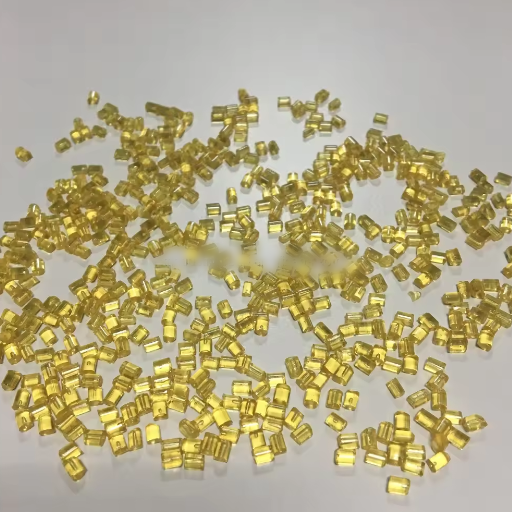

Polyetherimide (PEI) plastic pellets are transformative when high-end materials for challenging uses are needed. PEI pellets form months of strength from thermal stability and chemical resistance to their cutting-edge nuance in working across the aerospace or medical devices industries. This article will delve into the incredible benefits of PEI and explore why it remains at the top of most engineers’ and manufacturers’ minds for performance with reliability. The answer to a question about more durable products, design flexibility, or meeting demanding industry standards might strongly lie with PEI. Discover how this fascinating material can take your projects from good to great!

What are the Key Properties of PEI?

Understanding Mechanical Properties of PEI

Polyetherimide (PEI) is a unique material used in almost impossible applications due to its excellent mechanical properties. The strength and rigidity of PEI can be very high, from 85 to 105 MPa of tensile strength, depending upon grade and formulation. PEI displays stiffness with a stiff modulus of elasticity usually between 3.2 and 3.8 GPa, ensuring excellent dimensional stability when subjected to mechanical stress.

In addition, PEI fares well at higher temperatures of 170°C and above, without mechanical distortion and loss of mechanical properties. Additionally, this material is known for creep resistance over long periods, during which components conform to high stresses, making it greatly valuable in a creep-prone high-stress environment. Improvements in PEI can withstand wear and tear; therefore, where toughness and resistance to impact are necessary, PEI is deemed appropriate. Combining the above characteristics, PEI is accepted as a preferred material among the aerospace, automotive, and electronics industries that require precision, reliability, and thermal resistance.

Exploring the Thermal Expansion and Heat Resistance of PEI

One of polyetherimide’s perks is its excellent thermal stability; the polymer may be exposed to heat for a prolonged period without much degradation. The polymer is characterized by a high transition temperature, usually exceeding 215°C (419°F), and hence, remains fit for heavy industrial applications. PEI has a low coefficient of thermal expansion (CTE), which brings about dimensional stability under varying thermal settings. For instance, polyetherimide’s CTE is higher than polyethylene or polystyrene. Therefore, these properties make PEI a primary candidate for any components subjected to thermal cycling, as they are less likely to warp or deform.

Other than that, the heat resistance property lets a PEI component retain its strength even under intense thermal stresses. Engineers consider it a vital candidate in manufacturing. In the aerospace industry, PEI is said to withstand the high heat associated with jet engines. In contrast, in electronics, it serves as an insulation material for fabricating heat-generating devices. Its ability to balance thermal endurance with engineering precision makes PEI a versatile material, solving modern engineering challenges.

How Does PEI Provide Outstanding Electrical Properties?

Polyetherimide (PEI) has a reputation for its superlative electrical properties, allowing it to be used in many high-end applications. Among its electrical properties is dielectric strength, which prevents electrical breakdown even under very high voltages. Hence, it is primarily used for insulation in industrial and commercial electronics such as circuit boards, connectors, and electrical systems requiring high power. Since they want to keep maximum energy intact, the material’s dielectric constant is low, which is of particular concern in sensitive electronic devices.

Another desirable property that PEI offers is very high stability as an electrical insulator across a wide temperature range. In contrast with other materials whose electrical properties suffer at high temperatures, PEI manifests uniform electrical behavior under extreme thermal conditions. This feature is advantageous in high-tech environments like aerospace or automotive industries, where components are expected to operate reliably in harsher and ever-changing environmental conditions. It also resists arc tracking quite well, minimizing the potential for damage from electrical discharges and failures.

Further, the inherent flame-retardant properties of PEI improve its suitability in electrical applications from a safety standpoint and for strict regulatory requirements. Combined with high mechanical properties, chemical resistance, and ease of fabrication, the electrical performance of PEI elevates itself above just meeting industry requirements. With a unique amalgamation of thermal stability, electrical insulation, and robustness, PEI paves the road for high technology and electrical innovations.

Why is PEI a Preferred Material in Aerospace Applications?

The Role of High-Strength and Lightweight Features

Due to its exceptionally high-strength and lightweight attributes, polyetherimide (PEI) continues to enjoy a niche status in key aerospace applications. Weight optimization for aircraft, coupled with structural integrity and performance requirements, keeps pushing aerospace engineers to seek materials that could keep up with the demand. PEI successfully caters to these demands. This polymer offers tensile strength comparable to traditional metals such as aluminum but with a far lower density; hence, it contributes to greater fuel efficiency, lower emissions, and operational cost savings. Due to its dimensional stability even after being subjected to extreme mechanical stresses, PEI is an alternative for components exposed to high-load applications such as brackets, housings, and interior panels.

In addition, PEI is a lightweight material strongly resistant to any sort of wear-and-tear-related damages, environmental challenges being another major one in this case. It resists harsh temperature variations, from extreme cold at very high altitudes to heat generated due to exposure at very high speeds, thereby ensuring safety and durability in critical aerospace applications. Its high performance in severe operating conditions is one of the reasons for its integration into both primary and secondary structural elements. Apart from good performance, the choice of materials like PEI also fits well with the industry’s transition toward sustainable design, whereby PEI enables long-lasting yet fuel-efficient solutions. These are what a good mix of qualities requires to meet the industry’s call for innovative material solutions to tackle future aerospace challenges.

Benefits of Flame Resistance in Aerospace

Flame resistance is of utmost importance in aerospace applications. It ensures passenger safety, the safety of contingent equipment, and regulatory conformance. Materials possessing intrinsic flame-retardant properties further decrease the possibility of ignition; they additionally provide a lower rate of fire spread, thus affording more time for controlling measures. Accordingly, in terms of temperature, advanced polymers such as PEI (Polyetherimide) are thermally stable and can operate at an elevated temperature without undergoing any structural failure.

This property increases the mechanical strength of aircraft interiors, allowing panels, seating, cabin fixtures, etc., to be sufficiently strong while still weighing less. Other studies also show that flame-resistant materials can significantly reduce the risk factors of an in-flight fire. In conjunction with green considerations, these materials commonly attract acceptance under industry-specific regulations, such as FAR 25.853, assuring both safety and sustainability, which is the path aerospace manufacturers use to confront new-age challenges with intact performance.

How Does PEI Benefit the Automotive Industry?

Leveraging PEI’s Chemical Resistance in Automotive Parts

The excellent chemical resistance property made PEI a prestigious level material in the automotive industry. This thermoplastic of the highest grade resists aggressive automotive fluids such as engine oils, fuels, transmission fluids, and cleaners to assure vendors of component durability and reliability for an extended period. For example, PEI parts are relatively stable under prolonged exposure to elevated temperature and reactive chemicals, which are essential for any modern automotive application.

A huge advantage of polyetherimide is that it can serve a challenging under-the-hood environment full of stressors to components. By resisting the degradation caused by chemicals and heat, PEI increases the longevity of automotive parts such as fuel system components, electrical connectors, and housings. It is also lightweight, thereby contributing to the vehicle’s weight reduction and fuel efficiency improvement, which is a significant concern of sustainability in the industry.

The integration of PEI in manufacturing allows automotive designers and engineers to balance superior performance and adherence to very strict industry standards with lowered maintenance costs. These properties make PEI a critical material for today’s automotive development.

Enhancing Dimensional Stability in Vehicle Components

Dimensional stability remains crucial to ensure the reliability and safety of vehicle components. Materials such as polyetherimide maintain an excellent dimensional stability when subjected to a wide range of temperature fluctuations and mechanical stresses. Therefore, PEI has a low coefficient of thermal expansion and is preferred for engineering components subjected to high heat, such as engine housings or electrical system enclosures. Thus, less heat will be transferred onto the element, reducing its thermal expansion, warping, and distortion from heat, adversely affecting the precision and performance of critical automotive elements.

Advances in material science have succeeded in further modifying the PEI resins for improved resistance to environmental conditions such as moisture and prolonged UV exposure. Automotive test data show that PEI-based components retain their original dimensional tolerances even after prolonged thermal and ecological stress simulation cycles. Such reliable performance increases the life of vehicle components. It lowers maintenance costs, which aligns more with the industry’s push for durable and cost-effective solutions. Therefore, innovation and performance ensure that PEI will continue to be used in crafting future-generation vehicles that meet stringent quality and sustainability parameters.

What Makes PEI Suitable for Medical Device Applications?

The Importance of Sterilization Compatibility

Sterilization is an essential step in the material selection of medical devices to guarantee patient safety and regulatory compliance. Some sterilization methods that the devices are exposed to include autoclaving, ethylene oxide (EtO), gamma radiation, and chemical sterilants. To withstand such stringent sterilization processes, materials such as Polyetherimide (PEI) are designed to retain their mechanical strength, dimensional stability, and performance upon successive sterilization. Thus, the material has to be thoroughly compatible with sterilization methods.

PEI is an excellent bang-for-your-buck medical-grade polymer for those applications where high thermal stability is demanded and resistance to oxidation and chemical degradation is necessary. Reusable instruments undergo very high-temperature sterilization methods, making PEI an excellent choice in such applications because of its durability and safety. Furthermore, the biocompatibility of PEI adds another feather to its role in the medical sector, as it can safely be applied when it comes in contact with human tissues. When placed side-by-side with those advantages, manufacturers can reduce risk, maintain consistency, and meet the rigors of heightened quality standards in a competing medical device market.

Utilizing PEI’s Biocompatibility and Amorphous Nature

Among its niche applications, PEI requires biocompatibility and an amorphous molecular structure to offer high-performance applications. Because it is inherently biocompatible, it can be safely used in medical devices that directly contact human tissue, such as surgical instruments and implantable components. This characteristic shall meet stringent regulatory requirements and emphasize personalized and patient-specific medical solutions.

Amorphous polymers are dimensionally stable and transparent, making it possible to precisely manufacture tools for producing intricate and complicated geometries found in medical and industrial setups. For example, PEI resists hydrolysis and thermal degradation, guaranteeing its presence in harsh or sterilized environments. All these properties are essential for some medical, aerospace, and transportation service profiles. Thin-walled molding of PEI without compromising mechanical integrity represents manufacturing solutions that enable performance enhancement, safety improvement, and value in their products.

How do you select the right PEI grade for your needs?

Comparing Unfilled vs. Glass Fiber Reinforced PEI Grades

When I decide on unfilled or glass fiber reinforced PEI grades, I always consider the individual requirements of my project. Unfilled PEI is suitable where I require the best possible natural electrical insulation properties, chemical resistance, and dimensional stability. It is also of lighter weight and easier to machine, so it makes a suitable choice when working on parts that call for acceptable dimensional tolerances and intricate designs, where working with reinforcing fibers would have been an extra layer of complexity. Then, there are aesthetics, transparency, or tinting, requirements that favor unfilled PEI since it can be naturally amber or tinted without altering its properties.

On the other hand, applications that require mechanical strength and rigidity draw me to grades of glass fiber reinforcements. The glass fibers open up structural applications with continuous mechanical stress by granting tensile strength, flexural modulus, and impact resistance to withstand higher loads and extreme conditions. I find reinforced grades especially useful in high-temperature applications due to their thermal stability and reduced creep under load compared to unreinforced PEI.

Ultimately, it is a balancing act to find the extraordinary demands of the application with the corresponding advantages offered by each grade. If I require an easily machined general-purpose material with excellent insulation qualities, I tend to go with unfilled PEI. If my needs lean toward the rugged and high-performance side, glass fiber reinforced PEI is always on my mind as the answer. In understanding these differences, I know I can safely select the grade best suited for all performance, durability, and cost considerations.

Understanding PEI Resin Variants and Their Applications

In choosing the correct PEI resin type, the whole matter commences by appraising the specific requisites of the application. The unfilled PEI is often the best choice for general-purpose applications where the major requirements are cost and ease of processing. It has thermal stability, good insulation properties, and processability, making it suitable for components such as gears, bushings, and enclosures where accuracy and lightweight properties are of utmost importance.

In high-hard-usage cases, where enhanced strength and rigidity are required, glass fiber-reinforced PEI is the way to go. It has found application mainly in the aerospace and automotive industries, where mechanical loads, temperatures, and environments are harsher. The glass fibers augment tensile strength and dimensional stability, but the trade-off is that the material may become more brittle than its unfilled counterpart. Bearing this in mind aids in concentrating on the durability and performance attributes required, for which trade-offs must be considered.

In view of this, I now have the knowledge to select the right PEI based on the operating environment, mechanical demands, and cost constraints. This methodical selection of material promotes the top functioning of the final product, which also improves its reliability and longevity. This shows the clear importance of matching material properties to application needs.

Reference Sources

-

Polyetherimide for High-Performance Applications – Ensinger: Discusses the high heat resistance and processing expertise required for PEI.

-

PEI (Polyetherimide, ULTEM™) Plastic—Polymershapes: This section highlights the benefits of PEI, including dimensional stability and UV resistance.

-

Polyetherimide – An Overview – ScienceDirect: Provides an in-depth look at PEI’s properties, including strength, heat resistance, and flame retardancy.

-

Polyetherimide—Wikipedia: This article offers a general overview of PEI, including its adhesive properties and uses in 3D printing.

- Top PEI Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What is polyetherimide plastic? Why is it termed a high-performance thermoplastic?

A: Polyetherimide, in short PEI, known by the trade name Ultem®, is a high-performance thermoplastic respected for its excellent mechanical and electrical properties. This plastic material exhibits high tensile strength, resistance to high temperatures, and good dielectric properties. These hence require more demanding fields like medical devices, electrical connectors, etc.

Q: What are the properties and performance of Ultem PEI plastic?

A: The PEI plastic Ultem has excellent mechanical strength, thermal stability, and resistance to many chemicals, including hydrocarbon and alcohol solvents. It retains its mechanical properties for various temperatures, and its glass transition temperature is high enough for the temperature application.

Q: How does Ultem 2300 vary from the others in PEI grades?

A: Ultem 2300 is a specific grade of polyetherimide that is 30% glass fiber-reinforced, thus enhancing its stiffness and flexural modulus. Applications using it for high strength and rigidity are intensely interested in aerospace and automotive structural components.

Q: Can Ultem be used in food processing applications?

A: Ultem can be used in food processing applications. It has stable material properties and can resist high temperatures and autoclave sterilization. As a high-performance material, it guarantees the utmost safety and durability in food-contact environments.

Q: Why are polyetherimides great for electrical applications?

A: Polyetherimide is an excellent material for all electrical applications because of its insulating properties and temperature resistance. It is mainly used in electrical connectors, sockets, and other components that require performance assurance under electrical stress.

Q: How can the molding process affect Ultem plastics’ performance?

A: The molding process will significantly affect Ultem plastic’s performance characteristics. If properly injection-molded, Ultem plastic will show the best strength and dimensional stability in applications where its characteristics are highly demanded.

Q: Why is Ultem used in medicine?

A: Ultem is used in medical applications because it can tolerate repeated sterilization by autoclaving and gamma radiation. It is an excellent choice for medical devices and components because of its strong biocompatibility and mechanical strength.

Q: What are the typical applications of Ultem PEI in the oil and gas industry?

A: In the oil and gas industry, Ultem PEI is exploited for its high-performance characteristics for resisting high temperature and chemical exposure. It is used in machined parts and components where durability under rigorous environmental conditions is of the utmost priority.

Q: What advantages does Ultem have in machined parts?

A: Ultem has advantages in machined parts since it has high mechanical strength and stability at elevated temperatures. Its good machinability makes the precision manufacturing of components with complicated shapes possible and, hence, suitable in applications requiring tight tolerances and high performance.