The polyetherimide (PEI) thermoplastic, known by famous names like Ultem, is driving a new manufacturing discipline with its versatility and high performance. They exhibit strength-to-weight ratio characteristics, thermal stability, and resistance to corrosive environments, which are fostering advances in the aerospace, automotive, healthcare, and electronics sectors. As manufacturers contend with demands to create solutions that are both efficient and durable, PEI becomes the enabler for some of the most cutting-edge designs and applications. In this article, we’ll explore how PEI thermoplastic is evolving advanced manufacturing, providing an overview that discusses its properties, areas of application, and its role in pushing the frontiers of modern engineering.

Understanding PEI and Its Properties

What is Polyetherimide (PEI)?

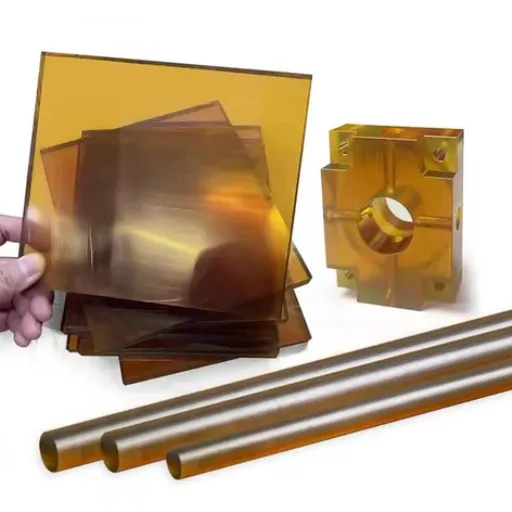

Polyetherimide (PEI) is described as an engineering thermoplastic with exceptional characteristics, including strength, thermal resistance, and chemical resistance. This material is more commonly classified as a high-performance polymer within the family of amorphous polymers; it is recognized for its transparency and exceptional toughness over a wide temperature range. The mechanical properties of PEI are extraordinary, including excellent tensile strength and rigidity. Therefore, it is well-suited for demanding environments where durability and dimensional accuracy are crucial.

Key Temperature Performance: Thermal resistance is one of the key features of PEI; it can be used continuously at a temperature of 338°F (170°C), with its properties remaining essentially unchanged over time. Among other desirable properties, PEI exhibits excellent dimensional stability, thereby resisting deformation caused by mechanical stresses or thermal cycling.

Additionally, the polymer is flame-resistant and has a tendency to produce very little smoke. The low smoke generation and fire resistance properties of PEI enable it to meet the most stringent safety, hazard, and environmental regulations for various industries, including aerospace and transportation.

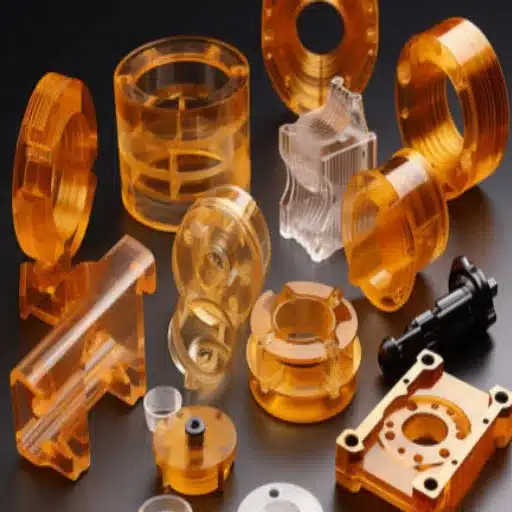

The reason behind PEI’s chemical resistance is that it exhibits high resistance against hydrocarbons, alcohols, and aqueous solutions, even after extended exposure in chemically aggressive environments. Beyond that, PEI materials can be processed using various methods, such as injection molding, 3D printing, and extrusion, which enable manufacturers to produce complex yet precise components with a high degree of repeatability. This given set of features has put PEI high in demand and preferred in applications in aerospace, automotive, electronics, and medical devices, where innovation and advanced manufacturing come together.

The Physical Properties of PEI and Ultem

Perhaps the most famous trade names for a blend of polymers being cultured as Polyetherimide are PEI and Ultem. The beautiful amalgamation of mechanical strength, thermal stability, and chemical resistance makes this polymer very famous. One thing that all polymers in this group have in common is their incredible heat resistance: PEI performs mechanically up to a temperature of 200 °C (392°F). Ultem, in its various grades, pushes this a little further, with the better grades giving in excess of 217°C (422°F). Both have heavy-duty service applications in extreme heat environments, such as automotive under-the-hood components and aerospace interiors.

Mechanical Strength Specifications

- Tensile modulus values: 3,100 to 3,800 MPa

- Superior rigidity and retention of mechanical properties under severe conditions

- Significant reliability for precision-engineered parts

Furthermore, PEI and Ultem exhibit impressive tensile strength, with tensile modulus values typically ranging from 3,100 to 3,800 MPa. Dually, both materials’ rigidity and retention of mechanical properties, even under severe conditions, provide significant reliability to precision-engineered parts. They are also chemically resistant to many substances, including hydrocarbons, acids, detergents, and chlorinated solvents, thus identifying them as potential materials for chemical processing or medical applications.

Low water absorption is another parameter, which conversely decreases any swelling or dimensional changes of these materials when exposed to humid environments. These characteristics, when considered together with their dielectric properties, make PEI and Ultem popular choices in electronics and electrical applications, such as connectors, insulators, and printed circuit board hardware.

Some grades of PEI and Ultem offer a high degree of transparency, allowing for applications that require optical clarity without compromising thermal and mechanical properties. A few grades of these materials are, in most cases, fully flame-retardant and certified to exacting industry standards, such as UL94 V-0 and FAR 25.853, guaranteeing precious safety in high-performance areas like aviation and mass transit.

These features make PEI and Ultem flexible materials suitable for high-performance manufacturing that demands lightweight and precise components across most industries. They continue to be the backbone of designs that require a strong and durable system to meet operational demands.

Comparison with Other Thermoplastics

| Material | Heat Resistance | Tensile Modulus | Key Advantages |

|---|---|---|---|

| PEI/Ultem | 200°C+ (392°F+) | 3,000+ MPa | High strength, flame retardant, chemical resistance |

| Polypropylene (PP) | ~100°C (212°F) | 1,500 MPa | Low cost, good chemical resistance |

| ABS | ~80°C (176°F) | 2,500 MPa | Good impact strength, easy to process |

| Polycarbonate (PC) | ~130°C (266°F) | 2,300 MPa | Good optical clarity, impact resistance |

Thermoplastics in general do not offer good heat resistance properties; however, PEI and Ultem more than make up for this with their superlative heat resistance, mechanical strength, and flame retardancy. Being so much better, PEI and Ultem stand out from the other common thermoplastics, such as polypropylene (PP)-L, induced PP, and polycarbonates (PCs), which lose their strength at a temperature below 200°C. High-heat applications require materials that retain their strength under high temperatures. To illustrate those with poor heat resistance, PP loses its ability to resist heat around 100°C, whereas PEI has a Tg above 215°C.

Furthermore, PEI and Ultem display higher strength and rigidity compared to acrylonitrile butadiene styrene (ABS). Their tensile modulus usually exceeds 3000 MPa, whereas that of ABS is around 2500 MPa, which makes they subject to high durability under mechanical loading. Chemically, PEI is resistant to acids, oils, and certain solvents, giving it an edge over polyamide (PA), which can absorb moisture and degrade in wet environments.

From the standpoint of design flexibility, these high-performance plastics can be machined into intricate geometries with tight tolerances, making them suitable for use in industries where high precision is required, such as aerospace and medical applications. Unlike PVC or PET, which are often used for consumer-grade applications, PEI and Ultem are designed for applications requiring long-term reliability and adherence to strict safety standards.

Analyzing the cost perspective, PEI and Ultem are often viewed as premium materials, with prices often far beyond that of commodity plastics such as polyethylene or polystyrene. However, when safety, durability, and higher performance are a necessity, this unique set of qualities could be said to make the price worth paying. It is this attractive combination of features that sets them apart for others, serving demanding industrial and technological growth.

Applications of Ultem in Aerospace and Beyond

Ultem in Aerospace Manufacturing

Due to the extreme safety and weight reduction requirements, coupled with the demanding demands for high-end performance, Ultem has become nearly indispensable in aerospace manufacturing. The materials possess good thermal stability and are flame-retardant, making them perfectly suitable for components exposed to high temperatures, such as electrical connectors and housings in an aircraft. Moreover, since Ultem is lightweight, it significantly contributes to the reduction in overall aircraft weight, which is crucial for improving fuel efficiency and emissions.

Aerospace Applications Include:

- Electrical connectors and housings

- Interior cabin applications (seating structures, ventilation systems, overhead bins)

- Structural parts requiring long-term stability

- Components meeting FAR 25.853 standards for flame, smoke, and toxicity

One striking property of Ultem is that it maintains excellent mechanical properties under harsh environmental conditions. This ensures long-term stability and serviceability for structural parts in aerospace environments. Ultem is also considered the best choice for interior cabin applications, such as seating structures, ventilation systems, and overhead bins, due to its compliance with demanding aerospace industry standards, including FAR 25.853, which addresses flame, smoke, and toxicity requirements.

Even greater versatility for Ultem in aerospace is achieved through advanced manufacturing techniques, such as 3D printing, which enable the rapid production of custom designs and prototypes, thereby drastically reducing production time without compromising accuracy. The increasing use of Ultem as an aeronautical material further reinforces the industry’s confidence in the material’s ability to meet the growing demands of modern aviation while providing seamless performance, safety, and cost efficiency.

Other Industries That Use PEI

Electronics Industry

High thermal resistance and electrical insulating characteristics make PEI suitable for connectors, circuit boards, and key electronic components that remain unaffected under extreme environmental conditions.

Medical Field

Biocompatibility, ability to withstand repeated sterilization cycles, and good mechanical strength make PEI ideal for surgical instruments, dental devices, and diagnostic equipment.

Automotive Industry

High strength-to-weight ratio and heat resistance make it suitable for under-the-hood components, lighting systems, interior panels, and EV battery modules and charging systems.

Food & Beverage

FDA-approved formulations that resist high temperatures maintain structural integrity for microwave cookware and reusable food containers, ensuring food safety during prolonged use.

Polyetherimide (PEI), especially the more well-known Ultem form, has found applications outside the aerospace industry. The electronic industry, in particular, makes extensive use of the special features of PEI. It is these features, such as high thermal resistance and electrical insulating characteristics, that make PEI a suitable choice for use in connectors, circuit boards, and other key components in electronics. This guarantees that, under certain extreme environmental conditions, such as high temperatures or chemical exposure, it will remain unaffected.

The medical field has constituted another central area of PEI application. Due to its biocompatibility, ability to withstand repeated sterilization cycles, and good mechanical strength, PEI is increasingly being employed in surgical instruments, dental devices, and diagnostic equipment. It’s being transparent and further resisting visible UV degradation in these highly specialized applications that cater to stringent health and safety standards.

The automotive industry aims to make cars lighter and maximize fuel efficiency, and PEI plays a significant role in this endeavor. Its high strength-to-weight ratio and heat resistance make it suitable for under-the-hood components, lighting systems, and interior panels. Additionally, with the growing popularity of EVs, the insulating properties of PEI in battery modules and charging systems are gaining prominence in terms of both performance and safety.

The food and beverage industry utilizes PEI to manufacture various cookware and containers, including microwave cookware and reusable food containers. It features FDA-approved formulations that resist high temperatures to maintain structural integrity and ensure food safety during prolonged use. Being a truly versatile material, PEI keeps abreast of innovations and evolving industry standards across these diverse sectors.

Future Trends in PEI Applications

Standing poised to be adopted in an increasingly larger number of emerging industries is Polyetherimide (PEI), owing to its somewhat unique set of characteristics-strength, heat resistance, and versatility. One trend pointing the way is the use of PEI with additive manufacturing, primarily 3D printing, in aerospace, automotive, and healthcare applications. Since the material can resist high temperatures and stresses, it would be well-suited for fabricating lightweight yet durable components for jet engines, electric vehicles, and custom medical implants.

Emerging Applications:

- Additive Manufacturing: 3D printing applications in aerospace, automotive, and healthcare

- High-Performance Electronics: Advanced insulators and thermal degraders for electronics

- Renewable Energy: Solar panel framing and wind turbine structural components

- Autonomous Technologies: Structural parts for drones and LiDAR system enclosures

Another growth avenue is the evolution of high-performance electronic products, where PEI has taken on a protagonist role as an insulator and thermal degrader. With the ever-expanding electronics market, the demand for rugged materials, such as PEI, for printed circuit boards and connectors is expected to skyrocket, paving the way for more integrated and compact designs.

Sustainability is another case in the evolution of PEI applications. As industries move towards green solutions, recyclability, and energy-saving manufacturing methods, PEI makes it an eager contender, vying against traditional materials. The renewable energy industry is exploring its application in solar panel framing, as well as wind turbine structural components, in line with the world’s push toward carbon neutrality.

As developments in autonomy and new mobility means continue, so do the PEI innovations. From structural parts in unmanned drones to thermal resistance enclosures for LiDAR systems, PEI’s capacity to endure extreme conditions continues to interest high-tech industries. Such developments indicate that PEI is capable of evolving with cutting-edge technologies and may even be on a long journey toward sustainable, efficient, and high-performance solutions.

Injection Molding with PEI Thermoplastic

Injection Molding PEI Advantages

The injection molding process with polyetherimide offers several advantages, which is why this material is chosen for high-performance sectors such as aerospace, automotive, and electronics. One advantage of PEI is its thermal stability, which also implies that the material withstands very high temperature environments without undergoing degradation. Thus, parts that are exposed to extreme conditions, such as those of engines or electronic housings, can be deemed suitable.

Key Injection Molding Benefits:

- Excellent thermal stability under high-temperature environments

- Superior mechanical robustness and rigidity for extended durability

- Dimensional stability maintaining exact tolerances and shape consistency

- Inherently flame-retardant with very low smoke generation

- High resistance to chemicals for longevity in corrosive environments

- Efficient production of intricate geometrical shapes with minimal post-processing

Another crucial advantage is that it is mechanically robust and rigid, providing durability to the parts for extended periods, even under heavy loading stresses. Furthermore, PEI is dimensionally stable and capable of maintaining exact tolerances and shape consistency in molded parts. It is also inherently flame-retardant, with very low smoke generation, thereby making it suitable for safety applications.

From the standpoint of manufacturing, the injection molding of PEI enables efficient production processing, including intricate geometrical shapes and minimal post-processing requirements. This allows manufacturers to scale up production while maintaining high-quality outputs. PEI is highly resistant to chemicals; thus, it will last longer and perform well even in corrosive environments.

All these advantages combine to make injection molding for PEI a skilled means of producing lightweight, durable, and high-performance components demanded by modern industry.

Issues and Solutions in PEI Molding

Being a material demanding tailoring in mold temperature and process, PEI molding is not without its complications. A primary drawback is the high process temperatures, exceeding 370°C (698°F), which require specialized equipment for such intense conditions and necessitate almost painstaking temperature control to prevent degradation or inconsistencies in the molded parts. Should the manufacturer not have access to such equipment, this indeed becomes a significant hurdle.

Common Molding Challenges & Solutions:

| Challenge | Solution |

|---|---|

| High Process Temperatures (>370°C) | Specialized equipment, painstaking temperature control |

| Low Melt Flow | Optimize runner design, higher injection pressures |

| Moisture Absorption | Pre-drying at 150°C for 4-6 hours |

| Warping and Shrinkage | Uniform cooling rates, high thermal conductivity molds |

| Internal Stresses | Post-molding annealing process |

Another challenge commonly faced is a property of its own: low melt flow. This means that it is challenging to fill complex molds or produce thin-walled sections. Such demands lend themselves to consideration of mold design, gating systems, and material flow paths. Methods to treat these issues include runner design optimization and injection at higher pressures.

Another point in its favor is the compelling tendency of PEI to absorb moisture. If this moisture is not efficiently eliminated before processing, it may cause hydrolysis during the molding procedure, resulting in a loss of mechanical properties or surface imperfections. The best way to deal with this is by strictly adhering to the pre-drying procedure, generally performed at approximately 150°C (302°F) for about 4 to 6 hours.

Warping and shrinkage can also occur in PEI molding, primarily due to unevenly distributed cooling or insufficiently designed molds. Both issues could be addressed by ensuring uniformity across cooling rates throughout the entire part and utilizing mold materials with high thermal conductivity. Further exploration with simulation tools would also predict situations of possible warpage and lead to the best mold parameters for the required uniformity.

Lastly, a great deal hinges on dimensional precision and the relief of post-molding stresses for PEI components in high-performance applications. They may be annealed after molding to relieve internal stresses, thereby enhancing the stability and hardness of the product.

Being able to resolve such issues through solution testing will allow PEI molders to evaluate their setup in top-grade and reliable quality terms, hence ensuring it wins the spotlight as a choice material in demanding industries.

Injection Molding Case Studies of PEI

🛩️ Aerospace Application

A leading aerospace manufacturer utilizes PEI injection molding to manufacture lightweight, high-performance components for aircraft interiors. Through optimized mold design and advanced post-molding annealing, the company achieved consistently stable dimensions crucial for parts experiencing varying temperatures and pressures.

🏥 Medical Device Manufacturing

A medical device manufacturer encountered problems with creating exact, heat-resistant, and chemically resistant parts that conventional machines couldn’t produce. The switch to PEI injection molding met specified requirements for part accuracy and biocompatibility.

🚗 Automotive Industry

An automotive manufacturer utilizes PEI injection molding to produce lighter and flame-resistant components for electric vehicle battery housings. Using sophisticated software simulations, the team optimized mold design to reduce cycle times without compromising strength.

Those case studies reiterate the variety of applications and benefits that PEI injection molding brings to the table. When manufacturers pursue tailor-made solutions in conjunction with rigorous quality control measures, they can leverage PEI’s characteristics to produce reliable and high-performance products.

High-Temperature Performance of PEI Materials

Thermal Stability and Resistance

Polyetherimides (PEIs) derive their name from their trademark qualities of thermal stability and resistance, which one cannot dispense with in making a high-temperature application in an industry. Polyetherimide, when set for continuous use, maintains its structural integrity and performance without degradation at a temperature of 340°F (170°C). Some grades even allow for short stops above this temperature. Therefore, it can be safely stored in components that operate in extreme thermal environments, such as those found in aerospace and automotive applications.

🌡️ Temperature Performance Specifications

Furthermore, PEI demonstrates the ability to overcome the hazards of thermal aging while maintaining extended functionality under cycles of heating and cooling. From here, having a low thermal coefficient of expansion, it is an indispensable feature for dimensional stability against temperature changes in precision industries. Hence, PEI perfectly suits applications where components must remain stable to ensure circuit reliability, such as in electronics, or for industrial machines where any heat distortion could jeopardize their functionality.

With natural flame resistance and a very high safety rating (UL 94 V-0), PEI can be used in applications where fire hazards need to be minimized. Therefore, the combination of thermal resistance and safety characteristics makes PEI a compelling choice for manufacturers concerned with durability, safety, and performance in hot environments.

Applications Requiring High-Temperature Materials

Being able to sustain extreme thermal conditions, these materials find uses in cutting industries that require high-temperature materials. To cite a few examples, in the aerospace industry, materials are required for turbine blades, insulating panels, and engine housings. These components are often exposed to extremely high temperatures; therefore, they must possess high thermal stability. Thus, in the automotive industry, materials are required for exhaust systems, engine manifolds, and various other under-the-hood components, which must work reliably under severe heat and mechanical stresses.

Industries Requiring High-Temperature Materials

🚀 Aerospace

- Turbine blades

- Insulating panels

- Engine housings

🔧 Electronics

- Circuit boards

- Semiconductor equipment

- Thermal cycling components

⚡ Energy Sector

- Power plant turbines

- Geothermal plants

- Solar power systems

🏥 Healthcare

- Autoclaves

- Sterilization devices

- High-temp medical equipment

Electronics are just another area where these materials find many applications, such as in the construction of circuit boards and semiconductor manufacturing equipment. There has been a growing push in modern electronics for materials that can resist rapid thermal cycling while being durable and flame-retardant. Some such materials include PEI (polyetherimide) and ceramic composites. Another field that encompasses these uses is the energy sector, where the need for high-temperature materials affects most power plants, including those with turbines, geothermal plants, and, more recently, concentrated solar power systems as well.

Besides healthcare facilities, equipment such as autoclaves and sterilization devices also require materials that can withstand extreme heat while still functioning correctly and remaining safe. It is the intersection of durability, heat resistance, and meeting safety standards that has basically kept high-temperature materials relevant in life-critical performance environments.

Assessment of PEI in Extreme Conditions

Polyetherimide (PEI), due to its outstanding thermal, mechanical, and chemical properties, has become a vital choice for engineers in high-end applications. This means that for continuous use, PEI can resist temperatures up to 356°F (180°C); for shorter periods, even higher temperatures can be tolerated. Its flame-retardant nature and low smoke emission capacity account for PEI enriching crucial environments where safety and reliability matter, such as the aerospace, automobile, and electronics industries.

🔬 Extreme Conditions Performance

- High-pressure and temperature resistance (autoclaving, advanced manufacturing)

- Maintained structural integrity under thermal deformation stress

- Chemical resistance to industrial solvents, acids, and oils

- Dimensional stability during 3D printing and extrusion processes

- Mechanical endurance under alternating thermal cycles

Being exposed to high-pressure and temperature conditions, such as those in autoclaving, advanced manufacturing, or other high-precision procedures, requires PEI to maintain its structural integrity. Studies have highlighted the high tensile strength of PEI and its ability to resist thermal deformation, making it the material of choice for applications requiring mechanical stability at elevated temperatures. Chemical resistance makes PEI impervious to degradation in the presence of typical industrial solvents, acids, and oils, which enables the carrier to exhibit longevity and performance even in chemically severe environments.

PEI brings its distinctive properties to advanced manufacturing trends, such as 3D printing. Materials such as ULTEM, a popular PEI brand, are dimensionally stable during extrusion processes, enabling the fine-detail manufacturing of components. Performance tests demonstrate PEI’s mechanical endurance and resistance to wear when subjected to alternating thermal cycles, highlighting its suitability in environmental conditions where operational conditions fluctuate, such as an engine compartment or a sterilization unit.

Being highly versatile and resistant to harsh conditions, PEI remains an essential material in modern, high-tech industries. It guarantees an active role for the material in developing solutions for life-or-death applications under severe conditions.

Future of PEI in Advanced Manufacturing

Innovations in PEI Resin Development

While considering PEI resin development, I realized that the more it is thought about, the more it becomes apparent that there is considerable room for innovation on many fronts. One of the key areas in which development has been pursued is the improvement of the resin’s thermal and mechanical properties to keep pace with the growing demands of high-performance industries. For example, manufacturers are testing modified PEI formulations to provide for greater heat resistance, dimensional stability, and long-term durability even under the rigors of adverse operating conditions. These modifications enable PEI to be utilized for next-generation applications in aerospace components and advanced medical devices, where utmost resilience and precision are required.

🔬 Innovation Focus Areas

Performance Enhancement

Improved thermal and mechanical properties, greater heat resistance, enhanced dimensional stability and long-term durability

Sustainability

Recycled raw materials usage, reduced energy consumption, waste reduction in manufacturing processes

Additive Manufacturing

3D printing formulations, design freedom maximization, complex geometry production capabilities

In sustainability, another key innovation is found. Being an environmentally conscious manufacturing process, this leads to the development of PEI resins using recycled raw materials, whenever performance can be maintained. The new manufacturing processes aim to decrease energy consumption and waste production, enabling advanced material science to align with global sustainability concerns. Innovations of this kind not only extend the range of uses of PEI but they also promote it as a material of choice in industries setting their path toward green practices.

3D technology and other adaptive manufacturing methods have forever changed how PEI resin is employed and applied. PEI, with better-grade formulations specifically designed for additive manufacturing, offers a level of design freedom that few other resins can match, along with the ability to produce relatively lightweight, three-dimensional, complex geometries on a fast track. These represent some of the very aspects that continue to drive PEI resin evolution far beyond the boundaries of engineering and design, catering to the needs demanded by inter- and cross-industries of today.

Possible Impact on Manufacturing Processes

According to my calculations, advancements encompassing factors such as PEI resins have a profound impact on manufacturing processes. Using technologies like 3D printing, manufacturers can drastically reduce lead times without compromising precision. This means that they will be able to conduct fast prototyping alongside triggering very short product cycles, allowing businesses to respond faster to market requirements. Additionally, because PEI components are both lightweight and strong, the products can be made more efficient while the raw materials and energy needed for their manufacture are utilized more economically.

📈 Manufacturing Process Benefits

Given their versatility in PEI resins and additive manufacturing, engineers are granted the opportunity to explore complex geometries that were heretofore impossible to work with in traditional methods. It means that design freedom is maximized while I retain better functionality in the end product. The aerospace, automotive, and medical fields are uniquely positioned to benefit from this kind of innovation, as lightweight, reliable components lead to performance enhancements and support sustainability objectives.

The idea essentially focuses on more innovative and agile manufacturing processes. Keeping up with state-of-the-art materials and technologies, manufacturers are well-positioned to handle contemporary challenges —and that includes improving efficiency and conforming to stricter environmental regulations. The concept is more about refashioning the entire scenario of producing quality products for fast-changing industrial needs.

Prediction for PEI Adoption in Various Sectors

When considering predictions for PEI adoption across various industries, the future appears both exciting and transformative. I particularly expect that PEIs will usher in a completely new wave of automation and intelligent production systems within the manufacturing sector. Advanced analytics-driven AI, working in concert with advanced robotics, will become the hallmark of standardized processes with lower costs and reduced waste. This, in turn, has the potential to be applied more widely in sustainable practices as several companies strive to become strictly environmentally friendly and maximize efficiency in their operations. Next-generation materials with higher durability or recyclability will further transform the production and maintenance of goods.

The healthcare sector is another one that will receive substantial PEI uptake. I expect advances in precision medicine and personalized therapies to result from AI-powered diagnostics and cutting-edge biotechnology. Medical interventions will then proceed more quickly and precisely, with better outcomes for patients. Moreover, wearables and IoT health devices will continue growing, featuring real-time monitoring and predictive insights to support efficient preventive care planning. These technologies will play a significant role in making patient care more proactive, accessible, and needs-based.

First of all, the entire energy sector is poised for a boom in PEI-fueled solutions in response to growing global demands and sustainability concerns. Energy storage systems will become the front-runners on the renewable energy side; advanced battery technologies and grid-scale storage innovations will play essential roles in this. Innovative grid technology, coupled with an AI-based energy management mechanism, will form efficient and responsive systems that meet demands in real-time with a reduced environmental impact. Thus, in any sector, the adoption of PEI will secondarily drive fundamental transformation, thereby contributing to making them smarter, greener, and more resilient to future challenges.

Reference Sources

-

PEI Material: Properties, Applications & Manufacturing Uses – This article discusses the properties of PEI and its applications in manufacturing, including injection molding and 3D printing.

-

PEI Plastic Custom Processing: How to Achieve Precision – Focuses on advanced processing techniques for PEI plastic to achieve precision and quality in manufacturing.

-

Exploring the World of PEI: The High-Performance Plastic – Highlights the unique mechanical strength, thermal endurance, and dimensional stability of PEI thermoplastic.

-

PEI Plastic – TECAPEI – Provides insights into typical applications of PEI in industries like electronics and aerospace.

-

Unlocking the Potential of Polyetherimide (PEI): Properties and Applications – Explores the properties of PEI and its use in high-performance electrical components.

- Find more info now.

Frequently Asked Questions (FAQs)

❓ What are the key properties of PEI thermoplastic?

It has an excellent set of mechanical properties and withstands high temperatures well. Due to its relatively high glass transition temperature, the polymer maintains structural integrity when subjected to temperatures on the higher side. A superb chemical resistance lends itself to various environments. It is amorphous and thus exhibits good electrical properties, making it useful in applications such as circuit boards and connectors. Its impact strength or resistance to impact, and tensile strength have contributed to its desirability in many demanding applications such as the aerospace and automotive industries.

❓ How does Ultem® compete with other thermoplastics?

Ultem®, a trademark for polyetherimide (PEI), is considered a high-performance plastic. This brand name embodies many superb characteristics associated with thermoplastics. Among many traditional plastics with different features, Ultem® holds the finest in thermal properties, which correlate with its applications in hot environments. It yields high strength and resistance to necking under the stress induced by mechanical processes-a factor that is very critical in mechanical stress-rich environments. In comparison to other thermoplastics, Ultem® enjoys a better strength-to-weight ratio and hence finds widespread use in medical fields that serve sterilization applications. The deployment of glass fiber reinforces the plastic in mechanical applications, thereby expanding its industrial uses.

❓ What are the applications of Ultem® plastics?

I would say that Ultem plastic enjoys extensive use in the aerospace, automotive, and medical device industries due to its superior properties. In aircraft, for instance, it’s used in components that require resistance to high temperatures and also need to be lightweight. Electrical insulation properties make it desirable in the electronics field for use in printed circuit boards and connectors. Ultem is also used in medical devices, wherein sterilization and chemical resistance of the instruments are necessary, such as surgical instruments and diagnostic equipment. Being a high-performance thermoplastic, it can be used in applications where gamma radiation is present.

❓ What does engineering mean to PEI resin?

Due to its thermal and mechanical properties, PEI resin plays a crucial role in various engineering applications. As an amorphous engineering thermoplastic, it can withstand elevated temperatures while maintaining its shape and functionality. Designed for applications where durability and reliability are crucial, it remains stable under varying conditions. It is suitable for electrical insulation and circuit board fabrication due to the resin’s electrical properties. The mechanical strength of the resin is further increased with glass fiber reinforcement, which is why it is accepted in rigorous engineering applications.

❓ Is PEI considered thermoplastic for medical applications?

PEI enjoys wide acceptance in medical applications due to its excellent sterilization properties and biocompatibility. Being capable of withstanding high heat and pressure, it can be sterilized in an autoclave. Chemical resistance of the polymer is also essential because medical devices may be exposed to a variety of fluids and chemicals in the healthcare environment. PEI mechanical properties can ensure that the devices can endure normal usage under stress. Different grades of PEI for medical applications have been developed by General Electric, ensuring safety and efficacy.

❓ What are the advantages of using glass fiber reinforcement in PEI?

Incorporation of glass fiber reinforcement in PEI significantly amplifies its mechanical properties. Such reinforcement improves the tensile and impact strength of the material, thereby making it highly suitable for applications subjected to high stresses. The glass fiber reinforcement offers the potential to impart a higher strength-to-weight ratio, which is crucial in the aerospace industry, given the constant need to reduce weight. The reinforced material also provides increased dimensional stability with minimal warpage during processing. In brief, glass fiber-reinforced PEI is an ideal candidate for applications requiring superior performance and reliability in hostile environments.