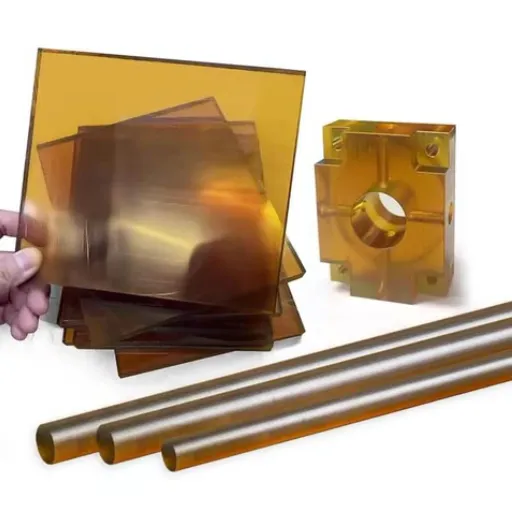

Somewhere between the amber thermoplastics lies a prestigious material: PEI, very quietly among the most valuable materials in today’s manufacturing. In the tough competition where vacuum metals were beating out aerospace components and medical devices, this thermoplastic delivered its best performance when others faltered. This guide delves into everything about PEI plastic from its properties and applications to its limitations and some perspectives for the future. Whether the engineer wishes to look upon materials for a new project or is simply curious about advanced manmade materials, one would find out why PEI just keeps gaining traction in several industries.

Understanding PEI Plastic and Its Properties

What is Polyetherimide?

Polyetherimide, or PEI for short, is an amorphous thermoplastic from the polyimide family. First marketed in the early 1980s by General Electric under the Ultem trademark, PEI quickly gained prominence as a material for applications that demanded thermal stability and mechanical strength.

Wherein most plastics tend to soften or degrade upon heating, PEI stands its ground under extreme conditions that would bring down machines made of other substances. This resistance stems from the polymer’s design, which consists of aromatic rings linked by ether and imide groups, creating a rigid molecular skeleton that withstands heat, chemicals, and stress.

Usually, PEI looks like a transparent amber material, but it can be manufactured as an opaque material or colored to suit a particular application. In its natural, transparent state, it is best suited for applications that require visual inspection or light transmission.

Key Characteristics of PEI Material

PEI offers a property combination that really sets it apart from more common plastics:

✓ Consistent Performance

PEI’s properties remain stable across its operating temperature range. Engineers can design with confidence because the material will not behave unexpectedly under changing environmental conditions.

PEI stands excellently against high temperatures. It has a glass transition temperature of 217°C (423°F) and may even be used in applications with continuous working temperatures up to 170°C (338°F). Peaks in temperature occur only during short-term application intervals, allowing PEI to undergo sterilization and other thermal cycling operations without being permanently damaged.

Mechanical Strength

Being relatively lightweight, PEI still gives you one of the best mechanical performances. PEI has high tensile strength, high dimensional stability, and moderately good impact resistance at low temperatures. In addition, this behavior is maintained across a wide temperature range, which is unusual for a thermoplastic.

Flame Resistance

PEI naturally resists combustion without flame-retardant additives. The material is certified V-0 under UL 94 flammability testing, which is the highest level that can be awarded. When exposed to flame, it produces relatively little smoke with hardly any toxic gases compared to many other plastics.

Chemical Resistance

PEI does not allow most hydrocarbons, alcohols, or aqueous solutions to act upon it. Therefore, it finds application wherever frequent contact with cleaning agents, fuels, and other common chemicals is expected. However, it is noteworthy that PEI is limited when in contact with some solvents, which shall be addressed later.

Electrical Properties

Its excellent dielectric strength and low moisture absorption make PEI a reliable material for electrical and electronic applications, even in an ambient-humid environment that can degrade many other materials.

Sterilization Compatibility

PEI can withstand multiple sterilization cycles using steam, gamma radiation, or ethylene oxide without significant degradation. It is thus of great value in the medical and food service applications.

Comparison of PEI vs Other High-Performance Plastics

How does PEI size against other high-performing thermoplastics? Some key comparisons to examine are:

| Comparison | Key Differences | Best Use Case |

|---|---|---|

| PEI vs PEEK | PEEK offers higher continuous use temperature (250°C) and better chemical resistance. PEI is cheaper, easier to process, and more transparent. | PEI is the more economical solution when extreme performance is not required. |

| PEI vs Polycarbonate | Polycarbonate offers transparency and good impact resistance. PEI is far superior in heat resistance and flame retardance. | PEI operates at temperatures where polycarbonate would soften or fail. |

| PEI vs Polyimide | Polyimides provide greater heat resistance (up to 300°C continuous). PEI is less expensive and easier to process. | PEI is a solution for applications needing very good thermal performance but not extreme ones. |

| PEI vs PSU/PES | PSU and PES share many characteristics with PEI including thermal stability and sterilization compatibility. | PEI generally offers better strength and higher heat resistance, though differences are usually marginal. |

Applications of PEI Plastic in Various Industries

Use of PEI in Aerospace Manufacturing

Aerospace is one of the most demanding areas for PEI applications. Aircraft manufacturers prized PEIs for several critical reasons:

- Weight Reduction: The material’s high strength-to-weight ratio allows the aircraft’s weight to be reduced without compromising safety or performance. A kilogram of weight saved translates into fuel savings over the aircraft’s working lifetime.

- Safety Standards: PEI components meet the stringent aviation standards because they offer flame resistance and emit very little smoke. In the event of a fire, such components will not increase the buildup of toxic smoke in the cabin. It is used for interior components such as seat parts, overhead bin housings, wall panels, and lighting.

- Temperature Stability: A material’s temperature stability is vital for aircraft because temperatures change rapidly during flight. PEI maintains its shape and function while subjected to heating during ground operations in desert climates or to cooling during high-altitude flight.

- Chemical Resistance: PEI may also be used for applications under the cupola in aerospace, where the components are exposed to fuels, hydraulic fluids, and lubricants. It provides chemical resistance to ensure that the components shall work fully for many years under these outright adverse conditions.

PEI Applications in Automotive Engineering

The automotive industry is turning toward PEI more and more for under-the-hood applications where traditional plastics fail:

Electrical Connectors

PEI’s temperature stability, and electrical properties give it an edge for connectors close to hot engine parts. These have to keep going through heat cycles and still make good electrical contact.

Lighting Components

Headlight reflectors and housings made of PEI endure the heat generation of high-intensity discharge lamps and LED arrays. Due to its inherent dimensional stability, PEI guarantees beam alignment throughout the vehicle’s lifetime.

Sensor Housings

PEI protects electronic sensors from heat, chemicals, and vibration. Mass airflow sensors, throttle position sensors, and other crucial components are often housed in PEI.

Fluid Handling

Transfer components in contact with hot coolant, hot transmission fluids, or fuel-due to their chemical resistance and thermal stability-pose an advantage for the use of PEI. Examples include thermostat housings, coolant tanks, and fuel system components.

With the increasing complexity of vehicles and the ever-growing crowding of engine compartments, materials capable of coping with several stress factors simultaneously become increasingly rare; PEI responds to this rare demand by offering a composite talk of thermal-mechanical-chemical performance in one single material.

Medical Applications of Ultem and PEI Resin

Healthcare applications demand materials that can undergo sterilization and remain biocompatible and chemically inert. PEI is great for this:

Surgical Instruments

Reusable surgical instruments made of PEI will endure thousands of steam sterilization cycles without degradation. These instruments are a cheaper alternative to metal instruments for specific applications, plus they are radiolucent (transparent to X-rays).

Medical Device Components

PEI is selected for sterilization resistance and mechanical strength in hospital equipment — from anesthesia components to housings for diagnostic devices. Its transparency permits visual inspection of the internal mechanisms.

Pharmaceutical Production

PEI components are used throughout pharmaceutical processing equipment, where they come into contact with aggressive chemicals during frequent cleaning and sterilization procedures. Manifold installations, valve components, chem-resistant installations for fluid control are some cases where PEI assures chemical resistance.

Dental Applications

Dental instruments and orthodontic devices are made from PEI, which withstands repeated autoclaving without warping or degradation. Also, the material’s natural color makes it aesthetically appealing for use in patient-facing applications.

Some grades of PEI have obtained various biocompatibility certifications (USP Class VI, ISO 10993), making them highly valued in applications involving direct or indirect patient contact.

Benefits of Using PEI in Manufacturing

High-Performance Effects of PEI

Some of PEI’s performance characteristics translate into tangible manufacturing advantages:

✓ Reduced Component Count

Combining these properties, PEI frequently allows a design to incorporate what would otherwise be two or more parts into a single component. The advantages of reduced assembly time, failure modes, and complexity follow from this.

✓ Design Flexibility

PEI can be molded using standard thermoplastic processes, including injection molding, extrusion, and thermoforming. This diversity gives manufacturers the option to pursue complex geometries that are not possible or are almost impossible with metals or thermosets.

✓ Weight Reduction

With a specific gravity of around 1.27, PEI is much lighter than metals but has similar strength in many applications. This advantageous weight factor extends beyond aerospace to any mass-considerate application.

Cost-Effectiveness of PEI in Long-Term Use

The initial investment for PEI is higher than that of commodity plastics. In many instances, however, the price that one pays throughout a product’s lifetime is the better bargain:

- 💰 Extended Service Life: Components fabricated from PEI rarely enter service for fewer years than their counterparts made of less durable materials. Fewer replacements mean lower maintenance costs and less trouble.

- 💰 Processing Efficiency: PEI’s processability enables efficient processing, with good cycle times and very little scrap. The scrap can be reground and reused, further reducing waste.

- 💰 Reduced Assembly Costs: Property conflict resolution enables part consolidation, reducing the number of components to buy, the inventory required, and the assembly time. This, in turn, simplifies supply chains and reduces labor costs.

- 💰 Lower System Costs: Using PEI can actually preclude secondary operations such as coating or special heat shielding. Otherwise said: The material, by its own nature, often provides enough performance without any additional steps.

When evaluating the cost-benefit ratios, the advantage of PEI over ultra-high-grade materials like PEEK becomes pronounced. Use of PEI whenever applications fall within its performance envelope can save very big bucks without impinging on reliability.

PEI As a Sustainable Material Choice

Increasingly, sustainability plays a part in material choice. PEI has many environmental benefits:

Longevity

PEI-made products generally have longer lifespans, which means fewer replacements and less environmental pollution from manufacturing new parts.

Recyclability

Because of its thermoplastic nature, PEI can be ground and reprocessed. Maybe it could experience some degradation of its properties in successive recycling cycles, but it can usually be blended with virgin resin to regain acceptable performance while using scrap material.

Reduced Material Use

PEI’s strength allows thinner wall sections and lighter components than many alternatives. Less material in a part means fewer resource acquired.

Energy Efficiency

In transportation, PEI’s lightweight nature improves fuel efficiency. These cumulative advantages across millions of vehicles or thousands of aircraft translate into meaningful reductions in energy consumption and emissions.

Reduced Hazardous Waste

PEI is highly resistant to degradation, so its components do not leach chemicals into the environment over time. Because of PEI’s flame-retardant properties, it does not require the toxic flame-retardant additives used in many other plastics.

Limitations of PEI Plastic

Some Common Challenges with PEI Resin

PEI resin has many advantages, but it is not perfect and may not be suitable for every application. Knowing the limitations will help engineers make an informed choice about material selection:

⚠️ Costs

PEI is more expensive than common commodity plastics, and even some engineering thermoplastics do not come at that high price. This price premium could be justified for applications of critical nature but would definitely put PEI out of consideration for cost-sensitive endeavors.

⚠️ Processing Requirements

PEI requires much higher processing temperatures than many plastics, typically in the 340-425°C range, so equipment capable of reaching and holding these temperatures must be available. Investment in equipment upgrades may be necessary, depending on whether manufacturers have previously processed high-performance thermoplastics.

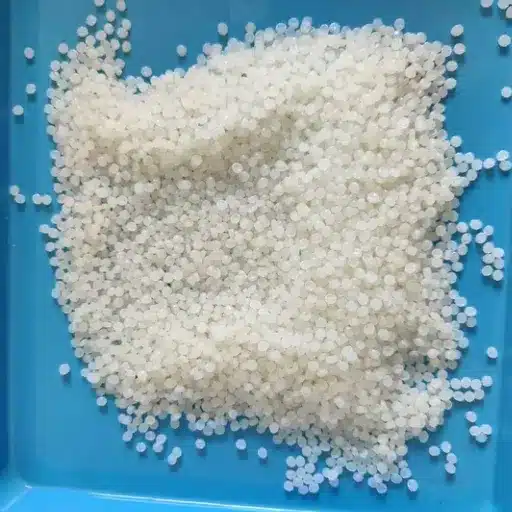

⚠️ Moisture Sensitivity Before Processing

While low moisture absorption is good for PEI resin in use, the resin must be dried thoroughly before processing. Inadequate drying may cause hydrolysis in the resin during processing, thereby decreasing molecular weight and nominal properties.

⚠️ Limited Color Options

PEI’s natural amber color may be unacceptable for applications that require a specific aesthetic. Opaque grades can be made in different colors, but the color range is still limited compared to commodities.

⚠️ Notch Sensitivity

PEI, like most amorphous thermoplastics, can be quite sensitive to corner radii and stress concentrations. Designing with proper radii can help eliminate this limitation.

Comparative Limitations of PEI vs Polyimide

While PEI belongs to the polyimide family, it stands apart from traditional polyimides in ways that present certain advantages, and conversely, limitations:

- Traditional polyimides typically offer higher continuous use temperatures, sometimes exceeding 300°C compared to PEI’s 170°C rating. For applications requiring extreme thermal performance, polyimides may be necessary despite their higher cost and more challenging processing.

- Between polyimide and PEI, polyimide generally offers better wear resistance and is preferred for high-friction applications. For most applications, however, PEI offers sufficient wear resistance, especially when lubricated.

- The processing advantage of PEI over polyimides is significant. Many polyimides are thermosets or require special processing; in contrast, PEI can be processed in standard thermoplastic equipment. Such accessibility makes PEI practical for a much wider range of manufacturers.

Confronting Solvent Resistance Issues

In spite of PEI being resistant to many chemicals, some solvents cannot go without affecting the substance:

| Solvent Type | Effect on PEI |

|---|---|

| Halogenated Solvents | Methylene chloride or chloroform will attack, dissolve, or swell PEI; thus, alternative materials must be sought with applications involving these solvents. |

| Strong Bases | Strong alkaline solutions attack PEI, especially at raised temperatures. The material is fine with weak bases, but extra care must be exercised in really alkaline environments. |

| Certain Organic Solvents | Some ketones and esters can affect PEI, depending on concentration, temperature, and exposure duration. |

Wherever solvent contact is an issue, compatibility testing with chemicals should be conducted in earnest, under application-oriented conditions. In most instances, reducing contact with solvents or using special PEI grades may alleviate concerns.

The Future of PEI Plastic in Manufacturing

Innovations in PEI Plastic Technology

The ongoing work in material science keeps opening new doors for PEI:

🔬 Reinforced Grades

PEI grades reinforced with glass and carbon fiber are developed for added strength and stiffness, a plus which maintains the thermal properties of the base polymer. This material allows the design and construction of even lighter yet stronger components for high-end applications.

🔬 Specialized Formulations

Manufacturers begin implementing processes to investigate other PEI-based materials optimized for different applications, such as those that offer superior wear resistance, ease of processing, and EMI shielding.

🔬 Additive Manufacturing

Among the newer uses for PEI is 3D printing products that require high-temperature resistance. With the evolving technology of additive manufacturing, PEI enables customers to have complex heat-resistant parts manufactured with no tooling cost.

🔬 Hybrid Materials

Other material mixtures are being explored for combination with PEI to create hybrid structures having the best of each constituent principle. Such developments can open new avenues for applications that could not be served by the materials individually.

Market Trends of High-Performance Plastics

These trends are expected to enhance the adoption of PEI and similar materials:

- Lightweighting: As aerospace, automotive, and other industries seek to reduce weight, demand for high-performance plastics that can replace metals continues to increase. PEI, with its high strength-to-weight ratio, is well positioned to benefit from this trend.

- Electrification: The shift toward electric vehicles is further opening many opportunities for using PEI in battery housings, electrical connectors, and thermal management systems. The material’s electrical properties, combined with its flame resistance, make it a worthy contender.

- Medical Device Growth: An aging global population and the development of medical technologies are, therefore, generating an increasing demand for materials that can stand sterilization and yet meet biocompatibility requirements. PEI is, and probably will continue to be for some time, quite well positioned in this expanding market.

- Sustainability Pressure: For environmental reasons, manufacturers are under increasing pressure to minimize their environmental impact. Despite this, a high-initial cost durable material such as PEI, allowing for a longer product life, could be an advantage.

New Potential Applications for PEI in 21st Century Manufacturing

With new technologies and advanced requirements, certain areas are possible candidates for new applications of PEI:

📡 5G Infrastructure

The development of 5G networks requires materials that can withstand higher frequency and temperature while providing reliable electrical insulation. Such requirements match well with PEI properties.

🌬️ Renewable Energy

Wind turbines, solar concentrators, and other systems of renewable energy materials require materials that are exposed to the elements and/or experience temperature extremes. Because it has durability properties, PEI is now considered for numerous components used in these systems.

💻 Advanced Electronics

Newly powerful and tiny electronic devices generate ever more heat in smaller spaces. PEI’s thermal performance may lead to innovative concepts for housing and protecting sensitive components.

🍽️ Food Processing

Due to its resistance to sterilization and chemical inertness, the use of PEI may grow in the areas of food processing equipment, most notably in those that involve high-temperature applications that are currently metal dominated.

💧 Water Treatment

Due to PEI’s chemical resistance, it may find applications in the water treatment and purification systems in which components have to undergo exposure to several chemicals and disinfection processes.

Reference Sources

- Polyetherimide for High-Performance Applications – Ensinger

- Polyetherimide (PEI): Resin for High-Performance Applications – Aprios

- PEI Plastic: Success Stories and Challenges Across Industries – BeePlastic

- Aviation & Aerospace Applications of PEI – Aurora Material Solutions

- PEI vs. Other High-Performance Plastics: A Comparison – BeePlastic

- View for more details.

Frequently Asked Questions (FAQs)

❓ What is PEI plastic and its key properties?

PEI plastic is an amorphous thermoplastic with extraordinary mechanical and thermal properties. The higher temperature resistance is good for many industrial applications where materials must be exposed to harsh environments. It provides good electrical insulation properties for electrical insulation applications. PEI is also chemically resistant, especially against chlorinated solvents, providing withstand in a large number of environments. In addition, its tensile strength and stiffness uphold its performance as an engineering thermoplastic.

❓ How does PEI compare to other engineering thermoplastics?

Compared with other engineering thermoplastics such as PEEK, PEI offers similar durability and heat resistance at a lower cost. As a result, PEI’s properties make it a versatile material for high-performance applications without the cost of other high-performance plastics. Also, PEI maintains a very high glass transition temperature when compared with many of its alternatives, thus sustaining its dimensional integrity throughout heat exposure. This comparison was carried out to direct attention to the advantages of PEI especially for those industries that are trying to find cost-intensive manufacturing processes without sacrificing quality.

❓ What are the applications of Ultem in various industries?

Popularly known used in several sectors for its high-performance characteristics, Ultem is usually considered for the production of machined plastic parts, printed circuit boards, and medical devices requiring biocompatibility. Flame-retardant and low-smoke-emission properties of Ultem make it applicable in the aerospace and automotive fields, where safety is a concern. It finds further use due to its ability to withstand varying-temperature environments where thermal stability is concentrated. In brief, applications accord Ultem a reputation of a highly versatile high-performance plastic.

❓ What are the drawbacks of PEI Plastic?

Although PEI plastics offer many advantages, they also have drawbacks worth considering. A major drawback includes stress cracking in certain situations. This can be detrimental when assessing its durability that is of paramount importance. Moreover, although it can withstand the heat, it may fare lower in performance compared to other materials in very high-temperature situations, such as PEEK. Its price, when compared to ordinary plastics, may also discourage manufacturers from using it for low-budget projects. Familiarity with the limitations is paramount to selecting the proper material for any application.

❓ Are you interested yet on how PEI plastics behave electrically?

Generally, PEI plastics are considered to have very good electrical properties, making them suitable for applications that require electrical insulation. A high dielectric strength is required for components in PCB manufacturing and electronic components to provide effective resistance to electrical conduction. Furthermore, PEI’s thermal properties enable it to retain its insulating properties even under differential temperature conditions. This set of attributes made PEI the choice material in the electronics industry where reliability and performance are the key concerns.

❓ Is PEI plastic suitable for 3D printing?

With its great mechanical strength and temperature resistance, PEI plastic is used in many 3D printing applications. It can handle the mechanical demands of high-performance 3D-printed parts, making it suitable for both prototyping and production. PEI requires proper printing settings to promote adhesion and prevent warping. Designing complex geometries in PEI opens up creative design options for many industries. In summary, 3D printing applications underlie the great versatility of PEI as a contemporary engineering thermoplastic.