Acrylic has been synonymous with flexibility, durability, and a wide range of applications. However, many are often left wondering: What is acrylic, really, and is it truly plastic? From its composition to its uniquely painful properties, acrylic has established itself as a fundamental production material in various industries, including building and design, technology, and health. This blog delves into the world of acrylic science, examining its chemical formulations, comparisons with other plastics, and what makes it highly applicable to numerous industries, offering virtually unmatched value. Eventually, in all seriousness speaking, you’ll come to respect acrylic as a modern engineering marvel.

What is Acrylic and Its Relationship with Plastic

Definition of Acrylic and Its Composition

Ranging in scientific jargon as polymethyl methacrylate (PMMA), Acrylic is simply a transparent thermoplastic with wide-ranging applications and is highly durable. Chemically speaking, acrylic is the polymerization product of methyl methacrylate (MMA); the molecules and molds of this polymer give it the best optical clarity properties and technical resistance to impact. Due to its molecular structure and various modifications, it can perform excellently in numerous climatic conditions and resist UV light and weathering, making it a potential glass substitute in many fields of use.

Key Properties at a Glance:

- Density: Approximately 1.18 g/cm³ (significantly lighter than glass)

- Impact Strength: 6 to 17 times greater than regular glass

- Melting Temperature: Around 160°C (320°F)

- Light Transmission: 92% of visible light

This set of characteristics truly makes acrylic on-demand a standout in many precision, durable, and aesthetically pleasing industries.

How Acrylic is Made: The Role of Methyl Methacrylate

The manufacture of acrylic basically begins with MMA, a transparent liquid considered the principal monomer. Polymerization is the process by which MMA is turned into PMMA, the actual technical name for acrylic. This is typically a free radical polymerization process, in which an initiator, such as a peroxide, causes a reaction that links the MMA molecules into a chain of molecules.

The production process of acrylic in modern high-side factories combines the polymerization of bulk and suspension methods with fine details to achieve the desired characteristics of the final product. Bulk polymerization is used for the manufacture of consistently sized transparent sheets, whereas suspension polymerization produces granules or beads. Such performing methods make sure that acrylic enjoys the beneficial properties, which include fantastic clarity and strength. Modern formulas provide the necessary stabilization and cross-linking agents to combat UV radiation, as well as thermal degradation and mechanical wear, thereby imparting the end product with the hardness required in the highly competitive world of construction, extending to the medical device field.

Acrylic vs. Other Plastics: Main Points of Differentiation

Also referred to by chemists as polymethyl methacrylate (PMMA), acrylic differs from other plastics such as polycarbonate, polyethylene, and polystyrene due to its unique ability to combine optical clarity with durability and versatility. It passes more light than does glass, which is another defining property; in fact, it allows 92% of visible light to pass through! Polycarbonate is considered highly impact-resistant, but it will yellow with age. In contrast, acrylic remains clear and is more resistant to scratches without requiring a hard coat.

The opposite, or contrasting nature of thermal resistance, aids acrylic’s distinctiveness. Acrylic can sustain moderate temperatures (generally up to 160°F for continuous use), but polycarbonate tolerates higher temperatures better. Hence, applications demanding clarity and rigidity under moderate conditions rely on acrylic, whereas performance-oriented applications employ polycarbonate. On the other hand, acrylics are inherently UV resistant, even more so than polyethylene and polypropylene. This gives the acrylic an advantage in old-world applications and architecture, such as signage and skylights, where significant breakdown would not occur.

On the machinability and finishing side, acrylic takes the lead. Whatever can be asked of it —cutting, molding, polishing —to bring it to precise dimensions and finish, acrylic performs well. With other plastics, such as polystyrene or polyethylene, having a reputation for being brittle or deforming during processing, acrylic stands out against them. After retaining a tensile strength that provides a firm structural alternative, it is also lightweight compared to glass. Lastly, having been recycled and available in a recycled form, acrylic is increasingly becoming a conscious and gentle choice in today’s eco-friendly manufacturing.

Types of Acrylic and Their Applications

Common Types of Acrylic Plastic

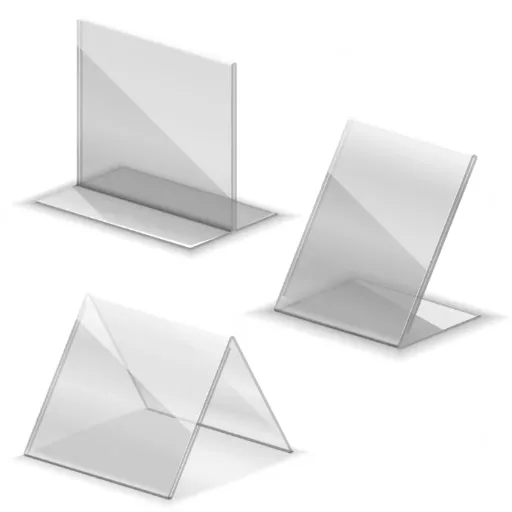

1. Cast Acrylic

The production of cast acrylic involves pouring liquid acrylic into moulds, thus yielding a variety of thicknesses and dimensions. Essentially, this process produces a sturdy material with excellent optical clarity, making it particularly suitable for applications such as display cases, aquariums, and signage. Furthermore, cast acrylic offers higher resistance to abrasion and corrosion, which enhances its longevity in both indoor and outdoor applications. Cast acrylic is easily machined, laser-cut, and thermoformed; therefore, it is ideal for designs requiring complex shapes.

2. Extruded Acrylic

Extruded acrylic is produced by pushing pellets through a mold to create sheets with uniform thicknesses at a significantly lower manufacturing cost. Slightly less durable than cast acrylic, extruded acrylic is less expensive and easier to cut; therefore, it is often used for point-of-sale displays, poster frames, and glazing applications. The melting point is lower for extruded acrylic, which means it is easier to thermoform, but sometimes renders it less useful for high-heat applications.

3. Impact-Modified Acrylic

Impact-modified acrylic is designed to enhance toughness by incorporating elastic polymer additives, which significantly increase its impact resistance. This material is best suited for situations requiring greater durability and shatter resistance, as well as ultraprotective barriers, automotive, and transportation-type applications. The addition of polymers to improve toughness does not compromise this acrylic’s lightweight nature and visually appealing appearance.

4. UV-Resistant Acrylic

UV-resistant acrylic is specifically designed to withstand prolonged exposure to daylight and ultraviolet radiation without degrading or discoloring. This allows the acrylic to be ideally used outdoors for architectural glazing, exterior signage, and greenhouses. Due to its resistance to UV damage, this acrylic maintains optical clarity and structural integrity for an extended period without requiring high levels of maintenance, thereby providing it with an extended lifespan even when exposed to harsh environments.

These various acrylics differ in their characteristics; thus, manufacturers and designers select the one that suits their exact needs, ensuring perfect performance and a competitive cost in any application.

Acrylics in Use in Daily Life

Due to their versatility, firmness, and inexpensive characteristics, acrylics have become relatively commonplace. One of their big applications is in household articles such as furniture and interior decoration. They are used to fabricate lightweight, shatterproof alternatives to glass, such as glass tops, shelves, and display cases. Its crystal clarity and colors, ranging from transparent to very subtle to somewhat conspicuous, present an aesthetic choice that complements either modern or older designs.

Yet another section that is very much used is oriented toward automotive manufacturing. Transparent acrylic sheets are used for crafting automobile windows, sunroofs, and light covers because of their impact resistance and high optical transparency. This resinous material ensures higher safety while maintaining lightweight properties, much needed for improving the fuel efficiency of vehicles.

In the application for medical equipment and apparatus, another high-use area is identified. Due to acrylic being non-toxic and highly biocompatible, incubators, protective barriers, and components for diagnostic machines are fabricated from it. Such properties ensure that acrylic is suitable and safe for use in environments that demand sterile conditions.

Acrylic materials also play a significant role in advertising and retail. Acrylic sheets are primarily used for signage, point-of-sale displays, and promotional stands because they hold colors brilliantly, ensuring they do not fade in sunlight over time.

Further advancements in acrylic technology have expanded its use, enabling better thermal performance, increased resistance to scratches, and a certain level of environmental friendliness. From providing functional solutions to enabling creative designs, the acrylic materials are everywhere, performing some kind of vital function across industries.

Acrylic Sheets Vs. Polycarbonate: Which One is Better?

A comparison of acrylic and polycarbonate sheeting necessitates an evaluation of their properties in terms of demanding performance criteria, application perspectives, and economic value. Acrylic sheets are the best in clarity, transmitting approximately 92% of light, which is more than that of almost any other plastic. They are light, practically impervious to UV radiation, and have excellent visual aesthetics. On the contrary, acrylic is more rigid and somewhat easier to crack or even shatter under high-impact load conditions.

Polycarbonate, in contrast, is the highest-grade thermoplastic, boasting nearly 250 times the shock resistance of glass, making it particularly suitable for glazing safety, machine guards, and barriers. Additionally, it has higher thermal resistance and can withstand temperatures between -40°F and 280°F without any deformation, whereas acrylic has a much lower temperature tolerance. For all its perks, polycarbonate scratches more easily and is less UV-resistant without coatings.

| Property | Acrylic | Polycarbonate |

|---|---|---|

| Light Transmission | ~92% | ~88% |

| Impact Resistance | Moderate | 250x stronger than glass |

| UV Resistance | Excellent (naturally) | Requires coating |

| Scratch Resistance | Better | Lower |

| Temperature Range | Up to 160°F | -40°F to 280°F |

| Cost | More affordable | Higher |

Due to economic reasons, acrylic is cheaper than polycarbonate, making it an option for those selling on a tight budget, where high durability is not a priority. To discern which is better, it mainly depends on the application’s needs, considering environmental factors, exposure considerations, and expected lifespan.

Properties of Acrylic Material

Physical Properties of Acrylic

Acrylics, also known as polymethyl methacrylates (PMMA), are famous for their transparency and are light-fast thermoplastics. The density of these plastics varies from 1.17 to 1.20 g/cm³. This makes them slightly lighter than glass but comparable in transparency, allowing nearly 92% of visible light to pass through. Acrylic exhibits excellent weather resistance, particularly in terms of tear and abrasion resistance, and maintains its appearance and integrity over a prolonged period of exposure to UV radiation and various environmental conditions. However, UV-stabilized grades are commercially available for greater durability.

| Physical Property | Value/Range |

|---|---|

| Density | 1.17 – 1.20 g/cm³ |

| Tensile Strength | 6,000 – 10,000 psi |

| Impact Strength vs. Glass | 6-17 times greater |

| Melting Point | ~160°C (320°F) |

| Thermal Conductivity | 0.19 W/m·K |

| Light Transmission | ~92% |

Depending upon the mechanical action used, Acrylic may display a tensile strength in the range of 6,000 to 10,000 psi, thus allowing it to resist medium mechanical stress. Although its impact strength is inferior to that of polycarbonate, it is still far superior to that of conventional glass, being 6-17 times greater. The material melts at approximately 160°C (320°F) and has a thermal conductivity of 0.19 W/m·K, thus functioning well as an insulator in specific settings.

⚠️ Important Note: The other side of the advantage is that acrylics can easily get scratched if not shielded by a protective coating. Otherwise, being a brittle material, it is particularly susceptible to crack propagation under stress. This makes it suitable, on the other hand, in applications where optical performance, low weight, and moderate durability are essential requirements, such as lighting, display cases, and glazing panels.

Advantages of Using Acrylic in Several Industries

With the combination of properties it offers, acrylic provides a competitive edge across various industries and stands as a winning choice for crafts that combine both form and function.

🏗️ Construction and Architecture

Being lightweight and able to transmit light up to 92% in clear grades, acrylic sheets are used for construction purposes. This high clarity makes it perfect for daylighting purposes, such as skylights, windows, or partitions. Apart from this, weather resistance adds longevity to any outdoor construction; therefore, it is an essential feature, especially in modern architectural expressions, as acrylic is resistant to UV and does not discolor.

🚗 Automotive

Automotive use of acrylics includes headlights, taillights, and interior components. Acrylic can be molded into complex shapes, thus allowing designs that would otherwise be impossible to create. Additionally, they feature scratch-resistant coatings that enhance performance and durability in various environmental conditions. Another factor in favor of acrylic contributing to fuel efficiency is its lightweight nature, which lowers the vehicle’s weight.

⚕️ Medical Sector

Acrylic is a vital material for the manufacture of medical devices and laboratory equipment, maintaining key attributes such as clarity, chemical stability, and compatibility with sterilization processes. For example, it is often used in the enclosure of medical instruments and as a protective barrier. Other applications about biocompatibility include dental prostheses and orthopedic implants.

🛍️ Retail and Displays

The optical clarity of acrylic, combined with its ability to withstand wear and tear, is beneficial in retail environments. Signage, consumer product displays, and protective screens are hence great Acrylic applications. It is color-customizable and resistant to yellowing when exposed to artificial light for long periods. This gives products a long-lasting visual appeal.

✈️ Aerospace and Aviation

The aerospace sector is a major consumer of acrylic materials, particularly for aircraft windows and canopy glazing, due to their ability to resist impacts, light weight, and excellent optical transparency under various atmospheric pressures. Acrylics procured for this purpose also have higher flame retardancy, making them safer.

☀️ Renewable Energy Industry

Acrylic is often used in solar applications as protective covers for photovoltaic cells, protecting high-level light transmission and enhancing weather resistance. It ensures maximum light absorption for energy conversion and provides strong protection for prolonged use.

In different industrial sectors, acrylic technology innovations are making possible a highly superior range of applications that require specialized treatment. They drive efficiency and innovation in specialized applications offered to various industrial sectors.

Durability and Sustainability of Acrylic Plastic

This acrylic plastic is highly durable and hence best suited for cases where the outside environment is severe. It resists rays, and therefore it will never yellow, degrade, or turn brittle with age, even when subjected to hours of sunlight throughout the day. It is physically more resistant to impact, 17 times the full strength of commonly tempered glass, which means it can sustain a significant pressure without breaking, and this significantly reduces replacement and maintenance costs.

♻️ Sustainability Highlights:

- Acrylic is 100% recyclable

- Chemical structure enables breakdown and reuse in new acrylic sheets

- Exemplifies the circular economy approach

- New manufacturing techniques minimize energy use and emissions

- Gradual improvement in recycling technologies and infrastructure

Sustainability considerations for acrylic have also experienced an upward trend in recent times. New manufacturing techniques have transformed production processes to minimize energy use and emissions. Additionally, acrylic is 100 percent recyclable. The chemical structure enables it to break down and be utilized in the production of new acrylic sheets, exemplifying the circular economy. Although environmental challenges surround plastics at the end of their lifecycle, on-the-fly technologies and infrastructure are gradually improving the recycling possibilities for acrylic, and therefore further cement the notion of acrylics as a long-standing, resilient material that is also becoming more sustainable.

Common Questions About Acrylic

Is Plexiglass the Same as Acrylic?

Plexiglass, being a trademarked name, refers to a specific type of acrylic material, but the terms are often confused. More accurately, Plexiglass is commonly used to refer to polymethyl methacrylate (PMMA), also known as acrylic, which is the transparent thermoplastic acrylic used for many applications. Acrylic is a broad category that encompasses PMMA materials produced by various companies under different brand names, including Plexiglass, Lucite, and Acrylite. These brand materials are chemically indistinguishable but can vary in manufacturing process and quality control and specific performance characteristics targeted toward a particular application. For example, one manufacturer may have a formulation with enhanced UV resistance, while another might focus its enhancements on impact strength or on optical clarity.

Can Acrylic be Recycled?

Being chemically called polymethyl methacrylate (PMMA), acrylics can be recycled in theory but may present more difficulties than the conventional “hard” plastics such as PET or HDPE. Recycling acrylic primarily involves chemical depolymerization, a process that converts acrylics into their basic ingredients, such as methyl methacrylate (MMA). These reclaimed monomers are then disinfected and repolymerized into acrylic products, with properties identical to those of virgin materials.

Current Challenge: In comparison to more popular plastics, however, the recycling infrastructure for acrylic remains scarce. This leads to a situation in which, in typical municipal programs, acrylic waste is generally classified as non-recyclable, as there is no suitable plant that can process it.

However, with the recent improvements in recycling technologies, more efficient recovery systems for MMA are developed, and some manufacturers are making use of recycled acrylic for their production.

Energy Savings: Standards say, if you recycle PMMA, there is an energy saving of about 70%, thus offering significant sustainability advantages.

For recycling to be efficient, acrylic items shall be collected separately alongside plastics and forwarded to depolymerization facilities. Increasing awareness about proper disposal and investing in recycling technologies is crucial to the widespread and meaningful impact of acrylic recycling.

What are the Limitations of Acrylic Materials?

Several limitations exist regarding acrylic materials, which render applications more complicated in terms of the beneficial properties of this material:

❌ Scratch Susceptibility

Firstly, acrylic is more durable and impact-resistant than glass; however, it falls short in terms of scratching and abrasion resistance. Thus, in applications where materials are subject to frequent handling or abrasive wear, acrylic will require coating or should be handled with care.

🌡️ Limited Heat Resistance

Another thing to remember is that acrylic typically does not exhibit high heat resistance, with a maximum service temperature that ranges between 80°C and 100°C, depending on the specific formulation used. Prolonged exposure to heat can lead to deformation, discoloration, or structural failure; therefore, acrylic should not be used in high-temperature environments.

☀️ Long-term Environmental Exposure

Other drawbacks are the durability aspects. Although acrylic remains weather-resistant and UV-stable to some extent, prolonged exposure to sunlight, harsh environmental conditions, or extreme temperatures can cause yellowing or brittleness over time. In outdoor applications, maintenance or replacement can be required to avoid this.

♻️ Recycling Challenges

While acrylic, being recyclable, is ideal from a sustainability perspective, the recycling process is complex and requires specialized facilities. Currently, with no widely spread infrastructure capable of acrylic recycling, the potential of acrylic to be a truly circular product is limited. Improper disposal, conversely, results in the accumulation of acrylic plastic waste, which persists for longer periods in landfills due to its non-biodegradable nature.

🏭 Manufacturing Environmental Impact

Lastly, the manufacture of acrylic requires synthetic petroleum-derived chemicals that deplete resources and emit greenhouse gases. These environmental costs call for the development of greener alternatives or improved production methods.

Being aware of these limitations will help in selecting materials whose specific applications align with their sustainability goals.

Where to Find Acrylic and Its Variants

Acrylic Sheet: Sizes and Thickness Available

When it comes to acrylic sheets, a wide range of sizes and thicknesses is available, depending on the specific application requirements. Typical sizes for acrylic sheets fall within, say, 48 x 96 inches (4 x 8 feet) or 48 x 120 inches (4 x 10 feet); however, they can often be fabricated to custom dimensions to suit specific project requirements. Pre-cut sheets, such as those measuring 12 x 24 inches or 24 x 24 inches, are considered common. These sheets are then available for cutting and trimming by manufacturers or end users to specific lengths.

| Thickness | Common Applications |

|---|---|

| 1/16″ – 3/16″ | Lightweight applications: photo frames, signs |

| 1/4″ – 3/8″ | Medium applications: displays, protective barriers |

| 1/2″ – 3/4″ | Heavy-duty: aquariums, architectural glazing, furniture |

| 1″ and greater | Industrial and high-performance applications |

Thickness options typically range from 1/16 inch (0.0625 inches) to 1 inch or greater, with variations that cater to the demands of both structural and aesthetic requirements. Lighter applications are well-suited for amounts that lean toward the thinner end of the spectrum (1/8″ or 3/16″ thick); photo frames or signs are a couple of such examples. Heavier sheets, such as 1/2″ or 3/4″ thick, are considered best for bearing loads such as aquariums, architectural glazing, or furniture. The highly specialized dealers may even carry thicker cast acrylic sheets, measuring up to a few inches in thickness, for industrial or high-performance applications.

Since every manufacturer offers different sizing options and thicknesses, cast or extruded acrylic typically shares these standard dimensions with slight deviations depending on the properties. It is always worth consulting the supplier directly to see what dimensions or thicknesses they hold in stock or would be willing to manufacture to custom specifications so that the material fits perfectly with the type of application.

Where to Buy Acrylic Products

For sourcing acrylic goods, I generally initiate sourcing from specialized suppliers who have a significant reputation for providing the best materials for every application. TAP Plastics, Acrylic Depot, and Piedmont Plastics are most commonly recognized for their prominent inventory of both cast and extruded acrylic sheets, in various sizes, thicknesses, and finishes. Most suppliers on this list also offer custom cut, fabrication, and design services, making them best suited for specialized projects or industrial requirements. Alternatively, large home improvement stores like Home Depot and Lowe’s typically stock acrylic sheets in standard sizes, which are ideal for DIY or smaller projects.

🛒 Where to Purchase:

Specialized Suppliers:

- TAP Plastics

- Acrylic Depot

- Piedmont Plastics

Home Improvement Stores:

- Home Depot

- Lowe’s

Online Platforms:

- ePlastics

- Regal Plastics

- Interstate Plastics

- Amazon (with careful review verification)

For online purchases, platforms such as ePlastics, Regal Plastics, and Interstate Plastics offer a complete selection of acrylic products. These companies provide detailed product descriptions, technical specifications, and complete clarity about the material’s properties, enabling buyers to make informed decisions. One can also find acrylic sheets on Amazon and other e-commerce sites. Still, it is essential to carefully review product details and ratings to ensure quality, as sellers can vary significantly.

Ultimately, larger factory demands or bulk buying necessitate a direct approach to manufacturers or distributors. Many organizations, such as Evonik or Plaskolite, have various arrangements with retailers and distributors and might even sell directly to you or refer you to a reputable third party. By being aware of these sources, you can establish trust in the materials offered to you and ensure that they meet your project’s specific excellence specifications. Always verify the reputation of suppliers and check for reviews and certifications to ensure your guarantees against low-quality acrylics.

Custom Acrylic Solutions for Businesses

As a manufacturing concern, we specialize in intricate acrylic-related works that demand high precision and quality for various market applications. Acrylic is a very versatile and durable material; hence, its uses may vary from signage, tableaus, and display works to medical appliances and architectural works. Working from client requirements, we employ processes such as CNC machining, laser cutting, and thermoforming, while selecting and implementing acrylic solutions. The use of these technologies enables us to fabricate intricate designs while maintaining tight tolerances that meet the product’s aesthetic and functional requirements. For every application, we select the finest acrylic material, ensuring clarity, durability, and strength.

🔧 Custom Services Offered:

- CNC Machining – Precision cutting and shaping

- Laser Cutting – Intricate designs and patterns

- Thermoforming – Complex 3D shapes

- UV Bonding – Seamless joins

- Screen Printing – Custom graphics and text

- Custom Finishing – Polishing and coating

With a focus on customization and collaboration, the company encourages the creation of unique solutions for all its clients. For example, retail outlets get attractive point-of-sale displays, while the healthcare sector gets painstakingly engineered protective barriers and enclosures for their equipment. We focus on value-added services, including UV bonding, screen printing, and custom finishing, to provide a comprehensive turnkey solution. Sustainability is also in our DNA. Whether it’s recycled acrylic materials or efficient manufacturing processes, we explore ways to lessen our footprint and waste generation.

Working with a supplier who possesses expertise in acrylic fabrication will achieve better results. Our teams ensure that every project is approached technically with painstaking detail, fostering cooperation throughout all stages of design and delivery. Staying current with innovations in the field while adhering to strict quality standards throughout every stage enables us to provide companies with solutions that look splendid and can endure the demands of their environments.

Reference Sources

- Acme Plastics – What is Acrylic / Plexiglass?: Explains acrylic as a versatile plastic material, its properties, and its wide range of applications.

- Wikipedia – Poly(methyl methacrylate): Provides detailed information on PMMA, commonly known as acrylic, including its composition and uses as a thermoplastic.

- Sewport – What is Acrylic Fabric?: Discusses the composition of acrylic fibers and their applications in various industries.

- Click here to read more.

Frequently Asked Questions (FAQs)

❓ What is acrylic, and is acrylic made of plastic?

PMMA, Short for polymethyl methacrylate, is a thermoplastic material that is generally used as a lightweight and shatterproof substitute for glass. It is a synthetic resin made by polymerizing the monomer methyl methacrylate. Acrylic is a category of plastic with attributes that are very different from those of other types of plastic, in that they are… Although it is sometimes referred to as plastic, acrylic finds extensive use in various industries, including signs, display cases, and general glazing. It is the unrivaled choice for many industries due to its clarity and durability.

❓ What are some properties of acrylic versus other plastics?

Mechanically, acrylic has so many advantages that it is placed above other plastics. It offers tensile strength — in fact, when compared, it is much stronger than glass, thus rendering it excellent for resisting improper impact. Acrylic is obvious and transparent; in applications where aesthetics take precedence, it is therefore considered an ideal choice. Additionally, acrylic is resistant to certain chemicals and has high heat resistance; thus, it can be installed both indoors and outdoors. Being lightweight, it has gained acceptance in a diverse set of industries.

❓ What different forms are acrylic made in?

The various types of acrylic include cast acrylic and extruded acrylic. Cast acrylic sheets are known to have higher optical clarity and are usually bought in applications requiring high-quality visuals: display cases, signs, etc. On the other hand, extruded acrylic sheets are made through a different process, which usually makes them cheaper and more popular for larger projects. Both are highly versatile and can be easily fabricated, cut, and shaped to address specific needs in construction for numerous applications.

❓ What distinguishes acrylic from polycarbonate?

Both acrylic and polycarbonate are transparent plastics; however, specific characteristics distinguish them. Acrylic, also known as acrylic glass, is recognized for its excellent clarity and lightweight properties, making it a preferred choice in many cases as a shatter-resistant alternative to glass. Polycarbonate, on the other hand, wields massive impact strength–200 times stronger than glass, in fact! Compared to polycarbonate, acrylic is more susceptible to surface scratches, whereas polycarbonate resists impact but can be more costly. Operations commonly specify acrylic or polycarbonate, depending on the required strength, clarity, and cost.

❓ In what kinds of applications is acrylic used?

Due to its versatility, acrylic finds implementation within numerous industries. It is widely used in architectural applications, such as skylights and canopies, where clarity and durability are essential factors to consider. Other typical uses include display cases, signs, and lighting fixtures. The capability of molding and fabrication makes acrylic an ideal choice for custom products in commercial and residential settings. Another very different application of acrylic is in medical devices and automotive applications, further proving the diverse nature of this plastic.

❓ What are the thermal characteristics of acrylic?

The thermal properties of acrylic are noteworthy, as they resist variations in temperature without compromising their integrity. With its heat resistance, acrylic remains suitable for uses that will encounter exposure to higher temperatures. Acrylic, however, while being above-average in heat resistance when compared to plastics, would still undergo warping if exposed to significantly higher temperature levels over time. Considering the thermal limits, treating an acrylic product well aids the preservation of the quality and life of the product.