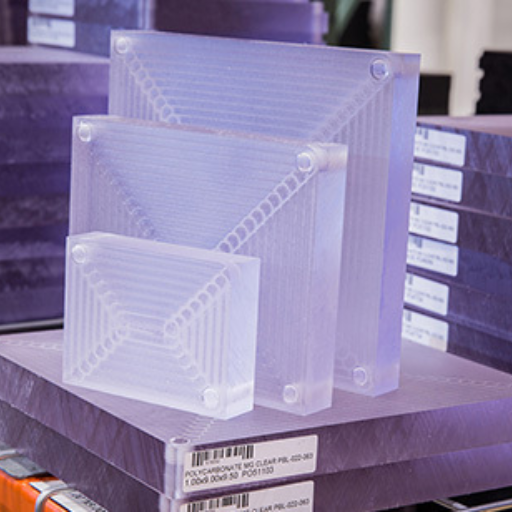

Thermoplastics are among the most sought-after materials for DIY projects and manufacturing due to their versatility. Two of the most commonly known and used plastics in various industries are Polycarbonate and ABS (Acrylonitrile Butadiene Styrene). Each material offers unique features, however, the crux of the matter remains which material solves the user’s problem? This post discusses the comparative analysis of ABS and Polycarbonate in terms of their key attributes, advantages, and optimal uses while measuring their performance in durability, flexibility, cost, and other. No matter whether you are an engineer, a designer, or just a hobbyist, knowledge about these materials will enhance your decision-making for upcoming projects. Read along as we discuss the critical differences and decide which thermoplastic is the right one for your needs.

What Are the Mechanical Properties of ABS vs Polycarbonate?

Acrylonitrile Butadiene Styrene, or ABS, has relatively moderate strength, good toughness, and makes an excellent impact-resistant material. It is a combination of rigid and flexible, thus it must be forgiving under stress. ABS works best in places where shock absorption or wear and tear is common.

Unlike the former, polycarbonate can endure far more impact harshness when compared to ABS. This also means a greater tensile strength. Additionally, polycarbonate is highly transparent and does not change with extreme temperatures, meaning it can withstand both high impact forces as well as thermal shock.

To sum things up, ABS is a low cost compared to polycarbonate which without a doubt excels at strength and heat resistance making them more suitable for heavy-duty applications necessitating high durability.

Understanding Impact Strength in ABS and Polycarbonate

In simple words, it is the ability of a material to sustain force or shock without breaking is termed impact strength. While analyzing ABS and polycarbonate in this regard, data shows distinct characteristics for the latter. For example, polycarbonate stands out with a blend impact strength of more than 60 kJ/m² as compared to ABS, which has only 15 kJ/m². Because of the ABS durability grade, it is used in moderately demanding mechanical applications. Polycarbonate, on the other hand, is suitable for extreme impact situations.

It’s also important to note how temperature affects impact strength. Consider Polycarbonate as an impact resisting material across wide range of temperatures which is ABS not. Because of these and many more reasons, Polycarbonate is the best option when it comes to safety equipment, automotive glazing, industrial machines parts and others.

Comparing Tensile Strength: ABS vs Polycarbonate

Comparing the two materials, Polycarbonate is known to have a lot more tensile strength than ABS. Polycarbonate has a tensile strength range of 55-75 MPa, which is higher than the ABS tensile strength range of 29-43 MPa. Thus, polycarbonate can be used in applications requiring greater force pulling the material without risking breakage or deformation. Polycarbonate is reliable due to its stronger durability, which proves useful in harsh conditions.

Analyzing the Toughness of ABS Plastic and Polycarbonate Plastic

Toughness is key when evaluating a material’s capacity to absorb energy and fail without buckling under stress. Polycarbonate demonstrates remarkable toughness, exceeding that of OABS, where impact resistance is a priority. For example, Charpy Impact Tests, which measure toughness, reveal that polycarbonate has an impact strength of about 60-80kJ/m² whereas ABS, on the other hand, usually ranges between 15-25 kJ/m². This is a significant discrepancy that explains the usage of polycarbonate for applications such as bulletproof glass, safety helmets, and high-resistance industrial components. Simultaneously, ABS, more susceptible to damage in high-impact situations, offers just sufficient resilience for the doors of automobiles and consumer electronics, where moderate impact defense is essential.

Besides the raw impact figures, polycarbonate is flexible enough to retain resilience throughout a large span of temperatures, -20 degrees to 120 degrees Celsius, and not degrade performance. ABS becomes severely less tough when temperatures dip above or below the, especially under heat over sustained durations. These differences highlight polycarbonate’s ideal use when impact tolerance and sustained durability of materials under harsh environmental conditions take precedence.

How Does UV Resistance Differ in ABS and Polycarbonate?

When comparing polycarbonate and ABS, the former exhibits stronger UV resistance. Polycarbonate can handle UV radiation for long periods with little harm while ABS is more susceptible to sunlight which regularly results in fading, increased fragility, and diminished mechanical strength. The use of polycarbonate is more suited for outdoor applications unless treated ABS UV stabilizers are used.

Evaluating UV Resistance in Polycarbonate vs ABS

Recent developments in material engineering have improved the UV resistance of polycarbonate and ABS. For instance, coating and advanced UV stabilizers incorporated into the material greatly increase its ability greatly withstand the sunlight. These modifications aid in the ABS’s form and thus construction enduring extremes, retaining shape and appearance, shielding, allowing it to withstand harsh conditions enclosed within ‘outer space’. Unprotected, untreated ABS’s impact strength tends to drop 50% after a year of sun exposure.

Modern improvements have further enhanced UV resistance of polycarbonate. Coatings designed for optical uses along with UV blockers serve dual purposes of protecting the material from the external environment and preserving them when placed outdoors. Additional protection to yellowing, surface cracking, lost durability of impact resistance due gradual erosion from harsh exposure to the outdoors enable prolonged use. Statistics indicate polycarbonate sustains exceeding 80% of its impact resistance after enduring long periods of exposure to UV light, making it advantageous for building materials, vehicles, and optical instruments.

It is important to understand the specific factors related to the outdoor environment and performance needs when choosing among these materials. While polycarbonate remains the industry leader in UV protection, innovations in ABS technology make it more viable for cost-sensitive applications.

Impact of UV on Durability of ABS vs Polycarbonate

While ABS and polycarbonate are evaluated in terms of their durability after continuous UV radiation exposure, their molecular structure and practical performance values should be taken into account. ABS thermoplastic has low resistance to UV due to its butadiene part, which is prone to UV-induced deterioration. Untreated ABS is estimated to undergo striking reductions in its impact strength, losing nearly 50% after 12 months of continuous UV exposure and undergoing scaling, discoloration, and brittleness outdoors.

On the other hand, polycarbonate makes the most of its inherent abilities to restrict UV penetration, which can be furthered by added UV-stabilizers or coating. Studies show that polycarbonate withstands significant exposure to UV radiation, retaining 80% or more of its impact strength even after five years, which provides a dominant advantage in high UV exposure areas. This is further enhanced by its stronger aromatic carbonate linkages that are less prone to photodegradation than those present in ABS.

Moreover, these findings are corroborated by practical use cases. For example, polycarbonate is used in automobile headlight covers and exterior windows where it weathers less and maintains its strength for significantly longer periods than ABS. Regardless, cost and application specifics frequently determine material selection. In less demanding outdoor applications, UV-stabilized ABS offers modest durability at a lower price, making it a budget-friendly option for more forgiving outdoor conditions.

It is evident that grasping these performance parameters is crucial in choosing the material, as the interplay among UV resistance, cost, and lifespan drastically impacts the project’s outcome.

Which Has Better Impact Resistance: ABS or Polycarbonate?

When comparing polycarbonate to acrylonitrile butadiene styrene (ABS) polycarbonate is remarkably more stronger. Although it is a versatile engineering plastic, ABS can only withstand moderate impacts, whereas polycarbonate excels in its remarkable impact resistance. This makes polycarbonate exceedingly superior in regards to safety and protection where comfort is frequently encountered.

Assessing High Impact Resistance in ABS and PC

In the context of high impact resistance properties, the comparison between ABS and polycarbonate (PC) requires measuring the values in terms of material properties. An example is the abrasion resistance impact strength of ABS (Acrylonitrile butadiene styrene) as a thermoplastic polymer, which measures a range between 200 to 350 J/m (Joules per meter). This level of resistance makes ABS suitable for applications such as consumer electronics, automotive interiors, and toys, which require some level of moderate durability.

Polycarbonate, on the contrary, stands out with its remarkable durability as it boasts an impact strength of over 600 J/m. This significant toughness is why Polycarbonate is so widely used in industries needing maximum durability, such as aerospace, industrial safety equipment, and bulletproof glass. Furthermore, it has been tested that polycarbonate absorbs much stronger impacts with comparatively great resilience as compared to other materials, which makes it ideal for extreme environments where high levels of stress are expected.

When selecting the appropriate materials based on particular specifications, understanding these variances helps. To sum it up, while ABS provides a balance between cost, sufficing durability, ease of processing or machining, and intermediate mechanical resistance, polycarbonate remains the favourable material where unmatched resilience is required, prioritizing safety, complexity, and exposure to great degrees of stress.

Comparing Impact Strength in Polycarbonate vs ABS

The impact strength of materials is crucial in determining how to use them, and it differs significantly between ABS and polycarbonate. Impact polystyrene has an impact strength of about 850 J/m, classified as “one of the strongest thermoplastics available” due to its exceptional toughness. This allows polycarbonate to endure extreme mechanical stress, like cracking or breaking. Conversely, ABS does not do as well as polycarbonate and usually scores 200-300 J/m. While strong enough for consumer electronics and automotive parts, polycarbonate’s resilience cannot be beaten.

This disparity becomes particularly significant in industries that demand high-performance materials. For instance, riot shields and safety eyewear are often made from polycarbonate due to its high-velocity shatter resistant impact capabilities. ABS tends to be popular in the low to mid range stress areas where materials need to perform while considering costs. These differences showcase the lack of focus put into choosing the right materials for they specific use case.

Are There Chemical Resistance Differences Between ABS and Polycarbonate?

Indeed, there are significant ABS polycarbonate chemical resistance differences. ABS resists many acids, alkalis, and oils; however, solvents such as acetone or alcohol-based cleaners may cause surface damage. Polycarbonate has better resistance to some solvents, but its long-term exposure to strong acids and alkalis makes it more susceptible to degradation. These distinctions make it important to analyze the specific chemicals the material will encounter when selecting between the two.

Exploring Chemical Resistance in ABS Plastic

While investigating the properties of ABS plastic, I discovered that it has reasonable resistance to water, oils, and the majority of acidic materials. On the other hand, solvents such as acetone, alcohols, and some hydrocarbons can erode its surface and make it vulnerable. Therefore, careful concern should be made towards environments with solvents to maintain lasting effectiveness.

Polycarbonate’s Chemical Resistance Compared to ABS

Polycarbonate continues to be popular due to its resistance to many chemicals. In comparison to ABS plastic, polycarbonate is more durable with respect to oils, greases, and many diluted acids or aliphatic hydrocarbons. It exhibits resistance to most alcohols and other aqueous solutions, which further strengthens the polycarbonate’s position in more sensitive industries such as medical, automotive, and industrial. Although polycarbonate cannot withstand aromatic and chlorinated hydrocarbons, as well as strong alkalis, long-term exposure often leads to surface degradation or stress cracking.

Clinical studies and data suggest that polycarbonate is chemically stable even with prolonged application of high temperatures and mechanical stress. For example, polycarbonate withstands structural damage and optical blur even under exposure to moderate levels of abrasive chemicals, unlike ABS. Different materials are optimal under different conditions; however, polycarbonates’ extreme tolerances to chemicals, especially in critical polycarbonate operating environments, increase their preference.

Choosing Between ABS and Polycarbonate: Which Is the Best Material?

What works best will depend on your particular needs. When cost savings, simplicity in fabrication, and average strength are concerned, ABS does best. It holds up well in everyday scenarios, such as with consumer electronics and other household products. If you need exceptional impact resistance, optically transparent materials, and strong durability for harsh environments, however, polycarbonate is the better option. Polycarbonate often outshines ABS in more demanding uses like safety gear or industrial applications.

Considering Specific Requirements for ABS vs Polycarbonate

The following aspects should be evaluated when analyzing the performance of ABS and polycarbonate with regard to specific needs:

- Impact Resistance

-

-

- ABS: Has a moderate impact resistance which is appropriate for low-risk applications such as plastic casing or other daily-use items.

- Polycarbonate: Exceptional impact strength due to withstanding high-force impacts such as those in bullet-resistant windows, helmets, and other safety gear.

-

- Temperature Tolerance

-

-

- ABS: Withstands temperatures ranging from -4°F to 176°F (-20°C to 80°C) before deforming, making it suitable for general purpose applications.

- Polycarbonate: High temperature endurance of up to 257°F (125°C) expands its use in high temperature environments.

-

- Weight

-

-

- ABS: lightweight nature provides ease in handling and reduction of costs in material during mass production.

- Polycarbonate: slightly heavier than ABS due to being denser, yet this improves strength and durability.

-

- Cost

-

-

- ABS: More Cost-Effective.Used by budget-minded projects because of its decent performance.

- Polycarbonate: Metalloid is more expensive due to its more advanced properties and other demanding applications.

-

- Optical Clarity

-

-

- ABS: Opaque.Has no application where transparency is needed.

- Polycarbonate: Very transparent.Used frequently to manufacture spectacles, windows of vehicles, and display screens.

-

- Ease of Manufacturing

-

-

- ABS: Easy to mold and shape. Lower production complexities, easily achievable deadlines.

- Polycarbonate: Molding is more complex than ten or twenty others. It can achieve far more complex shapes and designs on different axes of flexibility.

-

- UV Resistance

-

-

- ABS: Has limited UV resistance, which makes it susceptible to fading and deteriorating when subjected to prolonged exposure to sunlight.

- Polycarbonate: Possesses higher UV resistance than ABS, but often needs other protective coatings for extended outdoor use.

-

- Durability

-

-

- ABS: Offers reasonable durability for general use, but may break at the seam under heavy stress.

- Polycarbonate: Superior enduring capacity, with great resistance to cracking and shattering in tough settings.

-

When choosing a certain material for your project, performance and cost effectiveness are easily achieved by taking into account these factors.

Factors Influencing the Best Material Choice

When determining the most suitable material for your application, classic physical features need deeper evaluation like ecological sustainability, thermal behavior, and monetary value. For instance, ABS plastic is very economical which would serve well for budget-centered applications. However, polycarbonate materials seem to outshine others in demanding conditions owing to their superior clarity, resistance to high temperatures, and outstanding clarity.

According to recent statistics, polycarbonate can withstand temperatures up to 135 degrees Celsius (275 degrees Fahrenheit), making it a suitable material for locations that require prolonged exposure to heat without warping. However, ABS would have a lower thermal range with maximum working temperatures hovering around 80 degrees Celsius (176 degrees Fahrenheit). These distinctions may pose obstacles to performance in the case of heat-prone applications.

In terms of environmental impacts, polycarbonate materials have an edge over ABS plastics as they tend to be more recyclable. Life-cycle assessment demonstrates polycarbonate manufacturing entails considerably lower emission of greenhouse gases compared to non-recyclable plastics, which renders it a better choice for sustainability-conscious undertakings.

As such, considering thermal extent alongside other features such as cost and recyclability offers the prospect for alignment with ethical and economic standards as well as compliance with project requirements.

Price Comparison: Is Polycarbonate More Expensive Than ABS?

Polycarbonate is often more pricey than ABS because of its superior characteristics and greater variety of applications. Polycarbonate’s cost per pound ranges from $2.50 – $3.00 with ABS sitting at a lower range of $1.50 – $2.00 making it the more economical choice. Polycarbonates higher pricing comes from the critical impact resistance, optical clarity, and thermal stability needed for high-performance components and safety equipment.

With that being said, the pricing gap should be assessed regarding the particular situation. Industries that require more demanding attributes, such as durability and transparency,y will justify using polycarbonate over ABS. Other, less challenging applications that don’t require sophisticated compounds will economically benefit from using ABS. Unlike polycarbonate, ABS is cost-effective. Moreover, actual costs can change due to market volatility, supplier agreements, and purchase quantities, which means businesses can lower prices through bulk buying or contracts.

Reference Sources

- Thermo-oxidative Aging Study (2022)1:

- Focus: Examined the effects of accelerated aging on ABS, Polycarbonate (PC), and Polyoxymethylene (POM).

- Methodology: Used differential scanning calorimetry (DSC), dynamic mechanical analysis (DMA), and tensile tests at elevated temperatures.

- Findings: ABS showed significant property changes during the first 21 days of aging, while PC exhibited stable glass transition temperatures in aged and unaged samples.

- Fracture Behavior of PC/ABS Blends3:

- Focus: Investigated the fracture toughness of PC/ABS blends under various conditions.

- Methodology: Analyzed the influence of ABS structure, content, rubber content, strain rate, and temperature on fracture behavior.

- Findings: Blending PC with ABS reduces brittleness and improves toughness, addressing issues like environmental stress cracking.

- Mechanical Properties of PC/ABS Composites (2021):

- Focus: Studied the mechanical and microstructural properties of PC-reinforced ABS composites in 3D printing.

- Methodology: Tested composites with varying PC content (10%, 20%, 30%) for hardness, flexural strength, and impact resistance.

- Findings: Higher PC content improved hardness and strength, making the composite suitable for intricate 3D-printed components.

- Top ABS Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What are the main differences between ABS and Polycarbonate?

A: The main differences between ABS (Acrylonitrile Butadiene Styrene) and Polycarbonate include their properties and applications. ABS is known for its affordability, ease of processing, and good impact resistance, making it a popular choice for items like ABS luggage. Polycarbonate, on the other hand, offers higher impact strength and high heat resistance, making it suitable for more demanding applications. Understanding the differences between ABS and Polycarbonate helps in selecting the right material for specific uses.

Q: How does the melting point of ABS compare to that of Polycarbonate?

A: ABS plastic has a lower melting point compared to Polycarbonate. This makes ABS easier to process in manufacturing techniques such as injection molding, but it also means that Polycarbonate is better suited for applications requiring high heat resistance.

Q: What are the advantages of using ABS over Polycarbonate?

A: ABS offers several advantages, including being generally more affordable and easier to process. It also provides good impact resistance and can be easily injection molded, making it a cost-effective choice for many products, including consumer electronics housings and automotive parts.

Q: Is ABS recyclable compared to Polycarbonate?

A: Yes, ABS is recyclable, which makes it a sustainable choice in various industries. While Polycarbonate is also recyclable, the recycling processes and facilities available for ABS make it more commonly recycled, contributing to its popularity in manufacturing.

Q: How do ABS and Polycarbonate compare in terms of scratch resistance?

A: Polycarbonate generally offers better scratch resistance compared to ABS, which can be an important factor in applications where surface durability is critical. This property makes Polycarbonate ideal for use in eyewear lenses and protective covers.

Q: What is the impact of using Butadiene in ABS?

A: Butadiene in ABS contributes to its toughness and impact resistance. This component of the ABS material enhances its ability to withstand physical stress and shocks, which is why ABS is known for its high impact strength.

Q: When should you choose Polycarbonate over ABS?

A: You should choose Polycarbonate over ABS when you need high impact strength, high heat resistance, and superior durability. Polycarbonate is also a better choice for applications that demand excellent optical clarity, like in the production of transparent panels and lenses.

Q: How does the raw material cost of ABS compare to Polycarbonate?

A: ABS is generally more affordable as a raw material compared to Polycarbonate. This lower cost makes ABS a popular choice for mass-produced consumer products where cost-effectiveness is a priority.

Q: What are some common applications for ABS and Polycarbonate?

A: ABS is commonly used in applications such as automotive components, consumer electronics, and luggage due to its cost-effectiveness and ease of processing. Polycarbonate is used in applications requiring high impact resistance and optical clarity, such as protective gear, eyewear, and high-performance components.