Selecting the best materials is key as regards the possibility of producing qualitative and enduring items. In this regard, ABS (Acrylonitrile Butadiene Styrene) plastic pellets are one of the most ubiquitous and versatile of all thermoplastics, having in its possession a remarkable combination of characteristics where the compromise between strength and toughness on one hand and ease of processing on the other is very modest. Irrespective of whether it is a car factory, an electronics plant or a factory dealing with toy production; it will still be possible to consider the possibility of purchasing plenty of ABS plastic pellets. Such a purchase can be considered a natural strategic step for balancing customer outcome and the cost of implementation. Conveniently, To assist manufacturers in make fact based decisions whether to buy abs pellets in large volume – this review will entail all the necessary details from assessing product specifications to identifying trustworthy suppliers. This knowledge will be useful for developing the appropriate rational ultrapure water systems.

Understanding ABS Plastic Pellets

What Are ABS Plastic Granules?

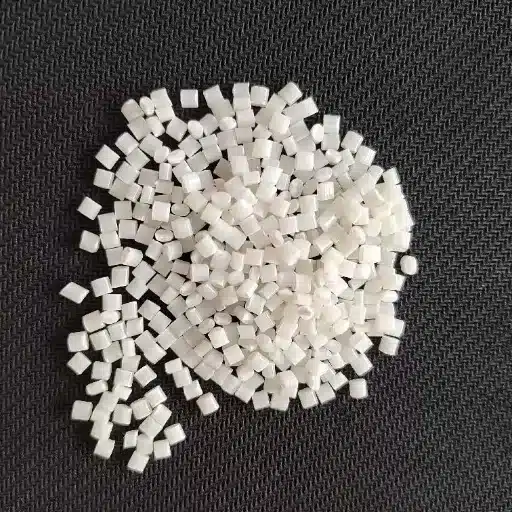

ABS plastic granules are a thermoplastic polymer that is useable in several sectors due to its very strong, tough, and flexible properties provided during processing. It is what is referred to as a three monomer polymer where the primary components are acrylonitrile, butadiene and styrene that almost guarantees excellent mechanical properties. Acrylonitrile is for excellent chemical resisting, thermal stabilizing behavior, imparting versatility and several other properties. Butadiene is used to improve the stiffness, hardness, yield strength, elongation at rupture and impact strength as well as the stamped hole elongational hole whip which other plastics that contain a urethane do wear off much easier. The other monomer is styrene that’s composed entirely of the type of monomer used. It does not contain particulate dispersed patterns. This also contributes to increasing the storage modulus, hardness and Tg of the blend. Conclusively the phase separation which is of less interest will be easily achieved thus mitigating the adverse effect caused by this phenomenon which is not desirable.

ABS is highly appreciated for its suitability for being shaped through the methods such as molding, extrusion, or even 3D printing efficiently and this is what makes it a multipurpose essential polymer for the manufacture of goods in the automotive, electronics, and consumer industries because of its superior characteristics. Additionally, ABS is available in granule form in different polymer grades having specific properties such as very high toughness, high gloss or even being non-burning. Its recycling aspect ensures that it’s in line with respect to environmental economics as it contributes to the sustainability practices in different sectors. When ABS pellets are to be acquired on large scale, their composition and properties come in handy in determination of whether they are compatible with the production line or the final product requirements.

ABS Plastic Properties

An Acronitrile or nitrile butadiene styrene (ABS) is known for its unique blend of mechanical properties along with easy of manufacturing: hence it finds usage in a number of applications in today’s manufacturing industries. It has a lot of practical use due to one major property above all which is its exceptional resistance to mechanical loading and level of pressure. This material also has very high tensile strength which is very good for structural applications.

Moving on, ABS materials have an impressive thermal performance i.e. they can function even as their Temperature of operation changes. It possesses a property of excellent dimensional stability which helps to maintain the shape of the parts produced in adverse conditions. Furthermore this polymer has a fair chemical resistance appropriate for environments where the product shall be in contact with oils or some solvents.

The next is its surface finish capabilities that are amazing. On certain occasions, it would be finished in glossy or brushed manner It depends on the requirements of the application. Additionally, the material weight is minimal, therefore, components can be produced where weight is critical yet no areas of the finished product are compromised technologically. To sum up, ABS plastic has remained the primary component for the variety of industries like automotive, electronics, as well as CPG thanks to its admirable properties and strength.

Benefits of Using ABS Pellets in Production

One of the major reasons that justify the use of ABS pellets is their thermal resistance. To be more precise, they present temperatures at molding temperatures. Hence, they are very useful in applications that require high heat conditions such as in the injection molding operation. It is true that the thermal properties are not the only benefit of ABS pellets. They also have a very high resistance capability to chemicals which makes their usage easier around such substances as oils, acids or alkali. Finished products may thus be expected to endure such harsh conditions with minimal damages.

ABS pellets are excellent in terms of a lot of desirable properties of plastics, such as toughness so that components made with them can resist high levels of mechanical loads. Automobile and construction are particularly notable, since fabrication of composites meeting certain specific performance and safety parameters is indispensable in these fields. Also, the ABS pellets have good dimensional stability that helps in making proper element placements and measurements in complex geometrical shapes according to the specifications.

ABS pellets have good elongation at breakdown and moderate quality of first cut indicating the efficient use of resources in production, thus saving expenditure and time and ensuring uniformity of products. This makes them the material of choice in many different application due to these qualities.

Types of ABS Plastic Pellets

Grades of ABS Plastic

ABS (Acrylonitrile Butadiene Styrene) plastic colors are available in different qualities mainly to fit types of applications and in industry, This types always differ with the physical and thermal properties and resistance to force which allow the specifications to widen for different applications:

General Grade: This is a cisymmetric grade that is good mostly everywhere. Meaning the balance in properties of set grade is quite suitable because there is some toughness in it but it is rigid enough to withstand some impacts. It is usually utilized in applications such as domestic applications, toys, and consumer’s goods.

High-impact Grade: Where more strength or toughness is needed, this grade can be chosen for application. In this grade the impact strength is the main concern. Some applications include segments of a motor vehicle, construction of helmets and very tough casings for electronic equipment.

Burn-resistant Types: with special flame-resistant compositions this modification is suitable for environments where inherent fire safety characteristics are needed e.g. electrical casings, or components and devices for the electronic and communication industries.

High-Temperature modification: silicones that resist higher temperatures better and shrink much less under stress will typically provide service in automotive under-the-hood applications including engines and cooling systems as well as in industrial equipment.

Electroplateable Types: These have surface properties which make them appropriate for application of metals in good quality and they can be used for decorative or natural purposes such as automobile plastic and consumer electronics.

Considering the many applications ABS pellets are used in, it is evident that each grade is formulated to satisfy the specific performance parameters or requirements of the industry.

Black ABS Pellets Continue / Natural ABS Pellets作ency

Black ABS pellets and natural ABS pellets differ because they come already colored in different forms. These pellets are black in color in any of the processing steps, there is no need for putting anymore pigment in them. As a result, the manufacturing process is made easier and more effective and it has its benefits in securing even color distribution (no overlap of colors) in the product and saves cost related to other additional pigments. Furthermore, some of these materials are also in high demand particularly if the end product has to be manufactured and has to constantly withstand UV rays like many automobile parts together with those used in making cases for pumps and even in consumer goods.

It is, however, the absence of color that is the most prevalent in natural ABS pellets. Such pellets offer a multitude of aspects to the user because their color does not limit how they can be used. It should be noted that the beige ABS is transparent removing all obstacles and that is why warranties and protection policies are achieved. Both larger and smaller batch quantities can be colored using a gambit of different pigments available on the ASB market. Moreover, a little number of grains are processed and yet the product can achieve the desired color due to the pigmentation and other methodological interventions.

Attributes such as resistance to fracture, dimensional stability, and the possibility of performing additional processing after molding conform while using either black or clear ABS particles. However, deciding on one type of ABS pellets over the other requires careful assessment of a number of items, including the aesthetic outcome, the demands put on the final product in terms of additional tasks, and costs to ensure the fulfillment of both functional and aesthetic requirements.

High flow Black ABS Pellets for Injection Molding

High efficiency injection molding is attributed to specially engineered high flow black ABS pellets. These pellets have a lower viscosity and so, they flow with ease in the mold making them suitable for molding especially in complicated shapes and those with parts that are less sturdy. This feature reduces the chances of hollow or incomplete sections being formed as components moulded will be of good quality.

Moreover, one of the appealing characteristics of high flow ABS resin pellets is that they have outstanding thermal performance, ensuring that performance is the same even after many cycles of high-temperature processing of parts. This is the reason why this material is extensively used in the industry sector like automotive parts, electric & consumer appliances casings among others where needed tight performance and low defect level are essential. They are even called ecological or environmental because they reduce manufacturing time and costs, and the authority measures aim at reducing the pollution cause by waste.

Those who wish to produce highly intricate parts should be able to take advantage of the pellets, which are characterized by good mechanical properties without sacrificing structural integrity. This emphasizes that these pellets can cope without loss with designed structural components in several industrial branches where there are both functional and design requirements.

Bulk Purchasing Considerations

Advantages of Purchasing Bulk ABS Plastic Pellets

There a number of cost benefits that come with a decision of buying ABS material pellets in a large scale: For instance, there is the reduced cost per unit. This is because every time an individual has to buy several units,they are able to get the same goods but incur a lesser cost per unit. This also spiral, round theories, and facilitates biting of the idea. Another cost saving is in the packaging since bulk always requires that less or no packaging be used. Associated charges are as well not given much thought about including the charges for packing since in any case, bulk amounts are involved. Such Pricing which suppliers use is also known as table pricing. This is when a certain % of discount gets accumulated through higher order placements subsequently enhancing the profit levels for manufacturers. The advantages have been accented, but there are also disturbing fears about shortage of supplies and limited working capital the more stock an item; the bigger the amount of funds which get locked up. Such purchasing strategy is more beneficial and can even be considered risky during periods of low production, since at least customers will stand long supply delays. It is applicable to those production activities which have stable demand and within an invisible level. However, as a caveat, it is impossible to raise the per unit quantity in order to reduce the P & L administrative costs of sourcing and management of goods and services including their transportation.

How to Look For A Reliable Supplier

Choosing a trustworthy supplier remains a crucial factor in ensuring effective flow in the supply chain activities and future growth of the company. This process starts from the verification of the supplier’s reputation and credibility in the field, which in turn requires references, case studies, or certifications. What can be helpful are the certifications such as ISO and industry-related awards or standards, which attest that the supplier maintains prescribed quality and operational levels. It should be as well noted that considering the stability of the financial records of a supplier is key. This is so because, it will involve checking the financial statements or even the financial ratios of a supplier when evaluating its stability or suitability for further engagements.

The supplier’s capacity to perform is just as critical. It is imperative to be sure that the proposed firm possesses the requisite infrastructure, workforce, and technology in order to adequately produce as per the given specifications in addition to other quality requirements. Thus it is proposed that a comprehensive quality appraisal be conducted to determine in particular the vendor’s quality conformance capabilities.

Apart from that, it is important to know the vendor’s lead time conditions and logistics tempo at day-to-day chain service, and request for such services and/or provisions only the vendor that can fit in these service chain time frames. Finally, the relationship flexibility is also important to consider for the supplier. The business relationship with a supplier should be able to adapt to the change in demand in a given period and also be able to assist in the growth of the organization.

Effective communication and proper level of transparency are the key to managing the supplier’s demands. Seek out suppliers who remain vigilant with respect to such monitoring and are communicative about issues that are bound to affect company performance such as inventory management, anticipated delays and the likes. This contrivance and adoption of coherent mechanisms although procedural seem to allow various uncertainties to be managed, supply chains to be optimised and partnership to be secured all in harmony by postponing utilization of tradeoff techniques.

Pricing for Bulk ABS Pellets: How Do They Work?

Understanding the correct pricing of Acrylonitrile Butadiene Styrene (ABS) pellets in large parts depends on many things such as buyers’ reaction to the overall price in the market place, the price of its direct ingredients, how it was made, how the material has been moving and many more. The major one of such influences is the price of oil and its products, which is not surprising since ABS has it for a base. Therefore any changes in the price of oil directly changes the cost of producing ABS and results in changes in the chain of pricing.

On the other hand, it is evident that supply chain enhancement and logistical solutions are equally important. Increasing or decreasing the shippings costs, disruption of shipments, or regional criticalities concerning the depletion of ABS is due, in manufacture capacity. The cost of ABS pellets may also retrieved by manipulating the manufacture capacities and developments in polymer technology. Before cost is found through the value set up of min use of ways and means it is paramount to the advanced generation technology when in need of some performance grades which requires investment.

Pricing is also dependent on the demand in the market especially in industries that are mainly in the automotive, electrical, and construction. It is also worth noting that there are also occasions where prices go up and start putting pressure on economies in times of high demand, particularly in high-value products like electronic materials. Such obstacles though, may be lifted as the economy shrinks or commercial activities grinds to a halt, and there is a matching decline in people’s disposable income, effectively reducing the prices.

Furthermore, there are other external dynamics which influence processes of value determination, namely regulatory elements such as those concerning ecology and foreign market policies. For instance, some raw materials become scarce due to restrictions or certain laws are enacted imposing additional burden such as carbon taxation and consequently making more expensive to produce products and trade globally thus changing import/export ABS rates. Knowing the above, helps businesses in anticipatory budgeting, securing better terms when negotiating and buying purchases at the most pocket-friendly prices.

Applications of ABS Plastic Pellets

Industries Utilizing ABS Pellets

ABS pallets are used in many different industries including automotive, electrical, and industries… ABS plastic pellets have good mechanical properties, are easy to use, and offer a high finish. As such, they are the ideal alternative for the household, leisure, or even industrial sectors to make anything that does not go through molding or casting. For example, a Section of the Cars Sector uses these pellets as they are appropriate for the following items: plastic designed intensive colored trim on the interior trims, tight retention of dash panels and bumpers and othere exterior trim that can resist impact and appeals the eyes at the same time. Same applies to the electronics and electricals industry, because of the rigorous use of ABS with constraints such as fire retardants. Graspable examples are the fabrication of enclosures and housings as well as mechanical parts.

The assembling of ABS in the customer products sector allows other lightweight and strong commodities to be made like bags, household tools and sport equipment. When applied in civil engineering one can come across designs of water, steel, or even sewers, ABS is used as it is not affected by worn out chemicals or heat. Biodegradable nature of materials makes it an environmentally friendly material, for which such material as ABS, with its high thermal biodegradation resistance has proved to be very essential now that up to stainless steel molds are in use in the production of some tapes and film. This is in fact the reasons for the extensive use of ABS plastic pellets in the processes for manufacturing in the two manufacturing industries. This also guarantees numerous surfaces of different types and purposes, from which the specified products can be made to perform the function and display the properties desired.

Some Typical Products from The ABS Plastic Family

Because of its great strength and resistance to shock and other factors affecting comparable materials,… ABS is used in almost every toy that is produced. There are some particular adornment items constructed out of ABS; then there are some high precision and good visibility electronic items constructed with it. Stepping out of the automative..the abovementioned items similarly are built from abs of barebone you need it mechanical items, sports equipments and presumably even musical instruments. ABS is ideal for making anime figures complete with glossy and detailed figures

It is also worth noting that the plastic is widely used in common household accessories like vacuum cleaner parts, all of such combine various functions with the durability. Hobbies, perhaps mainly among the children, but of course among the adults as well, are working with their hands – building with the ABS. is makes enrooting the material at far threats in the children’s product market It is also used in electrical housings and protective clothing increasingly thus exhibiting the relative significance in numerous manufacturing sectors where materials offering strength uphold design accuracy standards are required.

Effect of ABS Material on Performance of the Part

The different product segments of various industries are combined by the usage of ABS (Acrylonitrile Butadiene Styrene) material which is very popular among manufacturers. ABS has the unique characteristic of very high resistance to impact. This means that it helps products stay intact and perform their intended functions even under any mechanical toll. There are some fields where ABS materials have a great contribution in ensuring that the performance of the components is enhanced, some of such applications include automotive components among others. Apart from that there is also the fact that ABS poses excellent thermal stability and thus products made of it are able to function properly in different environments.

Aside from the durability, the fact that ABS material is light in weight reduces the load of other elements of the designing since there is no decrease in endurance, something that is critical in a field where effectiveness and minimizing costs is the ultimate goal. For example in the consumer electronics field, ABS enclosures continue to function as they are supposed to but the devices become easier to transport owing to them. Its also its resistance to corrosion by chemicals that enables products to serve for longer periods in harsh surroundings. All in all, when it comes to the parent material which is ABS, its composition makes it possible for one to achieve the required levels of art and architecture design, functional fitness and practicality, and even costs in a balance that satisfies the demands of manufacturers.

Storage and Handling of ABS Plastic Pellets

Precautions Required for Maintaining ABS Pellets’ Shelf Life

When it comes to the storage of ABS plastic pellets, I always ensure that proper environmental conditions are listed in order to keep the material quality. To begin, ABS pellets are ruinous and have a tendency to emit moisture from their surroundings, something that impairs their efficiency during manufacturing. This, thus proves why ABS plastic is tend to store in waterproof air-tight packages with desiccants and in temperature-controlled environments. The most desirable working environment usually sees around 15°C and 30°C (59°F and 86°F) normal temperatures with a humidity of less than 50%. This lowers the changes of any damages that may be caused by high shaking water.

I am also keen on ensuring that all materials are carefully handled to prevent dust or any other foreign particles from coming into contact with them. For instance, wherever possible I make sure that the pellets and ears are not exposed to open air without protection and are instead handled either by the use of clean instruments or automated assembly programs avoiding any manual handling. The bulk ABS plastic pellets are carefully put in storage bins and covered with tops that are intact and proper in all ways in a careful manner. The other usual practice is to check the packaging for any perforations or deterioration that might lead to pellets being polluted.

I also carry out inventory management and consumption of the materials on a first-in, first-out stock rotation strategy avoiding old material consumption. This is particularly important where the polymer material is used because it is protected from adverse effects for a shorter period due to the presence of aliphatic additives in its bulk properties. If these guidelines are still not working, I can quickly resolve in the absence of any other option.

When Handling Bulk ABS Plastic Materials

When working with bulk ABS plastics, It is very important to make precautions as this will help me ensure the quality of material and sync guarantee its safety. Firstly, ABS pellets I keep them free from moisture as the material is extremely prone to water which accumulates on surfaces in the form of droplets. When water gets through the pellets, the process will be affected resulting in defects like oozing and unevenness. This happens when water is absorbed by it, often leading to defects such as gassing and poor surface finish. And to avoid it, I put absorption containers inside for pellets with drying agents and, if necessary, takes measures to control the humidity level below comfort zone.

Besides this, I am careful in not exposing ABS materials to UV light or high temperatures for a lengthy period in order not to affect its mechanical properties as well as the color normalisation with time. The fact is that ABS behaves towards heat and that’s why I make sure that the storage area is not given to exceed the temperature of not more than 5°C or 30°C recommended by the manufacturer. I also see to that pallets or the containers are not placed directly on the bare ground and receive intrusion of sunlight too as an added measure of prevention of such loads.

When transporting or delivering ABS bulk components, I make sure to use appropriate protective equipment to prevent any unwanted particle or material contamination. For example, I have hermetically enclosed conveyors or suction feeders that prevent dust, dirt, and any other foreign matters from getting close to the substances perfect. Personal protection equipment (PPE) – which includes gloves and masks respirators is key in such scenario where ABS is being worked with to avoid contact with the skin and exposure to very small particles which are very convenient especially in processes which include dust. However these in depth procedures, there is also care to ensure that the life of ABS pellets remains as good as new and does not keep deteriorating with the meanderings of every manufacturing stage.

Reprocessing Of Recycled ABS Plastic Into Pellets

One of the major interesting facts about chemical recycling methods, is that it relates greatly to polymer waste and carbon oxide of which among them include Acrylonitrile Butadiene Styrene (ABS). However, the chemicals are wasted and the energy is also consumed in handling the heat necessary to cause polymer decomposition since the demand for all types of styrenes-containing co-polymers increases rapidly. By the way, the thermochemical process of depolymerization is also a typical example of acid recycling. I have already given you a clue of how acid and water pollutants affect the environment and health of homo sapiens. However the amounts of pollutants normally employed in chemical or physical waste treatment processes are clearly different in volumes.

As soon as the ABS is cleaned and sorted, it passes through a process called shredding which usually entails reducing it into small manageable pieces. The end product is usually granules, these granules are remelted and then re-extruded into ABS pellets which are of premium quality. This process involves me controlling the temperature and viscosity very hazardously so as to maintain the mechanical properties and thermal stability of the recycled material. When necessary, stabilizers, additives, and even virgin ABS could be mixed to increase the ability to recycle and function as expected in different environments by the resulting pellets. An assurance is given that the recycled products which are considered to recycling applications shall fulfil the target high performance through series of quality audits done at all levels of production areas.

In order to merge brand new ABS pellets into manufacturing processes and guarantee the overall strength as well as the durability of manufactured goods without degradation, the company is relying on most recent techniques in the field of recycling and the harshly regulated quality assurance techniques. This strategy does not only adhere to the long-standing conventions about sustainable measures but also leverages the principle of self-sufficiency in using materials and energy (circular economy) in reduction of wastage and vAL.

Reference Sources

3D Filament Production Unit Using Plastic Waste and Pellets – Discusses the production of ABS pellets and their use in extrusion processes.

Mechanical Reduction of Recycled Polymers for Extrusion and Reuse on a Campus Level – Explores polymerization methods and the properties of ABS plastics, including their resistance and applications.

Frequently Asked Questions (FAQs)

What are abs plastic pellets bulk and how do they differ from plastic resin pellets?

ABS pellet in bulk signifies a large number of plastic raw materials called as acrylonitrile butadiene styrene that are supplied to the users by marking a constant moldable quantity. They are a kind of plastic … provided in plastic resin pellet form with unique grades and performance features like toughness and low viscosity. The buyers determined to include ABS with other material options namely polycarbonate (PC) and HDPE for their production. A variety of abs colors such as black abs pellets are available for aesthetic purposes and color masterbatch for structural enhancements. Orders are typically placed in weights such as kg or lbs, and there are options for absorbing products in bags, crates, or super-sacks in manufacturers’ injection molding departments and on factory floors.

How do abs pellets behave in bulk during injection molding and for aggressive flow applications such as high temperature and high pressure molding?

ABS pellets in bulk, suitable for injection molding processes, have been optimized for mould filling to enhance the impact strength of the moulded product in addition to the strength itself. It is widely accepted that an elevated melt flow for these materials in comparison with other materials would reduce the cycle time in the machine while being detrimental to other mechanical properties. However, regarding most grades, the manufacturers are able to recommend which one to use when producing a part, concerning the aspects of the mould, the thickness of the wall and the surface quality needed, and even where extra caution is required in the processing, including the pertinent temperatures and drying times. In the case of automotive and consumer markets, choosing high quallity Chinese ABS granules suppliers or the local factories which deliver shorter production times and better quality products will improve production reliability. When placing an order, make sure to check availability, detail weights of bags (kg or lb) and designated factory price brackets for each quantity.

Can I buy the wholesale ABS black plastic dana and what are the reasonable factory price norms usually in such cases?

In fact, many manufacturers and suppliers offer the opportunity to acquire wholesale ABS Black Pellets through group orders or factory price agreements. Factory price mainly hinges on the material grade, colorant percentage of abs black, extra features such as flame retardants and UV protection enhancers, or if in general or custom resins etc The cost of sending relative to the lead-time of supply also influences the landed price, therefore many buyers hesitate to provide such details, instead requesting quotes that also incorporate pre-stuffing in bags or bulk containers and CIFnct frequency from factory or shippong point. The manufacturer should be obtained documentation of quality such as certificates of analysis, rebound testing, and physical resistance determinations. Moreover, many companies offer the cost in kg or lb and ordered goods enables setting and keeping a constant purchase voltage.

Is there any additives added to ABS granules while manufacturing molded articles?

In the production of ABS granules, it is common to modify the resin with certain additives such as impact modifiers, flame retardants, colorants, and also other stabilizers in order to tailor the plastic granules for specific applications, and to improve its chemical resistance properties. Polycarbonate (PC) is compounded with ABS and sometimes with other components to improve heat resistance and impact properties of the product, especially for automotive and electronics enclosures. Additives are selected depending on the intended application and include such categories: Automotive applications, solvent resistance, color matching, housekeeping, etc., different compounds are produced, the quantities are recorded and rationed, and the quality step is also covered by the control system. The mixture from producers can be sold in packets of various sizes on demand, and vendors can also ship bulk supplies for the processing machines at plants and factories. Before placing an order, ascertain if the additives are able to go through the same generation techniques and, if necessary, ask for samples and product specifications for preliminary tests.

Firstly how is unprocessed plastics transported and packed (what are the usual kg, lbs and bag options)?

For the ease in physically moving the goods, bulk plastic is usually delivered in the form of ABS in one of two forms; either in quantities of 25 kilograms or 50 lbs. with an easily sized up sack suitable for 500 kilograms of such materials or over in bulk bags or enclosed smaller bags and these are packed surrounded by wooden pallets for easy distribution. Also, the choice of the freight innovations as full container loads from China or factory in another region filled with cargo; LTL, when it comes to smaller pallets; high-tech systems of pneumatic tanker unloading, in the case of loose pellets, may or may not add up to a longer lsead time and higher cost. It has been noted that there different packaging more than one products in the same box options of providing the pellet to the compression machines available in the market by many manufacturers. To help in such situations different manufacturers would provide measures such as antistatic measures, compensatory measures against moisture, appropriate bagging and labelled boxes for the shops and means of delivery. And every time an order is made, buyers should determine what is actually held, the minimum requirement and how much one has to take as a minimum purchase and whether the supplier includes all necessary documentation such as MSDS and quality certification for each item ordered under the same conditions. Bulk purchases also benefit from evaluating options such as securing a wholesale price, better savings per kilogram or pounds and an improved process for purchasing more quantities in a streamlined manner.

What should be done while selecting ABS granules of an acceptable quality that will still provide a sufficient impact and longevity performance without any characteristics breaking down?

Choosing the appropriate type of acrylonitrile-butadiene-styrene material should be based on the level of toughness, strength, and processability suitable to the production conditions and tooling being used. Toughened-Abs (high impact) materials are typically suggested for products that are needed to perform and surpass failure traditional unmodified grades. ABS materials with high flow, help in the cast of difficult parts but may need additional testing with respect to long term performance. Also, it is advisable to inquire from the manufacturer the technical properties like Izod impact, heat distortion, and corrosion resistance, and perform the pulse check by asking for some trial shots on your Moulds to establish the shot times and the part appearance.