One specific example of a technique where the engineering materials used make the process possible is injection molding. This advances the production of several styles of solid material such as engineering components by often making lager amounts of shape. In this injection molding process, a huge list of diverse materials is used, ranging from herein before healthy rubber like or x-ray transmissive ultra high molecular weight polyethylene. Especially, however, ABS plastic pellets are preferred by many who undertake this process in any industrial sector. This paper is also prepared so as to answer the question as to why ABS pellets are useful in the injection molding applications, with respective to the properties of these pellets, their pros over the competitive polymers and their application in different industrial segments. ABS pellets combine efficiency and elegance, from their excellent physical and mechanical performance, their thermal stability and their aesthetics, which help in production and improve product quality. In other words, there are aspects how ABS plastic pellets will help you better to see the demands of the today’s technologies in manufacturing and also effectively participate in the changes in different industries.

Introduction to ABS Plastic and Its Composition

What is ABS Plastic?

Acrylonitrile Butadiene Styrene or what is more popularly known as ABS plastic is a tough and durable polymer being put to good use in practically almost any industry because it has very good mechanical properties, which at the same time are very easy to be worked on. In normal language the acronym alludes to the three basic chemicals constituting the ABS are acrylonitrile, butadiene and styrene. This material possesses a very unique structure which ensures both a strong and a ductile property while yet allowing it to be used in various applications which require an attractive appearance. Acrylonitrile helps in chemical resistance, butadiene gives the compound flexibility and shock resistance enhancement and styrene gives it a very smooth, hard, polished surface finish. As a result, Acrylonitrile Butadiene Styrene is well utilized in various applications such as car parts, 3d printing filaments for consumer electronics. It is learn that Acrylonitrile Butadiene Styrene can also be processed via methods such as injection molding, extrusion, and in the case of filaments, ABS materials for 3d printing. This is mainly because of the fact that the above mentioned methods this type of polymer can be with do the 3d printings, such high and precision unvolume requirements are accommodated from the usage of MP-OM-ABS materials. When you use it as an industrial material also in the field of production, due to its high level of utilization and the ease of employing a variety of additives, the optimum use of the best features of the ABS is achievable.

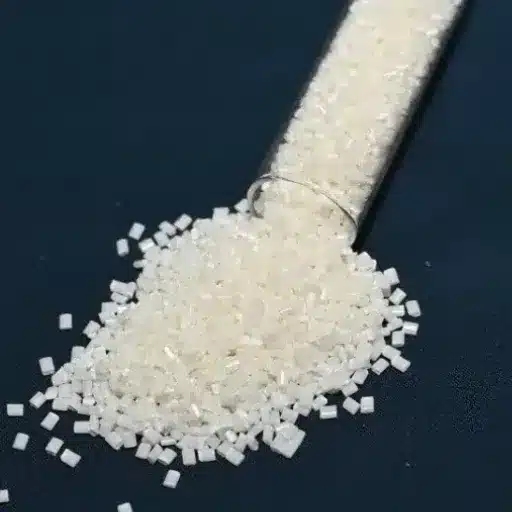

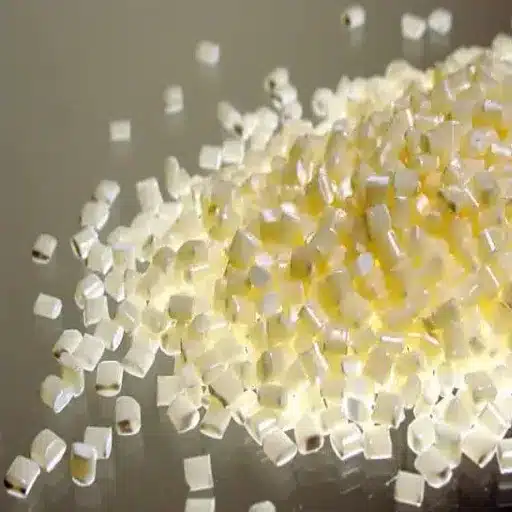

Composition of ABS Plastic Pellets

Acrylonitrile Butadiene Styrene (ABS) is a form of thermoplastic that is engineered through a specific mix of three most important monomers, as styrene, acrylonitrile and polybutadiene. The use of acrylonitrile provides the component with a degree of resistance to chemicals and enables it to be used in diverse settings characterised by high temperatures. Polybutadiene on the other hand, a synthetic rubber, plays the role of preventing damage from impact and stress either internal or environmental, rendering ABS thermal stresses proof. Finally, styrene is the main monomer that helps ABS beads to have an unblemished or untarnished finish as well as become firm if necessary as well as this monomer most especially on the surface business esthetics.

In the realm of recent science discoveries, one of the most incredible is improvements in polymer mixture science and the newfound precision which allows for the precise alteration of this substances’ contents, for instance ABS contents, with a view to their further usage in industry. Thus, in ABS which of course is a problem in period of service limitations in itself, it is common to add butadiene to increase flexibility and impact resistance of the material, and to add styrene copolymer to give the material better gloss and rigidity. Also, high-precision and high-melt materials are called instead of conductive, which have great acceptance in the market and are very popular as they provide the same results even if used in different devices such as injection, extrusion, and 3D printing.

Properties of Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS) is a polymer that falls into the category of thermoplastic and which is relatively easy to use, at least in terms of the mechanical strength, toughness, ruggedness, processing ease and cost effectiveness mix. In fact, the balance of properties of the material is so high that in most cases, it does not need additional reinforcement but remains very rigid and strong. The material also has high impact strength. It is, therefore, applied in situations where any sort of strength must be coupled with resistance to toughness. The element has a tensile strength of about 40 to 50 MPa, depending on the type of blending however its specific gravity is generally around 1.04 g cm^-3. All these properties make it to be very struible as well as light.

Thermal characteristics possess glass transition temperature of around 105°C and therefore ABS can react and perform well at moderate temperatures without significant distortion. The material has extremely low creep and strain, this mean it can withstand continuous physical tension and the shape of the design would be maintained even after years of use. In addition, ABS show fair chemical resistance where it can withstand even some acids, alkalis and certain oils although not many solvents inclusive of esters and ketones may act upon it.

Its usefulness in electronic devices is enhanced by its electrical insulating properties. That is why it is commonly used with enclosures and connectors. Also, ABS is a versatile material which can be combined with some chemical fillers, various flow promoters and other processing aids, and AL can with success be modified with service stabilizing substances, thus widening its application areas such as transportation and building. Numerous advantages contribute to the promising future of ABS.

Applications of ABS Plastic Pellets in Injection Molding

How ABS Pellets are Used in Various Industries

One of the most significant advantages of ABS plastic pellets in injection molding is their ability to remain solid, heat stable and easy to process. For example, automotive industry incorporates ABS significantly when it comes to the manufacturing of inner and outer car parts like dash, wheel cover, and side mirrors. They are also able to bear high loads and high endurance to changes in temperatures which ideally remain to be used in that case.

In the consumer electronics industry, the making of smartphone cases, laptop cases and household devices largely depends on use of ABS pellets. The polymer has optimal properties for producing sophisticated looking structures, and its properties as an insulator are used in electrics to ensure safe use of the equipment. As well as that, medicine employs medical-grade ABS to create very light equipment, such as inhalers and diagnostic tool casings, which can be washed easily.

The construction and plumbing sectors also find ABS pellets very instrumental in their setups, primarily because of their resistance to chemicals which makes it possible to create very strong piping systems that are free of leaks. There is more to the use of this material with a great deal of its use being concerned with the need to produce architectural materials that will withstand the extremes of weather; thus, it is often used in the production of window frames and sidings. The ability to modify or extend the above aspects of the ABS in conjunction with the incorporation of such additives as flame retardants that will complement will certainly make the engineering polymer So immediately effective for very specific and most demanding applications.

Advantages of Using ABS Plastic in Injection Molding

Acrylonitrile Butadiene Styrene plastic commonly referred to as ABS plastics is a material that has distinct advantages when used in the process of injection molding among other thermoplastic materials. This makes it among the most used materials in the production of goods in various industries. One of its key advantages includes the readily availability to low temperatures below its melting point and the high plasticity and ensure that it is possible efficiently to mold even the most difficult geometric shapes. Due to these unique characteristics all the above makes ABS most preferred in manufacturing the components which require very thin geometrical finishing.

In addition to this, it is known that ABS has an amazing ability to resist impact and high resistance to tearing making sure that all the moulded components are strong enough to withstand mechanical loads. Its tolerance of shapes in the environmental induced constraints most specifically the lower temperatures points out to its endurance and functionality in harsh conditions. The fact that ABS plastic is capable of supporting various forms of finishes such as gloss or matt, makes it useful when it comes to aesthetical or functional product design.

Additives compatibility with the material, such as UV stabilizers and flame inhibitors, provide the material increased performance in applications areas it is requested while at the same time activities reliability. Moreover, ABS is a plastic which is capable of delivering crucial mechanical properties where it weighs less hence minimizing material and production costs and most popularly, it can be recycled to encourage sustainable production processes. Such combination of properties has made ABS a material that is effective, performs well, and is cost-efficient in this day and age towards plastic fabrication through molding techniques.

Benefits of ABS Plastic Pellets

High Impact Resistance and Toughness

One of the reasons why ABS plastic granules has dominated the engineering plastics market is their unbeatable toughness and impact strength that can stand the most severe treatment in the applications. The mechanical properties of these materials are achieved due to the presence of acrylonitrile, butadiene, and styrene in the polymer matrix. The component butadiene accommodated within the material brings the most carbs for energy dissipation as well as resists the growth of any cracks in the material. As an example, ABS has an impact strength level of 200 to 400 J/m under normal circumstances, and stress and residual force are likely to crack the material to increase the impact strength with particles is very high changes. This is especially essential in elements such as vehicle parts, suitcases and accessories of electronic appliances, as it is a requirement for them to work even in adverse conditions. The latter is beneficial for maintaining the performance capabilities of the material and strength very well in the best and the worst of situations. As such, the material is aptly designed: there is no excessive rigidity or softness due to torture or abuse.

Versatility in Design and Manufacturing

Acrylonitrile Butadiene Styrene or ABS is incredibly versatile in its many design and manufacturing applications and is hence a popular choice in numerous industries. Its ease of forming and working character of, permits the production of highly complicated shapes and patterns with great geometrical certitude. Moreover, it is possible to incorporate other polymeric substances in or modify ABS plastic in order to achieve greater features such as, for example, impacts strength, UV resistance, fire resistance, and so on, supporting specific types of its applications. These applications can also include a number of enhancing additives that allow the use of ABS molding on so innovative areas as integrating plastic into 3D printers, extruders or injection molding machines. With all of said features, ABS cannot be found lacking especially in environments such as Wireless Communication, Auto mobiles, and Building and Construction where more customized designs together with efficient performance is needed.

Easy Processing and Melt Flow Characteristics

When you consider the material properties of ABS (Acrylonitrile Butadiene Styrene), one can say that it is celebrated for its ease of use and applicability across different fabrication processes, because it has excellent mlfowing characteristics. heat and material mass are composed of the better part of the ease of application, as it has a low melting point, that is typically estimated between hot 200C ad 250, which makes it quite easy to process in spite of the heat. This characteristic entails that the material is easy flowing during the processes of molding such that defects like warping or sinking are rarely witnessed which invariably leads to improved quality of production, handling of the materials and execution of projects. This partners with a mold ‘s reluctance to induce defects which may be attributed to the property of the material most known as shear thinning. Even molds with intricate designs and micro features are able to fill up because of this behavior of the ABS. The above characteristics do not lead to efficiency in the manufacturing of components only; they also help in the alterations of the material in order that it may have the requirements in regards to attributes such as the angle of friction and dimension.

Comparison with Other Plastic Materials

ABS vs. Polypropylene: Key Differences

ABS and polypropylene are two materials which are made from thermal resistance thermosetting polymer. The two materials: ABS and polypropylene are both characterized by their features that facilitate their use in different areas. ABS demonstrated extremely high tensile and impact strength, all why it is best material option to automotive components, consumer electronics enclosures, and material used for 3D printing. Also, ABS has a high modulus of elasticity and good inherent torque, which is essential for administrative sections.

One of the highest advantages of polypropylene in comparison to ABS is the resistance to most chemicals and its ability to be shaped. It has the potential to have less material weigh and costs since it has a deteriorated density than that of ABS. This polymer often adds strength to plastics, and as such, it is used in consumer equipment and food containers as well as the plumbing systems. This is because it can stand in all constraints without any further wear and tear being added by moisture, or acids, or aqueous alkali. Fatigue resistance is also high enough to tolerate these shifts therefore it is ideal for living hinges or containers you continue to keep using every day.

But, it is important to realize that despite their differences, these materials also offer overlapping benefits such as being easily moulded and reused. The decision of whether to use ABS or polypropylene is also influenced by the type of computations and applications to be conducted in the environment, as well as the cost limitation.

Performance of ABS Compared to Nylon and PVC

While assessing ABS compared to PVC and even Nylon, a set of important criteria should be taken on board, namely mechanical, thermal, chemical, and resistance to aggressive conditions/durability performance characteristics. ABS has an impressive shear and impact strength, so it is an ideal material for applications which call for it not to snap or yield under a certain force. Yet, when it comes to resistance to heat, ABS is not as good as Nylon whose glass transition temperature is higher and to this end is more appropriate for applications in which heat insulation is maintained for a long period, such as electricity and fire insulation.

As far as resistance to different chemicals is concerned, the ones posed to the environment are PVC and ABS. Luckily, PVC has shown the best resistance to acid, alkali and many chemical substances, and most importantly, high flexibility in its usage e.g. piping, chemical tanks and even being used in outdoor settings. Nylon, as it contributes a decent resistance to chemicals as well, has the capacity to provide better friction and wear characteristics, making it an excellent option for mechanical and automotive devices with moving components. Even though Nylon is a suitable material to use in frisbee bowls, the fact that it pulls water leads to swelling making it an unsuitable material for any Age-Base. Cellsider for PVC and ABS because they don’t swell.

ABS’s easy machinability and availability in a large choice of finishing enables industry designers to have more freedom in designing. PVC and Nylon are two materials that do put forward various positive points in performance optimization, fabrication of these plastics normally comes to the consideration of the costs of operation, specific service environments, and the expected structural responses. To make sure that performance remains a concern of practive for an end-use situation, each option must be scrutinized carefully with all its limitations and liabilities.

Cost-Effectiveness of Using ABS Over Other Resins

Acrylonitrile Butadiene Styrene (ABS) has earned a reputation as an inexpensive thermoplastic material due to its properties and ease of manufacturing. ABS provides the best of both worlds with its mechanical properties, longevity, ease of use and processability at a lower price when compared with most of the high end engineering resins such as Polycarbonate or PEEK. It experiences a lower melting point and has excellent mould flow characteristics which is why it is highly suited for injection moulding without a significant injection energy demand which would have been very costly. It can be used in warm applications which help to cure the molded parts more quickly or more deeply and the mold cost is the second most costly post a build. Besides, its applicability to various fabricating methods including those such as 3D printing increases the margin of designing prototypes and making small quantities of unique products therefore bringing down the cost of the projects.

Another important aspect is that items produced out of ABS have significantly reduced maintenance costs since the material has exceptional resistance to impact as well as appreciable dimensional stability. It is also important that ABS is widely distributed throughout the world, in demand and sometimes available in secondary, i.e. recycled or re-grind, sources. Such an advantage enables the manufacturers to economize on raw materials even more, being in compliance with environmental standards, with ABS plastic being the most suitable material in most cases. All the above reasons make ABS the best option cost-wise for very many consumer electronics, automotive, and industrial areas. However, the economic depression has to be estimated in relation to performance parameters in order to confirm the possibility of using the material in a particular situation or when making a certain type of enclosures.

Environmental Considerations and Reusability of ABS Pellets

Recycling and Sustainability of ABS Plastic

Acrylonitrile butadiene styrene (ABS) appears to be a type of polymer that can be used in the sustainable development of various industries if properly processed. ABS can be recycled. In the sense that minimal damage is done to it and at a quality that is sufficient for it to be incorporated into production again. Sometimes, the production of ABS might be composed of recycled one at the level of such items as car parts, building elements or objects of everyday use, which demonstrates a wide spectrum of applications and a bigger chance of reducing the environmental degradation. This process of reusing ABS material comes with its fair share of challenges, such as the need for specific installations that handle ABS, where it has to be collected, cleaned, and appropriately cooled so that its quality would not be affected when subsequent reusages are done.

Also, the life cycle of ABS plastic is an important determinant of its sustainability. The entities that have infused the use of recycled ABS in their networks have made a significant contribution to the concept of Tierra Circular within these companies, hence, a substantial decrease in unprocessed raw material use that is normally synthesized from petroleum can be expected. However, since ABS never their breakdown time and landfilling is at a prevalence, there’s the possibility that again in the long run, disposal of mismanaged ABS can lead to waste accumulation. As a means of fighting these issues, solutions such as the chemical recycling methods that are aimed at making it possible to achieve the destruction of ABS by its molecular ingredients thus making the ABS easy to recycle also without that harm to the environment are in the process of being worked on. In the future, the establishment of the broad use of systems of fast disposal of waste and the tackling of the problem of eco-friendly polymer manufacturing will require the most attention for the improvement of the ecological characteristics of ABS.

Impact of ABS on the Environment

It is not uncommon, therefore, that the environment and the life-systems have been strongly negatively affected as the widespread use of acrylonitrile butadiene styrene (ABS) has created problems related to its adaptability in modern producing structures, as well as factors hindering its degradation. Acrylonitrile butadiene styrene is a glassy and rigid engineering plastic known for its ability to withstand mechanical strains, dispersion of stresses even at weak junctions. Such qualities are appreciated in automotive, electronics, and even consumer products—like children’s toys and small home appliances. Nonetheless, as it happens to be non-degradable, old or no longer needed products made of this material, such as ABS articles, are deposited in the environment where they remain for a long time leading to long term landfill overlay. Last but not least, when used improperly, plastic’s degradation or incineration can result in the emission of dangerous compounds hence enhancing the pollution even more.

The production of ABS is long and difficult to automate and requires a tremendous amount of energy which is mostly in the form of fossil fuels like oil and gas, causing the production of unwanted harmful greenhouse gas emissions leading to the worsening of the earth’s climate. Also rapid advances in modem science and technology increase the production volumes and reduction of negative effects. The development of microelectronics, the chemicals used in this technology and the mentioned recycling of fr contains a number of economic, social and environmental barriers at all levels of the problem. Trapped in enormous patents fees, such innovative products are nearly buried.attered waste. This problem has deterred the recycling of most of the plastics.

This event is essential for us as we hope that the rejection of such plastics as the very concept of Plastic Recycling is not final. Indeed, it is virtually impossible for companies and governments to stop producing plastics altogether with such a concerted demand for plastics worldwide. This is among many other concerns addressed in Stranded Assets, one of the conclusions; the other is to make useful things out of what would have been waste. Plastic consumption with population increase and related demand for plastics to provide the needs of a significant part of the earth’s people is a complex and. With Stephen McCaffrey this dilemma takes the form of conflicting goals present in the Law of the Commons – legal waste and illegal encroachment. The party to which these goals correspond must be injured. A consumption driven society inevitably leads to frustration and anger during the time of abundance. This in turn raises the question of distribution and the allocation of the available resources.

Future of ABS in Eco-Friendly Manufacturing

In my opinion, advancements in material science and recycling technologies are the major drivers that will bring changes on how ABS is utilized in eco-friendly manufacturing. If possible, I suggest environmentalists and the plastic materials sector take ABS plastics as a unit project for their primary objective is to strive towards a complete recycling. This is achieved by continuing to process ABS plastics into high grade materials with no evident change in the performance of the material. This not only reduces waste but also declines the use of fossil fuels used to manufacture virgin ABS. New ways of recycling should be explored such as chemical recycling for example depolymerization which is at its best when swapping faces of post consumer ABS plastic material with its monomers through detaching and separating them for the entailed purpose of repolymerizing with very little loss in the materials properties.

Furthermore, bio-based ABS products are being produced as an environmentally friendly substitute for conventional plastics. With the adoption of PLA and similar plant-derived polymers as bio feedstocks, it is now possible to develop formulations that ensure the melt strength of regular ABS is met while meeting at least half the carbon footprint of conventional ABS. Concurrently with the progress made in material design, regulation as well as shared actions on sustainability challenges are expected to accelerate such changes, as companies encounter the requirements go for more eco-friendly practices and contribute towards circular economy efforts.

I am able to forecast things closing up or coming closer in the future with a positive angle, attributing it to the force of consumer demand. The power of environmental cause has moved producers into integrating the sustenance capacity of their production. Beautiful closed loop production following beautiful recycling solutions in particular offers a connection between raw material and the material after use. Because I believe that with the advancement of technology, legislation and ethics the role of Acrylonitrile Butadiene Styrene will be played by it in the future economy, but this time with a lot less commitment to human disturbance.

Reference Sources

- Comparison of Injection Molded ABS Using Conventional Steel – Missouri University of Science and Technology.

- Comparison of Part Weight in Injection Molding – Iowa State University.

- The Comparison of the Mechanical Characteristics of ABS – Scientific Research Publishing.

Frequently Asked Questions (FAQs)

What are the ABS pellets needed in injection molding?

ABS pellets could be defined as small beads of some acrylonitrile butadiene styrene copolymeric resin which is considered as one of the most frequent plastics used in plastic injection molding techniques. They are effectively dried resin pellets that are either in their original or a recycled form. They are often shaped into pellets, which are then placed into an injection molding machine to be melted for filling the mold. This mechanical polymer boasts of very good chemical resistance and dimensional stability, very good impact strength as well as glossiness rendering it suitable for the manufacture of a variety of end products. Each manufacturer provides ABS pellets in appropriate grades suitable for manufacturing appliance, automobile, cab, toys and decorative items, and some are in the form of raw pellets especially for 3D printing or extrusion. The definition should also include certain studies and measurements, such as density, flow rate (melt flow) and shrinkage, that would help processing molders to be able to minimize defects and meet quality goals.

How does ABS thermoplastic behave under temperature?

ABS is a thermoplastic. It softens when exposed to heat, and hardens when cooled, which is beneficial particularly for such applications as plastic injection molding and extrusion wherein the thermoplastic is used over and over again. Its heat resistance is reduced as compared to such engineered polymers as PC or acetal. Clients should always bear in mind the range of temperatures in which the structure will operate, as this will help in avoiding service failures on account of deformation or lack of strength. The hot melt and casting temperatures also effect the melt flow index, which in turn influence machine ability and such effects as sinking or weld lines when the process window is over. Because of this, ABS experiences no substantial dimensional changes under typical room-temperature conditions and this provides adequate resistance to impact for such applications as panels, housings, protective devices and headgears. Not all thermoplastics like PC or certain types of modified copolymers would be suitable for high-temperature work.

May the black ABS resin pellets be used to manufacture and automotive components?

The majority of automotive components including much of the interior and even the exterior wheel covers utilize ABS black cause of its tough surface, nice luster and good color uniformity. Generally, it is used for making automotive body parts and accessory items for higher impression strength and as well ensures stability against unraveling under pressure for ease of use on huge industrial injection moulding systems. It can perform well in harsh conditions and assure precision in VAZ parts fitting, except for some locations like oils and humidity under the bonnet where it is more reasonable to elastomerize ABS or combine it with polycarbonate or other high temperature thermoplastic materials. This is why characteristics including grade, density and shrinkage can be disclosed by manufacturers in the course of certain form of such acceptance standards towards achieved finish for assembly of the final product. Apart from an edifying spiel using black ABS for selecting 3D modeling materials, the claimed pellets produced from the black ABS are also used for stereolithography 3D printing or ABS filaments for FDM 3D printers to make working models with the same outlook as metal ones with the same strength.

What are the properties of ABS that affect melt rate and moldability?

There are numerous factors, such as composition (acrylonitrile, butadiene and styrene) of ABS, melt flow index (valuable for thin sections, e.g., parts) and density (with an influence on both weight and cooling speed), affecting the rate of melting and thus the requirements regarding the injection molding process. This also has to do with how the impact strength, gloss and heat stability would be influenced by their copolymer structure and certain ingredients added to ABS, allowing to control how much shrinkage and how many traskosvinok arise. Those factors include the layout of the mold, the level of the injection speed utilized, and temperature control within the injection mold. Specifically, thermoplastic ABS is efficient for general purposed usage and most often is used for the remediation of parts. However, it happens that more difficult to – fulfill applications are suited for such materials as polyethylene, polycarbonate or acetal based on the mechanical and thermal requirements. In addition, due to the standard/product enhancement obsession, the suppliers provide the representatives with a specific setting of recommended processing windows that would ensure minimize flow difficulty during mold filling.

Are virgin ABS granule and copolymer grades more durable for industrial parts?

Virgin ABS granules grades typically have a better uniformity, lower contamination and better physical appearance unlike recyled or reprocessed materials. This is because in such applications, defect free surfaces and repeatable mechanical responses are required. Particular copolymer families, however, can be tailored to provide specific characteristics for example improving the impact resistance or heat distortion temperatures of the finished part for protective or structural electronic or electroinc housings. For engineering components having a high loading/formulation, PMMA reinforced grades or polycarbonate blends, with or without modified overlapping formulations are commonly used to comply with toughness requirements for automotive and industrial applications. Blends susceptible to mechanical recycling will be more complicated to process if used, except in case of blow molding and/or pipe extrusion. It is essential to always consult pertinent material safety data sheets when considering a polymer for extrusion applications so that suitable processing conditions can be adhered and not be pushed for many polymers, especially for those for lighter density grades.

What limitations and defect risks should be considered with ABS plastic material?

ABS exterior has particular properties that makes them less effective than other types of plastics of right away: it cannot withstand high temperatures as high-performance plastics do, it is resistant to some chemicals and may be sensitized to certain processing conditions leading to appearance of defects such as sink marks, voids, or flow pattern lines. Nonetheless, the dimensional stability is estimated as normal, but taking into account that every product shrinks during the cooling process after compression of the plastic molding compound, the designer should build essential shrinkage allowance into the cavity/pattern in order to meet the dimensional requirements of the enclosures, panels or electrical housings. Additionally, the surface appearance and the smoothness of molds depend on the mold temperature and the cooling rate and since only compounds the need for a consistent process in the critical area of decorative parts and playthings. However, their limitations are as well such that it is difficult to promise them to highly corrosive environments, very long term outdoor or harmful exposure to both temperature and ultraviolet radiation; in such cases, materials which can resist high temperatures solvents and U. V would be suggested position like ‘acrylic, polyethylene or blends of PC. Beyond that, using caution and ordering the suitable grade and melt index of the right products saves time and ensures that, at the end of the injection molding process, the so produced products are both attractive and functional devoid of any defects.