Polycarbonate has proven to be a favorite in various industries and everyday applications where strength, versatility, and durability are essential. Famous for the impacts it withstands while maintaining its lightweight persona, sturdy thermoplastic is used in a wide range of applications, from industrial machinery components to household items such as ophthalmic lenses and water bottles. What makes polycarbonate so sturdy, and how does it hold up under harsh conditions? In this article, we will discuss the scientific aspects of polycarbonate’s outstanding durability. These industries utilize it, and it is regarded as a reliable material for both creative and practical applications. In case you are a working professional weighing the option of whether or not to use it for your next project, this article is going to prepare you well on the subject, or, in case you are just a curious buyer, this will pique your interest in polycarbonate.

Understanding Polycarbonate

What is Polycarbonate?

Polycarbonate is a highly versatile, durable thermoplastic polymer that offers excellent impact resistance, optical clarity, and lightness. Chemically, it is a long-chain polymer typically formed by synthesizing bisphenol A (BPA) and phosgene, or through an alternative, sustainable process. This material is widely recognized for its unique combination of strength and flexibility, making it suitable for a wide range of demanding fields.

When compared with glass, polycarbonate can transmit visible light rays more or less equally; yet, its impact resistance is over 200 times greater. Furthermore, the temperature resistance is high, as it can withstand a wide temperature range from -40°F to 250°F without deformation. It is inherently flame-retardant, classified under high safety standards. These properties, coupled with ease of fabrication, make it an industrial favorite among construction, automotive, electronic, and consumer goods. From polycarbonate used in protective clothing and glazing systems to electronic components, the list of applications where polycarbonate has proven its worth is indeed extensive.

Types of Polycarbonate Sheets

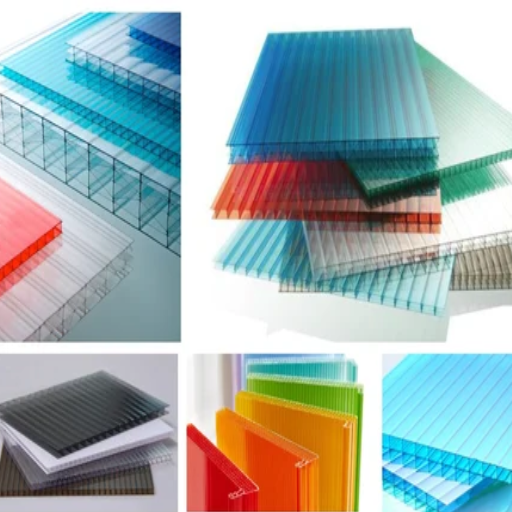

Polycarbonate sheets come in various types, each designed to fulfill a specific need within an industry. Thus, these types may include:

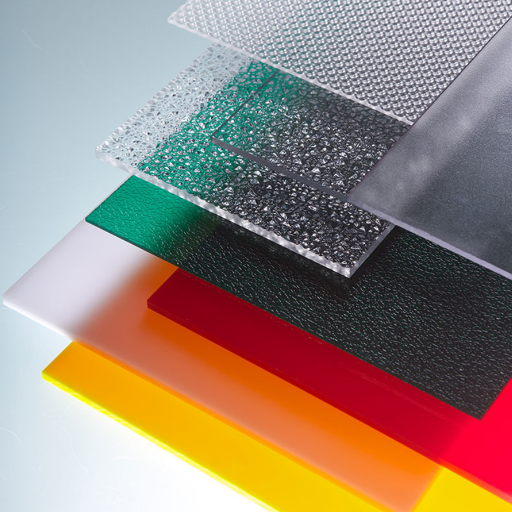

Solid Polycarbonate Sheets: With their strength and clarity, solid polycarbonate sheets are often preferred over glass for many applications. These provide excellent impact resistance and can be used for such purposes as safety glazing, protective barriers, and architectural designs.

Multi-Wall Polycarbonate Sheets: With a layered structure that contains air pockets between layers, these multi-wall sheets offer good thermal insulation while remaining fairly durable. They find wide-range use in schizophrenic greenhouses, skylights, and roofing systems, which require good temperature regulation and reduction of energy input.

Corrugated Polycarbonate Sheets: Being lightweight and highly weather-resistant, precorrugated sheets prove to be suitable for agricultural, industrial, and residential roofing and wall cladding. Their design attributes strengthen while keeping installation easy.

UV-Resistant Polycarbonate Sheets: These are designed to withstand prolonged exposure to the sun. Hence, they are protected against yellowing, cracking, and degradation due to the action of UV rays. They look well when used outdoors, including situations such as skylights and awnings.

Anti-Static Polycarbonate Sheets: These polycarbonate sheets prevent static buildup and are therefore used in the manufacture of electronic components and applications where electrostatic discharge is to be minimized.

Abrasion-Resistant Polycarbonate Sheets: With a hard coating, these abrasion-resistant sheets impart increased surface hardness, which is beneficial for sites where heavy wear and tear occur, such as machine guards or visors.

Colored Polycarbonate Sheets: Available in a wide range of colors and tints, these sheets combine aesthetics and functionality with UV protection and privacy. They get used for signage, interior décor, and decorative installations.

Each type of polycarbonate sheet addresses a specific industry requirement, demonstrating a great deal of versatility, ruggedness, and performance under various conditions. Selecting the right kind ensures durability, energy efficiency, and safety for multiple applications.

Strength of Polycarbonate Compared to Other Plastics

Polycarbonate is commonly regarded as a stronger and more impact-resistant material than any other plastic. It has an impact strength of about 250 times that of glass and almost 30 times that of acrylic, making it suitable for homeland uses such as bullet-proofing, safety goggles, and industrial machine guard protection.

Whereas most plastics become infinitely brittle under extreme environmental conditions, polycarbonate defies this scenario, retaining its integrity over a broad temperature spectrum of -40 °F to 248 °F, allowing it to perform well in both cold and high-heat scenarios. Furthermore, the polycarbonate structure allows absorbing a high amount of energy until significant deformation, which translates to a much lesser chance of cracking or fracturing if stressed.

The unparalleled strength and flexibility make polycarbonate an ideal choice in the automotive, construction, and aerospace sectors, where both security and durability are essential. Based on weight and transparency, polycarbonate offers an excellent alternative to traditional materials in these industries.

Advantages of Polycarbonate

Polycarbonate in Industrial Applications: Benefits

The unparalleled versatility and resilience of polycarbonate make it a valuable material in numerous industrial applications. What distances polycarbonate from other materials is its strength-to-weight ratio, which can perform such feats while offering the advantage of placing less load upon structures and machinery. One of the characteristic features of polycarbonate is that it resists impact to the extent that it does not break; thus, it is a far safer and more reliable alternative to glass and other conventional materials. Another appreciated feature is its thermal resistance and stability under extreme temperature conditions: thus, the aerospace and automotive industries cannot do without it.

Another significant advantage is the utmost flexibility offered during the fabrication. Polycarbonate is easily molded, cut, and shaped, which prevents the structure from compromising its integrity; hence, manufacturers can produce very complex designs efficiently. Advancements in UV-resistant coatings have further enhanced their durability against prolonged sunlight exposure, thereby ensuring a longer lifespan for outdoor applications, such as construction sites. Given its optical clarity, it is used for protective barriers, safety equipment, and high-performance glazing, thus significantly contributing to bridging the gap between utility and economical solutions in industrial applications.

Everyday Applications of Polycarbonate

Trading on a nanometer-attributed, very light refraction made possible only by special optics, polycarbonate’s unique properties, such as being very light and impact-resistant, enabled the human attenuation of rays in the window cones, where all requirements are durability and optical clarity. When it comes to creating reusable water bottles, polycarbonate is utilized creatively to mitigate environmental pollution, offering an eco-friendly alternative to disposable plastic bottles. The heat resistance and structural strength of polycarbonates make them suitable for use in some household consumer electronics, where industrial applications require robustness against wear and tear, as well as LED light covers and appliance covers, thereby ensuring safety and longer life. For automobile design, polycarbonate also finds application in headlight lenses and intumescent parts, thereby imparting durability to the vehicle and reducing weight to improve fuel efficiency. Through this panoply of applications, the ever-crisp polycarbonate has been, for some time, and continues to be, the go-to material for new-age design and practical innovations.

UV Resistance and Longevity

Polycarbonate has an excellent reputation for UV resistance and, therefore, is preferred for applications exposed to sunlight. Polycarbonate treated with advanced UV stabilizers offers long-lasting clarity and can keep well even after being exposed to harsh weather conditions. This feature proves very advantageous for outdoor uses—for example, greenhouse panels, skylights, and roofing sheets, wherein prolonged sun exposure might discolor or otherwise weaken or degrade conventional materials. By preventing the material from yellowing and minimizing UV-induced abrasion, this ensures the improved durability of polycarbonate in both residential and commercial areas.

Research indicates that UV-protected polycarbonate can resist considerable sunlight over time and maintain its optical clarity at up to 90 percent for years of use. This reliability ensures that the frequent need for replacements is not necessary, making it, in terms of cost, a viable alternative for users across different industries. All in all, its environmental stress resistance and cracking properties ensure that components, such as outdoor signage, protective barriers, and automotive parts, can sustain their functionality and aesthetic appeal for long-term use. Hence, polycarbonate emerges as an innovative material, considering its superiority and longevity, which are necessary for contemporary design, both in scope and sustainability.

Disadvantages of Polycarbonate

Peculiarities of Polycarbonate

Although it has its array of advantages, polycarbonate also carries certain limitations behind its fame. One of the unforeseen drawbacks is the susceptibility to being scratched. Unlike glass, polycarbonate is not inherently abrasion-resistant; therefore, during handling or prolonged use, it can be scratched more easily. A special coating on the surface can significantly reduce these occurrences, but, of course, at the expense of increased cost.

The other challenge is chemical resistance, or the apparent lack thereof. Strong acids or organic solvents can attack polycarbonate, thereby compromising its structural integrity and clarity over time. Environments full of these materials will not be suitable for this material.

Polycarbonate also tends to expand thermally more than substances like glass, thus causing dimensional instability in applications subjected to temperature fluctuations. Another factor for consideration is that its initial price is usually higher than that of some alternative plastics and might deter projects on a budget, despite being more durable and versatile.

Polycarbonate is considered environmentally superior to traditional plastics, as it can be reused; however, its production requires considerable energy consumption and resource use, thereby offsetting its overall ecological benefits. Mitigation of such drawbacks typically requires additional treatment or design considerations, which may impact both the manufacturing process and the end application.

Impact Resistance Concerns

Polycarbonates have been commonly touted for their ability to resist impact, sometimes being 250 times stronger than glass and significantly more durable than many other thermoplastics. Since not many applications require physical stress on the material, production would be limited to use in safety goggles, bulletproof windows, and machinery components. However, while they resist impact fairly well, they’re not very resilient against wear conditions. Years of exposure to the extremities of the environment or repeated high-impact blows can form microcracks and cause stress fractures, which contribute to compromising the integrity over time.

At the very front, one of the most significant considerations regarding polycarbonate’s impact resistance is the potential for environmental stress cracking, which can occur under certain conditions. When oils or solvents are transmitted during an industrial operation, resistance to these will be diminished, causing the material itself to fracture and/or undergo surface damage. The outer layers of polycarbonate are equally susceptible to degradation when exposed to high-energy UV rays and, in turn, become weak in resisting impacts, thereby becoming prone to brittle fracturing. At least to some extent, manufacturers enhance the resistance of polycarbonate surfaces through protective coatings and additives to counterbalance these vulnerabilities; however, the cost of production rises with them, and manufacturing recycling also proves to be a hindrance to sustainability.

Polycarbonate, with its excellent strength-to-weight ratio, is a suitable substitute for heavier materials. However, it may be unsuitable for applications under recurring or heavy mechanical stress for extended periods. For example, there are instances in the automotive and aerospace industries where materials undergo constant vibration and intense pressure. Polycarbonate components would then require either further reinforcements or a choice of alternative materials to meet the required performance criteria. A resolution of such problems would involve balancing design, function, long-term durability, environmental factors, and cost-effectiveness.

Cost considerations

When evaluating the costs of polycarbonate materials, several factors come into consideration, including raw material pricing, manufacturing processes, and application-specific requirements. Polycarbonate materials generally cost less than specialty materials such as composites or high-performance alloys, but still need a cost-benefit analysis. The cost of procuring raw polycarbonate is primarily dependent on the forces of demand and supply, as well as supply chain disruptions and regional availability. Furthermore, industries that require constant production at high volumes may use bulk buying or yearly agreements with suppliers, thereby saving them money.

Another aspect to consider is the costs involved in the manufacturing process. Injection molding or thermoforming are usual processes in the manufacture of polycarbonate parts due to their speed and precision. However, the addition of extra features, such as UV coatings, heat treatments, or chemical-resistant treatments, can increase production costs. These industries must assess these modifications in terms of the functional and environmental requirements for specific applications to ensure economic viability without sacrificing quality.

The polycarbonate parts, due to their durability and long lifetime, will often incur lesser maintenance and replacement costs, thus resulting in a larger financial gain in the long term. This excludes industries such as construction or electronics, where the nature of the work demands reliability, and it is impossible to keep fixing them constantly. Decision-makers should also factor lifecycle cost, sustainability measures, and recycling avenues into their cost analysis, which squarely address modern-day regulatory criteria and environmental aspirations, and, more importantly, can stand on its own financially.

Applications of Polycarbonate

Polycarbonate Windows in Greenhouses

The polycarbonate has become the material of choice for constructing greenhouses due to its durability, light transmission, and excellent thermal insulation properties. It transmits 90% of the light, which is sufficient for the plants as they receive ample sunlight. Thereafter, UV rays are filtered out to ensure healthy growth. Additionally, being many times stronger in impact resistance than glass makes the greenhouses secure against weather conditions such as hail, wind, and heavy snow, which could have caused damage and subsequent maintenance costs.

Another significant benefit of polycarbonate is its thermal insulation properties. The panels maintain internal temperatures by retaining heat during the winter and minimizing heat loss, thereby reducing energy consumption by heating systems. Multiwall polycarbonate sheets, in particular, lend even more insulation due to their air-layer structure and are thus considered a cost-effective and environmentally friendly solution by greenhouse operators.

Due to the lightweight nature of polycarbonate panels, transportation and installation are made much easier, minimizing labor efforts and costs. Sometimes, anti-condensation coatings are applied by manufacturers to prevent water droplets from forming within the surface layer, ensuring consistent light distribution and controlling the growth of fungi.

Generally, polycarbonate has revolutionized greenhouse construction, providing the necessary balance of strength, efficiency, and sustainability for current agricultural and horticultural markets.

Advantages and Uses of Polycarbonate Enclosures

Thin, tough, and highly flexible against impact forces, polycarbonate enclosures have found applications in a wide range of industries. More resistant to impact than glass or acrylic, which are usually employed, the enclosures are best suited to aggressive environments that demand safety and durability. They also resist UV rays so that upon prolonged exposure to the sun, they would neither yellow nor degrade.

The primary value of polycarbonate enclosures lies in their adaptability for outdoor and industrial uses. Protecting vital equipment from adverse weather conditions, such as rain, dust, or extreme temperatures, is critical in the electrical and telecommunications industries. Apart from being protective, the enclosures remain transparent, offering uninterrupted views of the equipment being monitored or any operation in progress without compromising strength.

The applications of polycarbonate enclosures span multiple industries, including construction, agriculture, and technology. In other contexts, particularly in agriculture, it would be used for greenhouse control panels, allowing the insulating yet lightweight qualities of the material to be utilized in energy management. Technology and electronics industries, on the other hand, use polycarbonate shells to protect devices from shocks. With recent developments in material manufacturing, many polycarbonate enclosures now also exhibit additional attributes, such as anti-scratch coatings and fire retardancy, thereby upgrading their safety and durability.

By filling the void left by performance, versatility, and durability, polycarbonate enclosures have continued to provide unmatched solutions that modern industries require, while also promoting sustainability through recyclability and minimal material wastage.

Types of Polycarbonate Roofing Solutions

Polycarbonate roofing offers a range of options, each tailored to specific applications and performance criteria. Such roofing solutions find application in various vocational settings, including construction, agriculture, and architectural establishments, thanks to their durability, transparency, and lightweight nature. They are typically the following types:

Solid Polycarbonate Sheets: Solid polycarbonate sheets offer sufficient clarity, making them ideal for applications where high light transmission is required, such as in greenhouses, skylights, or architectural designs. It boasts excellent UV-resistant properties and durability against adverse weather, ensuring extended performance.

Multiwall Polycarbonate Sheets: Multiwall polycarbonate designs offer energy efficiency and insulation. With hollow cells, air is trapped inside for thermal insulation while simultaneously allowing light to diffuse. Thus, this species of sheet finds use mostly in industrial settings, conservatories, and the roofing of sports facilities, where internal temperature modulation is essential.

Corrugated Polycarbonate Panels: Corrugated polycarbonate panels offer the dual benefits of low weight and high impact resistance, along with weather protection. They find use as roofing for warehouses, carports, and agricultural buildings that would otherwise be subject to heavy winds and rain. Plus, they are relatively easy to install.

Textured or Embossed Polycarbonate Sheets: For glare reduction and increased privacy, textured polycarbonate sheets are ideal for partitions or roofing, particularly in spaces that require softened or diffused lighting levels. They will have both hard-wearing and UV-resistant properties, providing an aesthetic feel to any commercial or residential design.

Anti-Drip Polycarbonate Sheets: In a greenhouse and agricultural environment, anti-drip polycarbonate sheets give the best results to prevent the formation of water drops on their surface. These sheets increase light transmission while minimizing water damage to plants.

Each kind of polycarbonate roofing has certain use cases to be further thinly plated with options such as UV protection, anti-scratch finish, or fire resistance. By selecting the right type, primary industries and homeowners can have roofing systems that are cost-effective, environmentally friendly, and sufficiently durable to meet their functional and aesthetic needs.

Conclusion About Polycarbonate

Considerations About Durability for Polycarbonate

From my perspective, the durability of polycarbonate is what truly makes it one of the most versatile materials for diverse applications. Since it is stronger than glass and acrylic by a fairly wide margin, it can sustain extreme environmental conditions, heavy impacts, and slight degradation from exposure until it finally yields. Over the years, my observations have revealed the trade-offs associated with the resilience of materials, where the lower frequency of replacements due to polycarbonate equates to cost savings over time, especially in demanding industries such as construction, automotive, or agriculture.

Polycarbonate is regarded as remarkably durable because this material can maintain its structural integrity under varying temperature conditions and UV exposure. Advances in the development of UV coatings have further enhanced their performance against discoloration, brittleness, and degradation over time. Bear in mind that this makes it a unique candidate not only for roofing or glazing applications, but also for high-traffic applications where wear and tear are a daily occurrence. Wherever durability and functionality stand tall in response to requirements, polycarbonate is always the safe choice.

Another notable feature of polycarbonate is that it is both light and resilient. This composition suits projects much better than doing it yourself, as polycarbonate is easy to handle and install, yet can withstand very high stress. I strongly believe that the strength, versatility, and durability of polycarbonate make it an ideal concept for anyone seeking sustainable yet high-performance solutions.

Future Trends in Polycarbonate Use

There is an enormous expected expansion of polycarbonate use in various industries. One major trend in this regard is the increased use of sustainable building materials. Since polycarbonate is durable and energy-efficient, it is considered perfect for green construction, including solar panels, skylights, and energy-efficient windows. As demand for environmentally friendly alternatives increases, I believe manufacturers will continue to innovate polycarbonate products for improved thermal insulation while safeguarding the environment.

Additionally, the application of polycarbonate is likely to increase within the automotive and transportation sectors. It is a lightweight yet impact-resistant material that is essential for achieving good fuel economy and ensuring passenger safety. Likewise, I envision the development of polycarbonate for EVs, where every ounce sacrificed yields some gains in battery performance. Beyond automobiles, polycarbonate’s potential applications in the aviation and railway industries may further transform these sectors.

Ultimately, I view polycarbonate as having promising prospects in both technology and consumer applications. Its clarity, toughness, and versatility lend themselves to electronic devices, medical equipment, and even body armor. With ongoing research into enhanced properties, such as UV resistance and recyclability, I believe that polycarbonate will continue to play a pivotal role in shaping a viable, innovative future as the material of choice today.

Recommendations for Choosing Polycarbonate Products

When selecting polycarbonate products, I first consider the application and specific qualities a task may require. Polycarbonate, being a versatile material, possesses particular properties such as impact resistance, lightweight nature, and optical clarity that make it suitable for specialized applications. For instance, if something is intended for outdoor use, I check to see if it has an ultraviolet-resistant coating, ensuring it can withstand prolonged exposure to the sun. Likewise, protective shields and safety gear are rated for high impact resistance.

Additionally, I pay attention to the transparency and thickness of the polycarbonate product. If the product must allow light to pass through or act as a clear protective cover, I always rely on high-grade optical polycarbonate. For projects requiring rigidity or structural strength, I always opt for the maximum thickness allowable by load and stress constraints. Certifying ones, such as fire-resistant or FDA-approved (depending on the nature of the application), further assures me of their quality and performance standards.

The decision further takes into account sustainability. I consider it essential for manufacturers to implement eco-friendly processes or, at the very least, offer products made from recycled polycarbonate. With the proper manufacturer and a focus on a specific project need, a polycarbonate product will perform and provide long-term value.

Reference Sources

-

How Durable is Polycarbonate

This blog discusses the inherent strength of polycarbonate and how its durability can be enhanced for industrial applications. -

The Ultimate Guide: Custom Polycarbonate Manufacturing

A detailed guide on polycarbonate’s impact resistance, heat resistance, and overall toughness. -

The Tensile Strength of Polycarbonate Sheet

This article examines the tensile strength and durability of polycarbonate in comparison to other materials. -

Polycarbonate in Daily Life – All Applications

A comprehensive PDF detailing polycarbonate’s robustness, chemical stability, and applications in daily life. -

View Polycarbonate Strength, Impact Resistance

This source highlights polycarbonate’s high impact strength, dimensional stability, and electrical properties. - Top Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Is polycarbonate considered a sturdy material?

Polycarbonate is extremely tough and is classified as a strong thermoplastic. It can withstand exposure to high or excessive degrees of heat, and it is 250 times more resistant to breakage compared to standard glass, making it almost unbreakable. One of the most interesting qualities of polycarbonate is its resistance to temperature changes, which makes it nearly perfect for situations that necessitate great strength and require prolonged focus. Additionally, it is pretty flexible and resistant to scratches or dents, which allows it to maintain its transparency and quality over time. The presence of greater strength, combined with excellent impact tolerance, encourages users to utilize the products even in environments where security is questionable, such as reinforcing glass windows.

What makes polycarbonate better than other types of plastics?

Polycarbonate has a high strength-to-weight ratio, making it less cumbersome than heavier materials, such as glass. The strength-to-weight ratio of polycarbonate is also superior compared to that of other plastic materials, and it is rugged enough to withstand breakage in most cases. Polycarbonate, furthermore, is itself optically clear and hence is used for applications where this property is crucial. Its temperature resistance distinguishes it from other plastics as it does not soften, warp, or distort excessively at elevated temperatures. Polycarbonate also does not dull with use from the sun and can therefore be used effectively in sun-exposed areas without diminishing over time.

What kind of polycarbonate sheets are available?

A selection of polycarbonate single sheets can be obtained in stock for a number of different types, such as solid and single-wall or perhaps a number of different colors and finishes. Solid polycarbonate is highly transparent and is often used in place of borosilicate glass. The double-wall version features air pockets and insulates exceptionally well, making it more suitable for roofing applications. Polycarbonate plastic roofing, for instance, has a strength that is remarkable, as it utilizes a plastic that can withstand at least five times the impact of glass or fiberglass materials. Consequently, the differences in the properties of each type of material correspond to determining the most suitable product for use.

What polycarbonate roofing material is the best to use?

Polycarbonate roofing solutions are available in flat, ornamented, and clouded formats, which tend to enhance the aesthetic value while providing protection. Multiple layers of polycarbonate roofing make it an ideal choice for insulation, which is why it is recommended for installing sheds and greenhouses. Additionally, there are trending corrugated stocks that are lighter but also quite durable, used explicitly for protecting polycarbonate roofing in industrial contexts. Polycarbonate has developed a system of reinforcing it, whether or not it iss covered, that can be employed in several ways. For polycarbonate roofing, there is no concern regarding heat, as it holds up well even under high temperatures, setting the stage for its excellent promise.

What are some drawbacks of using polycarbonate?

Overall, the benefits that come with polycarbonate fragility outweigh the demerits. One of the demerits is that it is expensive than other plastics and may restrict some consumers. What we mean is cost, in terms of the plastic move, you can have raised these factors andbe entitled to that. Additionally, some polycarbonates are prone to scratching, while others are designed to resist scratches. The latter is a more common practice. Likewise, polycarbonate may not be the best option in situations where perfect transparency is required, as it sometimes develops a cloudy appearance over time. After all, polycarbonate is very good at protecting its surface or structure from the effects of the sun’s rays, but there is a catch. Despite the resistance to light degradation, any such degradation can occur over an extended period; hence, higher-caliber materials must be used to ensure that their serviceability can be guaranteed.

Which applications are suited for polycarbonate enclosures?

Polycarbonate enclosures serve various applications, including safety barriers, machine guards, protective screens, and many more. Nevertheless, this protection is necessary in specific environments, as some of the components may cause cracks or injuries. On the other hand, polycarbonate can withstand humidity and any other weather changes including extreme temperatures, and can also be used effectively outside. The polycarbonate also has less weight, which makes its installation easier alongside other materials and products. Furthermore, the material is explicit and safe, yet also transparent, allowing for clear visibility. Polycarbonate is also widely used in various other applications, particularly in laboratories and industrial processes where chemicals are handled.