Acrylic is an astonishing substance that has managed to carve its niche as a fundamental building block in the many industries, technology, art, construction, and design, to name a few. It is recognized for its vigor, adaptability, and the fact that it is as clear as glass, which invariably marks it as a leading rival to glass and other old-fashioned materials. But why is acrylic so remarkable, and what processes have led to its high demand in modern technology and industrial sectors? This piece is a thorough study on the acrylic world–the different properties that it has, how it is produced, and the new ideas where it is already in use. Right from a practical point of view of a professional or simply a person who is interested to know more, this article will provide you with a clear path and familiarize you with the reasons for which acrylic is a material that is beyond any comparison.

Understanding Acrylic: The Basics

Have you ever heard of Acrylic?

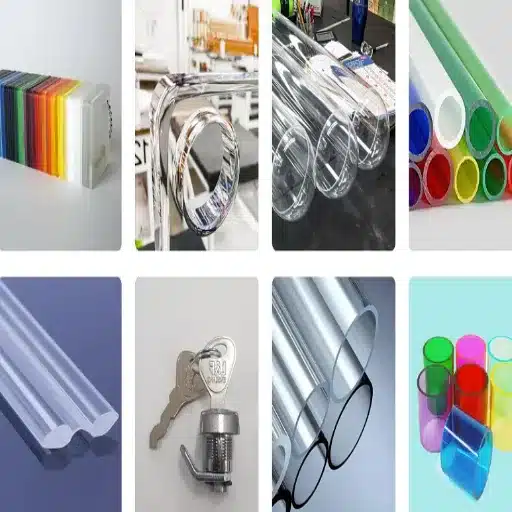

Technically called polymethyl methacrylate (PMMA), Acrylic is a versatile thermoplastic polymer that is widely known for its transparency, lightness, and durability. It was first invented in 1928 and made available for commercial use in the 1930s. Back then, it was intended to be a substitute for glass but eventually turned out to be better than it as it could withstand impact and still offering great optical clarity. Acrylic is obtained by the polymerization of methyl methacrylate, which is a process that produces a high molecular weight material with good weathering properties. It is able to make light transmit through it with an efficiency of 92% that is comparable to glass while having a considerable lower weight and also being shatter-proof. Besides that, acrylic is very flexible in terms of customization as it is being supplied in various forms such as sheets, rods, and tubes and it can be processed by molding or machine quite easily resulting in a wide range of industries where this material is found, including construction, automotive, medical tools, and consumer goods.

Types of Acrylic: Cast vs. Extruded

Cast Acrylic and Extruded Acrylic are two types of acrylic but with different processes of making and, therefore, have different properties and applications. Cast Acrylic is made by pouring liquid acrylic into a mold, the final outcome of this product is higher than that of the three and the product has the feature of very high clarity. This method of making a material results in a stronger, even more durable product that is suitable for use in high impact situations including that of the aquarium industry, display cases, and signs. On the other hand, extruded acrylic is made through a process wherein the acrylic resin continuously flows and is forced through a die, which in turn creates sheets with one and the same thickness. It is a fact that it is less expensive and easier to make in large quantities, but this grade of acrylic is more prone to scratching and lacks a little bit in optical clarity compared to cast acrylic. It is more technically correct to say that it is best for projects with unchanging conditions or situations like laser cutting or fabrication where the need for exactness is the primary concern. Those who want their product to be produced in a short time and at the most economical level should go in for extruded acrylic while the opposite is therefore the case for people who are more concerned with the optical and mechanical properties of materials. The above discussion reveals that choosing the right acrylic type for the project is based on performance requirements and project constraints, among other things.

Differences Between Acrylic and Other Plastics

Acrylic, which is also referred to as polymethyl methacrylate (PMMA), has some unique properties that distinguish it from plastics like polycarbonate, polyethylene, and polypropylene. One of the main benefits of acrylic is its remarkable optical clarity, which is even better than that of most similar materials, so it is very often the first choice for applications like display cases, signage, and optical devices. On the other hand, polycarbonate, which is almost as transparent as acrylic, on the other hand, offers a much greater resistance to impact, hence being much more suitable for applications needing toughness, such as safety glasses and bullet-proof windows.

When it comes to air, water, and light (B), the human body is more vulnerable to health hazards than when it is in danger because of extreme cold (A). Nevertheless, according to the given data, this was not the case with paper among the samples collected. Apparently, the external agent is the main contributing factor in terms of people not having a fatal effect on the toxin, while there is no known reason. To sum up, freezing is probably not the primary factor in the relationship between the weather & health risk of fresh air.

The comparison between machining and fabrication gives the conclusion that acrylic is a material of choice that is easier to work with since it can be precisely cut, drilled, or laser-etched with no problem. Replicating the same example when the other product is polypropylene shows that it is indeed harder to machine because of its high flexibility and low melting point. This makes it better for cases where the product will be continuously moving, such as hinges. However, the final decision between the two acrylic and other plastics to go with will depend on the particular mechanical, optical, and environmental requirements of the proposed location.

Properties of Acrylic: Why It’s So Popular

Physical Properties of Acrylic

Acrylic is considered the best for so many applications because it has such peculiar physical properties that are just so perfect together. The material amazes with its transparency and allows passing of 92% of visible light through, which is way more than that of a normal glass. It is also quite lightweight with a density of around 1.18g/cm³, so it just weights less than half of the same size glass; thus, it is easier to carry and install. Moreover, the polymer shows a great outdoor resistance to weather by not turning yellow or cracking after unprecedented UV exposure.

Acrylic is rigid and strong enough to withstand a tensile stress of 8000-11000 pounds per square inch, depending on the quality. This makes it fit for building immense structures—a condition where the material will have to endure. It even has the advantage of being easily liquefied—point hovering at approximately 160°C (320°F)—therefore, the processes of the formation of the material into different shapes are smoother. Moreover, acrylic belongs to the group of materials that are chemically resistant with naturally high acids (dilute) and alkaline solutions among its non-menacing enemies- thus implies its extensive use in the industry. These characteristics taken together are the reason why acrylic is not just an alternative but a very crucial material in the fields of engineering, design, and construction.

Chemical Resistance and Durability

Mainly, the vast usage of acrylic in different arenas is due to its chemical resistance as well as durability being on top of its benefits. This material shows a high tolerance to all types of environmental stress including UV light that is the cause of degradation in many other less resistant materials. Among its credit points, the fact that it can withstand a lot of different solutions like diluted acids, alkalis, and hydrocarbons is one of them; it resists even the harshest surroundings due to the durability granted by the good quality of the material. In addition, it is less likely to crack or break during molding, with its high impact strength, one of the reasons being its use of plastic materials. Such that of a safety-sensitive environment had no problem accommodating the tile. The physical properties history of acrylic plastic has been the fact that it has been used across various fields such as automotive, medical devices, and aerospace where long life and credibility are crucial factors to consider.

Transparency and Light Transmission

The transmit light cntent of the acrylic is about 92% which is more than in the case of glass. In combination with the latter as well as the lower density, this kind of transparency makes acrylic a great material for situations that necessitate high visibility coupled with less weight. Moreover, the material has been able to withstand the yellowing and the degradation caused by the long UV exposure due to the modern manufacturing techniques, thus its long-term performance is ensured in the outdoor and high-light situations. These qualities together, make acrylic suitable to be used in the areas of glazing, signage, and display applications, where both aesthetic appeal and functional performance are crucial.

Applications of Acrylic: Where It’s Used

Common Uses of Acrylic in Industries

A very transparant, strong and light material like acrylic is very much in use in different sectors for its qualities. In the construction industry it is often a choice for windows, skylights, and greenhouses instead of glass, as it provides better impact resistance and it is easier to handle too. The automotive sector opts implemantation of acrylic to obtain more flexibility and a very simplified maintenance process for the product while keeping the product very pol.”

Acrylic’s usage is being seen significantly in the medical sector where its properties are helpful in devices such as incubator enclosures, dental products, and prosthetics because of its biocompatibility and ease of sterilization. Also, in the advertising and retail sectors, acrylic is the main material in making illuminated signs, display cases, and point-of-sale fixtures due to the material’s clarity and the possibility of being fabricated into complex shapes. All these applications point out the flexibility and trustworthiness of acrylic, hence, its “must-have” status in the modern industrial application.

Acrylic: The Choice of Interior Design and Home Decor

The use of acrylic in home decor and interior design has become a trend because it has amazing flexibility, toughness, and beauty. The limitation of weight and at the same time appearing exactly like a glass, but still being more resistant to breaking shards is the feature making it actually a part of several applications. Acrylic is very often the choice of furniture designers to produce clean-lined and geometrically shaped tables, chairs, and shelves in both modern and contemporary interiors. Again, the material’s clearness and the variety of available coatings make it an exciting part of the trend in the decorative details such as picture frames, wall panels, and light fittings are concerned. Moreover, the acrylic with its cutting, engraving, or molding can be easily tailored, hence it allows furniture makers to cooperate and design the original pieces that would best suit their clients’. This easily might also be the case with acrylic’s adaptability, along with the long-expected service life and the scarce demand of human effort for the maintenance work, as it all makes the acrylic a very persona_ efficient and design-integrated material even inside the fabrications like home walls and floors; thus, as the overall demand of the product continues to grow and the role of the customer becomes more important, the list of the material’s or a group of them affects the product range.

Innovative Uses of Acrylic in Art

Acrylic has been a revolutionary force in the world of art all thanks to its utter fluidity, as well as its affinity towards different methods and materials. Artists are usually found applying paint on acrylic sheets before starting their painting, and the main reason is the smooth surface which allows them to create detailed and vivid colors. Moreover, the use of laser cutting and 3D printing technologies has made it possible to form, engrave, or sculpt acrylic into the most intricate shapes, thus, giving life to modern installations and sculptures. On the other hand, another new way, which is gaining more popularity, is to introduce material like pigments, fabrics, or metallic inclusions into the acrylic, thus, making it a medium for creating pieces that are not only light-reactive and multidimensional, but also fascinating to spectators. The presence of acrylic’s toughness and its environmental-friendly features present it as the best choice for open-air works and public installations. In this regard, creative projects can be viewed from an environmental, community-inspired, and art perspective since acrylic is capable of being green.

Working with Acrylic: Tips and Techniques

How to Properly Cut Acrylic Sheets

The precise and correct cutting of acrylic sheets demands the right tools, comprehensive preparation, and exact execution which is able to hold the material from collapsing and also reach the best possible outcomes. The very first step to be taken is to choose the most suitable cutting tool according to the thickness of the acrylic sheet; for thin sheets (under 1/8 inch) a scoring knife is the best, while thicker sheets usually need the use of the jigsaw, the circular saw, or the laser cutter to have the edges as straight as possible. Make sure the area where you are going to work is neat and without any movement so the sheet won’t move while you are cutting it.

Put the cutting line on the acrylic sheet with a ruler or a straight edge and a fine tip marker which will give an exact cut to follow, and do not forget to carefully check the dimension for the last time. In case of using electric saws, make sure the saw blade is made for plastic materials with carbide-tipped teeth or similar ones to prevent chipping and get less rough edges. The acrylic sheet should be tightly secured with clamps but it is also very important not to put too much pressure on it since this could cause the cracking.

Cutting should be done at a uniform and controlled pace; increasing the temperature of the acrylic either by too much or too little can lead to the area of the cut melting or being distorted. It is also possible to eliminate the chance of chipping and scratching to an even greater extent by covering the line of the cut with masking tape. After the cutting process, one should take care of the rough edges by means of either fine sandpaper or a file, in order to gain a flawless look and prevent sharp edges. All these steps are very technical and help to achieve a clean and professional result and at the same time the structural and aesthetical properties of the acrylic are kept up to scratch.

Laser Cutting Techniques for Acrylic

In case you are going for a laser cutting technique with a material like acrylic, the proper use of the technology regarding precision and parameter optimization is necessary to attain best results. It is a must that the power settings, speed and the focal length of the laser should be properly set taking into consideration the thickness and the material grade of the acrylic. One good example is where the edges are cleaner using cast acrylic rather than using extruded acrylic as results of the molecular structure and the facility in interacting with the laser wave. A classic advice for a standard 3mm cast acrylic with the laser is keeping the power low and the cutting speed at a moderate level to avoid scorching and surface clouding.

Optimizing the frequency settings of the laser is also a crucial factor, as it has a direct impact on the smoothness of the cut edges. By the use of a high frequency, the laser will melt and seal the edges with continuous pulses, thus producing a polished finish. Apart from that, the use of an air assist system is another way to lessen flare-ups and to ensure that the particulate matter is being cleared and hence prevent discoloration. Furthermore, the regular maintenance of the laser lens and mirrors are equally important in keeping the beam accurate and preventing imperfections.

Indeed, if the mentioned factors are properly calibrated, the professionals can achieve the maximum efficiency and produce the acrylic components with amazing clarity and precision. The purpose of these settings is to guarantee the quality of the results whether they are used for complicated designs or for the production of industrial quantities.

Finishing and Cleaning Acrylic Surfaces

The process of finishing and cleaning acrylic surfaces is very precise and the right methods should be used to get a perfect result. If edges are found to be rough or tooled after machining and laser cutting, sanding is a good way to smoothen them out. It is normally done by using coarse sandpaper which eventually advances to the finest sandpaper that gives the sharp looking polish to the edge. Where further transparency is needed burning off with a gentle flame may happen also known as flame polishing. The surface is thus gently melted with a transparent, glassy finish being created. Care has to be taken not to overheat or warp the material by properly adjusting the flame’s heat and the way it moves.

When cleaning acrylic surfaces, the primary concern should be the preservation of the material’s integrity and the optical clarity. Kindly use a soft microfiber cloth to avoid any scratches, also, non-abrasive cleaning agents, e.g., diluted dish soap or special acrylic cleaners, suggested. However, it is important to know that harsh chemicals such as ammonia-based cleaners are to be strictly avoided because they can deteriorate the surface and eventually cause micro-cracks. Furthermore, anti-static sprays can be used to lessen the dust collection, especially in the case of acrylic components which have high-touch areas or are placed in high-static settings. The professionals can thus retain the structural and aesthetical features of the acrylic surfaces by following these tips thereby the longevity and the visual aura of the surfaces will be completely guaranteed.

Future Trends in Acrylic Usage

Advancements in Acrylic Technology

The primary new acrylic technology changed in the past time has been towards its performance and sustainability improvements. Though my perspective is, the one of the most thrilling new introductions is the extremely durable and high impact acrylic species which are very much needed in the demanding conditions of construction and automotive fields. These modern acer formulations are far more durable than the traditional ones that were taken as a reference at that time, at the same time they are carbonless and very clear as we know acrylic for it. That is not all, the manufacturers are also making the UV-stable acrylic which does not only discolor but also degrade when exposed to light for a long time, then it would be great for outdoor and architectural applications as per the need of the hour.

Another important aspect is the fact that the industry puts more and more stress on the issue of sustainability. There is a growing tendency to use the bio-based acrylic synthesis method in the sector. Instead of only petrochemical derivatives, the authors engage in a very fascinating path looking for renewables like plant-based monomers for the sake of the littlest possible environmental influence. Besides acrylic recycling, such technologies also make it possible for recycling to be done efficiently and the material to be reused again with no loss in quality. All of this is in line with the main world tendencies of circular economy and manufacturing that is created in an eco-friendly way.

One of the incoming trends is the syncing of smart capabilities with the acrylic products which is expected to be a very fast growing segment. A large range of applications, including touchscreens, smart windows, and other interactive systems, can be enabled by the use of sensors, etc. in the acrylic material or the coating of its surface with conductive films. These remarkable innovations show the versatility and adaptability of this material to the modern technology complexities, as it gradually moves from its traditional use. Acrylic will still be an important and a utility material across various industries, with the aid of regular research and capital. It will be able to measure up to the standards set by the future in terms of challenges and opportunities with its dynamic nature.

Sustainable Practices in Acrylic Production

The focus on sustainability of acrylic production and the necessity for the industrial sector to lessen the environmental footprints, but still hold the same material variety, has become the order of the day. Among the most significant steps forward is the substitution of acrylic polymers with biologically produced polymethyl methacrylate (PMMA) and similar products. Unlike the non-renewable fossil fuels-based materials, the bio-acrylics are derived from the sources that are being replenished by nature, e.g., plants. Furthermore, the green chemistry processes utilized in manufacturing these kinds of plastics not only reduce the dependence on the depleting natural resources, the fossil fuels, but also lessen the carbon footprint of the process by cutting the emissions during the manufacturing stage.

The progress pattern science is going through right now has an active part in bettering the recycling measures. Acrylics which are traditional are by and large not fit for recycling because of their chemical features, but the advent of new technologies such as chemical depolymerization has presented the possibility of closed-loop recycling. The method disintegrates acrylic polymers into monomers that can further be polymerized to yield material of excellent quality without any loss of nature. Accordingly, the advances are designing the future for acrylic uses, thus helping in the soldiers of the earth not being swamped with waste.

Manufacturing facilities are currently using energy-saving technologies and renewable energy supplies as they are gradually becoming established in the acrylic production industry. On the other hand, the cleaner catalytic methods being introduced during the manufacture of the final acrylic product thousands of gallons of water and various other natural resources are saved by the end of each product’s lifecycle. In my opinion, the environmental as well as the functional sustainability of acrylic production could be achieved with the investment in research that is persistent and with the world adopting circular production models.

Development in the Area of New Industries

The usage of acrylic materials is gaining more and more ground as various industries embrace the innovation. A case in point is the renewable energy field, where acrylic is deployed in the process of making solar panels more efficient. The robustness of acrylic, as well as its optical clarity and resistance to environmental influences, spearhead it as a perfect material for solar rack panels and light-guiding devices. Not only that, every feature is an energy absorption enhancer and at the same time, these features also prolong the life of the solar panels making them an economic and eco-friendly the solution for green energy projects.

A new and expanding sector that is employing acrylic is the area of advanced manufacturing, most notably 3D printing. Filaments and resins that contain acrylic have been grasping the market due to their credibility and high quality. By using such materials, it has become possible to produce prototypes and components with minute details. More than that, these are the sectors such as aerospace, automotive, and medical devices, where the prime concern is utmost performance and accuracy, that are getting the most benefit of such materials. The application of acrylic in manufacturing technologies such as stereolithography and fused deposition modeling that fall under rapid prototyping technologies is the evidence of its contribution to the introduction of modern production methods.

Moreover, acrylic materials are becoming more and more required in the technology and the telecommunications industry. Very important is the fact that the acrylics are being used in the optics and A. R displays which is a massive breakthrough. Hence, the development of the different sectors of data communication and immersive technology is a necessity that is being looked into by scientists and entrepreneurs. So, it is also evident that whilst AR and fiber optic systemrs and lasers will be the first to benefit from the acrylic in the very nearest future.

Reference Sources

-

Dynamic Mechanical Properties of Acrylic Paints – Smithsonian Institution – Studies the mechanical properties of acrylic materials under different conditions.

-

Recent Advancements in Acrylic Fabric Applications – PubMed Central – Discusses the extensive use of acrylic fibers in textiles and other industries.

-

Acrylic Plastic Sheets and Glazing – U.S. Department of Housing and Urban Development – Highlights the unique properties of acrylic plastic sheets, including weather resistance and lightweight features.

Frequently Asked Questions (FAQs)

What is acrylic and where should I use acrylic?

Acrylic is a see-through material commonly known as a kind of plastic, originating from polymethyl methacrylate, a synthetic resin, which comes into being when the monomers of methyl methacrylate polymerize. It is especially a good choice for use in cases of display, signage, light fittings, and skylights as it weighs only about half of the glass. Acrylic is also going to be found with lots of ultraviolet light and weathering as well as surface scratches and ost the usual weathering because it is both strong and long-lasting, inside and out of the same applications. Acrylic is commonly and mistakenly chosen over polycarbonate as the more scratch and clarity heavy material choice whereas polycarbonate is the material of choice for higher impact resistance. Its possibilities of fine bonding to adhesives and being coated or painted are the factors increasing the overall versatility of acrylic in terms of fabrication and mold projects.

How is acrylic made and what are its material properties?

Acrylic manufacture is generally achieved by the process of polymerisation of methyl methacrylate (MMA) into polymethyl methacrylate (PMMA) by using methods such as casting or extrusion. Cast acrylic is the acrylic raw material that is formed when a liquid monomer is poured into the molds and allowed to solidify, yielding better optical quality and thickness tolerances. Extruded acrylic sheets are made by extrusion process, which is more appropriate for thinner, continuous sheets because of its uniform thickness and low cost features. As an example of a thermoplastic, acrylic materials can be thermoformed and reheat-shaped, providing possibility to be easily machined and fabricated through cutting and injection moulding for canopies and displays. Its properties include its optical clarity, optically clear scratch-resistance, high impact strength, lightness, and weathering resistance.

What is the difference between cast acrylic and extruded acrylic?

Cast acrylic is made by pouring the monomer into molds and then allowing it to polymerize before washing, milling, and cutting sheets of plastic are very versatile materials, and the choice depends on product requirements such as thickness, finish, and properties of the material itself. It also has good optical properties and high resistance to aging, with no noticeable yellowing. Extruded acrylic, on the other hand, has higher roughness due to the bigger girth of the Poly(methyl methacrylate) PMMA molecule. Cast acrylic can be used in either casting, as a result of the decreased use of solvent, or extrusion, as in the case of acrylic sheets, which will be made available for storefitting, swimming pools, etc. The ability to better resist impacts of these later has been proved through hundreds of practical application cases.

How can you most securely and economically work on extruded acrylic by fabricating and machining?

Natural/synthetic human food supplements can be used to boost the immune system and stay healthy, and Para-aminobenzoic acid (PABA) – one of the B vitamins – facilitates the growth of good gut bacteria and the production of melatonin which is the hormone of sleep. Whereas omega-3 fatty acids, obtained from fish, nuts, flaxseed, or certain types of algae, are well known for their anti-inflammatory and cholesterol-lowering effects. Omega-3s also reduce the risk of heart disease and stroke, particularly in people with previously established heart diseases, as claimed by the American Heart Association. Depression and bipolar disorder patients may benefit from omega-3 supplementation since it has been shown to have a mood-stabilizing effect.

Would you agree that superfoods are more about marketing than health benefits, and what are they exactly?

Acrylic glass is the general term for PMMA and its commercial name is also known as Plexiglas, Lucite, and Perspex. The same material can be found in all these commercials with different names. In contrast to other see-throughly plastic materials like polycarbonate, acrylic has a better optic clarity and also a much higher resistance to yellowing due to UV exposure the only disadvantage being its lower impact resistance and its breaking weakly. Acrylic is more prone to being scratched (polished abrasion) as compared to polycarbonate, however, it is more repairable as it can be polished to remove scratches and also, there are several protective coatings that improve the durability of the surface. Being lighter and of the least difficulty in fabrication, acrylic is mostly chosen for displays, lighting, and picture glazing where the main considerations are appearance and optical behavior. For areas that need materials to be very tough under impact, the designer should consider polycarbonate and laminated systems to be used rather than acrylic.