their unique traits. Whether you are selecting a material for a new product or just interested in staying updated about the latest polymers, this article answers all your questions. It will help you make wise strategic decisions.

What is PEEK, and how is it used?

Understanding PEEK as a High-performance Polymer

Polyetheretherketone, usually shortened to PEEK, is a high-performance thermoplastic known for extraordinary mechanical, chemical, and thermal characteristics. It combines strength, hydrolysis resistance, and thermal stability to serve demanding aerospace, automotive, medical devices, and electronics applications. PEEK can sustain continuous operations up to 250°C (482°F) temperature without losing performance. PEEK also has wear and fatigue resistance, while standing consolidated chemical resistance, including aggressive chemicals like acid, base, and hydrocarbons.

PEEK’s highest strength-to-weight ratio and biocompatibility have made it a suitable candidate to replace titanium and stainless steel metals in medical implants. Its superior dimensional stability and low flammability make it a favorite material for demanding aerospace and automotive applications. Advances in manufacturing technologies such as injection molding and additive manufacturing continue to build on PEEK’s versatility, nudging it toward providing unlimited possibilities for engineered-to-order solutions.

Applications of PEEK in Engineering and Medical Fields

Because of its special properties, PEEK (Polyether Ether Ketone) is utilized extensively in engineering and medicine. Its strength-to-weight ratio is high. It is rated among the foremost for applications requiring the utmost performance. It is used in bearings and seals in the aerospace and automotive industries with high-precision demand for durability. Its chemical resistance also keeps it well in environments with corrosive chemicals and extreme temperatures.

In medicine, PEEK is widely studied and considered a biocompatible material for applications such as implantations, which include spinal cages, dental implants, and orthopaedic implants. Research shows that the modulus of elasticity of PEEK is close to that of human bone, thereby reducing stress shielding and aiding the induction of natural bone growth better than conventional metal implants. Also, due to the development of PEEK-based composites, it is now possible to reinforce them with carbon fibers, thereby further improving their mechanical properties while still being lightweight.

Statistics indicate a substantial growth of the global PEEK market in the coming years, driven by applications in these industries. This means that the more these industries adopt it, the more the material gets recognized for its promise in performance, long-term durability, and dynamic enhancement by next-generation technologies, such as additive manufacturing, capable of intricate design and customization of components for highly specialized applications.

Advantages of Using PEEK in 3D Printing

Polyether ether ketone (PEEK) is a high-tech polymer that has distinguished itself in the 3D printing field due to its superior mechanical properties and versatility. One of its main advantages is its strength-to-weight ratio. This quality makes it possible to create lightweight and high-strength designs, allowing for ideal aerospace and automobile manufacturing applications. Besides, PEEK can withstand high temperatures and is suitable for applications requiring parts to be used continuously under extreme temperature conditions at around 260 °C.

The other great advantage of PEEK is its highly chemical-resistant nature. The polymer doesn’t degrade when exposed to most solvents, acids, and bases, which supports its application in the medical and industrial sectors. Moreover, it presents superb dimensional stability and creep performance, which ensures steady dimensional stability in applications requiring precision, persistence, and reliability.

PEEK’s biocompatibility and sterilization capabilities inject synergy into its viability through the race in additive manufacturing in highly sensitive areas like healthcare and electronics, where implants, surgical instruments, and other devices with complex geometries can be produced. The material’s electrical insulating nature also gives it an additional advantage, making it an ideal candidate in the electronics and telecommunications sector.

Finally, the fact that PEEK is utilized with current high-end 3D printing processes, such as fused filament fabrication and selective laser sintering, allows for the manufacture of highly customized intricate designs, thus catering to the growing need for bespoke offerings across sectors. This versatility allows PEEK to remain one of the key materials in modern 3D printing.

Exploring PEI: Characteristics and Applications

Defining PEI and Its Role as an Engineering Plastic

Polyetherimide or PEI is a high-performance engineering plastic with properties imparting excellent thermal stability, mechanical strength, and chemical resistance. An amorphous thermoplastic, PEI is flame-retardant and can sustain its properties indefinitely at high application temperatures, thus supporting some rather demanding applications. PEI, with its glass transition temperature around 217°C (423°F) and good dielectric properties, is usually employed for different aerospace-related applications, as well as automotive and electronics. These properties also help PEI in applications where metal components are being replaced in lightweight and cost-efficient solutions without forfeiting human performance.

Besides offering structural applications, PEI shows good resistance to hydrocarbons, halogenated solvents, and weak acids, thus providing toughness in chemically aggressive environments. Moreover, PEI, with its low CTE, will maintain good dimensional stability during temperature variations and support processing by injection molding, extrusion, and thermoforming techniques. Combining all those features allows PEI to satisfy the stringent requirements of high-performance industry demands while simultaneously helping the cause of material efficiency, sustainability, and design flexibility.

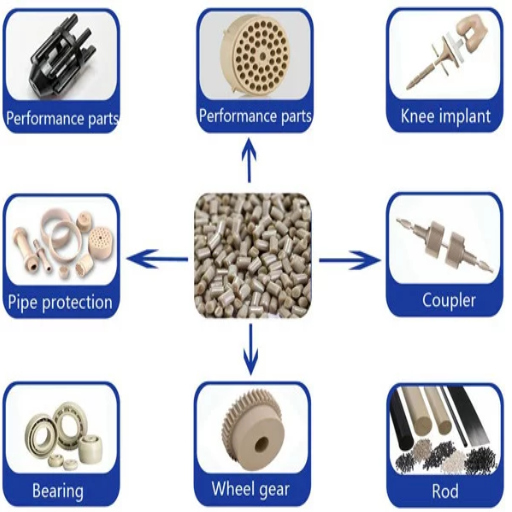

Common Uses of PEI in Industry

Polyetherimide is highly valued in several industries, emerging from its unique thermomechanical and chemical properties. Among the major uses, PEI is heavily applied in the aerospace industry for lightweight components in aircraft interiors. This reduces fuel consumption while meeting the stringent flame, smoke, and toxicity (FST) standards. Similarly, PEI is widely used in the automotive industry on various under-the-hood components such as housings, sensors, and connectors for high-temperature resistance and mechanical stresses, thus guaranteeing reliability over long life.

Additionally, PEI is picking up in the medical industry for surgical instruments, diagnostic devices, and sterilization trays. Its resistance to repeated sterilization processes, including autoclaving and chemicals, makes it suitable for medical applications. PEI gives excellent dielectric strength, flame-retardant quality, and dimensional stability to the electrical and electronic industries and is used for parts such as connectors, insulators, and circuit boards.

With the recent advances in manufacturing technologies, the possibilities for PEI applications have further widened. This, for example, includes 3D printing with PEI filaments to create highly customized and sturdy parts for prototyping and niche applications. These trends signify the ever-growing need for versatile materials that fit design criteria while fulfilling performance and environmental standards across various high-tech industries.

Comparing PEI to Ultem: Are They the Same?

Polyetherimide (PEI) and Ultem are often interchanged as synonyms, though a subtle difference exists, which is worth knowing. Ultem is a registered trademark of SABIC for its PEI products. In a nutshell, this means that all Ultem materials are a type of PEI, but not all PEI products are deemed to be Ultem. Most of the dissimilarity lies with the development and quality control processes associated with SABIC’s brand.

Chemically, PEI and Ultem are identical and share the same molecular structure, and they have similar physical properties like high heat resistance and strong mechanical strength. However, SABIC’s Ultem may also have proprietary formulations, wherein additional performance benefits could be engineered for particular application segments like aerospace or medical devices. These domain-specific grades might prove particularly beneficial in resisting heat, chemicals, or radiation.

From a performance standpoint, Ultem has a branded consistency that makes it eminently preferred by industries where reliability is paramount. For instance, a high-grade Ultem can easily withstand temperature ranges exceeding 200°C, under conditions where the material’s structural integrity must not be compromised. Generic grades of PEI, while competent, can fail to conform to the demanding global-level certifications required for many applications.

Thus, the factors of branding, proprietary standards, and possible formulations lie here. Whether designers and engineers go for Ultem or some other PEI product depends a lot on the project’s needs, the cost of Ultem, and whether Ultem has some performance attribute that will be required by their project. So, this subtle comparison reveals the versatility of PEI and its significance in advanced manufacturing today.

Comparing the Mechanical Properties of PEEK and PEI

Assessing Tensile Strength and Mechanical Strength

Regarding tensile strength, PEEK and PEI possess excellent mechanical properties, so they might be considered for demanding applications. PEEK usually offers higher tensile strengths, often recorded at 90-100 MPa, suitable for load-bearing and high-stress conditions. This immense strength is invaluable for holding up under mechanical stresses without undergoing much deformation, especially for aerospace and automotive engineering.

Having said this, PEI will allow a tensile strength in the 70-80 MPa range. It is slightly lower than PEEK but remains suitable for various engineering applications, especially where heat resistance and dimensional stability are paramount. Additionally, PEI is a go-to when interventions for transparency, lightweight, cost-effectiveness, and mechanical strength are involved.

Of course, both components will retain exceptional mechanical properties over a large temperature spectrum, with PEEK strength retained up to 250°C and PEI being functional and reliable at around 170°C. This makes it easy to understand why PEEK and PEI are often selected for different structural components and assemblies based on the operational stress and environmental considerations involved. The choice of polymer will finally rest upon which parameters of tensile strength, heat tolerance, and application concern are weighed more heavily.

Performance at Elevated Temperatures

Considering the performance at elevated temperatures, PEEK and PEI exhibit specific characteristics, making them suitable for demanding applications. PEEK must have high thermal stability, and it never gives up its mechanical strength at a continuous use temperature of 250°C, thus making it a higher extreme application in aerospace and automotive industries. PEI works perfectly at 170°C, sufficient for many applications where thermal resistance and cost must be compromised.

Studies have demonstrated the superior creep resistance of PEEK when subjected to prolonged high thermal stress, so it deforms less with time. It also resists thermal aging, essential for parts subject to temperature changes or constant exposure to high temperatures. On the other hand, PEI provides significant thermal load, dimensional stability, and insulating properties, making it ideal for electronics and electrical devices.

Both materials stand to harsh thermal cycling with little to no degradation of performance while guaranteeing reliability in applications requiring phases of elevation and reduction in temperature. Hence, they are tailored for industries where extremely high heat conditions demand precision and durability, with the choice between the two often being made for rather mundane reasons, dependent on the precise thermal and mechanical needs requested by the project.

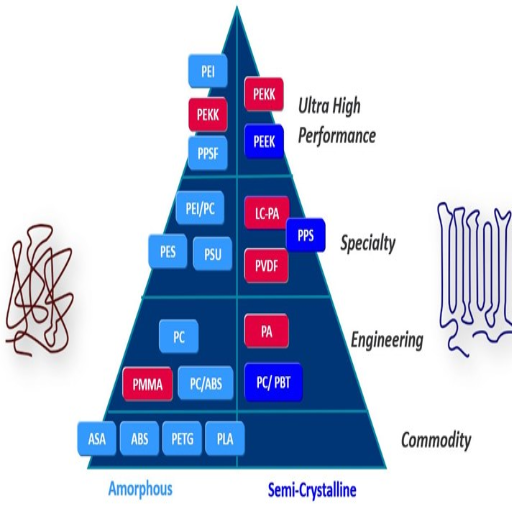

The Role of Semi-crystalline Structure in PEEK

The semi-crystalline structure of PEEK (polyether ether ketone) is an essential characteristic that distinguishes it in its applications in technical fields. An unusual molecular arrangement can balance mechanical properties, thermal stability, and chemical stability. The semi-crystalline nature occurs due to the orderly arrangement within the polymer, and these orderly regions coexist with amorphous areas to provide strength and flexibility.

One of the valuable advantages of PEEK, because of its semi-crystalline nature, is its resistance to high wear and fatigue and its ability to maintain good mechanical performance at high operating temperatures. It melts at nearly 343°C (649°F) and has its continuous service temperature set at about 260°C (500°F), making it fit for aerospace, automotive, and industrial machinery in demanding environments. Furthermore, this structure makes the material more resistant to wear and fatigue, allowing it to undergo prolonged service under severe friction-based applications such as bearing elements and pump gears.

Chemical resistance is yet another benefit owed to the semi-crystalline structure of PEEK. It can resist attack by harsh chemicals like acid, alkalis, and organic solvents without any form of degradation so that it can be used in chemical processing and medical device industries. Besides, its semi-crystalline structure provides excellent electrical insulation under thermal and electrical loads, confirming that PEEK is suitable for electronics.

Other research confirms that the crystallinity level may strongly influence the behavior of the polymer, especially where stiffness and creep resistance are key elements of the design. Altering the annealing procedure modifies the crystallinity, allowing the producer to adapt the properties to particular requirements. This adaptability still keeps PEEK high in the category of materials required in precision engineering and innovation in high-performance environments.

How Do Thermal Properties of PEEK Compare to PEI?

Glass Transition Temperature and Its Importance

The Tg of polymers satisfies a vital need in PEEK and PEI by representing the transition from mostly rigid, glass-like behavior at lower temperatures to higher flexibility and rubber-like behavior at higher temperatures. The Tg for PEEK can be broadly stated as 143°C, and PEI is comparatively lower, at about 217°C. These inherent thermal behaviors pin these materials down for different applications.

Especially for high-performance applications, it becomes crucial to consider Tg concerning operational temperatures and check if the polymer can withstand mechanical loads under those temperatures. A higher Tg means that PEEK will work excellently under severe operating conditions in aerospace, automotive, and medical fields, where the material should remain stable and not deform under heat. On the other hand, PEI, although slightly weaker in thermal resistance due to its somewhat lower Tg, can use that property in applications where the exposure to heat is comparatively less. These numbers are significant indications for design engineers and product designers to select their materials wisely, based on the performance criteria of such severe operating conditions.

Understanding High Temperature Resistance

Looking at high temperature stability with materials, a few factors come into play: chemical composition, molecular structure, and reinforcement additives. A material with strong covalent bonds, such as ceramics or specialty polymers like PEEK and PI, should feel most thermally stable by resisting release or breaking down when exposed to long-term heating. Cross-linked molecular structures also provide another mechanism of resistance by preventing material deformation at high temperatures.

Reinforcement additives like fibers of glass or carbon raise the temperature tolerance levels of these polymers in applications such as jet engines, semiconductor manufacturing, and industrial machinery. An example cited is that some PEEK composites can be used continuously at temperatures above 250°C without significantly losing mechanical properties. Such knowledge is essential for industries requiring reliable performance under extreme heat conditions, thus helping engineers and material specialists to formulate transformation solutions based on thermal-related demands.

Flammability and Thermal Stability

For high-performance polymers like PEEK (polyether ether ketone), flammability and thermal stability are all-important considerations for the more demanding applications. PEEK possesses excellent flame retardance, with very high LOI (Limiting Oxygen Index) values—usually above 35%—which means it will only burn in an environment with a much higher oxygen concentration than the normal 21%. These properties make PEEK suitable for applications in highly critical safety sectors, such as aerospace and automotive industries. Even more impressive is the ability of PEEK to garner UL 94 V-0 ratings in thin sections, giving manufacturers further confidence to specify it across a range of safety-critical components.

Regarding thermal stability, PEEK also performs superbly, retaining its properties on extended exposure to extreme temperatures. PEEK holds mechanical integrity at a continuous operating temperature of up to 250°C, thus posing as a good candidate under thermal stress. Degradation will commence at temperatures above 500°C, contributing to the polymer’s reliability concerning high thermal stability. For the oil and gas industry, for example, parts would be exposed to high temperatures and hazardous chemicals simultaneously, and they could capitalize on PEEK’s flame and thermal endurance properties. When burning, the low emission of smoke and toxic gases further endorses its use by industries concerned about product safety and the environment.

Because of PEEK’s unique ability to blend flammability resistance with the best thermal stability created a remarkable opening for material science and engineering. It is used for fabricating lightweight and durable alternatives to metals when safety and heat tolerance are at the forefront. This also leads to less maintenance cost and better operational efficiency, with manufacturers putting these into designing cutting-edge solutions that suit the extreme operating conditions. PEEK is the go-to material for any industry that does not want to compromise innovation for heat shields, insulators, or other essential components.

Applications and Limitations: PEEK vs. PEI

Choosing the Right Material for 3D-Printed Parts

I have always considered the requirements of a particular application when distinguishing between PEEK and PEI for 3D-printed parts. I pick PEEK when one requires extreme mechanical properties, high temperature, or super chemical resistance. For an environment such as aerospace or the manufacture of medical devices, where parts are forced to face extreme environments or legislative requirements, nothing can match PEEK. PEEK performs well under stresses and temperatures up to 500°F (260°C) without compromising its structural integrity, making it suitable for harsh conditions. However, the only thing I weigh in on is that it is expensive for some applications and pretty challenging to process.

I pick PEI if I need a cheaper option where performance can be compromised without hurting the design. PEI is still highly dependable, with very good temperature resistance and strength, but it is easier to process and cheaper to buy than PEEK. This makes it popular for automotive or consumer electronics applications where price efficiency is a primary consideration, together with a moderate thermal and mechanical application. PEI is also an attractive option for production scaling due to its built-in flame retardance and repeatability.

Ultimately, it depends on balancing the needs, processing capability, and budget of a given project. Considering each of these factors closely allows me to find the best-fit material to meet a functional requirement and an economic goal of any 3D printing application. PEEK and PEI have their benefits, and understanding their unique properties helps me provide the best results for every project.

Exploring PEEK and PEKK in High-performance Engineering

In high-performance engineering, PEEK (Polyetheretherketone) and PEKK (Polyetherketoneketone) are all about the highs: thermal stability, mechanical strength, and chemical resistance. PEEK commands a very special position: It has perhaps the best strength-to-weight ratio of all polymers and typically works well in extreme environments- a boon for aerospace, automotive, and medical applications. It melts at temperatures much higher, sharper than 360 °C, wear-resistant, and solvent-resistant; these characteristics give it a broader use when situations demand more complex considerations.

Compared with this, PEKK affords an even higher heat resistance and better suitability for applications requiring higher chemical compatibility. The crystallization rate of PEKK can be altered during processing to have finer control over material properties such as stiffness and toughness. Such tunability allows PEKK to be a better material for oil and gas and for industries that require highly customizable technical polymers.

In my view, the selection of PEEK and PEKK depends on the project’s needs. Typically, for applications where weight is paramount and secondary to the overall performance of the components, PEEK is the better candidate. However, where chemical resistance or thermal stability is required to the utmost level, PEKK is the most strategic option. My decision on which would best serve critical engineering needs features a close evaluation of the operating conditions and performance criteria.

Limitations and Challenges in Using PEI and PEEK

A few notable challenges have been encountered recently with using PEI and PEEK, affecting their implementation in several projects. One of the primary limitations is the high processing temperature. Molding or extruding these materials requires special equipment to handle the elevated temperatures, increasing manufacturing costs, and limiting the access of smaller businesses or educational institutions for use on their projects. This further compounds the problem of large-scale production runs that require more precise planning to realize the best outcome.

Yet another drawback is the cost. Each of these substances is a high-performance polymer, and their prices reflect their advanced features. For any project whose cost side is really stringent, these materials will not become the best economic alternative in comparison to others that are cheaper yet with a compromise in performance. Hence, more often than not, it becomes a question of balancing materials between costs and functionality.

Lastly, PEI and PEEK could be restrictive in impact-heavy uses due to their inherent stiffness and brittleness compared to more ductile materials. While their mechanical strength and thermal stability leave no room for question, their lack of elastomeric quality renders them ill-equipped for any project that requires a great deal of dynamic loading or high impact resilience. These factors are ones that I must consider thoroughly during material selection to arrive at an end product whose performance meets the expectations of the particular application.

Reference Sources

-

PEEK vs. PEI – MakeItFrom.com: A detailed comparison of material properties for both PEEK and PEI.

-

PEEK vs. Ultem® Material Matchup – Curbell Plastics: Highlights key differences, including morphological structures and applications.

-

PEI Vs. PEEK – Hony Plastic: Explains the structural differences and their implications for usage.

-

Exploring the Differences Between PEEK and PEI 9085—Mosaic Manufacturing: This paper focuses on their usability in 3D printing and other applications.

-

PEEK, PEI, PAEK, PEKK: What Does It All Mean? – Vision Miner: Discusses PEI as an alternative to PEEK and their shared high-performance characteristics.

- Top PEI Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What are the significant differences between PEI and PEEK materials?

A: PEI (Polyetherimide) and PEEK (Polyether Ether Ketone) are high-performance thermoplastics with excellent material attributes. The differences manifest in temperature resistance, chemical resistance, and mechanical properties. PEEK has higher temperature resistance, while PEI can not resist high temperatures. PEEK is further chosen where higher mechanical strength is required due to its superior chemical resistance, whereas PEI is suitable where dimensional stability and electrical properties are needed.

Q: How do PEEK and PEI compare as 3D printing materials?

A: In 3D printing, PEEK is generally selected for high temperature resistance and mechanical strength in more demanding applications. PEI is easier to print while also offering excellent dimensional stability. Both materials belong to the PAEK family of high-performance materials for 3D printing.

Q: What are the advantages of using PEEK in medical applications?

A: PEEK materials are preferred for biomedical applications owing to their biocompatibility, high mechanical strength, and chemical resistance. They are applied in implants and other medical devices whose stability and performance must be assured over a long period.

Q: Why is PEEK a high-performance thermoplastic?

A: PEEK is considered a high-performance thermoplastic due to its extraordinary material properties, such as high resistance to temperature, chemical resistance, and mechanical strength. It is capable of performing even in highly aggressive environments and hence has become a suitable candidate for the aerospace, oil and gas, and automotive fields.

Q: What are the electrical properties of PEEK and PEI?

A: Both PEEK and PEI are known for their electrical properties. PEEK is known for its excellent insulation resistance and dielectric strength, making it suitable for electrical and electronic applications. PEI also has good electrical insulating properties, and components with dimensional stability and flame resistance are often produced from PEI in the electronics industry.

Q: How does PEEK’s chemical resistance compare with PEI?

A: PEEK has superior resistance to chemicals compared to PEI. It resists almost every type of chemical, including acids and bases, and organic solvents. This makes it suitable for PEEK applications where corrosive agents are frequently used, and they do not worsen it.

Q: What is the significance of being semi-crystalline for PEEK?

A: With its semi-crystalline structure, PEEK attains high mechanical strength, chemical resistance, and thermal stability. Hence, PEEK can perform well in high-temperature and chemically aggressive environments. This makes it a preferred choice in very demanding applications.

Q: How does Ultem 9085 compare in performance with Ultem 1010?

A: Ultem 9085 and Ultem 1010 are both polyetherimide (PEI) materials, but they stand apart in their performance characteristics. Ultem 9085 is flame-retardant and has a high strength-to-weight ratio that makes it suitable for aerospace applications. Ultem 1010, by contrast, is more heat resistant and is often used in applications requiring high thermal performance.

Q: What are the typical applications of PEEK in the oil and gas industry?

A: PEEK finds applications in the oil and gas industry where the materials are needed to sustain harsh chemical and thermal environments. Typically, these can be sealing, bearing, or other components that require great performance under extreme conditions.

Q: What benefits are gained from using specialty bearing grades of PEEK?

A: Specialty bearing grades of PEEK ensure an enhanced wear resistance and low friction, making them suitable for bearing applications. These grades ensure long service life and dependable performance in aggressive environments at high temperatures, thus decreasing maintenance and downtime.