In the successful sourcing of plastic pellets for industrial use, buying from the appropriate supplier could make or break the operation in terms of quality, timeliness, and cost-effectiveness. Offering a wide array of product types and specifications, the suppliers can be difficult to navigate. This guide is designed to assist you by presenting the best plastic pellets suppliers, along with their offerings, knowledge, and standards, to support your conscious decision. Whatever you are after —raw materials for manufacturing, injection molding, or a specialty application —this information is all one needs to identify the most trustworthy and high-quality options.

Understanding Plastic Pellets and Their Applications

What Are Plastic Resin Pellets?

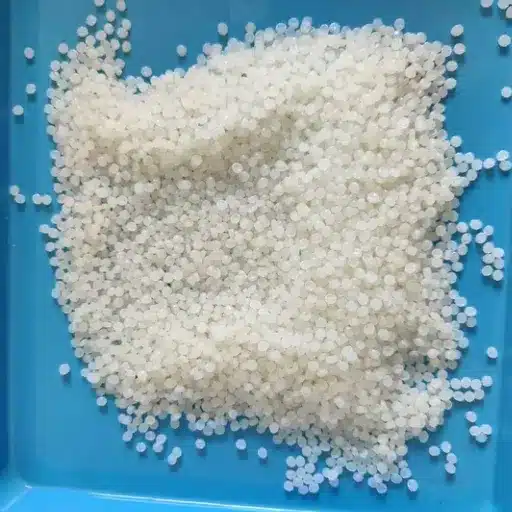

These pellets are small, granular materials that serve as the raw material for plastic products. The manufacturing of these pellets primarily involves the polymerization process, where a monomer is converted into a polymer, such as ethylene, propylene, or styrene, resulting in long polymer chains. The resin pellets, due to their uniform size and shape, are highly useful and easy to process; therefore, they are efficiently handled during manufacturing.

These pellets need to be categorized into resin types, such as thermoplastics, including PE, PP, and PS, and engineering resins, such as polycarbonate (PC) and nylon (PA). Each type of resin pellet is formulated based on several performance characteristics, ranging from durability, flexibility, heat resistance, and chemical resistance, and so is suitable for various applications. Plastic resin pellets are a material of choice in industries such as packaging, automotive, construction, and medical devices because of their versatility and ease of fabrication into final products through shaping techniques like injection molding, extrusion, and other methods.

Common Types of Plastic Pellets

In ranking plastic pellets, consideration is placed on their polymer composition, which sets down the physical and chemical characteristics of the pellets themselves. Some of the widely used plastic pellets are:

- Polyethylene (PE):

Polyethylene is an umbrella term for a universe of plastics existing in three versions: high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE). Among the impressive attributes that it enjoys and finds in popular demand are light-weight, flexibility, and resistance to water and chemicals. Thoroughly employed in film manufacturing, packing materials, and containers. - Polypropylene (PP):

Known for its fatigue resistance, high-temperature resistance, and durability, polypropylene is used in applications requiring repeated use, such as automotive parts, consumer goods, and food-safe containers. - Polyvinyl Chloride (PVC):

PVC pellets are noted for their versatility, offering both rigid and flexible forms. Rigid PVC is used for construction materials such as pipes and profiles, while flexible PVC is used for cables, medical devices, and synthetic leather. - Polystyrene (PS):

This type of plastic is both lightweight and rigid, and it exists in two forms: GPPS and HIPS. While GPPS is mostly used for packaging and disposable items, HIPS is tougher and is used in casings and trays. - Polycarbonate (PC):

Polycarbonate pellets offer impact resistance, optical clarity, and dimensional stability. These properties make it suitable for electronic housings, optical disks, and safety glazing panels. - Nylon (Polyamide, PA):

Due to its fame for strength, wear resistance, and self-lubricating property, nylon finds its utility in highly demanding applications like gears, bearings, and high-performance textiles.

These resin pellets serve as examples to demonstrate the diversity of materials available, each designed to provide specific mechanical, thermal, and environmental requirements. These alterations ensure plastic pellets remain of utmost importance in a wide array of industrial and consumer product applications.

Applications of Plastic Pellets in Industries

Because of their adaptable and customizable properties, plastic pellets are used in a large number of industries.

- Automotive Industry:

It is widely used by the automotive industry to create lightweight and durable components. Polyamide or polypropylene pellets are often used in treating engine parts, fuel tanks, and interior panels to reduce weight while maintaining structural integrity for fuel efficiency. - Consumer Electronics:

Polycarbonate and TPU pellets are known as hard-to-produce high-performance polymers and have been traditionally used in electronics manufacturing. By prioritizing their material properties, these plastics are used to make tough casings that withstand heat, connectors, and flexible cables, ensuring irreproachable reliability and compact design. - Medical Devices:

Biocompatible pellets of plastics like polyethylene and polyether ether ketone (PEEK) are commonly used in medical technology. Thanks to their being sterilization-resistant and non-reactive, they are used in making surgical instruments, implants, and diagnostic equipment. - Packaging Industry:

Polyethylene and polystyrene pellets rule the packaging industry, catering to rigid and flexible packaging requirements. Their lightness and low cost, besides being food-safe certified, make them the best fit for the production of bottles, films, and containers. - Textiles and Apparel:

Plastic pellets such as polyesters serve as essential precursors in the making of synthetic fiber used in outdoor and performance garments. These materials provide enhanced durability, moisture resistance, and thermal insulation. - Construction and Infrastructure:

PVC pellets are used in pipes, window frames, and insulation materials. They possess excellent tensile strength and resistance to environmental degradation, meeting the stringent requirements posed by construction projects.

The advanced developments in polymer formulation will ensure that plastic pellets can be made to suit specific industries, such as those that resist extreme temperatures, are more sustainable, or are subject to stringent safety standards. Such applications consequently reveal the indispensable roles plastic pellets play in manufacturing and product innovations today.

Key Suppliers of Plastic Pellets

Overview of Plastic Resin Suppliers

Several top players dominate the plastic resin market supply, offering their services with extensive distribution networks, wide product ranges, and materials considered innovative. The high-end resins suitable for automotive, construction, electronics, and health industry applications have been produced by the companies of Dow Inc., BASF, LyondellBasell, and SABIC. The suppliers from the buy side account for resins, including polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC), thereby ensuring adaptability.

In emerging suppliers, innovations are appearing for bio-based resins and sustainable solutions, seeking to meet an increasing demand for sustainable materials. Major suppliers, while featuring subsets, differ significantly from each other in terms of strict quality and safety standards, their flexibility in adapting to market changes, and their investment in modern manufacturing technologies. Additionally, some major suppliers offer technical support and tailor-made solutions that enhance efficiency and sustainability in downstream production processes.

This competitive landscape shows the range of abilities of individual suppliers and their choice for sustainability and adaptation in a rapidly changing global market.

Let’s Compare Suppliers: Quality and Price

| Supplier | Product Range | Quality Certifications | Price Range |

|---|---|---|---|

| Dow Inc. | PE, PP, PS, Advanced Polymers | ISO 9001, ISO 14001 | Premium |

| BASF | PE, PP, Engineering Resins | ISO 9001, REACH Compliant | Premium |

| LyondellBasell | PP, PE, PVC | ISO 9001, ISO 14001 | Mid to High |

| SABIC | PC, PP, PE, Specialty Resins | ISO 9001, ISO 14001 | Premium |

| Greenpath Recovery | Recycled HDPE, LDPE | Recycled Content Certified | Competitive |

Note: Price ranges vary based on order volume, delivery location, and specific product specifications. Contact suppliers directly for detailed quotations.

Types of Plastic Resins Offered by Suppliers

Polypropylene (PP) and Its Uses

Polypropylene, often referred to as PP, is a very adaptable thermoplastic polymer used in nearly every industry due to its lightweight, durable, and chemical-resistant properties. With an ability to provide good impact strength and retains a degree of softness, it goes into making automotive-related items; among such items are bumpers and interior trim, where its use serves to reduce the overall vehicle weight for better fuel mileage. With the ability to bend and withstand stress repeatedly while maintaining its shape, it is used extensively in the packaging of rigid containers, caps, and films. Furthermore, polypropylene, with its moisture resistance and compatibility with almost all chemicals, is considered suitable for making medical devices, laboratory apparatus, and piping. Advancements in polymer technology have enabled other uses of polypropylene, further enhancing its functionality, such as super-clear grades for consumer products and special formulations for ultra-low-temperature environments.

Characteristics of High-Density Polyethylene

High-Density Polyethylene (HDPE) is a thermoplastic polymer with an excellent strength-to-density ratio, chemical resistance, and robustness. It comes from petroleum by polymerizing the monomers of ethylene. With a higher tensile strength, low permeability, and excellent impact resistance, HDPE lends itself to a plethora of industrial applications.

The other significant property of HDPE includes resistance to most solvents, acids, and bases, ensuring long-term reliability under extreme environmental conditions. Therefore, it is widely used in piping systems, including water supply and gas distribution, due to its noncorrosive and nonchemical leaching properties. Its light structure provides ease of fabrication and makes it more cost-effective than traditional materials.

For HDPE, the characteristics remain stable under working and performing conditions at extremes of temperature—from freezing to moderate heat. In the field of material science, the development of HDPE cross-linking has significantly improved its thermal and impact properties, leading to great success in the present design, packaging, and automotive fields.

About Thermoplastic Elastomers

Thermoplastic elastomers (TPE) belong to a category of polymers possessing properties typical of both thermoplastics and elastomers, that is, processable like plastics yet flexible and resilient like rubber. This duality, depending on features, arises from the polymeric molecular configuration, typically characterized by the polydomain structure of the soft elastomeric segments, separated intermittently by complex thermoplastic domains allotted for physical cross-linking. Being systems of polymers, TPEs have one significant advantage over vulcanized rubber: they can be melted and reformed repeatedly. Plus, this reversibility makes it easy to recycle TPEs.

Recent improvements in the development of thermoplastic elastomers have allowed them to be tuned for specific applications with increased tensile strength properties, thermal stability, and better resistance to environmental stress cracking. These advances have positioned TPEs in an ever-growing number of industries, including automotive, medical devices, and consumer electronics. For instance, in automotive applications, TPEs are used in seals, gaskets, and interior trims where they can offer durability and light weight. Further, biocompatibility and flexibility pave the way for their use in medical tubing and wearable devices. Supported by continuing research and newer compounding techniques, the prominence of thermoplastic elastomers continues to grow in cutting-edge engineering and design applications.

The Importance of Recycling in the Plastic Pellets Industry

Environmental Impact of Plastic Production

Plastic production is closely associated with environmental problems: the workers at the feedstock, contrary to fossil fuel, and a heavy energy-consuming manufacturing process on-site. Whatever, 6% of the global oil consumption is accounted for by plastic production. As demand for the product continues to rise, so will the use of oil for plastic manufacture. When non-renewable resources are used, greenhouse gas emissions arise, contributing to climate change. The process of plastic synthesis also results in the emission of volatile organic compounds (VOCs) and various pollutants that can disrupt air quality.

Another important reason is the environmental issue, which encompasses improper disposal and degradation of plastic waste. When plastics are thrown away into landfills or leak into natural surroundings, these substances resist degradation and persist for a long time, depositing into the soil and the ocean. Microplastics, which are essentially smaller pieces formed from the splitting of larger plastics, have been detected in various ecosystems. They are increasingly being found in the food chain, threatening the welfare of both wildlife and human beings.

Other environmental conservation measures to mitigate these impacts could include obtaining energy from renewable sources during production, optimizing the efficiency of recycling systems, and promoting the use of biodegradable resin alternatives. The further development of closed-loop recycling, coupled with the widespread adoption of circular economy principles in all industry sectors, will be the primary means of reducing the adverse impacts related to plastic production and usage.

Recycling Processes for Pellet Plastic

Recycling plastic pellets involves a series of highly specialized processes meant to optimize material recovery while maintaining the level of quality required for reuse in different applications. The process discards the sorting system for plastic waste, which is typically sorted based on polymer type and contamination levels. In this sorting step, high-end optical and robotic sorting technology achieves very high accuracy by reducing impurities in the recycled batches.

The cleanup procedures treat the plastics to remove any matter that might contaminate them, such as food particles, adhesives, or dirt. This step can include both chemical and mechanical cleaning methods, of course, depending on what the material requires. Once cleaned, the plastics are shredded into smaller flake forms, which are, in turn, heated up during the extrusion process that leads to forming uniform pellets. Another advantage of melt filtration is that during extrusion, any impurities still found in the resin are filtered out, resulting in a better quality final product.

The various chemical recycling methods, such as depolymerization and pyrolysis, have expanded recycling options for polymers that society once deemed non-recyclable. These processes depolymerize plastics into monomeric units that can be fed into polymerization processes for virgin-quality recycled materials. When these methods are combined with classical mechanical recycling, industries reach higher recycling rates and extend the usage of recycled plastic pellets to high-performance applications.

Benefits of Recycled Plastic Resins

The recycled plastic resins present many benefits that make them a key in sustainable manufacturing. First and foremost, employing them leads to a greater shortage of virgin raw materials, which in turn increases the extraction of resources and environmental damage. Furthermore, in many cases, more energy is consumed in making virgin resins than in making recycled resins; hence down to the process level, we see a decrease in greenhouse gas emissions.

Performance-wise, technical advances in chemical and mechanical recycling have provided high-quality recycled resins that meet stringent material and durability requirements, applicable in the automotive, construction, and consumer goods industries. Additionally, incorporating recycled resin into a product helps manufacturers meet regulatory standards and achieve company sustainability goals, thereby partially implementing a circular economy. In view of several benefits, recycled plastic resins become a material of utmost importance toward innovation in green manufacturing.

Future Trends in Plastic Pellets and Supplier Dynamics

The Emerging Trends of Demand for Plastic Resins

Demand for plastic resins continues to evolve with technology, changing regulations, and consumers’ increasing consciousness of environmental sustainability matters. These days, an increasing number of industries look for bio-based or biodegradable resins, reducing their carbon footprint and conforming to some global sustainability goals. Some applications for these materials, made from renewable resources like corn starch or sugarcane, include packaging, agriculture, and medical devices.

There is also a surge in demand for recycled resins, courtesy of sharply stringent government mandates and corporate sustainability commitments. Recycling technology innovations, such as chemical recycling, have improved the quality of recycled materials, providing opportunities for their application in high-performance and food-grade applications. Another trend is the widening of resin applications due to demand in fast-growing sectors, including electric vehicles, renewable energy infrastructure, and advanced packaging solutions, which emphasize their barrier and lightweighting properties.

Together, these trends highlight the utmost need for resin suppliers to adapt their portfolios and supply chain strategies to meet industry demands. On this front, there is also a need to invest in R&D for advanced materials, develop partnerships with recyclers, and create circular economy frameworks that encompass performance and sustainability.

Impact of Sustainability on Supplier Choices

Several industries are increasingly integrating considerations of sustainability into their supplier selection practices. Companies are prioritizing suppliers that demonstrate a clear commitment to minimizing environmental impact by taking various steps, such as reducing greenhouse gas emissions, pursuing energy efficiency, and implementing closed-loop systems. This trend is emerging from both regulations and an increasingly strong consumer demand for environmentally friendly products. Environmental performance data, such as life cycle assessments (LCA) and carbon footprint evaluations, are now prerequisites from suppliers, as they find these demanded by their purchasing partners. On top of this, differing certifications, namely ISO 14001 for environmental management systems and compliance to extended producer responsibility (EPR) regulations, also become essential differentiators. This transition toward sustainable supply chains emphasizes implementing environmental measures as key performance indicators (KPIs) in supplier assessments to align with corporate sustainability objectives.

Industrial-Technological Innovations

From my point of view, the rapid advancement of technology is fundamentally changing the supply chain industry, with sustainability and efficiency being the two most significant issues. AI stands at the forefront of technological innovations currently changing the industry, with an enormous impact. From demand prediction with an unparalleled degree of accuracy and inventory management optimization to the reduction of waste across the supply chain, predictive analytics can reduce wasteful procurement, transportation, and warehousing. This reduction begins by identifying inefficiencies in procurement and transportation processes, thus minimizing greenhouse gas emissions and operational costs. The ability to interface with real-time data compounds the effectiveness of such tools, allowing companies to respond dynamically to market changes and environmental factors.

The other groundbreaking innovation posed is the use of blockchain technology for guaranteeing transparency and traceability across supply chains. The blockchain ensures immutable, decentralized records where every transaction or movement of goods is recorded, allowing stakeholders to monitor the sustainability and ethical sourcing of products. This is very important for industries like food and fashion, where consumers are increasingly demanding accountability regarding the sources and environmental impacts of the goods they purchase. Besides facilitating compliance with regulations, blockchain keeps partners and end-users together by imparting verifiable evidence of their confederacy to sustainability standards.

Furthermore, the advanced robotics and IoT are revolutionizing warehouse and logistics processes. IoT-enabled devices monitor real-time shipment conditions, such as temperature and humidity, which is critical to the pharmaceutical and food industries. Meanwhile, autonomous robots pick, pack, and transport goods through the distribution centers, providing great operational efficiency. Together, these innovations have changed supply chain management such that companies can comply with sustainability goals while continuing to compete in an increasingly complex global marketplace.

Reference Sources

- Plastic Resin Pellets Suppliers | ThomasNet

A comprehensive directory of plastic resin pellet suppliers for various industrial applications. - Resin Pellets for Injection Molding | Emco Plastics

Emco Plastics provides high-quality resin pellets suitable for a wide range of industries and applications. - Recycled Plastic Pellets and Regrind | Greenpath Recovery

Greenpath Recovery specializes in recycled plastic pellets, offering sustainable options like HDPE and LDPE. - Plastic Pellets Suppliers | Global Sources

A platform featuring verified manufacturers of plastic pellets, including PP, PLA, and ABS granules. - Victory Pellets | USA-Made Plastic Pellets

High-quality, USA-made plastic pellets designed for various uses, including industrial and DIY applications. - Find more info now.

Frequently Asked Questions (FAQs)

What are plastic pellets and their uses in injection molding?

Plastic pellets are small, round plastic particles used as raw material in various manufacturing processes, mainly in injection molding. They are typically made from thermoplastic resins such as polypropylene (PP), polyethylene (PE), and nylon. During injection molding, these pellets are heated until molten and injected into molds to manufacture plastic products. Thus, the applications of plastic pellets are immense, from automotive components to medical devices to consumer goods. Choosing the correct type of plastic resin pellets is essential to provide properties in the final product, such as good impact resistance, chemical resistance, etc.

How do plastic resin suppliers ensure the quality of their thermoplastic pellets?

Plastic resin suppliers maintain a high-quality standard through rigorous testing. This process involves checks for density, melt flow index, and impact resistance of thermoplastic pellets. Suppliers test with some of the best equipment to ensure that the pellets conform to particular industry standards. To maintain high-quality standards, several suppliers source their resins from some of the best manufacturers. And if the application requires special properties, suppliers can provide custom-compounded pellets to meet performance specifications.

What thermoplastic resins are predominantly supplied for extrusion?

Various types of thermoplastic resins are used in extrusion processes: polyethylene (PE), polypropylene (PP), polystyrene (PS), and nylon. Every resin has specific properties that suit particular applications. Take, for example, HDPE, which is well-known for its strength and can be utilized in plastic lumber as well as tubing products. Nylon is preferred for its durability and versatility in various applications, including automotive parts and medical devices. Regarding suppliers, they offer several options so that manufacturers can choose depending on their manufacturing process, especially extrusion or injection molding.

How does a supplier approach the recycling of plastic pellets?

There are many plastic pellet providers emphasizing sustainability by offering recycled materials. Recycled plastic pellets, generally from post-consumer waste, such as plastic bottles or plastic bags, minimize environmental impact and help preserve the quality. The suppliers may also promote acceptance of bio-based or environmentally friendly alternatives that perform in the same respect as conventional plastic resins. Suppliers contribute to a circular economy by promoting recycling and offering recycled options, thus encouraging manufacturers to choose sustainable materials whenever possible for their products.

What are the advantages of using acetal and polycarbonate in plastic products?

Polyethylene and polycarbonates are two types of special thermoplastics with special features suitable for various applications. Acetal resins possess mechanical excellence, low friction, and dimensional stability, making them apt for precision parts in automotive and industrial applications. Polycarbonate offers excellent impact resistance and optical clarity, making it suitable for safety goggles and some housings for electronics. Suppliers usually supply the materials in pellet form so as to facilitate processing by manufacturers through injection molding and extrusion.

How do plastic pellets assist in the manufacturing of medical devices?

Plastic pellets are essential in the manufacturing of medical equipment when precision and reliability are crucial. Common materials include thermoplastic elastomers (TPE) and thermoplastic polyolefins (TPO), which offer flexibility, durability, and biocompatibility. Suppliers provide special grades of these plastics to comply with regulatory requirements. Injection molding and extrusion are the processes by which these materials are shaped, ensuring consistent quality and performance in medical applications. Hence, high-grade pellets positively affect the safety and performance of medical devices.

How do plastic pellet suppliers support innovations for automotive applications?

The plastic pellet suppliers fully support automotive applications through innovation, focusing on mastering materials for performance and weight. Suppliers are polymer suppliers; the commonly used polymer types in vehicle components are TPO and ABS. Polymeric materials are engineered concerning the desired properties, i.e., thermal stability, or impact resistance. Suppliers collaborating with automotive manufacturers develop new solutions to meet the industry’s current requirements for producing more efficient and environmentally friendly vehicles.