HDPE pellets have entered the manufacturing world as a highly versatile product with excellent toughness and a water-resistant quality. From kitchen staples to advanced industrial processes, these tiny pellets, with immense potential, are behind many modern-day innovations across diverse industrial sectors. This article explores the diversities of HDPE pellet usage, highlighting their properties and how manufacturing processes worldwide are undergoing transformation through them. Are you reading this from the perspective of how cool packaging uses them or anything related to construction materials in new technology? This guide offers much insight into why HDPE pellets are one of the major drivers of excellent manufacturing efficiency.

Understanding HDPE Pellets

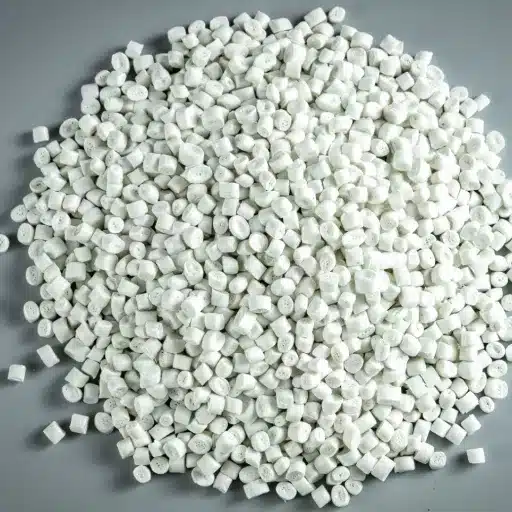

What are HDPE Pellets?

HDPE (High-Density Polyethylene) pellets consist of delicate beads or granules of thermoplastic polymer notable for their strength-to-mass ratio, durability, and versatility. Derived from petroleum, these pellets serve as raw materials in several processing activities, including blow molding, injection molding, and extrusion processes. HDPE pellets are lightweight yet strongly resistant to impact and chemicals, and they resist moisture, making them suitable for many uses. Once processed into containers, pipes, geomembranes, and other household articles, they remain durable.

Recent developments in HDPE pellet manufacture are directed toward higher sustainability and greater performance. Thus, newer formulations for HDPE use partially recycled materials to lessen the environmental impact while not downgrading quality or durability. Another aspect of HDPE pellets is their outstanding moldability rating and capability to endure extreme temperatures, making them an excellent option across industries from packaging to automotive. Research cites HDPE for eco-friendly initiatives due to its recyclability and smaller carbon footprint compared to other materials, such as PVC. All of these reasons make HDPE pellets uniquely positioned to stimulate innovation and efficiency across contemporary manufacturing domains.

Properties of High-Density Polyethylene

High-Density Polyethylene (HDPE) has a peculiar combination of properties that lend themselves to various applications. Being lightweight and able to withstand heavy compressive pressures or tensile stresses, while building a strength-to-density ratio, HDPE is resistant to chemicals such as acids, bases, and organic solvents. This makes it well-suited for chemical processing operations and chemical storage. With low moisture absorption and excellent resistance to environmental conditions, including UV light and extreme temperatures, HDPE ensures longevity in both indoor and outdoor applications.

Since it is thermoplastic, the moldable HDPE can be reheated and reshaped into new configurations without any loss of structural integrity; this facilitates the existence of custom solutions in various industries. The material has a melting range of roughly 120°-180°C, depending on the grade, making it suitable for high-heat conditions. In addition, it is highly impact-resistant, making it a reliable material for shock absorption needs. Being in a recycling-friendly category also helps it promote sustainability and hence reduce its environmental impact. An environment-conscious manufacturing industry is thus inclined to choose HDPE. On the other hand, these properties make HDPE extremely versatile and efficient, pushing the boundaries of innovation in packaging, construction, and automotive engineering.

Differences Between HDPE and LDPE

Polymers, HDPE, and LDPE are polyethylenes, but they differ significantly in structural composition, properties, and applications. HDPE is a linear polymer with a slight degree of branching. Being a dense material, HDPE benefits from accentuated tensile strength, impact resistance, and chemical stability compared to LDPE. On the contrary, LDPE is a polymer with a highly branched structure, making it light, flexible, and less dense. Polymers get molded into plastic bags, squeeze bottles, film wraps, etc., because of their flexibility.

When it comes to heat resistance, HDPE has an edge over LDPE. It has a melting point in the range of 120-180°C, which allows the HDPE to retain its characteristics even under high-temperature environments. LDPE, on the contrary, with a melting point of approximately 105-115°C, is better suited for situations where heat resistance is not of pivotal importance. While HDPE is solvent- and acid-resistant and would, therefore, be suitable for heavy industrial uses, LDPE works in a less demanding environment.

Environmentally speaking, both are recyclable, but HDPE, being a tough one and capable of facing harsher environments, could be more sustainable in the long run. In industries such as construction and automobile, HDPE is popular due to its toughness and ecological potential, whereas LDPE is preferred for lightweight packaging and disposable items.

Knowledge about these variances enables industrialists or decision-makers to select the materials best-suited to their specific needs. In so doing, they maximize performance, cost-efficiency, and environmental impact through various applications.

Applications of HDPE in Manufacturing

HDPE Pellets: Common Applications in the Plastics Industry

HDPE pellets, depending on the material grade and type, can be used in manufacturing like any other polymer due to their strength, durability, and versatility. Some primary end uses are:

Packaging Solutions: HDPE is one of the materials used to manufacture strong and lightweight packaging solutions. It is used in manufacturing bottles for milk, detergents, and personal care products that ought to be leak-resistant and have a long shelf life. HDPE pellets are used to manufacture caps, lids, and containers for both consumer and industrial markets.

Pipe and Conduit Systems: Recognized for its high-pressure resistance, high flexibility, and great strengths, HDPE is definitely chosen as a piping material for water supply, irrigation, and gaseous distribution systems. These are also prime conduit systems for electrical installations, as they give the best electrical insulation.

Automotive Components: The automotive industry uses HDPE pellets in manufacturing fuel tanks, interiors, and protective covers for automobiles. This is because of the material’s characteristics: it is high-impact resistant and lightweight, which enhances vehicle energy efficiency while maintaining safety standards.

Household and Consumer Goods: HDPE pellets are used to manufacture kitchenware, storage bins, and outdoor furniture, and can withstand all the elements, chemicals, and wear-and-tear put upon them daily. They are also recyclable, which is another big plus from an environmental manufacturing viewpoint.

Construction Materials: Construction-grade use of an HDPE geomembrane is for lining and also waterproofing. HDPE pellets are then processed into plastic lumber of persistent quality and reinforcement materials that promote sustainable construction.

The sale of HDPE pellets is dependent upon its impressive set of properties that include resistance to moisture, chemicals, and UV radiation. These properties contribute to sustainable manufacturing, as the HDPE pellets are highly recyclable and reusable, allowing industries to reduce waste while maintaining profitable operations. These features make HDPE an indispensable material for industries that seek to combine performance and environmental concern.

Blow Molding with HDPE: Techniques and Benefits

Blow molding is a very versatile manufacturing method for producing hollow plastic parts, with HDPE playing a major role due to its numerous material characteristics. The process generally entails heating HDPE pellets until molten, wherein the molten plastic is inflated within the mold with pressurized air. Hence, manufacturers can create a variety of shapes and sizes for containers, bottles, and industrial parts.

Among the essential properties of HDPE in blow molding is its high melt strength, which in turn provides ideal conditions for achieving a uniform wall thickness and structural integrity in the final product. This property becomes vital since such products need to be exceptionally sturdy to withstand mechanical stresses, exposure to chemicals, and rough handling. When combined with advanced techniques of extrusion blow molding and injection blow molding, this service caters to the manufacturing of complex shapes with precision for varying applications in sectors such as packaging, automotive, and construction.

In addition, blow molding with HDPE provides an efficient and cheap method for industries that require a large volume of production. The quality of recyclability enables manufacturers to undertake an environmentally friendly production process. With such advances in blowing methods and the innate advantages of HDPE, industries lay equal emphasis on performance and sustainability.

Injection Molding Applications for HDPE

Injection molding is yet another popular method used in the manufacturing of High-Density Polyethylene. With this process, molten HDPE is injected into molds to make precise and hardy products of several kinds. Key industries that rely on injection molding for HDPE production include consumer goods, medical devices, automotive components, and industrial packaging.

One of the distinguishing characteristics of HDPE in injection molding is its excellent strength-to-density ratio, which produces lightweight, strong products. For example, HDPE injection molding is used to manufacture fuel tanks, protective covers, and air ducts in the automotive industry since they have good resistance qualities that contribute to vehicle safety and operational efficiency. In consumer goods, HDPE is used for making load-bearing storage containers, kitchen utensils, and bottle caps through injection molding, thus offering a compromise between the durability and cost of goods.

Also, in medical applications where sterility and durability are of utmost importance, HDPE is used for syringe components and laboratory instruments due to its chemical and moisture resistance. And the recyclability provides a significant advantage for industries striving to fulfill sustainability goals without compromising their value or function.

Advancements in injection molding technology have greatly improved the scaling and optimization of HDPE applications, enabling higher precision, less waste during production, and shortened cycle times. Thus, achievements in injection molding technology ensured that HDPE would always be a material of choice among industries trying to satisfy the demands of performance, scalability, and environmental responsibility.

Benefits of Using Virgin HDPE Resin

Why Choose Virgin HDPE Over Recycled Options?

Virgin HDPE resin has distinct advantages over recycled HDPE when strength, consistency, and durability are determining factors in any application. As a resin created from virgin materials, it has better structural integrity and remains consistent in performance under rigorous conditions. Therefore, it becomes the perfect choice for critical products such as medical containers, food packaging, and high-pressure piping systems, all of which require strict adherence to safety standards and performance.

In addition, virgin HDPE has uniform material properties, such as relatively higher tensile strength and better resistance to cracking, which recycled ones usually lack due to prior degradation. This predictability significantly reduces the risk of manufacturing defects, guaranteeing better quality products and less costly downtime during production.

While sustainability is indeed an essential consideration, being recyclable and possessing an extended lifecycle often situates virgin HDPE as aligned with long-term environmental goals. It is a virgin resin that prevents the early replacement of products due to increased longevity, thereby supporting an eco-efficient material-use approach without compromising basic functional requirements.

Cost Efficiency and Performance of Virgin HDPE

Virgin HDPE presents a cost-effective alternative, especially for applications requiring enhanced durability and uniformity from a production standpoint. Its high tensile strength and impact resistance ensure reduced levels of material failure, which translates to lower maintenance costs and fewer interruptions. When examined under the microscope for long-term usage, it remains resistant to environmental stress cracking, even under the harsh conditions of piping, containers, and automobile applications.

Environmentally friendly, virgin HDPE benefits from superior polymer engineering, resulting in advanced processing capabilities with lower material yields. Its lightweight character cuts down economics on transportation, enhancing the fuel economy across shipping and logistics. The comparative condition of virgin HDPE is often lower in terms of total cost of ownership because it is much more durable and recyclable, thereby supporting initiatives that promote reuse cycles and material recovery.

Demand for virgin HDPE on the global market has been on the rise due to sustainable industrial practices, buildability, and adherence to safety and regulatory standards. Food packaging and healthcare industries are good examples where HDPE is allowed because it does not leach or become toxic, thereby providing the reliability needed for compliance. Thus, companies working with virgin HDPE minimize exposure to liability risks and track an increased brand trust, making it a strategic choice for high-performance applications.

Environmental Considerations in HDPE Production

The production of High-Density Polyethylene has dramatically evolved in green technologies that minimize the adverse environmental impact. Modern production methods are now shifting toward cleaner and greener production technologies with lowered greenhouse gas emissions. Among such production enhancements is the adoption of improved catalytic systems by many producers of HDPE to increase production efficiency and thus reduce net energy usage during polymerization.

Reducing plastic waste volume is another environmental priority. Some producers use post-consumer recycled HDPE in their production systems, which both saves plastic from landfill and reduces the demand for raw fossil-fuel-based feedstocks. Various industrial sources claim that the greater the share of recycled HDPE incorporated into new products, the more it can reduce carbon emissions, up to 25%, without compromising material standards.

Another line of emphasis is the use of water. Water conservation technologies and novel process cooling systems are being set up. At another level, some facilities are absorbing the heat and using it back into the system, thereby reducing the net energy usage and enhancing sustainability.

In the meantime, switching to renewable energy has caught the fancy of production plants. Companies are now responsible for using solar, wind, or hydroelectric energy to produce HDPE, further magnifying the ecological footprint. Such sustainability initiatives are in tandem with ever-changing consumer and regulatory requirements, thus placing HDPE on the map as a progressive, green material in modern-based industry.

Comparing HDPE with Other Thermoplastics

HDPE vs. Polypropylene (PP)

Firstly, consider the applicability: High-Density Polyethylene (HDPE) and Polypropylene (PP) are thermoplastics that find extensive application across industries, with their peculiar properties determining their distinctive usages. HDPE harbors superior tensile strength, making it suitable for piping systems, heavy-duty containers, and bottles. In contrast, PP is lighter and has a higher temperature resistance, making it more apt for food storage containers, automotive parts, and textiles.

Chemical resistance is yet another property that contrasts the two. While both materials are well-suited for non-corrosive environments, HDPE stands strong in resisting a broader range of chemicals, including strong acids and bases. PP does not wear with time and has more fatigue resistance, and is often used where this type of hinging movement is required, such as in flip-top bottle caps.

From a sustainability standpoint, the two polymers are recyclable. Still, because of the lower melting temperature of HDPE, it has an advantage: the heat energy expenditure for recycling is proportionally less. Conversely, HDPE’s ability to be blended with other polymers without losing structure opens another dimension to sustainability.

Application-wise, selecting HDPE or PP depends on how the demands, temperature resistance, chemical exposure, and end-of-life recycling background weigh against each other.

HDPE VS. Polycarbonate: Strengths and Weaknesses

In the HDPE (High-Density Polyethylene) vs. polycarbonate debate, considering the strengths and weaknesses of each helps determine their suitability for various applications.

| Material | Strengths | Weaknesses |

|---|---|---|

| HDPE |

|

|

| Polycarbonate |

|

|

HDPE Strengths: HDPE enjoys an excellent reputation for its chemical-resistant properties, making it the preferred material for storing solutions and applications exposed to harsh chemicals. Being a very light material that attains extreme impact resistance characteristics, it allows for the formation of durable products that are easy to transport. HDPE is also well-known for resisting moisture absorption, giving it an edge in hygric or wet environments. Another thing that makes HDPE very attractive to industries with a green inclination is its recyclability. The resin can be recycled into second-use applications virtually without any degradation in material properties.

Weaknesses of HDPE: HDPE also presents certain drawbacks when used at high temperatures. Its limit of usable temperature is a disadvantage vis-a-vis polycarbonate. In addition to being less stiff than polycarbonate, HDPE’s low optical clarity also limits its use in precision applications requiring high optical clarity.

Strengths of Polycarbonate: Polycarbonate is stronger than HDPE and more versatile in demanding environments. Known for excellent impact resistance and thermal stability, it is applied where high strength is needed, such as in automotive components, protective equipment, and safety glazing. Its optical clarity is also a significant benefit since it allows polycarbonate to be used extensively for light diffusion applications, such as lenses and windows. In addition to their strength, polycarbonates excel at retaining their shape when exposed to very high or low temperatures, making them reliable in secondary manufacturing or operational conditions that are quite rigorous.

Weaknesses of Polycarbonate: However, for a cost-conscious project, the high price of polycarbonate may be its limiting factor. Chemical degradation occurs with specific solvents and harsh chemicals, reducing the suitability of these systems for chemical containment. Further, although polycarbonate is considered durable, prolonged exposure to UV rays without the protection of a UV stabilizer can cause it to yellow and lose its strength over time.

Use Case Considerations: The ultimate decision between HDPE and polycarbonate depends on the requirements of the particular application. HDPE is best suited for applications needing resistant chemicals at a low price, while polycarbonate provides the best performance for applications that require transparency, strength, and thermal resistance. Both materials are designed upfront to meet the needs of present-day industrial and consumer markets, and the careful selection of both materials simultaneously ensures their functionality and sustainability.

Density Considerations in Different Thermoplastics

Density significantly influences whether a particular thermoplastic can effectively perform a range of applications, particularly in terms of its weight, durability, and cost-efficiency. High-density polyethylene has a relatively higher density than other polyethylenes, ranging between 0.93 and 0.97 g/cm³. These density values allow HDPE to have a greater strength-to-weight ratio. Therefore, it is helpful in piping, container, and lightweight construction applications.

Other thermoplastics, such as polycarbonate, tend to be denser, approximately 1.20 g/cm³. This prominent density comes with superior mechanical properties such as impact resistance and stiffness. Polycarbonate finds use in difficult areas such as automotive components, safety glass, and architectural glazing, wherein strength and clarity are equally paramount.

Comparatively, flexible designs call for low-density thermoplastics like polypropylene (PP), which are quite cost-effective, with densities around 0.89-0.92 g/cm³. Typically, being light ensures the following advantages for packaging and consumer goods: less raw material cost and transport efficiencies.

The manufacturers achieve good performance and efficiency for end uses by considering the density of each thermoplastic with all other important properties. Thus, materials having a higher density, such as polycarbonate, are suitable for those that require utmost precision. Those with a lower density, such as PP, fare well for general economic purposes.

Selecting a Reliable HDPE Supplier

Key Factors to Consider When Choosing a Supplier

Several factors need to be considered to select an HDPE supplier that guarantees consistency in quality, competitive prices, and dependable service. These are the significant factors to consider.

- Product Quality and Certifications: Make sure the supplier has workable HDPE that meets industry standards and is certified, for instance, ISO 9001. Materials that do not maintain consistent product quality will compromise the outcome of processes from packaging through to construction.

- Delivery Efficiency and Logistics: The logistics capabilities of the supplier must be assessed, including delivery time and efficiency. When delivery is delayed, the production schedule occasionally gets disturbed; therefore, it is better to work with suppliers who have an established transportation system and who have never failed to meet deadlines.

- Pricing Transparency and Competitiveness: The supplier’s price must be based on competitiveness and genuine cost considerations. Bizarrely low prices might indicate a lack of specific quality standards; hence, a tradeoff between affordability and offered value would be the way to go.

- Customization and Technical Support: Choose suppliers capable of customizing HDPE products according to your specific requirements, for example, custom grades or blends. Good technical support speeds up troubleshooting and helps people to integrate a new material into the production process.

- Sustainability Initiatives: Many sectors are pursuing sustainable practices. Check if any supplier uses recycled HDPE material or if their manufacturing process is sustainable, according to the corporate sustainability protocol.

- Market Reputation and Client Reviews: These are to be gathered for the industry. Positive testimonials, long-term client relationships, and case studies of major projects can be used as clout of proven reliability.

- Scalability and Production Capacity: For companies with fluctuating demands, a supplier able to ramp up production would guarantee the efficiency of the supply chain during peak periods.

- Technical Innovations and R&D Investments: Suppliers that invest in research and development generally offer innovative HDPE solutions to meet ever-changing industry standards. This might become the critical selling point as to why they should maintain the competitive performance of their products.

On a thorough evaluation of the foregoing aspects, companies can enter into association with HDPE suppliers who do well in quality, efficiency, and innovations–the very pillars of long-term success.

Performance-Evaluation, Conformance-Assessment, HDPE Products

While many factors are considered in assessing the quality and compliance standards of HDPE products to ensure they meet industry standards and my specific needs, some stand above others. My primary concern is whether the supplier conforms to well-known international certifications, preferably ISO 9001 for quality and ISO 14001 for environmental management. These certifications convey that the supplier consistently provides quality raw materials while being environmentally conscious in its operations. Moreover, I determine whether the HDPE complies with industry-specific standards, such as FDA requirements for food-grade HDPE or ASTM standards for construction and industrial applications, depending on its intended purpose.

Secondly, the property assessment of a material requires testing, evaluating, and determining. Trustworthy suppliers give an extensive technical data sheet that includes specifications like tensile strength, impact resistance, and chemical compatibility. I cross-check this data against independent laboratory test results wherever possible. Moreover, I consider documented case investigations or performance results from other industries, as these demonstrate that a material has been tested under different conditions and found to be reliable. These evaluation procedures are beneficial not only for asserting the quality of the materials but also for reducing the risk of material-related performance issues, which could lead to time-consuming and costly delays in production or legal disputes over compliance.

Lastly, transparency and supplier responsibility need to be upheld during evaluation. Trusted suppliers either can provide or publish clear documentation of raw material sourcing methods, records of compliance audits, and detailed responses to particular concerns regarding quality. Establishing open lines of communication with suppliers to address issues that may crop up before becoming major problems shall be an integral part of the process. That being said, this comprehensive approach to assessing the quality and compliance of HDPE products ensures the selection of materials that satisfy both operational needs and legal frameworks.

Grasping Pricing: Cost per Lbs of HDPE Pellets

When determining the cost price per pound of HDPE pellets, it is necessary to consider several factors: demand, crude oil price, and regional supply chain logistics. Being derived from petrochemicals, the price of HDPE remains stable through the global fluctuations in oil and natural gas prices. Recently, according to research-based data, the average cost of HDPE pellets ranges from seventy cents to $1.25 per pound, depending on the grade and supplier. Standard HDPE used for packaging or extrusion would generally cost less than its specialty-grade counterpart, which is slated for high-performance engineering service.

Balancing cost variability involves randomizing checks on suppliers for all aspects, starting from price transparency, cost breakdowns such as freight charges, and bulk discounts. Bulk purchases generally reduce the cost per pound quite significantly-there may be a 10-20% price cut for setting up hectoliter quantities. Other factors causing disruptions include supply chain disturbances due to inverse global economic changes or weather incidents, which influence the cost of pellets. Staying ahead of such issues helps in better anticipation of pricing fluctuations and, thereby, using this knowledge to schedule procurements.

Besides, quality certification is an essential factor. While price is important, I prefer buying HDPE pellets that adhere to compliance certifications to avoid inferior materials that could potentially harm sustainable output or cause regulatory issues. By working with suppliers who firmly stand for competitive yet stable prices and accept industry standards, I believe I can guarantee that the material needed for my projects meets both budget and quality requirements.

Reference Sources

•

R-HDPE Pellets and Their Applications – Eco Recycling Today

Characteristics And Applications of HDPE Pellets – Angreen

Applications of Recycled HDPE Pellets – Waste Trade

Applications of HDPE Granules – Saydaş Plastic

How HDPE is Revolutionizing the Plastic Industry – Blue Gator Pro

Frequently Asked Questions (FAQs)

The term High-density polyethylene, or simply HDPE, describes a polyethylene with a strong chain structure. It has high tensile strength and, therefore, can be used for packaging, containers, and pipe work. It is resistant against chemicals and weathering. The pellets from HDPE are lightweight but rigid, making them ideal for blow molding and extrusion processes. Moreover, it has good impact strength, so products made from HDPE can withstand physical stress.

Due to their flexibility and considerable tensile strength, HDPE pellets find application in blow molding. In the blow molding process, the pellets are melted and formed into hollow shapes such as bottles and jugs. HDPE can resist losing structural integrity even under higher temperatures, thus making it superior for blow molding applications. Manufacturers prefer HDPE for products that are durable yet light, which are really crucial for packaging. Also, using HDPE in production is economically efficient, as it will bring down material costs without compromising quality.

High-density polyethylene (HDPE) has several environmental benefits compared with its counterpart, low-density polyethylene (LDPE). HDPE being stiff and strong mostly translates to long-lasting products and, hence, wastes less. The recyclability of HDPE made it an environmentally friendly option for use as a packaging material and containers. Also, since it resists moisture and chemicals, one can reuse it several times without any degradation, contributing less to landfill accumulation. Production-wise, HDPE pellets require less energy than LDPE, resulting in a smaller carbon footprint.

Find a high range of 0.94 to 0.97 g/cm³ for the density of those HDPE pellets, which makes them generally denser compared to LDPE pellets, whose density ranges from 0.91 to 0.93 g/cm³. The greater density results in greater rigidity and strength of HDPE products. The molecular weight is higher for HDPE, which affects its mechanical properties, including tensile strength and impact resistance. HDPE, therefore, is considered to be used for more demanding activities, e.g., industrial containers and corrosion-resistant piping. Also, density is something that can distinguish the processing of the two types of polyethylene.

Because of its strength and versatility, HDPE pellets are widely employed in an array of packaging applications. Popular items are plastic bottles, jugs, and containers for household goods, industrial chemicals, and food products. Naturally, thanks to HDPE’s chemical resistance, many chemicals are stored in it by the manufacturers without the fear of leaching harmful effects on the substances. In addition, HDPE’s resistance to weathering has made it a standard packaging material for manufacturing reusable bins and pallets. HDPE is, therefore, vital in packaging for the manufacture of bags and sheets.

When compared to other thermoplastics, HDPE is observed to have higher impact resistance. This property is essential for applications where materials must bear physical stresses and resist shattering. Thus, one of the uses of HDPE in the manufacturing of hard containers and outdoor furniture is to enhance durability. Thermoplastic-type polypropylene may offer different advantages, such as flexibility, but it does not have substantial impact resistance. The choice between these materials would ultimately depend on what is required for the application: resistance to temperature, durability, and other relevant factors.