Whether you are a manufacturer, a consumer, or someone who works with silicone or thermoplastic elastomer (TPE), knowing their differences is key to identifying the materials. Both silicone and TPE have numerous applications in industries like medicine and consumer goods. However, their differences influence performance, longevity, and other valuable characteristics. Understanding the differences helps narrow options based on requirements and maximize project outcomes. In this article, we will study the differences between silicone and TPE, methods of distinguishing them, and their implications if one is used instead of the other in specific scenarios. Let’s uncover the secret behind these materials while exploring their remarkable properties.

What is the Difference Between TPE and Silicone?

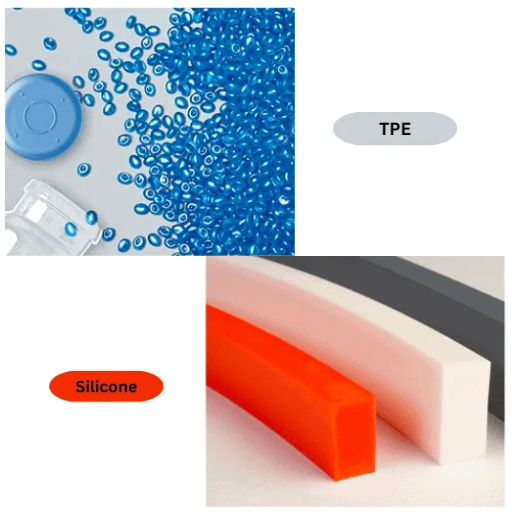

Thermoplastic Elastomers (TPE) and silicone possess unique characteristics that make them appropriate for specific applications. TPE is an elastic material prone to stretching like rubber and is as eas ily moldable as plastic. This makes TPE highly preferred when durability and ease of processing are required during manufacturing. Silicone is a synthetic polymer that is flexible, biocompatible, and high temperature resistant, thus used in medical and food grade applications and in machines that operate at high temperatures. The difference between them is that, in terms of raw materials and performance, TPE is thermoplastic and therefore recyclable. At the same time, silicone is more stable under extreme environmental conditions, rendering it non-recyclable through conventional methods.

Understanding TPE Material Properties

Thermoplastic elastomers, or TPEs, are one type of copolymer that integrates rubber properties with flexible polymer shaped like plastic. The most remarkable feature is that these copolymers can undergo repeated melt processing. Structurally, TPEs consist of hard and soft segments within their molecular chains. The soft segments lend flexibility along with elastic recovery, and the complex parts provide the polymer with mechanical strength and dimensional stability.

Key characteristics of TPEs focus on the degree of tensile strength, elongation at break, and hardness, which is measured using inline ‘Shore’ durometer scales. The UV and ozone resistance in TPEs is notable, along with weather resistance, which also provides resistance to many chemicals. These characteristics make TPEs suitable for rigorous applications in automobiles, consumer products, industry, and manufacturing. The modification capability through blending or compounding to achieve desired characteristics furthers their adaptability. For example, TPE grades resistant to oils and high-temperature environments increase their versatility.

From a sustainability overview, TPEs can be recycled, which is an advantage compared to other materials. TPE waste from consumers and industries can be processed with little degradation, aiding circular manufacturing systems. With the advancements in polymer technology, these TPE materials can meet multifunctional requirements and needs across multiple industries.

Key Characteristics of Silicone Rubber

Silicone rubber is an elastomer with unparalleled versatility due to its high thermal stability. It also has a chemical and electrical insulating property. It can endure very low and high temperatures ranging from -60°C to 250°C (-76°F to 482°F), which makes it useful for subzero and high-heat environments. Silicone rubber is also resistant to aging and prolonged exposure to UV radiation, ozone, and weathering.

Silicone rubber’s oils, water, and most common solvents do not affect it chemically, making it durable in chemically exposed environments. Its low compression set helps it retain flexibility and elongation even after prolonged stress. Silicone rubbers are versatile since they can be modified from 10 to 80 Shore A and used as gaskets and seals or in medical devices.

Silicone rubbers are biocompatible, which broadens their usefulness in the healthcare field because silicone rubbers die provide strict regulatory guidelines dictated by the law for medical grade goods. Moreover, silicone rubbers are low-toxicity, inert, and safe to interact with food, drugs, and pharmaceuticals. Also, silicone rubbers have noteworthy electrical insulation attributes since they perform equally well within different frequencies and conditions. Therefore, Silicone rubbers are used in the electronics and automotive industries.

Due to technological innovations in formulating materials, silicone rubbers are used more widely in the aerospace sector, consumer goods, and even renewable energy technologies because of the trust placed in them in such critical situations. The most crucial silicone rubbers are essential for modern manufacturing and engineering, and the ability to combine physical, thermal, and chemical properties.

Comparing TPE vs Silicone in Applications

The purpose of serving distinct industries differs for thermoplastic elastomers (TPE) and silicone based on their characteristics, methods of processing, and suitability to the application. Automotive seals, medical tubing, and consumer goods use flexible and durable thermoplastics (TPEs), which can be melted and reformed. Additionally, they are economically attractive due to ease of recycling and low production costs, enabling mass manufacture.

Thermoplastics are not the only materials with advantages, as silicone demonstrates from its applications in medical-grade implants, high-performance automobile parts, and insulating electrical components. Exposed to extreme environments like -50 to 200 °C, even beyond for specific formulations, chemicals, and mechanical stress, silicone stands undeterred as it is void of losing its structural integrity. Unlike TPEs, silicone retains functionality under the same conditions.

Although TPEs are notably lacking in structure, silicone is superior in terms of elasticity, compression set, and harmful UV and ozone exposure. Thus, the required operational environment and performance specifications determine the selection of either Silicone or TPE.

How Can You Identify Silicone Products?

Silicone products’ distinguishing traits include a soft, rubber-like feel and bending flexibility. They can withstand rot and heat, do not stick to other materials, and are resistant to water and certain chemicals; thus, they are suitable for extreme conditions. Silicones are also durable and tend to keep their functionality and shape over time. Examples include kitchen medical devices, utensils, seals, gaskets, and kitchenware. Often, manufacturers provide markings or specifications whereby the silicone is explicitly stated as a material composition.

Visual Inspection of Silicone Material

When visually inspecting silicone materials, contours allow one to ascertain the degree and nature of their composition and rectitude. Silicones are rubbery and glossy/transparent in coloration, although the latter could sometimes appear silky matte. Regarding uniformity, silicones are relatively consistent, although some pigments are used to tailor additives, which may or may not be applied for specific uses.

The elastic material can freely stretch and bend without losing structural integrity. Surface irregularities, bubbles, and uneven textures can suggest problems with the molding process. Silicone materials have a unique ability to resist outward pressure without deformation, and are even less resilient than other materials.

Silicone is identifiable through its thermal characteristics. For instance, its heat protection is reinforced by not showing any visible deformation at higher temperatures. Color fading or surface abrasion may indicate overexposure to heating elements, UV radiation, or both. Using all of these factors together enables one to perform a visual check that ensures the selection of the appropriate silicone for demanding applications.

Common Uses of Silicone in Products

Widely Accessible Silicone’s remarkable combination of attributes, including flexibility, chemical resistance, high thermal stability, and others, makes it an incredibly versatile material for use across numerous industries. Silicone has one of the most prominent contributions in medicine, where it is used to manufacture implants, prosthetics, and tubing due to its biocompatibility and ability to be sterilized without degradation.

In that regard, silicone is also prominently used in electronics as an electrically insulating material for devices, electronic enclosure sealants, and thermal interface materials that enhance component heat transfer. Other industries, including automotive, use silicone in the form of silicone gaskets, O-rings, and hoses that endure high operating temperatures and exposure to diverse fluids, especially in the context of durable silicone parts.

Silicone is found in many everyday products, such as kitchen items like baking mats, spatulas, and pliable molds, as well as beauty products like cosmetic applicators and skin-safe adhesives. In construction, silicone is helpful as a weatherproof sealant for windows, doors, roofs, and façade systems.

Testing for Heat Resistance in Silicone

Evaluating silicone’s resistance to overheating involves various lab techniques to measure the silicone’s structure, physical integrity, and functionality under high temperatures. One common technique is thermal gravimetric analysis, which measures the weight loss of a material with temperature increase. This helps elucidate the material’s decomposition profile and the onset of thermal decomposition.

Research on silicone’s elastic properties uses dynamic mechanical analysis (DMA) to examine the effect of heat on elasticity, tensile strength, and other mechanical characteristics. Researchers apply cyclic stress to the material at a constant temperature and measure the shift in performance indicators.

Another frequent practice is heat aging, where silicone samples are subjected to elevated, constant temperatures of 200°C or greater to simulate long-term use. The silicone is inspected for its relative hardness, flexibility, and structural characteristics during this assessment. Furthermore, internal changes within the polymer matrix can be monitored using infrared spectroscopy, thus ensuring the material’s integrity.

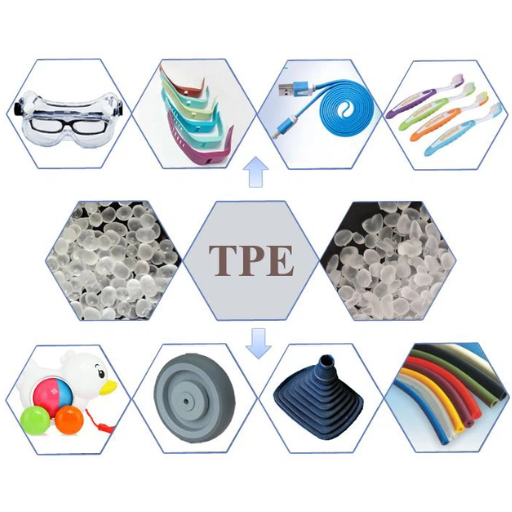

What are the Applications of TPE?

Thermoplastic elastomers (TPEs) can take different forms, allowing them multiple applications across several industries. They are frequently utilized in the automotive industry for automobile trim, exterior seals, gaskets, and airbags because of their ease and long-lasting nature. TPE can also be found in consumer products like tool grips and household products, such as soft grips, where ease of use is a priority. Moreover, TPE is used in the medical industry to make soft tubing, seals, and other parts because it is safe and flexible while meeting burdensome regulations. TPE also provides advantages in electronics by insulating and protective coverings for cables due to their protective nature and pleasing visuals. These applications show the useful adaptiveness of the material.

Common Uses of Thermoplastic Elastomer

The blend of rubber-like elasticity with TPE’s thermoplastic qualities has made it popular across various industries. In the automotive sector, TPEs are heavily utilized for airbag covers, weather seals, gaskets, and interior parts. The automotive industry is well known for being rough on materials. However, enduring extreme shifts from hot to cold and continuous mechanical beating, like the temperature extremes and constant mechanical strain found during driving, makes TPEs a perfect choice for materials.

There are notable soft-touch grips for toothbrushes, kitchen tools, and personal care items that showcase further use in the consumer goods sector. Their ease of use ergonomically improves the functionality and beauty of mechanically manufactured goods.

TPEs have significant advantages in healthcare and medicine because they can be your body’s friend and be sterilized. They are used in medical tubing, syringe seals, and wearables, which keep patients safe and comfortable during treatment. At the same time, the devices comply with the medical equipment guidelines.

TPE’s usefulness in electronics as a cable, connector, and enclosure for electronic device coatings, due to its electrical insulation and flexibility, benefits the industry. Also, its energy-damping characteristics aid in reducing noise and vibration in electronic equipment.

Advancements in TPE Material in Medical Devices

Thermoplastic elastomers (TPEs) have undergone significant advancements, driving their widespread adoption in the medical field due to their unique flexibility, durability, and biocompatibility combination. Below are the key advancements and their specific contributions to medical device manufacturing:

- Biocompatibility and Safety Enhancements

Recent developments in TPE formulations have focused on ensuring stringent compliance with medical-grade certifications such as ISO 10993 and USP Class VI. This ensures their biocompatibility, making them ideal for applications in contact with human tissues and bodily fluids. For example, soft TPE materials are extensively used in surgical tubing, masks, and gloves due to their hypoallergenic properties.

- Customization Capabilities

Advances in blending and compounding technologies have allowed TPEs to be tailored for specific medical applications. Their Shore hardness range has been expanded, allowing for flexible to semi-rigid designs. This level of customization meets the demanding requirements for products like catheter tips, IV bags, and stoppers.

- Improved Sterilization Resistance

Modern TPE materials exhibit excellent stability under various sterilization methods, such as gamma radiation, ethylene oxide (EtO), and autoclaving. For example, data shows that specially formulated TPEs maintain structural integrity after exposure to gamma sterilization up to 50kGy without significant degradation.

- Latex-Free Alternatives

TPEs provide a latex-free solution for medical devices traditionally made from natural rubber. This development has significantly reduced the risk of allergic reactions in patients and healthcare providers. Applications include syringe plungers, gaskets, and seals where latex-free performance is critical.

- Innovations in Drug Delivery Systems

Advanced TPEs have enabled precision in drug delivery systems by offering consistent mechanical properties over an extended period. Micro-molding technology has significantly benefited from these materials, creating components for auto-injectors and customized implantable devices.

- Sustainability and Eco-Friendliness

Manufacturers are now focusing on recyclable TPE formulations tailored for medical use. The ability to reprocess and recycle unused or discarded TPE components has decreased production waste while maintaining critical performance characteristics, especially in disposable medical devices.

- High Transparency Grades for Diagnostics

Medical diagnostics have seen increased use of high-clarity TPEs that offer optical transparency comparable to rigid plastics. These materials are employed in components such as IV connectors and blood reservoir devices, aiding medical professionals by allowing clear visual inspection.

The continuous innovations in TPE materials enhance their reliability and utility in medical devices, meeting the growing demands of modern healthcare while ensuring safety, precision, and sustainability.

Injection Molding with TPE

Based on my knowledge of injection molding TPE, it is both practical and multifunctional. The process includes heating thermoplastic elastomer to a molten state, then flowing it to a mold cavity where it cools to solidify into the desired shape. This technology has benefits like precision machining of intricate shapes and steady manufacturing quality. Thermoplastic elastomers are easily processed with injection molding; their economical flexibility, toughness, and suitability for bonding with other materials make them useful in healthcare, consumer products, automotive, and many other fields.

Is Silicone Safe to Use Compared to TPE?

Both silicone and Thermoplastic Elastomers (TPEs) share benefits such as ease of use, strength, durability, flexibility, and resistance to heat and chemicals. The primary difference is silicone’s greater resistance to high-temperature degradation or melting. TPEs and silicone elastomers are both biocompatible and non-toxic, allowing them to be safely used in healthcare and consumer products. The final decision of selecting silicone or TPE would depend on specific application details, such as extreme temperatures or elasticity requirements.

Health and Safety Considerations for Silicone

With its applications emerging in multiple industries like healthcare, food, and manufacturing, products made with silicone are perceived as safe and durable. Biocompatibility is one vital health and safety concern that silicone strongly fulfills, as it doesn’t damage tissues or provoke adverse reactions on contact. As a result, silicone has proven beneficial as a material for medical devices like catheters, implants, and prosthetics. Moreover, silicone’s thermal stability enhances safety against chemical degradation under high temperatures, making it a reliable choice for cookware and bakeware.

Silicone is not highly reactive to changes in surrounding conditions, meaning that off-gassing is minimized. Its toughness also mitigates the need for replacement, which decreases long-term exposure to material breakdown byproducts. Although silicones are considered non-toxic, it is critical to verify that the grade used is either food-grade or medical-grade silicone for applications where human contact is necessary. Proper manufacturing and quality regulations also form an equally essential component of the safety profile.

Evaluating Chemical Resistance of TPE and Silicone

Both silicone and thermoplastic elastomers (TPE) are renowned for their exceptional chemical resistance. The base structure is notable for its chemical resistance toward acids, bases, and oils; however, it depends on the material’s specific formulation or blending. Moreover, this resilience varies significantly across different grades, so specialized attention must be given to the chemical environment it is meant to be. Silicone is more resistant to more chemicals than TPE and most other materials, especially at high temperatures. It remains stable with many oxidizing agents, solvents, and oils, but is poorly stable with some concentrated acids and alkaline compounds.

The recent breakthroughs in silicone manufacturing have further improved its resistance to environmental stress cracking from chemical exposure. This makes silicone even more preferred for critical medical devices and industrial seals. At the same time, TPE blends have gained custom formulation options and can now be used in applications that were traditionally the domain of silicone, broadening their use. In the case of TPE and silicone selection for environments with chemicals, the operating temperature, nature of the chemical agents, and mechanical stress need to be thoroughly analyzed for safety and performance.

Environmental Impact of TPE vs Silicone

Understanding the environmental impact of TPE and silicone requires analyzing the material’s sourcing, production methods, recyclability, and disposal at the end of life. Thermoplastic elastomers are often seen as more eco-friendly within the scope of these parameters. This is because TPE can be processed and recycled, making it less wasteful at the end of its life cycle. Furthermore, the energy required to produce TPE is lower than that needed to produce silicone, which undergoes curing and polymerization processes that demand extensive energy during manufacturing.

While silicone is challenging and doesn’t wear out easily, recycling it isn’t easy. Thermoset silicones are not recyclable using conventional methods due to their chemical structure, which prevents re-melting or re-formation. Programs specifically designed for recycling silicone are still limited in availability, but they do exist. On the other hand, TPE is fully recyclable under standard thermoplastic recycling streams, which aids in reducing waste and facilitates the use of materials in a circular fashion within industrial systems.

Silicone production emits more CO2 than TPE due to silica extraction and the over-tapering construction of silicone polymers, which requires lots of energy. However, in some long-term applications, silicone’s longer functional lifespan and better resistance to most environmental factors can compensate for its initial ecological costs.

Ultimately, the decision on TPE or silicone should be made by considering a complete lifecycle assessment that includes the entire scope of the product’s life: production, use, and disposal, to decide which option is more sustainable for particular cases.

What are the Differences Between Liquid Silicone Rubber and TPE?

Liquid Silicone Rubber (LSR) and Thermoplastic Elastomers (TPE) differ primarily in their material properties, processing methods, and typical applications:

- Material Properties: LSR is a thermoset material that undergoes a chemical curing process to become permanently set and resistant to high temperatures. TPE is a thermoplastic that can be melted and remolded multiple times, offering greater flexibility in recycling.

- Processing: LSR requires specialized injection molding equipment and a curing phase, making its manufacturing process more complex. TPE, in contrast, can be processed using standard thermoplastic molding techniques, often reducing production time and cost.

- Applications: LSR is ideal for high-performance, durable applications, such as medical devices and automotive components, due to its excellent thermal and chemical resistance. TPE is commonly used in consumer goods, soft-touch products, and applications requiring flexibility and ease of recycling.

Both materials serve distinct purposes, and the selection depends on the application’s specific requirements, including performance, cost, and sustainability considerations.

Defining Liquid Silicone Rubber

Liquid Silicone Rubber (LSR) is a two-part elastomer with exceptional versatility in mechanical properties and unparalleled resistance to extreme conditions. It consists of long-chain silicone polymers and reinforcing fillers cured, usually through a platinum-catalyzed addition process. LSR silicones rank highly for their temperature stability from -60°C to 200°C (-76°F to 392°F), good dielectric properties, and biocompatibility.

Improvements in LSR technologies have expanded their scope to precision molding. These components are now made with increased consistency across the parameters of the part performance—the low viscosity of LSR before curing aids in injection molding, especially at mass manufacturing stages. In addition, silicone rubbers are classified as LSRs and are deemed non-toxic, hypoallergenic, and resistant to UV radiation, ozone, and other chemicals. Such properties have made it an essential material for healthcare, automotive, and electronics. These industries greatly benefit from the strength-to-weight ratio with harsh condition durability.

Material Properties of Liquid Silicone Rubber

Liquid silicone rubber (LSR) has remarkable thermal and mechanical properties and versatile applications in different industries. With a formulation, LSR’s tensile strength can be between 4 and 12 MPa, and elongation at break can be up to 700%. These strengths and flexibility are particularly beneficial for dynamic use, such as gaskets and seals.

Thermally, LSR has extreme operational temperature ranges of -50°C to 250°C. Specialized grades even sharpen reliability in high-temperature automotive components or industrial machinery by tolerating greater peaks than typically operational. Because of its relentless thermal stability, LSR rubber balances reduction in structural integrity over time, even with swift temperature changes.

A less than 30% compression set guarantees long-term elasticity and shape retention, making LSR beneficial for enduring continuous mechanical stress. Due to superior dielectric properties garnered from 20 kV/mm strengths, LSR is preferred for use in electrical and electronic systems, where insulation is needed. Collectively, these features make LSR a precision and enduring solution in demanding applications, providing high-performance dependability.

Comparative Analysis: Liquid Silicone Rubber vs TPE

There are clear distinctions between Liquid Silicone Rubber (LSR) and Thermoplastic Elastomers (TPE) regarding their material characteristics, processing methods, and application suitability. LSR is a two-component thermosetting elastomer that cures using a platinum catalyst. This gives the material exceptional toughness, temperature resistance from -60°C to over 200°C, and biological inertness. Thus, LSR can be used in medical devices, automotive seals, and high-performance electronics where low failure rates and thermal reliability are crucial.

On the other hand, TPE is the combination of rubber elasticity and thermoplastic ease of processing in a single material. Because they are thermoplastic, TPEs have better recyclability and shorter production cycles, making them valuable and inexpensive for consumer goods, soft grips, and automobile interiors. The performance of TPEs, however, is quite limited at both hot and cold extremes, usually functioning between -50°C and 125°C. Also, TPEs are characterized by high compression set values. This makes LSR more desirable for usages that require a material to maintain its shape and stiffness in long-term mechanical loads.

Both materials present opportunities; however, LSR is known to perform better in chemical resistance, biocompatibility, and long-term resilience than TPR, which does better in ease of processing and cost for simpler applications. In the end, both materials rely on the preferences of the applying party to focus on specifics such as longevity, budgetary concerns, and ecological impact.

How Do You Choose Between TPE or Silicone for Your Project?

Start evaluating your project’s requirements when choosing between TPE and silicone. For less demanding applications, choose TPE for its ease of processing and cost-effectiveness. Select silicone for projects requiring higher chemical resistance, biocompatibility, product longevity, or extreme temperature resilience. Also, environmental exposures to harsh substances or constant mechanical strain should be considered because silicone often outperforms in these areas. Ultimately, the decision should align with the desired application’s durability, silicone and TPE budget needs, and performance benchmarks.

Factors to Consider: Durability and Flexibility

Durability and flexibility are essential when selecting materials for engineering and manufacturing applications. A material’s durability encompasses its resistance to wear, impact, harsh weather conditions, and other forms of degradation. Key metrics to durability include tensile strength, hardness, and abrasion resistance; together, these define flex dura. Flexibility describes a material’s ability to deform without breaking, making it essential to achieve in a broad range of loads and movements.

A product must maintain durability and temperature flexibility while mitigating cyclic stresses. Every material has weaknesses and strengths, but silicone elastomers outperform most thanks to their exceptional elasticity, long-term endurance, and resistance to UV light. Silicone’s ability to maintain its flexibility over a wide temperature range makes it far superior to many other materials in harsh conditions. During the design process, engineers strive to balance a product’s flexibility and durability for optimal performance throughout its lifetime and enhance its durability and lifetime.

Cost Analysis of TPE vs Silicone Materials

When evaluating TPEs and Silicones, one must consider both the long-term benefits and the upfront TPE acquisition cost. Thermoplastic elastomers have a cheaper initial acquisition cost due to their lower-priced production and use of scrap materials. This economic advantage makes TPEs worthwhile in high-demand/low-cost settings.

In contrast, silicone usually has a higher initial price, but it is more cost-effective in durability and performance over time. With its remarkable stability from extreme temperatures, resilience against chemicals, and longevity, silicone usually minimizes maintenance and replacement expenses. Moreover, silicone’s ability to withstand extreme temperatures without degradation makes it perfect for high-performance silicone-required industries like healthcare and aerospace.

The selection of material should fit the product’s intended use and lifecycle. In critical high-performance environments, where material failure would mean heavy losses, expensive TPEs would initially be cost-effective, but silicone’s strong attributes would prove it more economical. Thus, the choice of material should undergo comprehensive cost-benefit evaluations.

Specific Applications for TPE and Silicone

Distinct differences in material properties lead to differing applications of TPE and silicone. Due to its ease of manufacturing and flexibility, TPE is mainly used in consumer goods, such as handles, grips, and seals. It can also be processed and reprocessed as a lightweight material, making it suitable for automotive parts such as gaskets, bushings, and interior components. Furthermore, grades of TPE that are safe to the skin are widely used in medical gadgets like syringes, tubing, and wearable parts, including fitness bands.

On the other hand, silicone is widely accepted in aerospace, medicine, and even the food industry, where high-performance materials are essential. These sectors need aerospace parts and medical implants to withstand extreme temperatures and environmental stressors. In addition to these industries, silicone is a critical material in prosthetics and surgical tools because of its excellent biocompatibility. It also withstands high-stress conditions, perfecting critical HVAC and industrial machinery sealing systems. When looking at TPE and silicone, the silicone solution is preferred for high-endurance industries, while TPE is used in less critical applications because of its lower price.

Reference Sources

-

- Key Findings: This study compared the performance of medical devices made from different materials, including thermoplastic elastomers (TPE). It highlighted the unique properties of TPE, such as its gel-like consistency, which improves usability in medical applications.

- Methodology: The study involved a simulation-based comparison of devices, focusing on ease of use, success rates, and material performance under clinical conditions.

-

Ethylene-Propylene Diene Rubber as a Futuristic Elastomer for Insulation of Solid Rocket Motors (2023)

- Key Findings: While primarily focused on EPDM, this paper discussed the comparative properties of various elastomers, including silicone. It emphasized the thermal and mechanical advantages of silicone in high-stress environments, which could aid in distinguishing it from TPE.

- Methodology: The research reviewed material properties and performance in aerospace applications, providing insights into the identification and selection of elastomers.

- Top TPE Plastic Pellets Suppliers in China

Frequently Asked Questions

Q: How can I tell if a product is made from silicone or TPE?

A: You can often identify the material by checking for specific characteristics. Silicone typically has a more rubber-like feel, while TPE can feel more like plastic. Additionally, silicone is known for its durability and resistance to high temperatures, making it ideal for applications where heat resistance is crucial.

Q: What are the main differences between silicone and TPE?

A: Silicone is a synthetic rubber that is highly durable and heat-resistant, often used in high-temperature applications. TPE, or thermoplastic elastomer, combines the properties of plastic and rubber, making it flexible and more cost-effective for specific applications. When comparing silicone vs. TPE, consider your project’s specific requirements.

Q: What are some typical applications of silicone?

A: Silicone is used in various applications, including kitchenware, medical devices, and automotive parts. Its ability to withstand high temperatures and chemical resistance makes it a preferred choice in many industries.

Q: Are TPE and silicone materials interchangeable?

A: While TPE and silicone can sometimes be used in similar applications, they have distinct properties. Silicone offers higher temperature resistance and better durability compared to TPE. Therefore, when choosing between TPE and silicone for a specific application, it is essential to consider the environmental conditions and performance needs.

Q: What is TPE made from?

A: TPE, or thermoplastic elastomer, is made from a blend of plastic and rubber polymers. This combination provides the flexibility of rubber with the processing advantages of thermoplastics, making TPE a versatile synthetic material.

Q: Can silicone and TPE be used in food-related applications?

A: Both silicone and TPE can be used in food-related applications, but it is crucial to ensure they are food-grade materials. Silicone is commonly used for bakeware and kitchen tools due to its non-toxic properties, while TPE offers specific applications in food packaging.

Q: How do silicone elastomers differ from TPE?

A: Silicone elastomers are a specific type of silicone known for their elasticity and durability. They are often used in applications requiring flexibility and heat resistance. In contrast, TPE provides a different blend of plastic and rubber properties, making it suitable for applications where cost and ease of manufacturing are prioritized.

Q: Is TPE a sustainable material compared to silicone?

A: TPE is generally considered more sustainable than traditional plastics due to its recyclability and reduced environmental impact during production. However, silicone is also sustainable, particularly when produced through environmentally friendly processes. The sustainability of either material will depend on the specific production methods used.

Q: What are some pros and cons of using silicone vs TPE?

A: Silicone’s pros include its excellent temperature resistance, durability, and application versatility. However, it can be more expensive. TPE, conversely, is cost-effective and easy to mold, but it may not perform as well under high temperatures. The choice between silicone and TPE will ultimately depend on your project’s requirements.