The majority of the population come in contact with acrylic material in their daily life, in the present knowledge, these materials could be durable windows, radiant signage, or even elegant home decorations. Nevertheless, have you ever thought about its scientific classification and properties? more specifically, is acrylic a thermoplastic, and what effect does that have on its behavior and malleability? This article is going into the detailed realm of acrylic to try and answer some of these questions. We will put it into the class of materials, we will present how it behaves under different circumstances, and we will show how unique the characteristics are that make it a favorite in a variety of industries. By the end of the day, you will be able to see the role of acrylic in the present-day industries and the difference that its thermoplastic feature makes.

Understanding Acrylic and Its Composition

What exactly is acrylic?

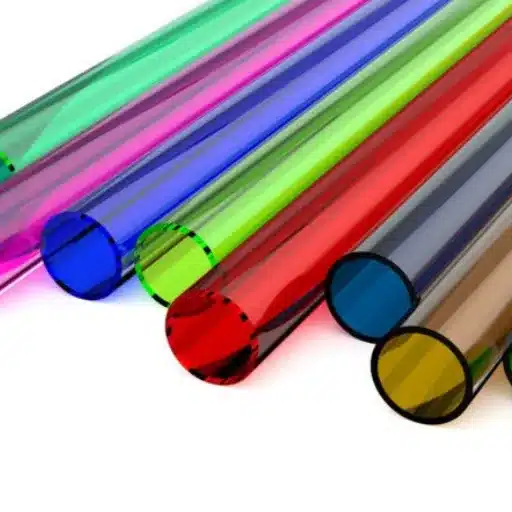

Acrylic, which is mainly called polymethyl methacrylate (PMMA), is a thermoplastic which is very easy to work with, is transparent, shatter-resistant, and has high durability. Acrylic is a perfect alternative to the traditional glass counterpart by being easy to manipulate and thus, it has a wide range of applications. Acrylic is said to be the major polymer of acrylic among other polymer derivatives. It is a commonly used material in the construction, automobile and design sectors because of the fact that it can perform well even under strong weather conditions and still have a clear view. The combination of its adaptability and cost-efficiency has made this material very popular and it is now the initial flavor among various products like signage, windows, aquariums, and, even medical devices.

The Chemistry of Acrylic Resin

Free radical polymerization is used to make acrylic resin in the crosslinked structure. Amongst the monomers used in this process, methyl methacrylate (MMA) plays the key role and initiators such as are needed to activate it. resulting nylon-like polymerization that is the main thing of strength and toughness of the -made product. It is the dense molecular bonds of acrylic resin that give it such a good level of resistance to UV radiation and environmental degradation.

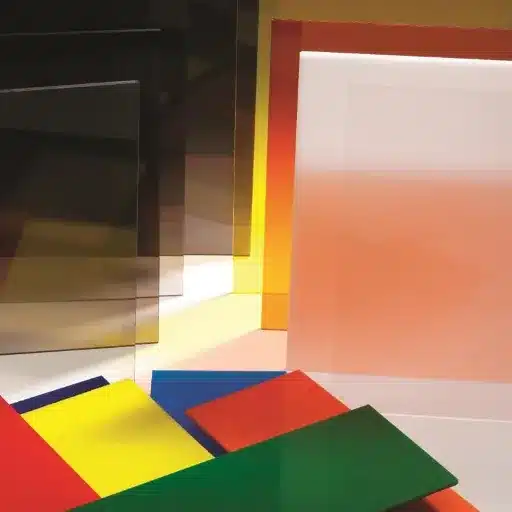

Even the progress in chemistry engineering has made it possible for the creation of the perfect acrylic formulations that chemical engineers think of by reducing them through stabilizers, pigments, and impact modifiers. Therefore, these developments make the acrylic resin not only mechanically stronger but also useful in various industries. Acrylic can be modified using different chemicals so that its properties can be adjusted to meet the stringent requirements of the aesthetic and practical uses. Compared with other plastics, acrylic is known for its strength, flexibility and it is easy to shape, weld, and paint due to its fine properties that are also the reason that it is popular for the decorative uses as well as for the construction purposes. The use of optical brighteners in the production of acrylic resin gives it a high level of brilliance, resulting in attractive products, including outdoor signage and displays with excellent visibility.

What is it that makes Acrylic a Thermoplastic?

Thermoplastic is Acrylic, which exhibits a rare ability to become soft upon heating and become solid when cooled, even though it does not experience any significant chemical transitions. This specific quality is conjoined to the artificial structure of acrylic—a sequence of the same molecular units attached to each other. These molecular chains are connected with quite weak intermolecular interactions making it possible, with the help of heat, to shape the material as many times as one can without any considerable loss in the material. This particularity is indeed the one that makes thermoplastics just the opposite of thermosetting plastics, as the latter ones lose their hardness as soon as they are cured. The thermoplastic behaviour of acrylic material provides it with the possibility of being the right material for circumstances when it is necessary to get exactly the required shape or change the shape, for example, automotive parts, architectural projects, up to even personal electronic gadgets, showing at the same time strength and pliability.

Characteristics and Properties of Acrylic

Physical Properties of Acrylic

Acrylic is a well-known material due to its light weight and high strength-to-weight ratio, this feature makes it predominantly used in several industries. At the same time, it is also very transparent material, and its optical clarity is very close to glass if not even better, one more beneficial aspect is that it remains such while it is far more break-proof. The density of acrylic is around 1.18 g/cm^3, thus it is lighter than glass which normally has a density of 2.4 to 2.8 g/cm^3, likewise, the surface hardness of the material gives it long life and enables it to remain shiny with only a little defect in light of modest use although some kinds of coatings are found to be very effective in scratch prevention.

It is worth noting that acrylic is highly weather-resistant. The plastic does not turn yellow or brittle even when regularly exposed to sunlight and severe atmospheric conditions such as pollution. The fact that it has a high melting point of approximately 320 degrees Fahrenheit (160 degrees Celsius) further makes it capable of holding its shape at temperatures below extreme heat, hence making it possible to use it for both indoor and outdoor applications. On top of this, the acrylic can let through as much as 92% of the visible light, thus exceeding the clarity of many plastics, and can also filter out the harmful UV rays with the help of appropriate treatment. All these make acrylic a very strong material both for functional and aesthetic purposes.

Thermal Properties and Behavior

It is often pointed out that acrylic is an excellent material for various applications. The glass transition temperature of Acrylic which is about 320°F (160°C) is the point where the material starts to soften hence its reliability in places with moderate heat better environments. Being a thermoplastic material, acrylic can be reshaped and won’t lose its strength in the process as long as the temperatures are tightly controlled. In addition, it has a very low thermal conductivity, which could be an advantage as far as the reduction of heat transfer is concerned and which therefore could be suitable for industrial and residential insulation. On top of that, the advances in acrylic formulations have given rise to better heat resistance properties, thus, for some grades, they can bear higher temperatures without degrading. These not only imply but also demand thermal and mechanical stability and also adaptability as a condition of acrylic’s engaging and supportive presence even in case of the use of advanced and not very manageable materials in the future.

Comparison with Other Thermoplastic Materials

In comparison with other thermoplastic materials, acrylic offers a distinctive properties equilibrium. For example, polycarbonate, another highly used thermoplastic, features a better impact resistance, therefore, it is more suitable for the heavy-duty applications. Nevertheless, in the aspects of visual clarity and resistance to ultraviolet light, acrylic is better than polycarbonate, hence, it is the first choice for applications for outdoors and decorative purposes.

In an opposite way, polypropylene with its great chemical resistance and very low mass is often the material of the application that was in between light weight yet still long-lasting materials. However, it doesn’t have the aesthetic value and beautiful surface properties which are inherent in acrylic. Acrylonitrile butadiene styrene (ABS), much loved for its robustness and fabricational ease, is a typical structural component alternative. Although ABS might be stronger, it is not the same when it comes to acrylic’s weathering endurance and its clearness.

These differences underline the possible relative advantages of acrylic in different applications. The blend of thermal resilience, clearness, robustness, and creative output adaptability, often, makes it a top choice for businesses that involve both aesthetic and performance like signage, glazing, and displays.

Fabrication Techniques for Acrylic Materials

Common methods for working with acrylic

Acrylic is a versatile material and can take several processes to acquire precise shapes, textures, and functionalities. Listed below are most frequently used methods in working with acrylic:

Cutting: One of the main uses of Acrylic sheets is cutting by machines that are particularly versatile and accurate such as laser, CNC and a table saw. In particular, high-speed laser cutting method is very suitable for detailed and highly precise applications like signs and artworks due to its ability to have very clean edges and even make small, intricate designs.

Polishing: That can be the case when the acrylic edges should be polished after cutting and machining, to have them clarified and look fully professional. In most cases, flame polishing becomes the choicest way to have the edges smoothed with gentle heat, or buffing with the use of polishing compounds is employed that renders a high-gloss surface and adds to the appeal of the part visually.

Bending and Thermoforming: Acrylic when heated is bendable and can be made into different shapes by thermoforming. The pliability of the material is achieved using strip heaters or ovens, thus the fabricators can produce curved designs or complex forms that can be mainly attributed to retail displays or protective barriers.

Bonding and Gluing: Acrylic can be put together using adhesives or solvent-based cements that have been specifically developed for this purpose. These materials impinge in the creation of very strong, clear bonds, although they are as good as invisible, so they are very popular in paints and tanks of water or even furniture.

Engraving: Engraving on transparent acrylic, for example, provides both attractive and functional effects, for instance, text, logos, and patterns. Laser engraving is one of the most precise ways of getting these designs and mechanical engraving tools are great for large-scale projects.

Painting and Coating: Acrylic surfaces can undergo painting or the application of protective coatings to achieve certain aesthetics or functions. Some of the paints are made to bond with the material, making the colors vivid or the textures rough and, “on the other hand,” the application of anti-UV coatings will increase the product’s life cycle.

Incorporation of these techniques rightly will not only increase the versatility and charm of the acrylic parts but will also secure the strength and duration for various industrial and decorative demands.

Positive Aspects of Acrylic in Manufacturing

Acrylic is always the first choice for manufacturing due to its unmatched adaptability, strength, and appealing looks. A significant attraction is its being light in weight, which means no problem lifting and moving it, as it is much lighter than glass or other materials although it is very strong and resists impact to a great extent. Even more, acrylic shares advantages like the ability to be even more transparent than glass and thus allowing up to 92% of the light to pass through which makes it just perfect for instances like display cases, signage, and highlights of a building.

Acrylic can be bent, cut, and formed with extreme accuracy when it comes to making custom products, which is to say that it is a very hopeless choice for various designs that should be both functional and beautiful. The material is also resistant to weather, so it can be used for outdoor purposes since it stands up to sunlight, rain, and extreme temperatures with minimal changes in its quality. Moreover, the production of acrylic items is cost-effective as the products have a very long lifespan and require minimal maintenance, which decreases the costs associated with replacement and repair. Together, these properties make acrylic a material that is highly appreciated by the industries in fields like construction, design, and retail.

Challenges in Acrylic Processing

In spite of the many benefits of using acrylic, processing the material is not without its share of difficulties. The biggest among them is the heat sensitivity of acrylic at the time of fabrication. If the temperature is too high, the result is either warping, the formation of surface cracks, or in most of the cases, the material might get the wrong color, which otherwise could affect both the look and the strength of the product. It is also interesting to know that when modifying the material, it often occurs that there are visible signs of damages on the surface, e.g., scratches and chipping, and so on, which cannot be avoided, so it might be necessary to use a method to get rid of these damages manually, e.g. by polishing.

Joining acrylic is generally considered to be difficult, and one major reason is that there are not very many adhesives that can make joints that are as reliable and clear as wanted. Moreover, not a few wrong ways to bond may end up with the development of cracks due to stress throughout the period, especially in the case of different environmental conditions or a varying mechanical load. Moreover, recycling of acrylic has its own problems; being theoretically recyclable but not a straightforward process as with the other materials, and the recycling infrastructure that is intended to support large-scale recycling is not wide spread yet. The only way to overcome these challenges is by using very high-precision manufacturing methods, high-quality tools, and new types of up-to-date and sustainable adhesives and processing methods.

Applications and Uses of Acrylic

Industrial Applications of Acrylic Plastic

It is well known that acrylic plastic is found in the industrial sector, and the major cause of that is its ability to be used. It is durable, clear and thus under the vast market, it is found almost any industry. It is most often found in the building and architecture sector where its low weight and high strength make it suitable for the manufacture of skylights, windows, and partitions. It is also suitable for the production of safety shields and machine guards which is a common use of plastic materials in this sector and such products made of acrylic are resistant to breaks and are transparent.

Besides its being used as a sign-making and display material, acrylic has proved to be a valuable resource in the automotive industry due to its high UV resistance, design flexibility, and overall looks. For this reason, the material is a good choice for a wide range of lighting applications like headlights, tail lamps and interior components such as the dashboard and door panels.

Given its great cleaning capacity and high durability, scientific gear is another beneficiary of acrylic’s properties, being used for example in incubator covers, protective barriers, and display cases for sterile tools. In addition to the above, the weather resistance and the capability that it has of withstanding high-pressure conditions have made acrylic an indispensable material in the field of aerospace and marine manufacturing. For example, it is used for aircraft windows, submarine periscopes, and other special components.

Acrylic is used in Art and Design

The introduction of acrylic has resulted in a new era in the art and design industries due to its benefits such as the large range of colors, durability, and good looks. Acrylic paint for example is mainly used by artists for its color range options, fast drying and hence workability with various and even not conventional mediums like wood and metal. Among many other things, the ability to replicate textures, from shinny to the hard textures of matte surfaces, allows artists to do their experiments and have a conversation through their expression with the text.

Besides paint, acrylic sheets are a must-have in the contemporary design. They are employed in making elegant furniture, splendid sculptures, and decorations for interiors, blending the aesthetics and power of the material in one experience. Due to their properties, acrylics possess the ability to have any form, be of any color, have many marks or even be lighted up by LED lights and thus, they are the most used material for installations and exhibits (source). Furthermore, thanks to their low weight the material and they are not seen as heavy on the users (source foralglass) that is because of improper handling. Thus, the material itself is a safety factor as well as the use of hardware that secures the joints, bolts etc., luminaires, and circulation ducts to the beams as falling objects etc.

Whatever the designer wants to create, the lightweight of the acrylic will not hinder him unlike in the case of glass. The trend of the usage of acrylic is changing daily whereby new concepts are getting mounted into physical being through these modern techniques.

Household Uses of Acrylic Products

Acrylic products are an essential thing in the construction of the modern household and people are attracted to them for their manifold usability, long-lasting traits, and the looks they bring. The living area and bedrooms are the most popular locations where acrylic is being used in the form of furniture and other accessories because they the room look very modern and at the same time, these products are light and unbreakable. Acrylic shelves, photo frames, and table tops are the commonly seen items that people will use to add the luxurious touch, as they can be made in different colors and textures to match the tastes of various individualistic people.

In addition, it is very common to see acrylic being used in various kitchen and bathroom articles like an organizer, this is not only due to the fact that it does not absorb water but also because it is very easy to clean. It is also recommended that one considers installing acrylic lighting fixtures as it will make the house look so modern and at the same time, the lightening will be even and also he will save a lot of money as the electricity bill will be less. If you have children or pets at home, then the best alternative to make the house look good and still have a safety measure would be by using acrylic instead of glass because of the former being a robust and easy to clean material.

The use of acrylic in the manufacture of storage articles is another very considerable practical advantage. The so-called stackable acrylic bins and the transparent shoe organizers are typical examples of such products, not only useful but also contributing to the beauty of the place by the way of visual appearance. Such factors as the great variety of ways of application and the adaptability influence people’s decision-making getting in favor of choosing the acrylic as the main ingredient of their home improvement project.

Future Trends in Acrylic and Thermoplastics

Innovations in Acrylic Manufacturing

Sustainability and precision engineering drive the transformation of the acrylic manufacturing industry. The main positive change here: the invention of bio-based acrylics, which such things as transforming non-renewable fossil fuels into the petroleum-derived materials used for producing acrylics that will not be necessary anymore. This means the production process becomes much less environmentally harmful. Moreover, more advanced and faster polymerization methods now available permit producers to have a wider range of customization thus creating different acrylics having specific properties, such as effective in protecting against UV light, much stronger in resisting impacts, or even having the power to self-heal.

Automation and digital tech further alter the industry part. By embracing AI and ML in a lot of ways, the whole production process itself makes use of machine learning in such a way as to improve quality control and waste reduction at the same time as this system is applied throughout the pipeline of production. Moreover, through the employment of acrylic materials and 3D printing, high precision is achieved and the possibilities for complex shapes and designs are extended, with this exposure attracting both automotive and health care sectors among others. Acrylic is therefore established as a technology and innovation inciter, rather than only a material with a wide range of uses.

Sustainability Considerations for Acrylic Plastics

Acrylic plastics sustainability is being questioned by plenty of people, and I have to say that I share this opinion to a certain extent. The advantages of this material being very strong and the ability to recycle it make it a good alternative for certain specific applications. The long life of the product is also a factor that minimizes the number of replacements and in return, the environmental impact is lower compared to materials that are less durable. Moreover, the recycling technology has been progressing, which allows the material to be broken down and reused, thus, the new plastic material from petroleum is not the only option and it is also a part of the transition to the circular economy.

That being said, it is important to consider the limitations as well. The process of creating acrylic depends on fossil fuels and the greenhouse gases are being released during the manufacturing process, which raises concerns about the environmental impact. Moreover, not properly disposing of acrylic can lead to the slow but a constant damage to the environment; since it’s not biodegradable. The approach to the situation, hence, primarily through dealing with the issues of inadequate recycling rates and switching to bio-based acrylics seem to be the direction of the future changes. Moreover, the companies are in quest of more delicate and less energy-consuming production techniques to overall drop the emissions further.

To me, the path to future acrylics would have to pass through a trade-off between withstanding over the long-term and being completely recyclable at the same time as tackling its green issues head-on. The key to being the first material to offer real sustainability is in the recycling programs of the most advanced kind and the designing of environmentally friendly acrylics. However, informing the public on the issue of being mindful of the way we use and throw away the products can also be a major supporting factor in the new and eco-friendly approach to acrylic products.

The Future of Thermoplastic Acrylics in Various Industries

As seen by me, in many sectors, the future of thermoplastic acrylics is expected to include significant favorable conditions and drawback possibilities. Having their outstanding durability, optical clarity, and versatility, thermoplastic acrylics are set to be the major material still playing in the same league with construction and healthcare and on a different occasion with both. In by the light of the construction sector, their light weight and the fact that they do not get destroyed by bad weather are great for the purpose of making energy-saving windows, skylights, and protective coatings from them. Furthermore, the whole thing is not just either health or construction but industry-wide in the sense that in the manufacturing area there are technological advances that are leading to the production of new-custom-built-acrylics which are completely environment-friendly and this makes the architects and the builders carry out a more passable and green work that is in compliance with the environmental laws strictly.

On the other hand, automotive and aerospace have at the same time expressed interest in thermoplastic acrylics as that is an option for slashing the weight of components while sustaining the mechanical and appeal quality. It is highly necessary that the part that is referent to this critical point should be played by the said industry sectors in enhancing fuel-efficiency and serving the objectives of sustainable development. This is also the case at the healthcare and medical device fields with the biocompatibility of acrylics and their resistance to pathogens being the most important factors that have been directly under scrutiny leading to the use of acrylic in medical equipment and protective barriers in hospitals, for example. The continual advancement in this field, with polymers and sustainable production practices as the main contributing factors, will merge the industries in deeper integration, which is a very critical point for these sectors.

Nonetheless, with the increase of the use of the thermoplastic acrylics, it is very important to the life cycle of the same, to think about the sustainability and recyclability always. The companies still need to search for new ways of getting green together with the developing of the acrylics that are easier to be recycled or those made from the bio-based materials. It is my conviction that synergies between the material scientists, the manufacturers, and the policymakers will have a critical role in forming a new reality where thermoplastic acrylics can exist and flourish in the market as well as on the planet. The brightest possible future lies in taking advantage of the positive qualities of acrylics and at the same time striving so hard that we only get to see very few of the disadvantages of their use in the industrial scene.

Reference Sources

- Acrylic Resin – Wikipedia

Provides an overview of acrylic resin, explaining its classification as a thermoplastic or thermosetting plastic. - Are ACRYLITE® Acrylic Sheet Products a Thermoset or Thermoplastic? – ACRYLITE

Discusses the thermoplastic nature of acrylic sheets and their manufacturing processes. - Facts and Innovative Uses of Acrylic Plastic – Laird Plastics

Highlights acrylic plastic as a transparent thermoplastic and its applications as a glass alternative. - What is Acrylic? – Midton

Explains acrylic as a transparent thermoplastic made from methyl methacrylate, detailing its properties and uses. - Understanding Thermoplastic Acrylic Resin – POM Material

Focuses on the chemical resistance and sterilization capabilities of thermoplastic acrylic, especially in medical applications.

Frequently Asked Questions (FAQs)

Is acrylic a thermoplastic material?

Yes, acrylic is a type of a thermoplastic. That is, the material can be heated and formed into different shapes without any chemical reaction. The leading ingredient of acrylic is the polymer known as polymethyl methacrylate (PMMA). At higher temperatures, PMMA turns into a mass, and due to this, it can be formed using methods like thermoforming and injection molding. This property makes acrylic very versatile and hence very suitable for a lot of different types of products. The upside of thermoplastic acrylics is that it can be reshaped several times and still keeps its main characteristics.

What are the characteristics of acrylic as a thermoplastic?

There are a number of well-recognized features that make acrylic a good thermoplastic material. Not only is it highly resistant to impacts, but it is also a shatter-proof substitute for glass. Furthermore, acrylic is superior in terms of its optical clarity and light transmission properties, making it the top choice for cases where transparency is a must. Moreover, the fact that the material is durable and can withstand different weather conditions implies that it can readily be employed outdoors without major issues related to corrosion. Moreover, it can be shaped either as sheets or as complex objects by molding which makes it adaptable to various manufacturing processes.

What areas of consumer products can acrylic be found in?

Because of its effectiveness, acrylic has found its way to consumer products besides heavy use in the industry. Clear acrylic displays and protective barriers are the most commonly used products, and they are the same when it comes to optical clarity. Acrylic sheets are also widely used for the production of furniture, signage, and decorative elements. It is a very light material, only half as heavy as glass, hence, very suitable for many products. Besides, acrylic paints and emulsion are the two main liquid types to be used for art and decorating that in turn show the material’s versatility.

How can the properties of acrylic and polycarbonate be seen side by side?

Acrylic and polycarbonate are both known as high-quality transparent materials; however, they have distinctive characteristics. Acrylic, referred to as PMMA, is a material known for its extraordinary transparency that is usually applied as a glass that does not break easily. Its counterpart, polycarbonate, is found to be more resilient to impact compared to acrylic and hence is used in safety glasses and bulletproof windows, which must be the most durable ones. Acrylic, meanwhile, is said to be more resistant to scratches than polycarbonate, thereby making it a better fit for such applications where the quality of the surface is crucial. Both of the two materials are beneficial in their own ways, and the selection is made based on the particular needs of the application.

What is the definition of cast acrylic and how does extruded acrylic differ from it?

The creation of cast acrylic or extruded acrylic material involves two different technologies. Cast acrylic is the sheet is inspired by pouring the liquid acrylic resin into a die and allowing the polymer to set. On the other hand, extruded acrylic is manufactured by forcing the acrylic melt through a die, leading to thinner sheets of which the manufacturing process is faster and cheaper. Nonetheless, each of them has its advantages, and the final decision is usually determined by the product’s needs.

What are the physical properties of acrylic that make it suitable for outdoor applications?

Acrylic is endowed with a handful of physical characteristics that justify its use for outdoor purposes. Thus, the polymer’s ability to resist ultraviolet radiation is a great advantage that also gives a great deal of protection against yellowing and degradation when put under the sun, thus, assuring long life. Moreover, with its impact resistance, it is a good choice for harsh climatic conditions, as it will not easily break, thus, practical for outdoor signboards and shelters. The lightness of acrylate at the same time, catering to the users’ choice, is another main positive point as far as its advantageous transport and convenient installation are concerned. Dealing with the material is very easy and it opens wide opportunities for customization, thus, it is a very good choice for many different outdoor projects.