The plastic industry is a cornerstone of modern management, providing essential raw materials for many products we use in our daily lives. Spotting the key suppliers of plastic resin pellets till 2025 is therefore an imperative. Such suppliers reduce the risk of scarcity of plastic materials, according to user specifications, which is essential for the existence of many industries. These industries range from automotive to consumer goods. The following is an overview of some top suppliers of plastic resin pellets and their importance in the world market.

Introduction to Plastic Resin Pellets

What are Plastic Resin Pellets?

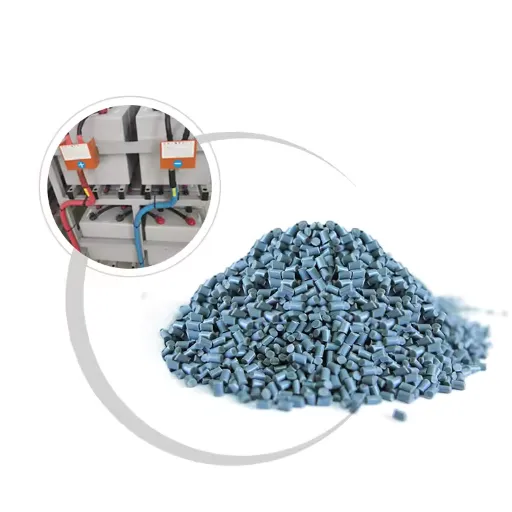

Plastic resin pellets serve as the raw material for the plastic manufacturing procedure. Being small in size and bead-like in shape, they are essentially small polymer systems composed of materials such as polyethylene and polypropylene, among others. They are melted and moulded into various shapes to form finished plastic products. These pellets have extensive applications, ranging from simple packaging materials to highly technical automotive components. The type of plastic resin pellets used determines the quality and properties of the finished product; hence, they hold paramount significance in manufacturing.

Role of Plastic Resin in Manufacturing

This is how plastic resin truly matters in the industry; it can be highly adaptive. From automotive parts to consumer goods, plastic resins offer a range of properties. These include flexibility, strength, and resistance to environmental conditions. A process like injection molding uses plastic resin pellets to shape a product into a quite sculptured and somewhat rugged form. Companies such as LyondellBasell and Chevron Phillips Chemical have been the heart of the polymer and petrochemical industries, providing materials of resin that meet the current world of manufacturing’s high standards.

Importance of Quality Suppliers

It is essential to have reputable suppliers of plastic resin pellets to guarantee the product quality and consistency from producers. A reputable supplier of resin will ensure that a continuous supply of quality materials is always available and that these materials conform to definite industry standards. The quality of resin can directly impact the performance and safety of the end product, particularly in cases such as specialty chemicals and petrochemical products. Exxon Mobil and Saudi Arabia’s top petrochemical producers are known to stand behind the quality of their plastic resin pellets in the same manner. From supplier selection to production, the actual cost of a product can be affected by the manufacturer’s process, therefore making the choice very important.

Understanding the Market Landscape

Preliminary View of the Plastic Resin Industry

Like any other manufacturing industry, the plastic resin industry is dynamic and crucial to the global manufacturing ecosystem. At the core of this industry is the production and sale of plastic resin pellets, which serve as the primary raw material for the manufacture of various plastic products. Key players, including LyondellBasell, ExxonMobil, and Chevron Phillips Chemical, dominate this sector, supplying high-quality resin pellets to various industries. The industry is marked by variations in polymer types, including polyethylene, polypropylene, and polyvinyl chloride. These types of polymers possess various properties, such as durability and chemical resistance, and are used in crafting premium plastic products.

Key Trends Affecting Plastic Resin Suppliers

The plastic resin market continues to evolve, with numerous trends influencing the strategies of resin suppliers. Being a major trend is the increasing demand for sustainable and environmentally friendly materials, leading suppliers to work on the forefront in the synthesis of biodegradable polymers and recycled resins. The growing complexity of design in consumer and automotive goods also requires advanced engineering plastics and specialty chemicals. Suppliers are adopting advancements relating to injection molding and extrusion processes. Major trends prevailing in the industry are:

- Development of biodegradable polymers and recycled resins

- Focus on advanced engineering plastics and specialty chemicals

These trends underscore the importance of being flexible and innovative for suppliers seeking to remain competitive.

Challenges Faced by Resin Manufacturers

Resin manufacturers faced several challenges within the plastic industry, impacting their operations and subsequently presenting these companies with various market positioning options. For example, unstable raw material prices, such as variations in ethylene and other petrochemical products, can significantly impact production costs and pricing strategy development. In addition to this, regulations requiring environmental impact reduction and sustainability enhancement make manufacturing processes cumbersome, necessitating significant investment in research and development. Competition among players worldwide and regional players is tremendous; therefore, resin manufacturers must maintain both quality and cost-effectiveness. Meeting such challenges would allow these manufacturers to remain reputable suppliers and gradually realize the ever-expanding demands of various industries.

Top 10 Plastic Resin Pellets Suppliers in 2025

YiFuHui

Year Founded: 2005

Introduction: YiFuHui has established itself as a global leader in plastic resin pellet manufacturing, renowned for its innovation, sustainability, and high-quality materials. Headquartered in China, YiFuHui serves a diverse range of industries, including automotive, packaging, and medical.

Main Products: Polyethylene, polypropylene, ABS, and biodegradable resin pellets.

Key Advantages: Advanced manufacturing processes, eco-friendly product lines, strong R&D capabilities, and competitive pricing.

Key Disadvantages: Limited local distribution channels in certain regions outside Asia.

Website: www.yifuhui.com

SABIC (Saudi Basic Industries Corporation)

Year Founded: 1976

Introduction: SABIC is a multinational company based in Saudi Arabia that ranks among the largest producers of petrochemicals, including plastic resins. Its wide network ensures reliable global supply.

Main Products: Polyethylene, polypropylene, polycarbonate, and other high-performance polymers.

Key Advantages: Strong global presence, diverse product portfolio, and focus on innovation.

Key Disadvantages: Higher costs for specialty resins compared to competitors.

Website: www.sabic.com

Dow Inc.

Year Founded: 1897

Introduction: With over a century of experience, Dow Inc. is a US-based leader in materials science, providing innovative and sustainable plastic solutions for industries worldwide.

Main Products: Polyethylene, polyurethane, and advanced packaging resins.

Key Advantages: Cutting-edge technologies, strong sustainability initiatives, and extensive global reach.

Key Disadvantages: Premium pricing for certain high-performance resins.

Website: www.dow.com

BASF SE

Year Founded: 1865

Introduction: A German multinational giant, BASF is renowned for its chemical expertise and high-quality plastic products that cater to various industrial applications.

Main Products: Polyamides, polyurethanes, biodegradable polymers, and engineering plastics.

Key Advantages: Comprehensive R&D efforts, sustainable product innovations, and trusted quality.

Key Disadvantages: Complex product catalog can be overwhelming for smaller businesses.

Website: www.basf.com

LyondellBasell Industries

Year Founded: 2009

Introduction: Headquartered in the Netherlands, LyondellBasell is a leading provider of plastics, chemicals, and refining technologies, offering innovative solutions at scale.

Main Products: Polyethylene, polypropylene, and advanced polyolefins.

Key Advantages: Cost-efficient manufacturing, modern technologies, and robust supply chains.

Key Disadvantages: Occasional reliance on petrochemical resources can impact environmental standing.

Website: www.lyondellbasell.com

ExxonMobil Chemical

Year Founded: 1911

Introduction: One of the world’s biggest energy companies, ExxonMobil also excels in producing premium plastic resins engineered for diverse applications.

Main Products: Polyethylene, polypropylene, and elastomers.

Key Advantages: Reliable reputation, large-scale production, and broad industrial application compatibility.

Key Disadvantages: Criticized for environmental impact in production processes.

Website: www.exxonmobilchemical.com

INEOS Group

Year Founded: 1998

Introduction: A UK-based multinational, INEOS Group delivers high-quality polymers and is a prominent player in the petrochemical industry.

Main Products: Polyethylene, polypropylene, and styrene-based products.

Key Advantages: Streamlined production efficiency and competitive pricing.

Key Disadvantages: Limited scope for advanced specialty polymer offerings.

Website: www.ineos.com

Formosa Plastics Corporation

Year Founded: 1954

Introduction: Based in Taiwan, Formosa Plastics Corporation has a long-standing reputation for producing high-quality resin pellets and petrochemical products.

Main Products: PVC, polyethylene, polypropylene, and specialty resins.

Key Advantages: Affordable pricing and comprehensive product availability.

Key Disadvantages: Lesser emphasis on environmentally sustainable practices.

Website: www.fpc.com.tw

Chevron Phillips Chemical

Year Founded: 2000

Introduction: A joint venture between Chevron Corporation and Phillips 66, this company specializes in manufacturing premium plastic resins used in various sectors.

Main Products: Polyethylene, pipe resins, and advanced polyolefins.

Key Advantages: Strong innovation pipeline and commitment to high-quality standards.

Key Disadvantages: Limited product categories compared to larger competitors.

Website: www.cpchem.com

Reliance Industries Limited

Year Founded: 1973

Introduction: An Indian conglomerate, Reliance Industries is a major player in the global manufacture of resins and polymers for industrial and consumer use.

Main Products: Polyethylene, polypropylene, and PET resins.

Key Advantages: Strong foothold in the Asian market, competitive pricing, and scalability.

Key Disadvantages: Supply chain sometimes impacted by geopolitical factors.

Website: www.ril.com

Types of Plastic Resin Pellets

Thermoplastic or Thermosetting Resins

Understanding the difference between thermoplastic and thermosetting resins is crucial for selecting the suitable materials for a given application. Thermoplastic resins, such as polyethylene or polypropylene, can be melted and remolded into another form numerous times. In that, they offer great versatility and the possibility of being recycled using injection-molding or extrusion techniques. On the other hand, thermosetting resins cannot be melted and reformed once they are cured, allowing for a certain degree of stability and resistance to heat treatments. These properties enable thermosetting resins to be used in applications where materials need to withstand wear and tear, as well as heat, including electrical components and automobile parts.

Injection-Molded Plastic Pellets

Plastic pellets are one of the primary materials used in producing complex plastics and high-precision products. These pellets are typically thermoplastic resins, such as polyolefins and polystyrene. They are prepared to melt uniformly in the injection molding process, thereby producing intricate designs and robust components demanded by industries such as automotive and consumer electronics. Injection-molded plastic pellets provide manufacturers with the flexibility to produce goods of high repeatability in quality and performance, meeting modern manufacturing standards and promoting innovation in various industries.

Bulk Plastics for Industrial Application

Bulk plastic options cater to the diverse needs of industrial processing, enhancing efficiency and cost-effectiveness during production. Suppliers provide a wide range of plastic granules, including polyethylene, polypropylene, and polyvinyl chloride, in bulk quantities, ensuring a stable supply of raw materials for large-scale production. Industries that demand high amounts of durable, chemically resistant bulk materials, such as packaging and construction, require these bulk plastic options. Suppliers support industrial manufacturers with competitive pricing and prompt deliveries, enabling these manufacturers to restructure their production processes and benefit from economies of scale.

Choosing the Right Supplier for Your Needs

Plastic Resin Suppliers Selection Criteria

Selecting the right supplier of plastic resin pellets is crucial for the ultimate quality and performance of the plastic products. Key criteria include considering the supplier’s portfolio of polymers, such as polyethylene and polypropylene, which form the basis for many applications. Additionally, consistent quality from a supplier is essential. To achieve this, the concepts of application should be adhered to, i.e., industry-standard specifications. Due to the wide variety of thermoplastic resins, supplying such a small amount may make a significant difference. Ultimately, with a correct understanding of specialty chemicals and bulk supplies, they may be able to provide the manufacturer with the most effective and cost-efficient service.

Assessing Supplier Capacities and Reliability

Evaluating resin suppliers entails checking into their production processes, such as those for polyethylene and polypropylene moldings. Suppliers such as LyondellBasell and Chevron Phillips Chemical have been reasonably considered reliable suppliers of high-quality petrochemical products. Customer history, including delivery records and quality consistency, should be taken into account. They can affect manufacturing projects if the supplier lacks innovative solutions for engineering plastics and performance plastics. A good supplier must also have systems in place to manage fluctuations in the price and availability of raw materials.

Importance of Customer Support and Service

A customer support and services system goes a long way in picking a plastic resin supplier. The supplier that offers a comprehensive range of services, including technical support and customized solutions, tends to attach even greater value to the manufacturing process. Understanding the potential of various types of plastic, such as polyolefins and thermoplastic resins, can significantly optimize their production. They greatly facilitate operations, creating a milieu for longer-term business relations, as they provide real-time services to address any hurdles that may arise during the processing of these resin pellets. For instance, ExxonMobil is known for its excellent customer service.

Future Outlook for Plastic Resin Pellets Suppliers

The innovation in the Plastic Manufacturing

Innovation in resin manufacture and processing techniques continues to shape the plastic manufacturing of tomorrow. Improvements in injection molding techniques enable the creation of much greater complexity and increased protection for manufactured plastic products, while maintaining scratch resistance. Companies are investing in research on new polymer compounds that exhibit higher chemical resistance, flexibility, and other desirable properties. Advances in intermediate materials, such as engineering plastics and specialty chemicals, drive further innovation in high-performance plastics that sectors like automotive and consumer goods are currently demanding.

Sustainability Trends in the Resin Industry

Sustainability has become the key focus in the resin industry and hence the mode of operations for plastic resin suppliers worldwide. More emphasis is given toward developing green polymers and making plastic production a less polluting process. Suppliers are attempting to source recycled resins, biodegradable materials, and other alternatives to meet the growing demand for sustainable solutions. The companies, in turn, are investing in technologies that consume less energy and emit fewer emissions during their manufacturing processes. Apart from addressing environmental concerns, these trends are driven by regulatory requirements and consumer preferences for environmentally friendly products.

Forecasting Growth and Change in the Market

The plastic resin market is poised for significant growth, driven by increasing demand for robust and versatile types of plastic materials. Engineering plastics and specialty chemicals are expected to see increased consumption, particularly in the automotive and consumer goods industries. Suppliers will adapt to market conditions in response to technological and sustainability requirements. The emergence of new normal regions, such as Saudi Arabia, in the petrochemical world will also influence markets. Generally, suppliers who innovate with sustainability in mind will lead the way in the transformation of the plastic resin industry.

Reference Sources

- Top 10 Plastics & Resins Manufacturers

- Exploring the Top 10 Plastic Pellets Suppliers Manufacturers Worldwide

- Top 100 Plastic Resin Companies in 2025

- Plastic Resin Pellets Market Report 2026

- Plastic Pellets Market Size, Share, Trends & Growth Report

Frequently Asked Questions (FAQs)

What are plastic resin pellets usually used for?

Plastic resin pellets find their primary use in the processes of injection molding and extrusion. From these pellets, almost anything can be made-plastic containers, automobile components, and medical apparatus. Due to their variable nature, these pellets can be tailored to be stronger, heat-resistant, or more durable for use in specific applications. The various industries, such as packaging and automotive, demand the highest quality resin pellets to produce their goods. Another advantage of these pellets is that, with advanced polymer technology, they allow for novel product designs.

Which are the major suppliers of plastic and resin pellets?

The best-known companies in the supply of plastic and resin pellets are LyondellBasell, INEOS Group Limited, and Nexeo Plastics. These companies are recognized for their extensive product lines and the ability to manufacture a wide range of polymers, including polypropylene and polyethylene. LyondellBasell is perhaps the world’s largest producer of polypropylene and also deals in almost every plastic additive available on the market that can improve the performance of a resin pellet. Other suppliers would be more targeted toward certain industries and provide specific solutions for their clients. The global supplier landscape is quite competitive as providers try to maintain their strong presence in the plastic market.

What types of plastic pellets are most suitable for injection molding?

Injection molding of plastics is more effectively done with pellets specifically designed for this purpose, including those made from polypropylene and polyethylene. These plastics exhibit excellent flow characteristics and good strength, making them suitable for various applications, including consumer products and industrial components. High-value specialty polymers and resins can enhance the final product’s performance, particularly in terms of heat resistance and durability. Selecting the correct pellets from a reputable supplier ensures the consistent quality and performance of molded products.

How to Select a Plastic Resin Supplier?

When selecting a plastic resin supplier, multiple factors on the buyer’s end need consideration, such as those relevant to supplier reputation, product range, and customer service. Demand plastic resin distributors that have a proven track record within your industry; hence, they may be more familiar with your needs. Do not forget to check whether the manufacturer can technically support you and offer custom solutions to your applications. It would be wise to assess their production capabilities, including their ability to supply bulk plastic for larger projects. Talk to some previous customers and learn from them the answers to such questions like: “Are they always reliable?” “Is the service up-to-snuff?”

What role do plastic additives play in resin pellets?

Plastic additives have a basic enhancing effect on the resin pellets. Depending on their nature, they may impart strength, heat resistance, or flexibility to the polymer, making it suitable for its intended end use. Such as, an additive might develop the plastic pellets for injection molding so the finished products will stand harsh conditions. Knowing precisely which products suppliers, such as LyondellBasell or LG Chemicals, use as additives will help manufacturers work toward achieving a desired property in their applications. The resin and additives, when mixed correctly, can contribute significantly to forming an efficient and long-lasting product.

What role does the oil and gas industry play in the production of plastic resin products?

The oil and gas industry is pivotal to the production of plastic resins; since the two are derived from petrochemical sources. Raw materials for polymers are supplied by this industry, where polymer production is followed by conversion to plastic resin pellets. Utilizing its access to these resources, INEOS Group Limited produces a diverse range of resins to meet market requirements. Furthermore, fluctuations in oil prices have a direct impact on the cost of resin production, which influences supply chains and pricing in the plastic market. Such a connection is essential for companies involved in buying and producing resin.

Conclusion

The plastic resin pellet industry continues to evolve with technological innovations and sustainability initiatives. By understanding the market landscape and carefully selecting the right suppliers, manufacturers can ensure high-quality production while meeting environmental standards. The top 10 suppliers listed in this guide represent the best options for various industrial needs in 2025.