In immense numbers of industrial and daily consumer applications, High Density Polyethylene (HDPE) pellets is utilized to an extent that it is associated with great attributes of versatility, resilience, and performance efficiency. However, the cost of HDPE pellets is subject to change, and this sharp contrasts often causes people to question the material quality versus the cost available. Irrespective of people in the entire supply chain, product quality, performance, efficiency, cost, and even meeting compliance requirements are all predefined by such understanding. This article scrutinizes how the two conceots of fetchctual economiucs interact in determine the price of HDPE pellets and the frequetnt factors marikl ob use that are put into these processes, the relevance and how the quality aquiring armor capacities contributes to the quality control procedure within the product cycle, as was illustrated above, how to equip do them. Whether you are involved in purchasing or you are more concerned with organizational process improvement, this study is helpful as it concentrates on the information in this regard where the issues cost and quality can only be addressed by blending technical and managerial perspectives.

Understanding HDPE Pellets and Their Applications

What are HDPE Pellets?

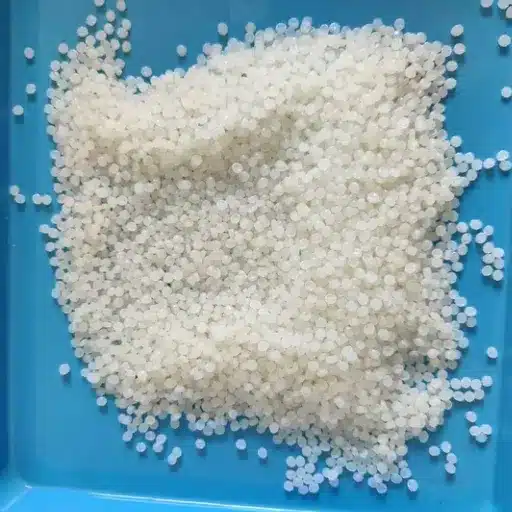

HDPE resin is a thermoplastic found in the form of small uniform granules. ‘HDPE’ is an acronym for High Density Polyethylene. It has exceptional resistance/strength to density. The pellets are formed through the polymerization of ethylene where the resultant structure is a highly crystalline one which is strong, chemically resistant and has the ability to support large loads along its length. The HDPE pellets are a convenient part of the process and help make many different finished products right from pipes, bottles, parts in cars, households. It is considered to be the most common plastic material.

Among others, the properties of which their applications are largely influenced include low water absorption, impact and corruption resistance, and high thermal stability. Furthermore, the ability to recycle of HDPE has made it the preferred material in most industries which seek to achieve sustainability objectives. The demand for HDPE pellets is projected to continue on the upward trend based on their use as packaging, infrastructure, and bio-based material development sectors factors. These pellets play a very important role in present day society especially where manufacturing is concerned as well as advancements for the betterment of the planet.

Common Uses of HDPE in Industries

High-density polyethylene (HDPE) is a thermoplastic material with a unique balance of mechanical properties. Because of the combination of strength, flexibility and resistance to chemicals; it has convinced many industries to include it in the list of essential materials. The use of HDPE in the packaging industry finds one of the highest numbers of uses considering every other application the material has. This material is used in making bottles, containers and closures for various consumer products, such as food, drinks, and chemicals. Its low apparent density, non-porous surface, and food grade features make it perfect for use in the production and safety of the diagrammatic products.

In the contraction and infrastructure sectors, HDPE is widely used for its flexibility, and durability. HDPE is among the most commonly used materials for the production of pipes, commonly used for water, sewage and gas systems. With the exception of a few countries, most of the corrosion and environmental cracking issues found with metal are replaced by HDPE. Besides, in the context of environmental works, HDPE (high-density polyethylene) geomembranes are used mainly for lining shafts in landfills and when carrying out such operations in the mining industry.

HDPE has also found acceptance in the automotive industry as a leading edge material in lightweight parts like fuel tanks for vehicles. This approach helps to build vehicles with better gas mileage and lower exhaust gas emissions. Solar panels, and wind turbines similarly are able to take advantage of HDPE thanks to its resistance to climate and abrasion without which there would not be very effective frame work for these figures wraps.

The many ways this material can be used demonstrates its importance not only in increasing efficiency in the production process but also in finding practical solutions to many of the contemporary concerns about the environment, thanks to the present ability of recycling it and adding to its economic worth.

The Role of HDPE in Injection Molding

High-density polyethylene (HDPE) is a commonly used material in injection molding primarily due to the splendid equilibrium it displays concerning strength, rubber attributes, and lower cost factors. This is due to the structure of the chain which is oriented and local. Indeed, this material can withstand tension effectively although the material is light hence very flexible. That is, it is used in applications of high traffic with medium to heavy body parts as willingness allows short layering. Clearly, the fairly low melting point of HDPE is helpful for remelting processes in the mould hence minimizing the use of electrical energy. Additionally, it is able to withstand hazardous and damp situations very well which makes it the most choice for engineering of automotive or medical elements.

Recently, improvement in the techniques used in the process of injection molding have improved the accuracy and structure of the HDPE products. This is seen when high cavitation molds and integrated cooling setups helps to produce maximum same quality parts in a short production time, efficiency and reducing wastage. Moreover, the material HDPE’s ability to be reused – can be very useful especially in “green” or sustainable manufacturing. This is a system that involves the continuous recycle of the off cuts materials that could be reused without so much loss of the components’ qualities. Without a doubt, bonding agents HDPE is the building block of manufacturing through needing designer friendly and cost effective procedures.

The Factors Influencing HDPE Pellets Price

Material Quality and Its Impact on Pricing

HDPE pellets have always exhibited a rising scale in the market but it can be very simple to guess that the most expensive material is that which is generally purchased as the-enhanced performance category is corrupt-significance materials. Factors such as density, purity, and molecular weight have a direct and important effect on the physical traits of HDPE, such as strength, elasticity, and its ability to withstand infant failure. Impurities, as well as inconsistencies in the composition of pellet composition, can lead to the poor performance of the material and it is for this reason that quality assurance has to be carried out during the manufacture of the material. Likewise, there is always great demand of these high grade HDPE classes that require more advanced and extensive details in manufacturing and therefore come at a higher price. However, importantly, those HDPE pellets on offer to those with much lower performance requirements and requirements are priced very affordably. These ‘pegs of material-related qualities’ are very essential in understanding the economic implication of all of these characteristics to various sectors.

Market Demand for High-Density Polyethylene

The demand for high-density polyethylene, also known as HDPE, is derived from two major factors; its attributes and why is HDPE in demand. The demands in High – Density Polyethylene are usually in place because the market has the capacities of the said numerical values. Its wide scope of application encompasses such industries as packaging, construction, and, agriculture as well as automotive which in turn results in the demand of this plastic. There should be an introduction of sustainability in the HDPE guise of recyclable and reusable packaging solutions. The environmental requirements for building structures include the use of highly efficient, “green”, low-maintenance materials. HDPE piping systems, geomembranes for lining and shelters, and insulation all use the HDPE material for their high strength features and corrosion resistance.

New market research indicates a strong shift towards bio-based HDPE that is most popular among institutions trying to set themselves in conformity with environmental laws while diminishing the carbon footprint. Off-shore countries like Asia are developing more on this because there are changes taking place in cities mostly due to increasing buildings alongside industrial production. Urbanization and cost-effective polymer solutions go hand in hand. This development corresponds to the need for certain vehicle parts to lose weight so that the vehicle operates with less fuel and causes lower air pollution encouraging further adoption of HDPE in the consumer goods manufacturing activities which is of great importance. Experts predict that HDPE market growth is likely to continue as large investments in construction and food consumption will occur in the emerging countries.

The Effect of Raw Material Costs on HDPE Prices

The prices of High Density Polyethylene (HDPE) are highly influenced by the cost of procurement of the raw materials. Polyethylene is made from the basic feedstock ethylene, which is obtained from either natural gas or crude oil. This means that the prices of crude oil and the situation prevailing in the natural gas market heavily influences the cost of petrochemicals, especially HDPE. For example, violence between countries or the future production rates of crude at OPEC meetings generally affects crude prices directly and hence ethylene prices and availability.

Furthermore, the cost of transport and energy input used during production processes is also affecting the expenditure on raw materials. They introduce stringent rules to minimize carbon emissions and try to affect the pricing framework the more toward HDPE. At a higher lever, problem of HDPE pricing grows to be acute because other petrochemical products—such as PET and other polymers/ plastics – compete heavily for the supplies of ethylene. With time, this creates inflation on prices due to deficits in the availability of ethylene which is used as a feedstock for the production of HDPE.

These coordinated forces pointing out the importance of activity in controlling the raw material cost trends, especially now as the demand for a wide range of polymeric materials is still seeing an upward trend. Effective implementation of measures such as raising procurement time with bulk purchases or finding other sources of the raw material component, serve as a shield against fluctuations in raw material prices and leakages of price more scheduler friendly for the end user.

Comparing Virgin and Recycled HDPE Pellets

Differences in Quality Between Virgin and Recycled HDPE

Virgin HDPE pellets are directly produced from petrochemical feedstocks leading to an almost homogeneous polymer throughout the cross section so that the average molecular weight, Mw, is quite uniform and that the size and shape of the polymer chains have predictable physical properties. This uniformity however means that the overall physical properties, which include high tensile properties, high impact resistance and strong chemical attack, are better when compared to other materials of the same case. This is why virgin HDPE has been widely used in industries, which many regulatory agencies have set stiff environmental standards, including but not limited to food packaging pharmaceuticals and healthcare devices.

On the other hand, when it comes to the use of recycled HDPE, derived either from post-consumer or post-industrial wastes, that has a much wider range of properties with performance than pure plastic, because that retention quality contains impurities and imposes the previous service decompositions, or a recycling imperfections. In this case, such a feature in any polymer is seen as a drawback since the polymer might undergo changes such as reduction of strength, reduction of transparency and thereby increase the danger of contaminating whatever the polymer is intended to protect. Over a certain period of time, the quality of recycled HDPE has therefore changed for the better due to the use and improvements in recycling technologies: for instance, nowadays there are well-designed push – pull type and high-performance type sorting facilities and efficient washing systems with a capability of reducing the difficulties associated with physical dirt such as stubborn UV ink therefore value of reclaimed HDPE has also improved with the time which has increased the so called “quality parity” of virgin and recycled materials.

Recycled HDPE has immense potential in the context of environmental conservation. In point of fact, the inevitable benefits of recycled HDPE concerning carbon footprints are quite reduced. However, here comes the complexity of balancing environmental benefits vis-à-vis economic and qualitative packaging properties. Both the new and secondary materials play an important role in the circular economy with high -vis virgin HDPE.

Price Variations: Virgin vs. Recycled HDPE Pellets

Price differences in virgin and recycled HDPE pellets are people of interest due to the difference production processes, market demand, and resource constraints. Virgin HDPE pellets sells a higher premium because of the overall costs earned from their extraction, purification, and manufacturing due to increased petrochemical feedstock use. However, the costs of manufacturing are lowed with the use of recycled HDPE pellets due to the historical cost of waste creation and heightened measures of waste reduction in production activities.

Moreover, shifts in supply and demand relationships, such as price volatilities in the oil market, are known to greatly affect global crude-oil prices, which constitute a primary raw material cost constituent for virgin polyethylene. Recycled polyethylene (PE) on the other hand may have the price of the resin either increase or decrease; depending upon the quantity and the quality of the processed waste, the in-use PE, and the technology that has advanced for R&D. Such economic factors must be weighed in for the industries that require both efficient production methods and concern for conservation. Ultimately, this evaluation includes application-specific performance requirements and the related decisions to choose between virgin and recycled HDPE.

Environmental Benefits of Using Recycled HDPE

It is a fact that using recycled HDPE is much more environmentally friendly when it comes to plastics. By reusing materials that have been used and need to be removed or by products that have been cast-off, the demand for new resources is minimized due to the use of recycled HDPE, which makes it possible to diminish the need for the consumption of fossil fuels. The increased use of recycled HDPE affects the production and the processes are less harmful to the environment compared to those in the extraction of crude oil for producing virgin HDPE. This is because the recycling facilities use less energy hence operating reduces the amount of greenhouse gases released at the end of the day. In addition, using recycled HDPE ensures that waste is minimized positively impacting on the environment as less plastic ends up in the dumpsites and other natural ecosystems Therefore, issues of long term pollution and problems associated with destruction of the inhabitants habitats are taken care of thus recycling is good.

Whilst recycling the use of HDPE helps advance the reuse and recycling tenets of circular economy, the balanced ratio of percentages plays a pivotal factor in minimizing the environmental cost of production Now, the focus is on increasing the share of waste-based over virgin HDPE applications. In such cases, society is directly invested in decreasing plastic flow into unwanted ecological paths and encourages reuse and recycling However, we should resist this inclination to simply do more Of course, proper design is important, but direct action is not out of the question.

Quality Standards for HDPE Pellets

Industry Standards and Certifications for HDPE

A number of quality control standards and industry accreditations have been put in place for High-Density Polyethylene (or HDPE) to be of standards and performance as well as environmental regulations need be met. One well known standard is ASTM D4976, which is concerned with the properties and category of polyethylene plastic. Another example might be ISO 4427-2 which serves as the standard to be employed in respect of the utilization of HDPE materials in existing pipe work with the objectives of toughness, pressure capacity, and life span applicable for water and gas.

What makes ASTM D1260 important is that it is designed to analyze plastics in order to achieve a safe quality level for HDPE pipes particularly waste water applications. In regard to fitting water pipes carrying drinking water, should not commence except upon compliance with NSF/ANSI 61 standard as per the Environmental Protection Agency requirements, and approval confirming that such HDPE does not affect water quality is issued. Where will you place the welding rod in the slot and Dastm F2620 you can perform hydrostatic tests immediately after insertion of the adapters into the pipe ends.

In regards to being eco-friendly, these standards indeed play an important role and act as trend drivers within the recycled HDPE market. Workable procedures that are required by the standard are regulated by an interested party and an established auditing body to make sure that the ISO 14001 standard or any other relevant administrative support for managing waste is incorporated in the manufacturing process. Protection of the environment has a common goal of promoting a wasteless society, and therefore, the applications of HDPE are among the preferred substances used in manufactured products.

How Quality Affects the Performance of HDPE in Molding

The physical characteristics of High Density Polyethylene (HDPE) resin to a very large extent determine its performance in molding applications due to its direct role in the mechanical properties, production efficiency as well as the life span of a product. Those HDPE resins with more or less pure resins contain almost the same molecular weight also have better viscoelastic characteristics such as better melt flow during processing. This means that the flow front in a molded product is fairly accurately and uniformly defined in thickness, and the internal stresses are relatively low in comparison to the current issues such as warpage or sink marks.

In addition, the introduction of contaminants in HDPE, particularly in the case of recycled resin types, may have severe consequences to the final product. More so, intrusion of impurities specifically foreign polymers, one-dimensional materials, reduced curve resins etc. Compositions affects the mechanical features, some solvent attack as well as shock resistance of the plastics. The manufacturers resort to advanced techniques of filtration, specifically applying them in the completion of the various stages of production, prevention of variability and ensuring consistent quality of each batch.

In addition to improving the intrinsic material properties of HDPE, the development of value-added additives and specialty grades also demonstrates how closely the material quality matches with its application-specific performance. With these advancements, it is possible to create components that have excellent strength to weight ratios superior to any existing technology options and utilize resources for longer periods thus increasing potential applications such as in automotive and packaging among others. At the end of the day, the best extrusion results are achieved when satisfactory resins are made available and are good at all stages of the process, rather than relying on the ability to reinvent the resin or appealing solely to the machinability aspects without considering all other functional performance requirements required for the specific product.

Identifying High-Quality HDPE Pellets

Specific characteristics of High Density Polyethylene (HDPE) pellets show typical properties that makes them ideal for use under tough conditions. The consistence of the pellet weight and shape is important as that enhances the uniformity of the pellet dissolution and processing. The pellets should possess a remarkable level of purity which does not entail inclusions such as dirt, water or other alien matters, which interfere with the activities of extruding or shaping the material.

Molecular weight distribution is also an aspect of high importance that should be taken into account. Polyethylene with narrow molecular weight distributions can usually be processed more stably which is beneficial for producing better fitting dimensional products with the required mechanical properties. Optimum crystallinity has to be attained for achieving the ultimate characteristics of high tensile strength, impact strength and long service life of the manufactured products indeed.

Besides, the effect of density and melt flow index (MFI) on pellet quality is of paramount importance. Density of HDPE pellets varies from 0.940 to 0.970 g/cm³ and itemized, target oriented Melt Flow Index (MFI) guarantees a given degree of hardness, impact strength and processability. Given these factors, it is possible to establish a technical specification in relation to all other standardized grades of HDPE suitable for manufacture which enables technical persons to objectively choose the most appropriate material for the selected requirements.

Cost-Effective Strategies for Sourcing HDPE Pellets

Finding Factory Prices for HDPE Pellets

To determine the manufacturer’s price for HDPE beads, a system-wide process starts with industry understanding and supply chain issues. This is in view that; the costs of production and delivery may be distored due to the volume of financial resources and geographical location of different areas as well as specific constitutions of certain types of industries, for example; packaging, construction and automotives. As a result, the most cost-effective prices are normally positioned in direct interaction with the actual producers through purchases due to the absence of middlemen’s services which contain firm revenue burdens.

Also, generators of such platforms as specialized in various negotiations or supply chains as including exhibitions suppliers access directly to factories offering large quantities (in particular to bulk orders) of goods. A – the best – quote from several suppliers that is related to a project and reviewed with integers. Keep in mind that: Resin Price Calendars; Ocean and Air Haulage Costs; Warehousing and Storage Costs; are cost aspects that cannot be overlooked when striving to achieve the best mineral sourcing. This data enables companies to MMC users analysis that allows it to record HDPE pellets at competitive.

Negotiating Discounts on Bulk Purchases

In negotiating for discounts on large buys, I usually exploit three factors such as – quantity available, relationship with the supplier, insights on industry operations. Frequently, by ordering higher amounts, one is able to secure a pricing plan that lowers the cost per one piece. Nevertheless, to bolster my negotiation approaches, I make sure that I understand the environment in which things work including such issues as the changes in the prices of raw materials or disruption of a goods chain that can impact the cost structure. I also make efforts to look ahead both backwards in contacts, envisaging in many cases contracts that require recurrent orders to be made to the company in return for a more beneficial commercial solution.

Additionally, when selecting a vendor, I depend on the specific parameters supplied, verify their data with at least three quotations, and make estimates concerning the delivery time windows. It is by showing comprehensively the average pricing for the market that a buyer can demand suppliers to drop their prices matching or even ahead of those used by the competition. The moment at which negotiations are done is also a critical aspect to consider. Thus, It is often better negotiating when stocks are over supplied or when the overall market demand for the particular products is low. Lastly, I check the availability of such benefits as discounted shipping for combined deliveries or relief from extra charges, all of which help in the realization of cost reduction.

To thrive in these discussions, effective dialogue is needed. As a result, I attempt to show no pretense and communicate reasonably but firmly with the prospects of both parties trusting each other. Still, it’s also a priority for me to be able to assess the situation and look at both sides of the problem… that is, be prepared to admit at certain moments that the expected gain or commercial benefit at the expense of the suppliers may not have a complete observance of the situation. It is this blended forefront strategy that has assisted me in securing realistically priced quotations and dispelling uncomplimentary stimuli against my suppliers fostering a strong long-term working relationship.

Evaluating Supplier Reliability and Quality

Assess supplier trustworthiness and sufficiency of delivered goods, I rely on a scientific approach founded on quantifiable results and market targets. Beginning with the stability of the fetus Savior is only responsible for the provision of such terms as her/his forecast of on – time delivery and observance of the agreed conditions and rates of defects of the medical equipment. These standardized data are thus useful to have a flat and unbiased perception of their reliability. It is also essential how well they substantively adhere to requirements in terms of appropriate coincide of ISO 9001 approval which is commitment to the quality management system and reduction. And followed by the compliance with the previous mentioned norms, it is worth making an effort to study available customer reviews, case studies, as well as the causes that may result in difficulties in their change management that is, waiting time issues in transportation or lack of materials.

What is more, evaluation of execution quality in the frame of on-site checks is very important for me. In the scope of such meetings I put down their production management regime, taxation, accounting and their adaptation to the changes in volume of production. A colapetral aspect in this connection – techno-logical characteristics of equipment, qualities of available employees and, naturally, –polyraw material bases– export coal, modified by obtaining the technological and organizational features characteristic of the country of utilization – are surveyed and analyzed as well. Encircling those; the means and strategies can be for managing disputes in case they happen, that reinforces the originality of concept of operations. Supplier quality is beyond the portrayal of a defined product; it all revolves around how well a supplier sustains itself, sits within proper maternity regimen and its labour activity is guided by some acceptable standards, without last being, pollution and social issues.

Making use of quantified data analysis alongside qualitative appraisal it is possible to judge precisely whether a supplier corresponds with operational standards and strategic goals. This integrated appraisal procedure assumes two critical roles of risk reduction as well as ensuring that the business undertaking is predicated on trust, values and joint commitment to quality.

Reference Sources

- Mechanical, Thermal, Flammability Analyses of HDPE | University of Alabama – Discusses the impact of thermal degradation on HDPE quality and its implications for pricing.

- Recyclability and Quality of HDPE | MIT – Examines how recycled resin quality and performance standards influence HDPE pricing.

- Best Operational Practices Manual for Recyclers | Chicago State University – Highlights the price differential and quality issues in marketing HDPE.

Frequently Asked Questions (FAQs)

What possibly making price range of hdpe pellets per kilograms or pounds stand at?

The cost of making hdpe pellets is largely determined by the costs of raw materials such as HDPE and some resin colors, the level of demand worldwide for polyethylene and resin grades. A consideration for the cost of these materials would then depend on the kind of resin nature in which these materials are provided. Also applicable is the price of the ocean or vessel cost for Coca ships where two options are available a combination or separate figures unless a customerwants to ship something anyway in this and the kind of packaging that is popular – e.g. bulk or polythene bags. For above-average consumption quantity shipments, wholesale pricing is normally granted by the suppliers. Processing restrictions, equipment capability and size and virginity level of the granules also impact on the total price. Respective changes in consuming climates and costs of the chemicals under consideration may have another impact on pricing.

How do I find accredited sellers of hdpe pellets or manufacturers who will cater to my specific needs?

The identification of a suitable manufacturer or distributor of hdpe pelets as well as hdpe injection grade for products requires procuring information regarding the background of manufacturers, license, and other product specification. Operations involving a browser search include consideration of suppliers with verifiable presence on platforms such as alibaba.com along with their various hdpe polyethylene granules products carefully detailed. Perspectives for potential anti uv resin, polymer proof powder, uv coated resins manufacturers providers; with user1 friendly menus with different anti uv resins for different applications. Also ensuring that you have a sample of the hdpe resin pellet and an image; this also includes a test report of its strength, average t termination, and other aspects of the hdpe production characteristics. Clarify what is being shipped, the packaging and its costs, any limits in quantity, shipping terms whether FCL or LCL, as well as any documents that will be needed. Assessing the level of notice beforehand and, any foreseeable complications, the preferable way to load and unload equipment, and any related specially recommended maintenance end treatment of equipment.

What are the average grades and features of hdpe resin pellets?

A variety of grades are highlighted in specific polyethylene, i.e. hdpe which include: injection molding, blow molding, and extrusion grades for use in bottles, or pipes, or even industrial films, where theprocessingsuch as machine lines that are oriented in a particulardirection and typical requirements are prepared for your easy reference. These line also have characteristics as, high tensile strength, good chemical resistance, and a variety of melt flow index values that depend on howchromatic organization is being done on the machine. As a result, in the case of phenotypes regarded as untouched or pure hdpe or pe, they also fetchhigher prices but adapted usage to comprised food or medical applications as they are quite free of charge. Options experiment with differ visibility such as clear, white, and green additions for retaining or increasing attack strength due to the presence of sunlight vibrations can also be added or altered. It is important for both users and producers, get the grade thatstill meets their processing requirements and the condition of their finally produced item.

Can HDPE pellets be purchased in Large Quantities for Manufacturing purposes, offered at Reduced Prices?

It becomes possible to avail HDPE pellets at cheaper rates only when you procure them in bulk and deal with the producer or an authorized distributor personally even agreeing to the rates. Such purchases remove a considerable amount on the per lb, or even per kg, and they also have a qualification for lower-cost bulk packages. Whenever you are analyzing such quotes, don not forget to also calculate the total cost including shipping, customs as well as storage and relate them against economies of size and your warehousing limits. For plastics material purchasing, it is important to use accredited suppliers and have them certify the appropriate materials. Moreover, one should think of the process requirements such as machine outputs and yield to avoid unnecessary expenses that would be incurred downstream.

How do they keep hdpe granules or resin pellets for best result?

One of the first concerns when storing hdpe granules or virgin resin pellets is the necessity to keep the properties of the material unchanged and to avoid the penetration of foreign substances. It is recommended that, the pellet is stored in plastic bags or sacks in a dry, warm building away from the floor and without any sunrays so that deterioration does not occur. Manage your stocks according to the most used material so that the oldest material possible is used first and also, all the bags in which the pellets are kept, need to be in the best condition possible when checked. Temporary storage should be dry and warm but the materials should not be exposed to moisture or heat and tests for off-order smells should be carried out often. Such a measure saves durability and provides for effective further processing items on your manufacturing machines.

How can hdpe granules be packaged and dispatched?

There are different options of packages available for purchasers due to the obligations of suppliers, it could include a 25 kg or a 50 lb bag, a large bag in bulk, or even a container without any sales elements depending on the price of the purchase and the structure or a seller. Individual purchasers usually order such goods in small parcels, but concerns of the manufacturer are usually taken care of by shipping the goods in large containers with the lowest possible cost per kg. Such transportation and this handling are referred to as intermodal. Safety measures had to be put in stone, mainly for the purpose of preventing moisture or dust while the goods were being made ready for exports. Procedures and strategies, in loading or unloading, are the application of some devices referred to as cranes. This kind of transportation is facilitated by the use of motor vehicles, railroads or ships, and this is referred to intermodal transport. Each method of delivery has its own advantages and disadvantages, we only need to find how to capitalize on them, after determining those for each method of delivery. If this is the case, please let me know the delivery time, as well as the incoterms, insurance, and import associated papers in advance to buying from suppliers.