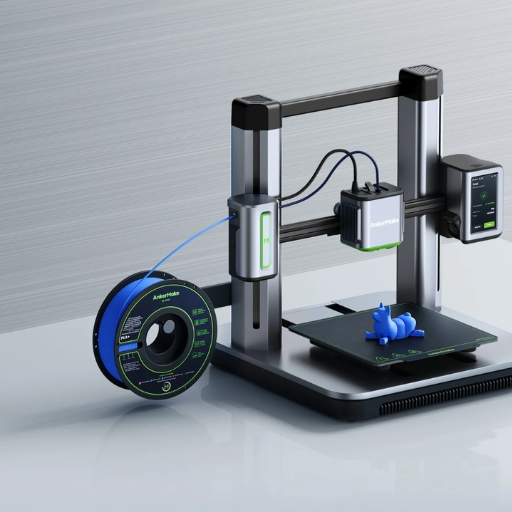

Choosing the right filament for 3D printing can mean the difference between an immaculate centerpiece and a barren, featureless wasteland. As with everything in life, there is more than one option, which begs the age-old question on every 3D printing enthusiast’s lips: which one should I choose? Two of the most well-known options, ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid), both have their pros and cons associated with them. In this article, we review the most important factors of both types of filaments, their uses, and the outcomes one can expect, so you don’t have to make the same mistakes we did. Whether you’re an expert or new to the game, we’ve got you covered with all the information you need to capture the essence of 3D printing. Arm yourself with one critical piece of information – the decisive differences between the two filaments, and get ready to explode the possibilities for your next project.

What are the material properties of PLA and ABS?

Both PLA and ABS materials are widely used in 3D printing due to their unique properties.

- PLA (Polylactic Acid):

- It is sourced from renewable materials like sugarcane or cornstarch, which makes it biodegradable.

- It can be printed easily as it has a low melting temperature (approx. 190-220°C).

- It adheres to the printing surface with minimal warping, producing precise and smooth prints.

- Compared to ABS, it is less durable and heat resistant since it softens at around 60°C.

- ABS (Acrylonitrile Butadiene Styrene):

- It is non-biodegradable as it is derived from petroleum.

- It has a high melting temperature (approx. 210-250°C), therefore requiring a heated bed for printing.

- It is more durable and impact-resistant, making it ideal for functional parts.

-

During printing, it is prone to warping, which emits fumes, so good ventilation is required.

Knowing these qualities aids in selecting the ideal material for your project while factoring in its longevity, printability, and ecological impact.

Understanding the difference between PLA and ABS

While comparing PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene), bear in mind their characteristics, uses, and ecological factors to form the best conclusion for your project:

1. Physical Properties

- Strength and Durability:

- PLA’s tensile strength is moderate; however, it is brittle in nature, which makes it apt for ornamental or low-stress applications.

- However, ABS is tough and impact-resistant, making it well-suited for functional parts and prototypes that undergo physical stress.

- Temperature Resistance:

- Due to ABS having a lower temperature softening threshold of 60°C, its application in high-temperature environments is restricted.

-

Weakness against heat is absent when considering ABS, as it is able to maintain structural strength and integrity up to ~100°C.

2. Ease of Printing

- PLA poses very little trouble when printing because of its lower melting temperature of 180-220°C. This not only decreases the chances of warping but also makes PLA very beginner-friendly.

-

Advanced setups are required for successful printing of ABS due to its need for higher printing temperatures (210-250°C) and a heated bed to prevent warping.

3. Environmental Impact

- Because PLA is made from renewable resources such as cornstarch or sugarcane, it is biodegradable and poses less threat to the environment.

- Unlike PLA, ABS is derived from petroleum, which makes it non-biodegradable and contributes to greater environmental damage. Nonetheless, it can be recycled in certain situations.

4. Applications

- Due to its ease of processing and smooth surface finish, PLA is frequently used for all-appearance projects, prototypes, toys, and model displays.

-

Because of its great strength and durability, ABS is widely used in the manufacture of mechanical and automotive parts as well as their enclosures.

Your project requirements will determine whether you opt for PLA or ABS. Take into account stress, heat, surrounding conditions, and eco-friendly needs. Every material has its uses, like PLA’s emission of harmful chemicals and ABS’s strength for tough tasks.

Comparing the mechanical properties of PLA and ABS

It is essential to compare the mechanical properties, including strength, flexibility, and durability, of PLA and ABS to analyze the differences between the two materials.

Tensile Strength: Except for some applications that require impact resistance, PLA, with its higher tensile strength of 60 MPa, is a better option compared to ABS, whose tensile strength lies between 30-45 MPa. It is safe to say that ABS compensates for this lack of strength with greater toughness. PLA is ideal for parts that require rigidity and stability, whereas ABS serves its purpose better in impact-prone environments.

Flexural Strength and Elongation: ABS far surpasses PLA when it comes to coming if increasing flexibility. However, PLA is more brittle with stronger average flexural strength values of 83 MPa. In terms of bending without breaking, ABS outperforms PLA, with a lower borderline flexural strength of 70 MPa. Owing to these characteristics, ABS is better suited for objects subjected to physical stress.

Impact Resistance: Impact resistance is an area where PLA is strong and tends to be weak. Materials such as automotive and electronic device housings are made using super-strong and highly resistant components. These devices and appliances must withstand severe shocks and vibrations during daily use. It would be safer to say that the absence of mechanical shock resistance makes PLA weak, and the impact shock resistance makes it strong.

Resistance to Heat: Unlike PLA, which has a heat deflection temperature between 50-60°C, ABS can tolerate substantially higher temperatures (~90 °C, true to its heat deflection temperature). Therefore, PLA’s use in high-temperature zones is quite restricted.

Weight: Compared to SPLA (Polylactic Acid), ABS is lighter because PLA weighs more at 1.24 g/cm³, while ABS is 1.04 g/cm³. This makes parts made from ABS more desirable for employment in low-weight-sensitive environments.

Tailoring the work of a project to be done in ABS/PLA as the materials used must correlate with the goals of a specific project. Suppose someone is focusing on enhanced aesthetics coupled with environmentally friendly materials. In that case, PLA is a good contender, but for sustained exposure to impact, heat, and relentless stress, ABS is more effective.

How does acrylonitrile butadiene styrene perform?

Acrylonitrile butadiene styrene, commonly known as ABS, is one of the most widely used plastics today due to its exceptional mechanical properties. For example, it has impressive impact resistance, meaning it can withstand shocks or drops without cracking. This durability has made ABS one of the preferred choices in the modern automotive industry, construction and for electronics. Additionally, ABS has high deflection temperatures of 90 to 105 °C, allowing it to maintain its physical shape during moderately hot conditions.

ABS can further enhance its applicability in machine work due to the offered versatility and ease of working with it. Regardless of the performed action, whether it’s post-processed, painted, or sanded, the outcome is always improved aesthetics. And, despite its strength, rigidity, and temperature resistance, it still possesses decent flexibility. On the environmental side, it is great that ABS is non-biodegradable, but also concerning due to the fumes emitted when melted, indicating that safety measures and eco-friendly actions are necessary when working with ABS.

How to choose between ABS and PLA for your 3D printing project?

Here are some key things to understand before deciding between ABS and PLA for your 3D printing project:

- Strength and Durability: For long-term use and impact resistance, ABS is ideal, while PLA is more suitable for decorative items and less durable prototypes.

- Ease of Use: PLA is the easier of the two to work with as it does not require a specialized heated bed, nor does it produce excessive fumes while being printed.

- Environmental Impact: ABS does not rank highly in terms of its environmental impact and pollution, whereas PLA is biodegradable and can be considered eco-friendly.

- Heat Resistance: Items exposed to warm conditions are better suited for ABS as it has greater heat resistance, whereas PLA can deform under heat.

- Post-Processing: Elastomer blends of styrene (ABS) exhibit greater flexibility during sanding and painting, making post-processing easier. In contrast, PLA is more rigid, which limits its scope for post-processing.

Select according to your project needs, considering durability, printability, and ecological factors.

When to use PLA over ABS?

The following is an easily gleaned overview of PLA filament.

PLA is an excellent filament for prototyping due to its ease of use, environmental friendliness, and aesthetic-led features. PLA, as a filament, is often used in prototype models due to its exceptional biodegradability. Because its printing temperature is approximately between 190-220°C, and it is less likely to warp when compared to other materials like ABS, it offers success in printing with minimal challenges for novice users.

For models requiring precision and high surface finishing, it is recommended that PLA be used since it provides a smooth finish with less post-processing having to be done owing to its rigidity and strong cooling features. PLA appears to perform best on decorative items, snapshot models, or lightweight things because where supreme strength is not so critical. Also, the fact that PLA has a low-level odor means that it does not stink, nor is it harmful when used for printing in closed rooms.

Instruments of evaluation targeting educators and hobbyists show specific benefits which include lack of undue strength requirement, thermal resistance, or unexplainable long-term durability as well as broad compatibility with almost every 3D printer all while sustaining caring for the environment.

Situations where ABS offers advantages

Its strength, durability, and impact resistance make ABS (Acrylonitrile Butadiene Styrene) one of the most widely recognized materials fit for applications that require robustness. STRONG. Its high melting point enables it to endure elevated temperatures without losing structural integrity, making it extremely useful for heat-exposed components like electronic housings and automotive parts. In addition, ABS is very machinable, making sanding, paint application, and even drilling, post-processing tasks effective and simple.

In comparison to PLA’s impact resistance, ABS does approximately 3 to 5 times better, which makes it suitable for industrial prototypes, mechanical parts, or functional tools. Its ability to withstand rough use makes it ideal for outdoor applications such as sports equipment or garden tools. Not to mention, ABS also shows good chemical resistance, making it useful in applications where contact with oils, acids, and other industrial chemicals is inevitable.

Because of needing a higher printing temperature (usually 210-250°C) and having an uncontained environment which leads to alteration, advanced printers with heated beds and enclosures work well combating these issues. The long term integrity makes ABS the ideal material for professionals requiring reliable and enduring 3D prints.

Considering print temperature in your decision

Recognizing the importance of temperature settings and their implications on print quality, layer adhesion, and material strength is critical when evaluating print temperature. For example, PLA is easier to print since its material temperature ranges between 190-220°C, making it more suitable for novices. Conversely, as previously noted, ABS and Nylon require significantly higher temperatures (between 210-250°C for optimal ABS performance and 260 °C and above) due to their robust mechanical properties. Polycarbonate also falls under the same category.

Research indicates how critical avoiding overheating or underheating is for avoiding stringing, warping, or inter-layer bonding issues. Modern printers that come with temperature sensors and adjustable heaters cater to such needs. Moreover, the development of heated beds and enclosures has simplified managing issues related to high-temperature materials such as ABS or PETG. These factors necessitate assessing a filament’s material to ensure a printer is capable of operating at a safe yet effective temperature range without undermining safety or print quality.

What are the printing requirements for PLA and ABS?

Printing Requirements for PLA and ABS

- PLA:

- Printing temperature ranges from 190°C to 220°C.

- Bed temperature ranges from 20°C to 60°C. (Printing is often successful on an unheated bed). . . .

- PLA needs adequate cooling in order to improve the quality of the prints.

- Easy to print with slight warping.

- ABS:

- Printing temperature ranges from: 80°C to 110°C (a heated bed is needed to prevent warping).

- Best printed in enclosed compartments for improved control of temperatures and reduced air currents.

-

Adhesion aids can be glue sticks or Kapton tape, as they help prevent lifting.

Optimal PLA filament settings

Using a fan enhances the cooling greatly which in turn enhances the quality of the prints and makes the filament adhere better to the platform. Enhanced cooling also makes sure that the internal fractures in the Print Platter do not pose as an issue.

When it comes to personal use, I suggest setting the print temperature to anywhere between 190-220°C with the bed temperature set to 20-60°C. An unheated bed works perfectly well in most conditions. Of course, these ranges should be narrowed further to balance between print temperature and cooling.

Essential ABS filament considerations

Acrylonitrile Butadiene Styrene, also known as ABS, is a highly sought filament because of its heat-resistance properties, making it ideal for mechanical and functional parts. Due to its warping tendencies, an optimal ABS print requires a stable environment. Recommended temperatures are 220-250 °C for printing and 90-110 °C for the heated bed. Enclosure chambers are useful for maintaining stable temperatures, which decreases the chances of warping. Draft shields also offer similar utilities.

In comparison to active cooling systems, turning on cooling fans during printing should be avoided to not exacerbate warping stresses. Stress is best controlled through slow and managed cooling during and immediately after printing. Fumes emitted during the printing processes also need to be filtered out with an effective filtration system. To improve adhesion, PEI sheets and adhesives made of acetone and ABS can be added to the bed template. Correct ventilation, along with precisely configured printing parameters, enables strong and long-lasting prints made from ABS filament.

Addressing the high temperature needs of ABS

When using ABS filament, keeping temperature settings with great precision is essential for achieving quality results. Different brands and formulations of ABS filament have different requirements, but the extruder temperature must be kept within the range of 210°C and 250 °C. This range guarantees full melting of the filtered plastic and the right bonding on each layer. Meanwhile, a heated bed requires 90°C and 110°C during operation to reduce cooling imbalance-related warping.

It is highly recommended to put the printer inside a hot enclosure, also known as a heated chamber, which makes a great deal of difference. The potential for thermal stress in prints is significantly reduced in a controlled environment of 45 °C to 65 °C, especially for larger models, eliminating the risk of cracks or layer separation. According to data, these adjustments enhance accuracy to a great extent, resulting in reduced failure rates based on ABS-dependent projects by as much as 30%.

Management of structural integrity is greatly influenced by post-printing temperature, as constant monitoring and even cooling make a difference. Fairly slow cooling provides potential for stabilization. The dynamic approach to heat management makes prints durable, smooth, and robust, allowing them to achieve an industry standard for applications that focus on durability.

How do PLA and ABS filaments impact the environment?

The difference between PLA and ABS plastics stems from the filaments’ eco-friendly characteristics. The starch found in corn makes PLA filaments renewable and compostable under industrial conditions, which makes it less harmful to the environment. Still, if composting facilities are not available, then it can be counterproductive. In contrast, ABS does come with some drawbacks; getting petroleum-based sources makes it impossible to biodegrade into the long-lasting plastic waste. PLA does surpass it in greenhouse emissions, though, since ABS is known for spewing them out during production. The environmental consumption of both materials requires responsible social handling, or else they will end up being mismanaged and put to grave waste.

Is PLA biodegradable?

Certainly, PLA (Polylactic Acid) is biodegradable, but it has specific requirements to break down, replenishing resources like corn starch or sugar cane, geared towards more sustainable growth compared to ABS, which is derived from petroleum-based resources. However, like all biodegradable processes, PLA requires industrial composting to facilitate temperature moderation (above 140°F or 60°C) and heightened moisture levels. Under optimal conditions, PLA can fully break down to base water, organic matter, and carbon dioxide, surging for several months.

In contrast, PLA breaks down at a substantially slower pace in oceans or soil, making its decomposition susceptible to depletion spans for years devoid of optimal breakdown resources. Contemplating recent studies, it is suggested that PLA requires around 6-12 weeks for bio-degradation to occur in compost facilities, but poses significant increases in the period within landfills. This signifies the value and necessity of efficient waste segregation and accessible infrastructure to compost as pivotal to PLA benefits.

Environmental concerns with ABS

ABS or Acrylonitrile Butadiene Styrene is a thermoplastic that can be easily worked with and is based on petroleum. It is very popular across various sectors for its rigidity and impact resistance. Regardless, it poses a major threat to the environment. Fossil fuels are the backbone of its manufacturing process, which in turn, releases a staggering amount of greenhouse gases. Compiled with ABS being a non-biodegradable material, harmful effects can be catastrophic to nature if it isn’t tossed in a recycling bin.

It has been estimated that over 300 million tons of plastic are produced globally, which includes a fair portion of ABS in electronics, automotive, and even 3D printing. Even though it can be recycled, improper washing-up systems end up wasting a chunk of ABS plastic, which eventually clogs up landfills. Tossing ABS into landfills is a mischievous act, as they can dissolve into microplastic litter, which heavily damages marine environments. Shifting the narrative to scrapping eco-friendly controllable production methods can strongly address these problems.

Recycling options for 3D printing material

Recycling 3D Printing materials is one way to mitigate resource wastage. Filament recycling machines, which accept failed prints and shavings, are the most adopted solutions; they convert scraps and failed prints into filament, which can be reused later. These machines grind the plastic into pieces and subsequently melt and extrude it into spools that can be reused in different projects. For instance, PL, which is one of the most popular materials used in 3D printing, can be composted in an industrial setting or, if properly processed, can be converted back into filament.

Furthermore, the development of closed-loop recycling systems for large-scale industrial use has been expanding. There are now companies that accept used or failed prints from customers and recycle them into new raw materials; these are known as take-back programs. Other studies indicate that some incorporating recycling programs can reduce the adverse effects of 3D printing up to 65% depending on the material used and the processes followed.

Another hopeful avenue can be found in the use of more sustainable materials like PLA+, which is durable and biodegradable, as well as PETG, a thermoplastic used for recycling bottles. The growing supply of bio-based filaments manufactured from corn or cellulose offer another dynamic solution for mitigating the strain on the environment. Together with growing public awareness and education, these changes mark the path for significantly lessening the impact of 3D printing on the environment.

What are the costs associated with 3D printing with PLA and ABS?

The costs pertaining to 3D printing using PLA and ABS materials are based primarily on the cost of materials, maintenance of the printer, and their energy expenditure:

- Material Costs: The price of PLA usually falls between 20and20and35 per kilogram depending on its quality and brand which makes it more accessible. On the other hand, ABS is a bit pricier owing to its greater heat resistnace and durability, being sold between 25and25and45 per kilogram.

- Printer Maintenance: Both materials add costs in terms maintenance expenditures from replacing nozzles to cleaning build plates. In case of ABS, additional expenses may incur from needing a heated bed or an enclosure to prevent the prints from warping during the printing process.

- Energy Usage: Generally, ABS printing consumes more energy due to higher required temperatures for printing (220°C-250°C) and the need for a heated bed. In comparison, PLA uses less energy from operating temperatures around 190°C-220°C and lacks of need for a heated bed.

By considering these factors, users can better evaluate the overall expenses associated with 3D printing using PLA and ABS.

Comparing the cost of PLA vs ABS

When looking for the best filament for 3D printing, whether it is PLA or ABS, there are important points to note, such as the base prices, the effectiveness of the printing, the operational costs, and the overall cost efficiency of using the material. Starting from any brand, PLA is in most cases is listed at $15-$25 per kilogram and is considered the most economical, whereas Abs filaments list from $18-$30 per kilogram which is considered slightly more costly due to the infrastructure and resources put into the process of manufacturing its properties.

In the end, at no time should material handling efficiency be overlooked. For people who are trying to use ABS, the ease of handling and fewer failed prints when using PLA makes a significant difference in terms of waste. Where waste reduction helps save money, cost-effective materials like ABS when enclosed or used with additional resources carry additional costs. Particularly with PLA, the reduced expenses of additional enclosures or ventilation systems alongside the durable heat resistance make a big difference.

Moreover, the energy consumption of each material has the potential to affect total costs. PLA prints more easily than ABS since it has lower operating temperatures and does not require a heated bed. This difference in energy used may increase expenses over time, particularly for high-volume printing. Considering these factors—initial cost of the filament, printing speed, energy expenditure, and project efficiency—provided users with a way to tailor decisions to their budget and precise needs.

Determining the value for money in different projects

I know that assessing a project’s value for money requires a thorough evaluation of material costs, efficiency, and durability. Consider the case of 3D printing filaments. PLA, which is one of the most used filaments, sells for approximately $20 – $30 per kg. On the other hand, ABS is sold at a marginally higher price range, $25 – $40 per kg, depending on the quality and brand. Although PLA is cheaper, its downside is that it is only useful for low-stress environments. It presents low-strength areas like decorative items or prototypes.

Energy use PLA is defined by low energy consumption, and that is the case when comparing it with ABS. PLA requires less energy to print (~190 – 220 °C) compared to ABS which requires 220 – 250 °C and extra heating for the print bed. Depending on which filament the printer used, studies show energy use can vary from 25 – 50%, which is significant for businesses that do high volume or repetitive work.

Durability, particularly for functional parts, is another critical aspect of value. For parts exposed to greater stresses, both thermally and mechanically, ABS performs better in strength and heat resistance than PLA. This makes ABS the filament of choice for mechanical parts. However, for parts that solely require biodegradable materials, PLA does have an advantage.

Analyzing these variables together with the user’s requirements, for example, within small-scale hobbyist projects and within heavy-duty industrial production, helps users determine what material meets their performance expectations and falls within their budget. The value obtained and resources utilized are further optimized by narrowing the focus to specific, customized requirements.

Long-term investment in 3D printing materials

Printing materials for 3D printers require careful consideration for long-term investment. With an emerging level of consideration and adjustment for technology, we have to think now about where the industry will be in the future. Spending time on material warranties, versatility, and expense needs to be evaluated. It also includes high-performance thermoplastics, which are becoming more useful in other fields like aerospace, automotive, and medical.

An analysis shows that there is a global market for 3D printing materials, which is likely to expand greatly. This is made possible due to an expected growth rate (CAGR) of over 20 % between 2023 and 2030. New emerging materials such as carbon composites, glass fiber filaments provide greater strength while being lightweight, and they are desirable at the same time for completing prototypes as well as functional end-use parts. Along with that, there is also an increase in demand for PLA biocompatible and sustainable materials that focus on eco-friendly manufacturing practices.

“When planning long-term investments, it is equally important in consideration to consider factors like material shelf life and storage conditions. Higher quality materials also put less of a strain over time, like more sensitive filaments such as Nylon deluxe packaging, and moisture-proof storage, while less sensitive materials like ABS don’t degrade as quickly under improper confinement. With proper storage systems than what is already available, there is decreased waste, which ensures stable performance, which guarantees that materials are indeed high quality, thus maximizing returns.”

Reference Sources

- Study on Degradation and Long-Term Behavior1:

- Focus: Examined the chemical, morphological, and colorimetric changes in ABS and PLA after UV and temperature aging.

- Findings: ABS showed significant degradation under UV exposure, while PLA was more resistant but altered more under high temperatures.

- Methodology: Used Fourier-transform infrared spectroscopy, gas chromatography-mass spectrometry, and scanning electron microscopy.

- Flexural Properties Comparison2:

- Focus: Compared the mechanical properties of ABS, PLA, and PLA-wood composites.

- Findings: PLA and PLA-wood composites were more rigid, while ABS exhibited greater flexibility before breaking.

- Methodology: Conducted four-point bending tests using ASTM standards.

- Tribological Parameters Study3:

- Focus: Investigated wear rate and friction coefficients of ABS and PLA under different 3D printing parameters.

- Findings: Identified optimal parameter combinations for durability and wear resistance.

- Methodology: Used pin-on-disc testing and design of experiments (DOE) analysis.

- Top ABS Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What are the main differences between ABS and PLA in 3D printing?

A: ABS and PLA are both popular types of filament used in 3D printing. ABS is a thermoplastic known for its strength and better impact resistance, making it ideal for functional prototypes. PLA, on the other hand, is a biodegradable material that is easy to print with, making it suitable for beginners and hobbyists.

Q: Why choose ABS material over PLA for 3D printing?

A: ABS has a higher glass transition temperature compared to PLA, which means it can withstand higher temperatures before deforming. This makes ABS a better choice for parts that need to endure heat. It also offers better impact resistance and durability, which is why it’s often used in industrial applications.

Q: Can PLA be printed at lower temperatures compared to ABS?

A: Yes, PLA can be printed at lower temperatures, typically around 180-220°C, whereas ABS requires higher temperatures, around 230-250°C. This makes PLA more energy-efficient and less demanding on 3D printers.

Q: How does the 3D printing process differ when using PLA or ABS?

A: The 3D printing process with PLA is generally easier and less prone to warping, as it adheres well to print surfaces. ABS requires a heated bed to prevent warping and may emit fumes, necessitating good ventilation.

Q: Is ABS filament stiffer than PLA, and how does that affect printing?

A: PLA is generally stiffer than ABS, which means it holds its shape well and is easier for precision printing. However, ABS offers better flexibility and toughness, which can be advantageous for parts that need to withstand stress without breaking.

Q: How should I store PLA or ABS filaments to ensure their longevity?

A: Both PLA and ABS filaments should be stored in a cool, dry place away from moisture. PLA is particularly sensitive to humidity, so keeping it in a sealed bag with desiccant is advisable.

Q: What considerations should I take into account when deciding to print with ABS material?

A: When printing with ABS, consider the need for a heated bed and proper ventilation due to the fumes it emits. ABS can also be more challenging to adhere to the print bed, so using a suitable adhesive or print surface is recommended.

Q: Are there any environmental benefits to using PLA over ABS?

A: PLA is made from renewable resources like corn starch, making it a more environmentally friendly option. It is biodegradable under industrial composting conditions, whereas ABS is petroleum-based and not biodegradable.

Q: Which type of filament is better for beginners in 3D printing?

A: PLA is generally better for beginners in 3D printing. It is easier to print with due to its lower temperature requirements and minimal warping issues, making it a user-friendly choice for 3D printing enthusiasts.