Plastic pellets are the backbone of any industry and are the raw material used in packaging, automotive components, household goods, and medical devices. With the ever-growing importance of plastic pellets in modern production processes, it becomes essential for any company to ensure the best-quality plastic pellet suppliers and manufacturers to stay competitive. The blog post takes you through the top 10 international plastic pellets suppliers and manufacturers, offering a deep insight into the industry’s leaders. From basic understandings about their products to the magnitude of their operations worldwide, there is information about how these companies stand out and about giving them weight in your sourcing judgments. Suppose you optimize your supply chain, improve product quality, or better understand the market. In that case, this exhaustive list will surely afford such insights and essential data for the success of your business. Stay with us as we reveal the innovators shaping the future of plastic pellets production.

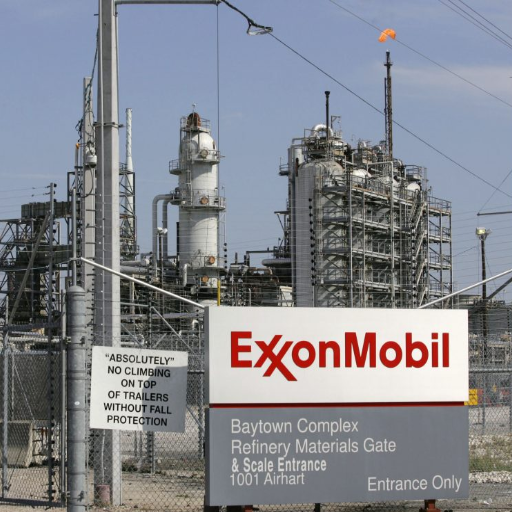

1. ExxonMobil Chemical

Year Founded: 1911

Introduction: ExxonMobil Chemical is a division of ExxonMobil and one of the world’s largest producers of petrochemicals. The firm is well known for its highly innovative chemical solutions and its commitment to sustainability and efficiency. The company manufactures high-quality plastic materials, including polyethylene and polypropylene, for different industrial uses.

Main Products: Polyethylene (PE), Polypropylene (PP), Synthetic Rubber, Adhesives.

Advantages: Globally recognized, with an edge in research and development, and an extensive product range.

Disadvantages: Heavy dependency on the oil and gas market, and environmental issues concerning their production processes.

Website: ExxonMobil Chemical

2. Basell Polyolefins (LyondellBasell)

Year Founded: 2007 (merger of Lyondell and Basell)

Introduction: A leading plastics, chemicals, and refining company in the polyolefin resin manufacturing and sale businesses, LyondellBasell is at the forefront of polyolefin technology, supplying plastic pellets and equipment in specialty and commodity grades for use across multiple industries.

Main Products: Polypropylene, Polyethylene, and Advanced Polyolefin.

Advantages: Up-to-date production techniques for polyolefin solutions and high emphasis on innovation.

Disadvantages: The consideration of other plastic resins is minimal, as they are mostly polyolefins.

Website: LyondellBasell

3. SABIC (Saudi Basic Industries Corporation)

Year Founded: 1976

Introduction: SABIC is a global leader in diversified chemicals with great manufacturing capacity in plastic resins. With headquarters in Riyadh, Saudi Arabia, SABIC provides its customers with innovative, reliable material solutions for industrial applications.

Main Products: Polyethylene, Polypropylene, Polycarbonate, and Polystyrene.

Advantages: Technological expertise, strong presence in Middle Eastern markets, diversified product portfolio.

Disadvantages: Geographical dependency and fluctuating energy markets affect the prices of raw materials.

Website: SABIC

4. Dow Chemistry Company

Year Founded: 1897

Introduction: Dow is a global materials science company that is a leader in plastics and specialty chemicals. It stands for sustainability and delivers high-performance solutions, including plastic pellets, to international markets.

Main Products: Polyethylene, Polyurethane, Silicones, Industrial Resin Compounds.

Advantages: A well-accessible supply chain worldwide, owning cutting-edge technological innovations.

Disadvantages: Extreme fluctuation of markets due to the costs of raw materials and competition.

Website: Dow

5. INEOS Olefins & Polymers (INEOS Group)

Year Founded: 1998

Introduction: INEOS is one of the largest chemical companies in the world. It produces a wide range of virgin polymers and plastic pellets for different sectors. Modern scientific innovations focus on nanoscale materials.

Main Products: Polyethylene, Polypropylene, Polystyrene, ABS.

Advantages: Reliability on large-scale production and sustainable solutions.

Disadvantages: Mostly focused on large industrial clients rather than the smaller market.

Website: INEOS Group

6. Braskem

Year Founded: 2002

Introduction: Braskem is a major petrochemical company in the Americas and one of the biggest producers of polypropylene worldwide. Its focus is on creating new, sustainable, and recyclable material solutions for all sorts of applications.

Main Products: Polypropylene, Polyethylene, and Bio-based Polyethylene (Green PE).

Advantages: Focus on bio-based material issues and greenhouse gas mitigation.

Disadvantages: Trouble with competitive expansion on a global scale.

Website: Braskem

7. TotalEnergies Petrochemicals

Year Founded: 1924.

Introduction: As a division of TotalEnergies, the company leads in polymer production, offering performance materials made from both virgin and sustainable plastics to various industries, including automotive, packaging, and consumer goods.

Main Products: Polyethylene, Polypropylene, and Specialty Plastics.

Advantages: Wide international reach and sustainable focus on its manufacturing methods.

Disadvantages: Volatile raw material costs and less diversification.

Website: TotalEnergies

8. Chevron Phillips Chemical Company

Year Founded: 2000

Introduction: Chevron Phillips focuses on quality plastic resins, which account for a large share of polyolefin demand worldwide. It also develops renewable and circular polymer solutions.

Main Products: Polyethylene, Polypropylene, and HDPE.

Advantages: Strong manufacturing bases and innovation on sustainability.

Disadvantages: Regionally focused company; less global expansion than the competition.

Website: Chevron Phillips Chemical

9. LG Chem

Year Founded: 1947

Introduction: LG Chem is a world leader in specialty chemicals and polymers. It innovates and supplies high-performance plastic materials for electronics, automobiles, packaging, and many other applications.

Main Products: ABS, Polycarbonate, Polyethylene, Polypropylene.

Advantages: Highly innovative product and specialty material expertise.

Disadvantages: A good part of its business remains in the Asian area.

Website: LG Chem

10. Formosa Plastics Corporation

Year Founded: 1954

Introduction: Formosa Plastics Corporation offers quality PVC and polyolefin products worldwide, which are the icing on many markets around the world.

Main Products: Polyethylene, Polypropylene, Polivinil Cloride (PVC), and ABS.

Advantages: Superior in manufacturing and competitively priced in materials.

Disadvantages: Less attention is paid to specialty resins, and traditional production methods cause environmental concerns.

Website: Formosa Plastics

View PC Plastic Pellets Manufacturers in China

Frequently Asked Questions (FAQs)

What are plastic pellets, and what are their uses?

Plastic resin pellets are the preferred technical name for plastic raw materials. Various plastic resins, including polyethylene, polypropylene, and nylon, are used in production. Any plastic raw material for injection molding and extrusion must come in pellet form to be heated and molded into the desired final plastic product. There is practically no end to what can be produced from these plastic pellets, from automotive parts to packaging materials to consumer goods. Understanding what pellets one needs for a given application is key to obtaining the right results.

How can I choose a dependable supplier of plastic pellets?

A good supplier should be ready to ensure the quality of pellets, keep up with delivery times, and provide good customer service. Suppliers should have a good variety of plastic resins, not just general plastics, but engineering plastics and thermoplastic materials. Ensure the supplier recycles industrial resin, which will speak for their sustainability aspect. You may also want to investigate many reviews and even ask for samples to see if the supplier can deliver pellets that are suited to your needs in terms of quality and consistency.

What are the types of plastic pellets available in the market?

There are many types of plastic pellets suitable for different applications. Some of these common varieties are polyethylene (PE), polypropylene (PP), polystyrene (PS), and such engineering-grade plastics as nylon and polycarbonate. Beyond these are specialty types tailored for particular purposes, such as high-impact polystyrene for durability and low-density polyethylene for flexibility. A sound knowledge of each type’s properties and applications is imperative to correctly selecting plastic pellets for your job.

What do plastic pellets do for injection molding?

Plastic pellets are probably the most crucial consideration in injection molding because they are the material that melt, transform, and fill a cavity to become products. Pellets must be present to be melted and casted into a mold with high pressure, which allows for exact shaping and detailing of the product. This is a typical means of creating plastic parts for use in the automotive, consumer goods, and electronic industries. Selecting suitable plastic resin pellets is essential in fulfilling performance requirements imposed on positive molding.

Can plastic pellets be recycled?

Yes, plastic pellets can be recycled, and many suppliers often accept doing plastic recycling in efforts toward waste reduction. Recycling means taking used plastic materials and turning them back into pellets that can be used to make new plastic products. This procedure preserves resources, thus reducing environmental impacts. It is advisable to select suppliers concerned about sustainability that offer recycled plastic resin options, promoting the circular economy.

What are the benefits of thermoplastic resin pellets?

A thermoplastic resin pellet can be helpful for processing and manufacturing purposes, including recyclability. The pellets can be melted down and rebuilt many times without significant degradation and, hence, can be used in various manufacturing processes such as injection molding and extrusion. They come in several different formulations, such as elastomers and high-density polyethylene, that are suited to particular application needs. Thermoplastic resin pellets, thus, improve product performance and sustainability by providing recycling options.

How can I ensure the quality of plastic resin pellets?

Ensuring the quality of plastic resin pellets can be achieved by first picking reputable suppliers that follow industry standards and processes of quality control. These suppliers should help you obtain detailed technical specifications and certifications for the products in use. You could test the pellets for consistency in size, melt flow rate, and mechanical properties. These ensure you can maintain and ascertain quality. Further, suppliers offering samples for you to test could satisfy unique requirements even before linking through larger orders.