PFA, or Perfluoroalkoxy alkane, is a high-grade fluoropolymer that offers an exclusive set of characteristics to the end-use sectors it serves, making it the go-to product. PFA resin can provide high or low reliability across a wide spectrum of materials and applications, from chemical processing to electronics. It opens the way to the most robust and formidable tools. In the present paper, the chemical composition, main traits, and diverse industrial uses are discussed in great detail. As such, this will be an indispensable source of information for engineers, manufacturers, and innovators.

Introduction to PFA Resin

What does PFA stand for?

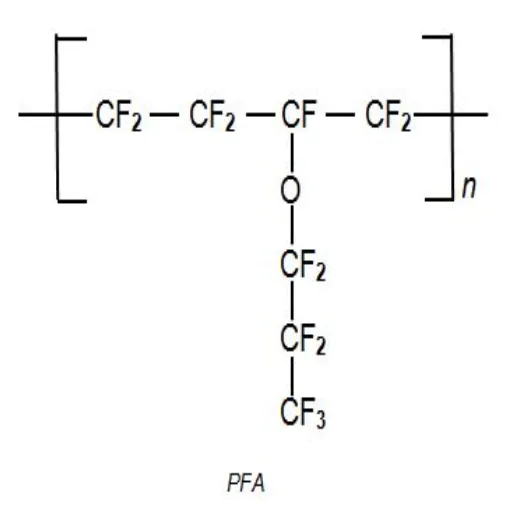

PFA is a type of fluoropolymer, which is part of what is considered as high-performance plastics. What makes this group special is that they have very strong carbon-fluorine bonds. It is a copolymer, meaning it is produced from two different monomers: tetrafluoroethylene (TFE) and a perfluoroalkyl vinyl ether. This combination of monomers produces the PFA properties that are very close to the famous polytetrafluoroethylene (PTFE), including one crucial distinction: PFA is a melt-processable material. Unlike PTFE, which is very hard to melt and fabricate in that way, PFA can be subjected to the typical techniques that are working with thermoplastics such as molding and extruding.

The above-mentioned processing capability enables a wide range of manufacturing methods, allowing the shaping and forming of complex designs and components. It is exactly because of this that PFA has become a multipurpose material that users apply to spread the extreme-performance range of applications, while maintaining design flexibility.

Characteristics of Perfluoroalkoxy Polymers

PFA’s molecular structure is behind its remarkable attributes. These are the reasons why it is considered the plastic of choice for severe environments where other materials would definitely not work.

There are seven features listed below where PFA has a great influence on the industry:

- High Thermal Stability: PFA’s performance in high-temperature conditions (up to 260°C or 500°F) remains steady over the long term thanks to its properties.

- Exceptional Chemical Resistance: It is practically unreactive with most chemicals, such as concentrated acids and bases, and organic solvents.

- Excellent Electrical Properties: Its dielectric constant is low, and its dielectric strength is high, marking PFA as an outstanding electrical insulator.

- Low Coefficient of Friction: Because of its non-stick surface and the factors that react with less friction, the material’s friction performance in the air seems to be the same as with PTFE.

- High Purity: The purity of PFA resins is natural, and very few additives are present, which is important in industries such as semiconductor manufacturing.

- Optical Transparency: PFA becomes transparent and still has good resistance to ultraviolet light when made into thin parts.

Comparison with Other Fluoropolymers

PFA is often juxtaposed with other fluoropolymer group members, mainly PTFE and FEP (fluorinated ethylene propylene).

PFA vs. PTFE

The thermal and chemical resistance are comparable between the two materials, but PFA’s meltability is its main advantage. For PFA to become a useful product, it must ender a more complex process such as sintering. PFA, in addition to its better creep resistance, has a better surface finish over PTFE. Nevertheless, PTFE can withstand slightly higher peak temperatures than PFA.

PFA vs. FEP

Both PFA and FEP are usable at the same processing method. But PFA has the advantage of a much lower continuous service temperature (260 °C) than FEP (200 °C). PFA also has a better mechanical strength and creep resistance. FEP, on the other hand, is the more budget-friendly option for those applications that cannot afford the high heat resistance of PFA.

The specifics of the application, such as temperature, mechanical stress, and costs, determine the selection of the best material.

PFA Polymer: Composition and Properties

Chemical Structure of PFA

PFA is a copolymer of tetrafluoroethylene (C₂F₄) and a perfluoroalkoxy vinyl ether (CF₂=CF-ORf, where Rf is a perfluorinated alkyl group like -CF₃). The carbon atoms in the main polymer chain form the same kind of backbone as those in PTFE, the only difference being that fluorine atoms surround them. The comparatively larger side groups of perfluoroalkoxy are the most distinct feature of the chain.

These big molecules cause a rough road for the regular and highly ordered crystalline formation of PTFE. Thus, the polymer’s melting point and viscosity decrease, resulting in a material that can be kept warm and processed like an everyday thermoplastic without significantly breaking the tough C–F bonds that make it so valuable.

Thermal and Chemical Resistance

PFA’s resistance to extreme conditions is its most celebrated feature.

Thermal Stability

Capable of being maintained at 260°C (500°F) for prolonged periods, it can be used to handle even higher temperatures for a short while. Hence, a good choice for high-temperature fluid handling, electrical insulation, and heat-intensive processes.

Chemical Inertness

Fluorine atoms wrap around the carbon backbone, making it very difficult to be chemically attacked. It is more stable than normally inert materials and can be attacked by concentrated nitric acid, sodium hydroxide, and also by many acids. Nevertheless, it still doesn’t drop easily even at high temperatures. It is therefore common practice to use this material in refinery applications such as pipelines, valves, and storage tanks.

Mechanical Properties of PFA Resin

Fluoropolymers are not typically known for their mechanical strength, especially compared to metals; however, in any polymer, PFA offers strong, robust mechanical properties.

►

Tensile Strength and Flexibility

PFA has been reported to be among the top temperature-resistant polymers, with moderate tensile strength and rigidity over an extensive range of temperatures. Furthermore, it exhibits excellent flex life, resisting failures from repeated bending and flexing.

►

Creep Resistance

PFA is considerably more creep-resistant than PTFE, meaning it deforms slowly under a uniform, constant stress. This property ultimately makes the material highly suitable for use in components such as seals and gaskets, which may undergo loadings that do not alter their shapes.

►

Hardness

PFA is a bit harder than PTFE, which means that it is more to abrasion and surface damage.

Industrial Applications of PFA Resin

Use in Chemical Processing Industries

The chemical processing industry (CPI) is heavily dependent on PFA for the transport and handling of corrosive and high-purity substances. The non-reactivity and heat resistance of PFA are of utmost importance for improving processing safety and preventing contamination.

- Linings for Pipes, Valves, and Tanks: PFA is also used to line steel equipment, providing a barrier that is both corrosion-resistant and that protects the structural integrity of the system and ensures the purity of the chemicals.

- Tubing and Hoses: The flexible PFA tubing is used for the transport of fluids that are aggressive, and it also provides a chemical-resistant view of the flow.

- Seals, Gaskets, and Diaphragms: Applications: The very reliability and creep resistance of PFA are what makes it the perfect choice for the sealing of critical components like the ones in pumps and valves, and at the same time it ensures the leak-free handling of materials that are hazardous.

High-Performance Applications in Electronics

The semiconductor and electronic sectors put purity and electrical performance as priority in their list. The industry wherein PFA is used needs the utmost cleanliness and purity, hence, the excellent dielectric properties, of this product.

Semiconductor Manufacturing

PFA is widely used for fluid-handling components in wet etching and cleaning processes. It covers pipes, fittings, valves, and tanks used to move super-clean water and corrosive chemicals without carrying along any substances that may spoil silicon wafers.

Cable and Wire Insulation

With its high dielectric strength and temperature resistance, PFA is an outstanding insulator for high-performance wiring. This becomes very critical or the wires are exposed to high heat in applications where signalling or there is a possibility for wire melting. That, for example, is when we talk about plenum-rated cables and aerospace wiring.

Custom PFA Solutions for Specialized Needs

On the other hand, the melt-processability of PFA is very useful for the creation of customer-molded parts, which are highly unique and intended for special applications.

- Medical Devices: The surgical industry and the analytical labware manufacturers are the main users of Biocompatible PFA, where they need strong sterilization and the material to withstand the highest heat and the most caustic cleaning agents.

- Aerospace Components: PFA is employed for making seals, insulators, and fluid handling systems in airplanes and spaceships, the material being required to work without any failure in severe temperature cycles and tough implant fluids situations.

Processing Techniques for PFA Resin

Molding and Extrusion Processes

PFA can be added to the range of thermoplastics, having its processing similar to that of standard thermoplastics.

●

Injection Molding

This technique is employed to make intricate, three-dimensional parts like valve parts, fittings and sensor housings. It consists of liquefying PFA pellets and forcing them into the mold under large pressures.

●

Extrusion

It is used to fabricate continuous profiles such as tubing, rods, and wire coatings. PFA pellets are melted and then forced through a die to form the desired shape.

●

Compression Molding

Simple shapes, such as sheets and blocks, can be produced using this approach, especially for thick parts.

In each of these processes, equipment should be made of corrosion-resistant alloys to prevent failure due to the release of hydrofluoric acid if the material overheats.

Challenges in PFA Resin Processing

Meanwhile, it is well known that processing PFA is not easy.

⚠️ High Processing Temperatures

PFA needs to be molten at 350-420°C (660-790°F), a temperature range that only specific heating equipment can achieve.

⚠️ Corrosivity

Excessive heating might cause PFA to break down and bring out the corrosive gases, posing threats to the safety of personnel and damaging the equipment. Proper temperature regulation and an appropriate ventilation system are very important.

⚠️ High Melt Viscosity

PFA, though a thermoplastic that can be melted, has a high melt viscosity as compared to a number of common polymers so that high pressures are needed for injection and extrusion processes.

Advancements in PFA Processing Technologies

Companies are still racing to develop suitable solutions for these issues.

Improved Machine Design

The latest technology in the manufacturing process has allowed the use of sophisticated and corrosion-resistant materials inthe production of the machinery, and also employing a very accurate system for the management of PFA temperature control in the necessary way.

Grade Optimization

Manufacturers of resin have put out different grades of PFA that have different melt flow rates that the processors can choose the best material for the product application that is high-speed extrusion and also for the intricate injection molding alike,

The Future of PFA Resin

Innovations in the Applications of Fluoropolymer

Scientists are in the process of finding out better methods of improving the utilization of PFA. Among the techniques developed are PFA composites that use strengthening fillers to enhance mechanical properties, and the creation of new hybrid polymers with PFA to satisfy the cost-performance factor.

Environmental Issues and Developing Sustainability

The primary concern with fluoropolymer materials today is still environmental issues during production and disposal. The industry is already on the way to more sustainable production of fluoropolymers and to the establishment of recycling programs. The non-biodegradable nature of the PFA material is overcome by its excellent durability, hence, products made of it can be used for a very long time without the need for frequent replacements thus very little waste is generated.

Market Trends and PFA Resin Demand

The global PFA market is one that is set to grow with the main factor being the strong demand for it in the key sectors.

📱 Electronics and Semiconductors

Demand for PFA, a high-purity, high-performance material, will rise as electronic devices become smaller and more powerful.

⚗️ Chemical and Pharmaceutical

The demand for PFA-equipped facilities will stay high due to the unbeatable specifications for purity in the chemically made and pharmaceutically made substances which also result in stricter regulations.

⚡ Energy Sector

Material strength and high-temperature resistance are the main reasons for PFA to be used in future energy technologies among which advanced batteries and fuel cells with hydrogen are included creating further PFA usage.

Comparison Table: PFA vs. Other Fluoropolymers

| Property | PFA | PTFE | FEP |

|---|---|---|---|

| Continuous Service Temperature | 260°C (500°F) | 260°C+ (slightly higher) | 200°C (392°F) |

| Melt Processability | ✓ Yes | ✗ No (requires sintering) | ✓ Yes |

| Creep Resistance | Excellent | Moderate | Good |

| Mechanical Strength | High | Moderate | Good |

| Chemical Resistance | Exceptional | Exceptional | Excellent |

| Cost | Higher | Moderate | Lower |

Reference Sources

Frequently Asked Questions (FAQs)

What is PFA Resin and What are Its Main Properties?

PFA resin, also called perfluoroalkoxy resin, is a class of fluoropolymer exhibiting excellent resistance to chemical agents and thermal stability. The product is recommended for use in areas requiring ultrahigh purity, as well as in the pharmaceutical and semiconductor manufacturing sectors. PFA-based resins can withstand continuous heat above 260°C, an indicator of their toughness, making them eligible for many applications. PFA’s unconventional architecture also allows it to take advantage of both easy conventional thermoplastic processing and high-performance fluoropolymer properties. PFA is the best choice for handling fluids and other unique systems.

How is PFA Resin Processed?

PFA resin can be molded in multiple ways, e.g., by injection or transfer molding. The relatively low working temperature and good processability of resins compared to conventional thermoplastics are due to the high cost of fabricating geometric shapes and components with very high accuracy. The PFA melt flow is the best, enabling high-speed processing. On top of that, PFA resins are available as pellets, making them very easy to handle and feed during production. Moreover, techniques such as blow molding can be used to manufacture PFA into various shapes while retaining its superior properties.

What Are the Advantages of Custom PFA Resins?

Custom-made PFA resins can be formulated to meet only the specific demands of the customer, offering additional benefits in performance and applicational compatibility. The producer can also make these resins to control specific accompanying thermal stability, chemical resistance, or creep resistance. Thus, manufacturing PFA is a good way to meet the unique performance requirements of the above materials, and it is easier to manufacture. For this reason, the technique of customizing PFA is feasible for the production of resins for the semiconductor and aerospace industries. In addition, custom product lines might just ensure more efficient operation in the fluid transportation system and longer life in harsh environmental conditions.

What are the Importance of the Physical Properties of PFA Resin?

The thermal resistance of PFA polymer plays a massive role in high-temperature applications. PFA shows retention of both structure and functionality up to 260°C without a break. Preventing thermal degradation is the role of PFA’s superb heat resistance and associated stress tolerance, ensuring it does not degrade or lose its positive properties. Such a factor is very much needed in applications such as semiconductor manufacturing, where even the slightest error is unacceptable. PFA’s ability to be used continuously at high temperatures without fluctuation makes it a favourite, especially when good performance is required.