Acrylic —a material that, in many ways, has quietly revolutionized industries and everyday life —has been largely overlooked in popular information regarding its fascinating origin and possibilities. From workable household décor to car parts that withstand weathering, the exceptional beauty of acrylic lends itself to numerous applications. In this light, one might wonder how acrylic is produced and what confers on it its versatility. This blog post delves behind the scenes to explore the science of acrylic production, presenting the chemistry and processes that transform raw materials into one of today’s most widely used plastics. While doing this, one can also learn about various ways in which acrylic shapes our present world and continues to spur innovations in different industries. Whether you are just a curious consumer or an industry professional, this article offers an in-depth explanation of why acrylic is one of the miracles of modern-day materials.

Understanding Acrylic and Its Raw Materials

What is Acrylic Plastic?

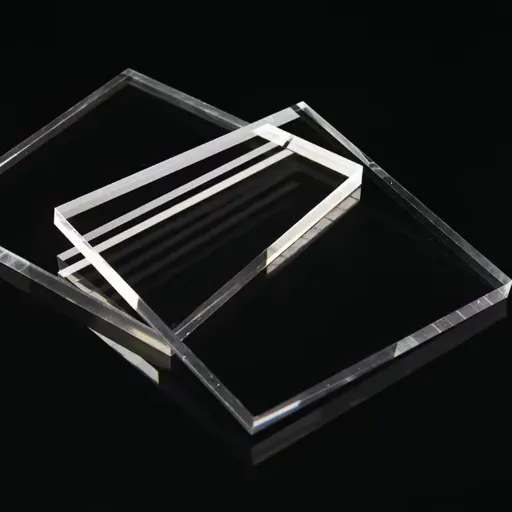

Acrylic plastic, also known as polymethyl methacrylate (PMMA), is a versatile, transparent thermoplastic material that is often used as a lightweight and shatter-resistant alternative to glass. Developed in the early part of the last century, acrylic has become an essential product in many industries due to its durability, resistance to weather, and optical clarity. The material is formed by the polymerization of methyl methacrylate (MMA) into a strong, transparent resin that can be easily worked into shape.

Key Fact: Acrylic plastics transmit around 92% of light, more than glass, thus being suitable for applications such as windows, lenses, and signboards.

Acrylic plastics are anything but contemporary; they have actually been present for many years. They allow for a greater degree of rank distortion while maintaining sound clarity; in this realm, it is no surprise they are known as “plexiglass.” Yellowing can sometimes occur due to aging and exposure to sunlight. On the other hand, acrylic plastic does not yellow significantly, making it ideal for outdoor use. Moreover, its enormous temperature range and ease of fabrication put it in great demand for industries ranging from automotive and construction to healthcare and consumer goods. Acrylic plastic, which balances strength with clarity and versatility, has been a key characteristic for innovation and functionality in contemporary design and technology.

The Role of Methyl Methacrylate in Acrylic Production

Methyl methacrylate (MMA) is a crucial raw material in the production of acrylics since it is the monomer that forms the backbone of PMMA. Under this context, it is this chemical that provides the characteristic high clarity, durability, and versatility associated with acrylic. The worldwide demand for MMA has risen in tandem with its multifaceted applications across various industries, including automotive, construction, and healthcare. To cite a few examples, MMA is used to create alternatives to shatter-resistant glass, lightweight vehicle parts, and robust medical devices.

Developments in MMA production techniques, such as bio-based processes and highly efficient catalysts, have made the utilization of the compound more sustainable and economical. Secondly, another aspect affecting the growth in the production capacity of MMA worldwide is ongoing infrastructure development, as well as increasing demands for PMMA products. In turn, the quality of MMA is a crucial aspect impacting the most important properties of acrylic materials for PMMA products, which include impact strength and optical clarity. Therefore, manufacturers emphasize the latest production technologies to combine sustainability with performance, fostering innovation across various industries.

Types of Raw Material Used in Acrylic Manufacturing

Depending on the type of polymer to be produced, acrylic polymerization requires various raw materials, each with its own set of characteristics. Methyl methacrylate is the primary raw material, referred to as a monomer essential for the synthesis of polymethyl methacrylate, or bona fide acrylic sheets, films, and resins. MMA is widely used for injection molding of automotive parts, signage, and electronics as it provides excellent optical clarity and impact resistance.

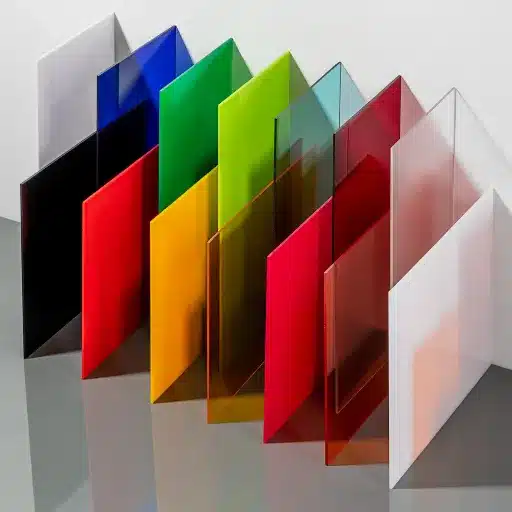

- Initiators: Organic peroxides to inorganic initiators for polymerization

- Additives: UV stabilizers, plasticizers for improved weatherproofing and flexibility

- Colorants: Pigments and dyes for aesthetic and functional needs

- Sustainable Materials: Bio-based materials and recycled MMA

Moreover, manufacturers are increasingly green-minded by incorporating bio-based materials and recycled MMA into their production processes. This endeavor aims to minimize environmental impact while preserving the performance of materials, serving as a testament to the industry’s commitment to innovation and environmental responsibility.

The Manufacturing Process of Acrylic Plastics

Overview of Acrylic Manufacturing Operations

Several key stages are required in the acrylic manufacturing process, resulting in a versatile plastic that is equally durable and used in a host of industries. Polymerization of methyl methacrylate (MMA) is the initial stage in any acrylic production. The process can be undertaken by either bulk polymerization or suspension polymerization, depending on the desired properties and applications. These fine conditions produce acrylic sheets, blocks, and other forms and finishes of very high quality.

Manufacturing Process Steps:

- Polymerization of methyl methacrylate (MMA)

- Bulk or suspension polymerization process

- Casting or extrusion into final form

- Processing operations (cutting, shaping, polishing)

Advanced manufacturing technologies can now contribute to addressing issues such as transparency, toughness, and thermal stability. Another essential environmental virtue is the use of recycled MMA and bio-based alternatives in the mix to help mitigate the environmental impact associated with conventional industrial methods. The polymerized acrylic can then be cast or extruded into its final product form and subjected to further processing operations, such as cutting, shaping, and polishing, to meet specific design requirements. Acrylic manufacture gives a perfect example where technical efficiency is well balanced with environmental consideration.

A Closer Look at Casting for Acrylic

In casting acrylics, a liquid monomer is first prepared, with methyl methacrylate (MMA) being the most commonly used. The monomer is first mixed with the catalyst for polymerization. This mixture is poured into molds, which are mostly comprised of glass plates held apart by seals to acquire the shape and thickness of the acrylic sheet or object.

Once poured into the mold, the liquid is usually maintained under a controlled environment for its polymerization to occur gradually. This step accurately describes the slow and steady solidification of liquid monomer into acrylic, which is carefully temperature-regulated to prevent warping or bubbles. During this stage, dye, UV stabilizer, and impact modifiers may be introduced as additives to enhance a few select properties, depending on the final application.

After the formation stages are completed, it is removed from its mold, and during curing, it attains strength and stability. Some curing operations involve subjecting the acrylic to specific temperatures for a defined time to achieve uniformity and durability in the final product. The finishing process entails surface treatments, such as polishing, sanding, or machining, to impart the requisite transparency, gloss, or dimensional precision. Throughout the process, high standards of quality control ensure that the product performs consistently and remains visually pleasing.

Extrusion Techniques in Acrylic Production

The extrusion process is fundamental in acrylic material production as it can form sheets, rods, and other profiles with extreme precision and efficiency. During this phase of manufacturing, acrylic resins—pellets or beads—are fed into an extrusion machine, where controlled heating takes place. The resins melt down into a viscous fluid state and are then forced through a custom-made die that imparts the desired cross-sectional shape to the material. An advanced temperature-regulating system ensures that the material maintains a consistent viscosity during extrusion, resulting in a flawless product with improved clarity.

Modern Extrusion Features:

- Multilayer coextrusion for different acrylic formulations

- Properties enhancement: UV resistance, impact strength, optical clarity

- Precision monitors and automated feedback systems

- Sustainability focus with recycled acrylic materials

Modern extrusion processes typically employ the multilayer coextrusion method, allowing different acrylic formulations to be incorporated into a single profile. A manufacturer can utilize this method to purchase properties such as UV resistance, impact strength, or optical clarity at the lowest price. Then, precision monitors, along with automated feedback systems, ensure the dimensional accuracy and thickness uniformity required by industries such as aerospace, building, and automotive sectors. Newer trends in orientation are focused on sustainability, utilizing recycled acrylic materials that are reintroduced into the extrusion process without compromising their performance. This evolution has continued into extrusion techniques to satisfy the various needs of a modern market.

Types of Acrylic Sheets and Their Applications

Main Differences Between Cast Acrylic and Extruded Acrylic

Cast and extruded acrylic sheets are two distinct acrylic sheets differing in manufacturing, properties, and uses. The main difference between cast acrylic and extruded acrylic is that the former is made by pouring liquid acrylic into molds; hence, cast acrylic is more complex and more durable than the extruded kind. Another difference is that cast acrylic has superior optical clarity and chemical resistance compared to extruded acrylic. Therefore, such materials find application in places where optical clarity and toughness are essential, such as aquariums, signs, and display cases.

| Feature | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Manufacturing | Poured into molds | Pushed through rollers |

| Durability | More durable | Less durable |

| Optical Clarity | Superior clarity | Good clarity |

| Cost | Higher cost | More affordable |

| Surface Quality | Harder surface | Softer, may scratch |

On the other hand, extruded acrylic is created by continuously pushing the acrylic material through rollers, resulting in sheets with consistent thicknesses. This process makes extruded acrylic more affordable and easy to work with, including cutting and forming. However, the surface could be softer and might scratch at any time, which could be the deciding factor against its use in high-traffic locations or highly demanding working environments. Hence, extruded acrylics find the largest applications in glazing, skylights, and point-of-purchase displays due to their low pricing and uniformity.

Both types of acrylic have advantages and disadvantages, but the choice between cast and extruded acrylic depends mainly on the end-use requirements, including budget, clarity, durability, and ease of fabrication.

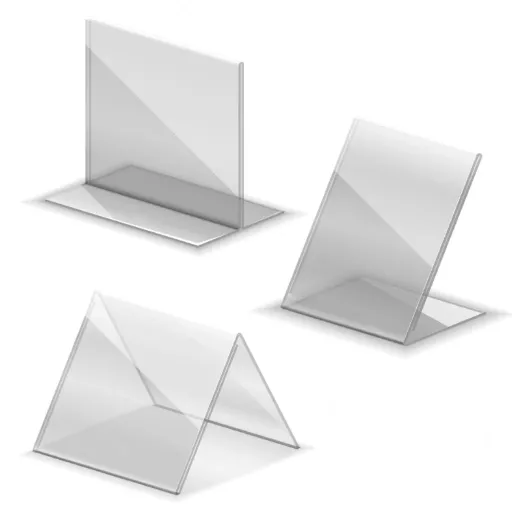

Various Applications of Cast Acrylic Sheets

Cast acrylic sheets offer numerous possibilities due to their exceptional optical clarity, durability, and adaptability; hence, they find applications in a wide range of industries. The most common use is for signage, where acrylic can be fabricated easily and retains its colors remarkably well for both indoor and outdoor purposes. They are also used in architecture; decorative panels, partitions, and display cases all serve both aesthetic and functional purposes.

Primary Applications of Cast Acrylic:

- Signage and displays

- Architectural panels

- Aquaria and terrariums

- Window glazing

- Medical devices

- Laboratory equipment

Additionally, due to their strength and impact resistance compared to glass, cast acrylic sheets are frequently used for aquaria and terrariums. Their lightweight nature and weather resistance make them suitable for outdoor applications such as glazing windows and barrier protection. In addition, the use of cast acrylic is often preferred when manufacturing medical and laboratory devices, where accuracy and clarity are paramount. It can further be fabricated via laser cutting, engraving, and thermoforming, giving cast acrylic a broader range of uses in a myriad of projects.

Extruded Acrylic Sheets Applications in Several Industries

Since extrusion produces the acrylic sheets, many of their working qualities, which are a billion-dollar keyword industry, can endure in pricing and application. Besides being used in advertising for making illuminated signs, display stands, and billboards, acrylic sheets are also popular in extrusions. Due to its even light transmission and excellent weather resistance, it is suitable for both indoor and outdoor use.

Additionally, extruded acrylic can be widely used in construction and architecture. It finds use as an inexpensive glass alternative for windows, splitting, and skylights that maintain excellent transparency and good impact resistance. The lightweight nature of extruded acrylic also facilitates easy installation and transportation, thereby reducing labor costs for large-scale projects.

Another significant application is in the retail and interior design fields. Extruded acrylic sheets are commonly used in the manufacture of displays, shelving systems, and decorative panels for retail outlets. Since these sheets are manufactured in a myriad range of colors, textures, and finishes, the designer can get away with a high-profile look on a budget.

Extruded acrylic has proven to be a reliable material in the automotive industry, particularly in applications such as light covers, instrument panels, and protective closures. Its excellent weather resistance, optical clarity, and ability to withstand temperature changes are favorable features considered by most vehicle manufacturers.

In general, extruded acrylic sheets are pretty versatile and adaptable. They are used across many industries, offering practical solutions that are also economical, meeting the varied production and design-related requirements.

Understanding the Properties of Acrylic Plastic

Durability and Impact Resistance of Acrylic

Acrylic resin is highly regarded for its exceptional resistance to degradation, serving as a benchmark for both indoor and outdoor applications. Another significant attribute it possesses is high impact resistance against which great forces are applied; the resin will hardly give in and shatter, unlike glass. Research has revealed that acrylic offers approximately 17 times the impact resistance of standard glass, which may be one of the reasons for its widespread use in areas where strength and safety are of concern. Acrylic also resists structural changes, thereby performing against weathering incidents such as ultraviolet radiation, sudden temperature changes, and physical abrasion. Such resistance powerfully ensures its performance over long periods and reduces the need for frequent replacement, thus providing a more cost-effective solution in fields ranging from architecture to transportation.

Impact Resistance Comparison

17x

More impact resistant than standard glass

Optical Clarity and Its Importance in Acrylic Applications

One of the significant features acrylic is known for is its extraordinary optical clarity, making it a material of choice when transparency and light transmission are desired. Acrylic allows about 92% of visible light to pass through it and, therefore, is much clearer and brighter than traditional glass. Hence, what you have before you is an acrylic surface that is crystal clear, with no more than a slight whitish-green tint, unlike glass. This clarity of acrylic remains forever, as it does not yellow due to exposure to sunlight for long periods or continued UV radiation.

Acrylic’s transparency serves to make an item visible and to give it aesthetic appeal. It finds application as an optical lens, display case, and protective barrier. For instance, in retail and museum displays, acrylic acts as a nearly invisible barrier, allowing observers to view the items without distortion. Furthermore, its lightweight nature makes it a convenient choice for realizing high-clarity installations where weight reduction is the primary consideration. This optical property of acrylic is available to be exploited in the aeronautics sector or in the medical imaging industry, where a consistently transparent medium is crucial for the safety and precision of operations. That equally renders it durable and valuable.

Thermal Properties of Acrylic and Their Implications

Acrylic has a distinct set of thermal properties, which is why it is used in many applications. The melting point is approximately 320 degrees Fahrenheit (160 degrees Celsius), and its thermal conductivity is close to 0.2 W/(m·K), making it an ideal material for environments requiring controlled heat transfer. This property provides a degree of safety to acrylics, which is particularly important in industrial and consumer settings. High heat, however, does soften acrylic rather than setting it ablaze immediately. High-temperature exposure for lengthy durations above the heat deflection temperature, typically ranging from 203°F to 95 °C, can deform or compromise their structural integrity. Any heat-dependent environment, such as a lighting enclosure, protective barrier, and another heated enclosure, takes these attributes into special consideration. Its moderate heat resistance, combined with a reasonable degree of softness when heated, makes it a favored plastic for thermoplastic parts where exacting standards in dimensional measurements and durability are essential.

Key Thermal Properties:

- Melting Point: 320°F (160°C)

- Thermal Conductivity: 0.2 W/(m·K)

- Heat Deflection Temperature: 203°F to 95°C

Innovations in Acrylic Manufacturing

Recent Advances in Acrylic Production Processes

Improvements in acrylic production technologies have immensely influenced and diversified the properties and applications of acrylic materials. One major reform over the past few years has been the introduction and evolution of polymerization methods, resulting in acrylic sheets of higher quality in terms of clarity, impact resistance, and heat tolerance. Better formulations now retain their color even after prolonged exposure to UV radiation and are therefore used for outdoor applications, such as signs and architectural installations.

On the other hand, precision molding, CNC machining, and laser cutting enable manufacturers to create acrylic components with extreme accuracy and minimal waste. These methods respond to the ever-growing demand for custom and intricate designs across industries. Moreover, researchers are developing a bio-based alternative to acrylic, aiming to produce sustainable processes by reducing the demand for petroleum or petroleum-based resources. Considering these developments, it is clear that the acrylic manufacturing domain is continually evolving, continually moving toward greater efficiency, design, and engineering possibilities.

Environmentally Friendly Practices in Acrylic Manufacturing

Sustainability is increasingly emphasized in acrylic manufacturing, making the adoption of environmentally friendly measures crucial. Some key points include recycling acrylic materials to reduce waste and lessen pressure on virgin sources. Closed-loop operations are also implemented to utilize waste or offcuts generated during production, converting them into new acrylic products. Furthermore, energy-efficient technologies, such as solar extrusion and solar-powered plants, help keep carbon emissions low during the process. Water conservation is also a trigger for incorporating water recycling systems to reduce consumption. These initiatives, in turn, create greener processes and evolve in response to consumer concerns for more environmentally friendly products. In working towards sustainability, this industry will, in the long run, provide access to an environmentally conscious future without compromising its product measures or processing methods.

Sustainable Manufacturing Practices:

- Material Recycling: Recycling acrylic materials to reduce waste

- Closed-Loop Operations: Converting production waste into new products

- Energy Efficiency: Solar-powered plants and efficient technologies

- Water Conservation: Water recycling systems implementation

Future perspective on Acrylic as Sustainable Plastic Material

I would say the future of acrylic as a sustainable plastic material is driven by advances in technology, coupled with a growing concern for the environment worldwide. Manufacturers are currently exploring several methods, each aimed at ensuring the greener production of acrylic, ranging from the use of renewable raw materials to minimizing the energy requirements of the manufacturing process. Apart from this, acrylic recycling is increasingly gaining ground, so that rather than disposing of this versatile plastic, it may be reconstituted and recycled, thereby reducing waste in landfills.

The material can be viewed from the standpoint of acrylic’s sustainability, particularly in terms of durability and longevity. Unlike cheaper and lower-quality counterparts, high-quality acrylic can withstand wear and tear, meaning there is hardly any chance of replacement whatsoever, which helps reduce the overall eco-impact. Additionally, being lightweight, it results in less transportation pollution, which is a significant advantage for industries seeking environmental sustainability.

In the future, it is the balancing of utility with sustainability that will be key. I am convinced that, by further investing in research and pursuing greener manufacturing routes, acrylic can be developed into a product even more sustainable, a reconciliation that allows for both industry needs and consumers eager to exist in a world that supports the environment.

Reference Sources

- The Science Behind Acrylic: How It’s Made and Why It’s So Durable – TT Plastic Land

- Everything You Need to Know About Acrylic and Its Uses – Xometry

- Acrylic Polymers – MC Polymers

- Acrylic: Properties, Structure, and Applications – Vedantu

Frequently Asked Questions (FAQs)

From raw materials, how is acrylic manufactured?

Acrylic is made from acrylic acid and methacrylic acid, which are derivatives of acrylic acid. The operations begin with the polymerization of its monomers from polymethyl methacrylate, which is the polymer that endows acrylic with its distinctive properties. This polymerization can be carried out in several ways, including bulk polymerization and suspension polymerization. After the initial formation, the polymer is transformed into various forms, such as sheets, through extrusion or casting. The plastic formed is exceptionally clear and resistant to chemicals, and therefore finds a multitude of applications. Understanding the process involved in manufacturing acrylic is necessary for industries that operate with this versatile material.

What are the different types of acrylic sheets available?

Acrylic sheets are chiefly of two kinds: cast acrylic and extruded acrylic. Cast acrylic sheets are made by pouring liquid acrylic into a mold gently, allowing for the creation of thicker sheets with minimal internal stresses. Extruded acrylic sheets, conversely, are made by forcing acrylic through a die to create flat sheets. Each of these types has its peculiarities: for instance, cast acrylic is generally chosen for applications due to its high optical clarity; extruded acrylic, on the other hand, is almost always more affordable, making it easier to work with for custom acrylic projects. Thus, it is essential to understand the differences between these two types of acrylic to determine which one is most suitable for your needs.

How is the casting process realized?

The casting process entails pouring the liquid acrylic mixture into a mold and allowing it to cure and solidify. This procedure is suitable mainly for thick acrylic sheets and complex shapes. During casting, polymerization of the monomers results in long polymer chains, giving that material strength and transparency. After curing, these acrylics may be removed from their mold and further processed, e.g., laser cut to the sizes so that it is desired. Furthermore, cast acrylic sheets can be customized; hence, they are sought for numerous uses, ranging from signage to artistic displays. The casting process yields attractive cast acrylic with excellent optical qualities.

Could you explain the extrusion method in acrylic plastic fabrication?

The extrusion process is one of the key methods in producing acrylic plastic, as it eliminates the discontinuous production of acrylic sheets and other shapes. Acrylic pellets are heated to the molten stage, fed into a die, and then forced through it to create flat sheets or profiles. In general, extruded acrylic sheets tend to be fairly uniform in thickness and are extruded in large quantities, thereby making them relatively inexpensive. Thin sheets of acrylic, produced using this method, are most often utilized in displays, light fixtures, and safety barriers. Hence, the extrusion process holds significant importance in industries that rely on efficient and cost-effective acrylic production.

What are the different uses for acrylic material?

Acrylic material is known as a versatile material with a wide range of applications. Due to its resistance to UV light and weather conditions, acrylic is commonly used for outdoor signage, skylights, and protective barriers. It is also used in the production of acrylic safety glass, a safer alternative to conventional glass. Design-wise, acrylic panels are applied to custom furniture, decorative pieces, and lighting. For the mass manufacture of aircraft and automotive parts, acrylic material is considered lightweight yet sturdy. Its wide applications prove why acrylic has been a favorite candidate amongst engineers and designers alike.

What is it that makes acrylic a perfect material for various industries?

It can be said that acrylic has become an ideal material for various industries, owing to its durability, lightweight nature, and high level of transparency. Acrylic is often used as an alternative to glass because it is shatter-resistant and chemically resistant. It enables easy processing through operations such as laser cutting and bending, allowing for intricate formations and custom shapes. Acrylic plastic is also less expensive than glass, making it a more affordable choice for commercial or residential projects. Due to this flexibility, it can be used in a multitude of applications, ranging from safety shields to art installations. Acrylic is a popular choice among many due to its unique attributes that meet well with engineering and design requirements.