Choosing the right fabric for clothing, activewear, or upholstery often calls for a debate: polyamide or polyester. Both are synthetic and look alike, but they differ in nature and have entirely different uses. With today’s textile science shaping the modern fabric performance in 2025, the differences in fabrics have become crucial. This guide aims to examine the unique characteristics of polyamide and polyester, comparing their durability, comfort, day-to-day suitability, and environmental impacts. Whether you are a designer, a backpacker, or simply someone interested in selecting suitable fabric for your daily use, this blog will empower you with the knowledge to decide which fabric better suits your needs. Let’s walk through the finer drawbacks and find out which one better suits your individual needs.

Understanding Polyamide and Polyester

What is the Polyester Fabric?

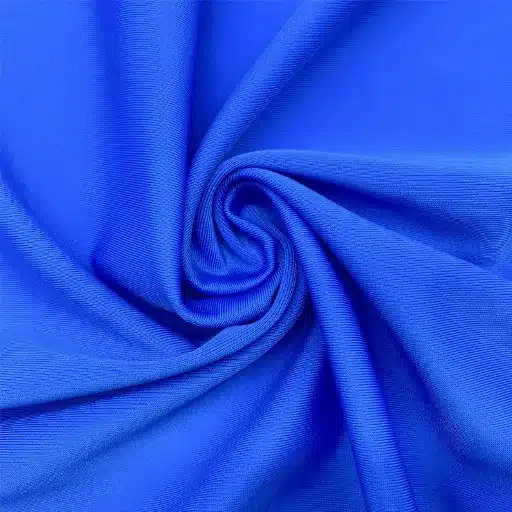

Polyester is a class of synthetic fabric, most often made from polyester, formed from petroleum-based polymers, although sometimes also from polyethylene terephthalate polymers. A vinyl plastic material, it is made via a polycondensation reaction that occurs when ethylene glycol and terephthalic acid come into contact. These fibers are robust and lightweight and may be woven or knitted into all forms of textile. Being strong, they ensure that the polyester fabrics do not stretch, shrink, or wrinkle, and hence serve best for activewear, outerwear, and furnishings.

Due to its hydrophobic nature, polyester repels moisture; thus, its quick-drying properties make it suitable for sports and outdoor activities. Furthermore, with advancements in textile technology, recycled polyester —an environmentally friendly option made from post-consumer PET bottles —has emerged, thereby overcoming sustainability-related issues. Yet, polyester is not devoid of disadvantages; for instance, it is less breathable to some extent compared to natural fabrics, and it also raises environmental concerns about microplastic shedding with every wash.

What is Polyamide Fabric?

Polyamide, also known as nylon, is a synthetic polymer widely considered the textile industry’s choice due to its extraordinary strength and durability, along with high flexibility and elasticity. It was first developed as an alternative to silk. Polyamides are synthesized by the polymerization of monomers, such as adipic acid and hexamethylenediamine, into a highly versatile material. This polymer is considered lightweight and abrasion-resistant, with the added benefit of quick-drying. Hence, it lends itself well to applications in activewear, swimwear, and outdoor gear.

Polyamide fabric exhibits excellent wear and tear resistance, with tensile strength characteristics superior to those of many natural fibers. Its moisture absorption is very low, allowing it to retain its shape well and perform effectively in humid conditions. Conversely, since polyamides are thermoplastics, they deform easily when subjected to high-temperature conditions. More recently, polyamide production has seen research into bio-based and recyclable alternatives, thereby addressing environmental sustainability concerns associated with its conventional manufacturing process. It is these developments that try to keep the performance advantage of polyamide while reducing its ecological footprint.

Key Differences Between Polyamide and Polyester

Polyamide and polyester are two widely used synthetic polymers that vary distinctly in their properties, applications, and performance characteristics.

Chemical Composition and Structure

Polyamides are primarily derived from polymerized amides, with repeating units linked by amide bonds (-CONH-). These amide groups strongly contribute to ensuring the material’s high strength and resistance to abrasion. Polyester, however, is composed of ester groups (-COO-) within its molecular structure. This renders the material hydrophobic and chemically resistant, but it lacks the elasticity exhibited by polyamides.

Moisture Absorption

Polyamides, such as nylons, are hygroscopic and can absorb a significant amount of moisture, up to 8-10% by weight, from the atmosphere. This can affect their strength and stiffness after some time. Polyester fibers have a low moisture regain (below 1%), which enables their use in water-resistant applications, such as outdoor apparel and swimwear.

Thermal Properties

Polyamide has a higher melting point, which would vary between 410°F (210°C) and 500°F (260°C), depending on its type. Polyester melts at a somewhat lower temperature, usually around 482°F (250°C). Both materials are typically considered mechanically durable, but polyamide resists heat more; therefore, it is utilized in specialty areas such as insulating cables or high-performance textiles.

Durability and Wear Resistance

While both types of material are believed to be strong, polyamide typically exceeds polyester in terms of tensile strength and abrasion resistance. It is usually considered the best choice for industrial applications where good flexibility and abrasion resistance are required. In contrast, polyester, although slightly less intense, is best suited for UV and weather resistance applications, typically used outdoors.

Environmental Impacts

The conventional production of polyamide is based on petrochemicals; however, more recently, bio-based nylon derived from renewable resources has been developed to address specific sustainability concerns. Polyester production, again heavily dependent on petrochemicals, has been relatively developed with recycling technologies, including those that give rPET. Currently, polyester is more widely recycled than polyamide, which creates a stronger emphasis on its circular economy opportunities.

Applications

Polyamide, being extremely abrasion-resistant and strong, is used for various purposes, such as carpets, airbags, and industrial fibers. Polyester is excellent for moisture resistance and fast drying; therefore, it is widely used in activewear, outdoor gear, and automotive upholstery.

Ultimately, the choice between polyamide and polyester depends mainly on the intended application and the associated performance characteristics expected. Alternative factors related to sustainability are becoming increasingly important considerations in selecting a material.

Comparing Polyester vs Polyamide

Durability and Abrasion Resistance

Polyamide has been considered a strong material with high durability and resistance to abrasion under specific conditions, making it a preferred choice for applications that require strength. Its molecular structure, consisting of strong polyamide chains, accounts for its ability to resist wear when subjected to repeated stress and friction. This ability is essential, as heavy fabrics, ropes, or tires are some products where mechanical forces are involved, requiring utmost consideration.

Polyester tends to abrade a bit less than polyamide. From this characteristic, polyester is said to be stretch-resistant and shrink-resistant by nature. With this polymer property, polyester is better suited to applications where shape retention under continuous strain is desired, such as upholstery or sportswear. Studies report that polyamide performs better in areas of high friction, while polyester is superior for moderate abrasion levels, with more retention in dimensional stability.

Both are also supplemented by additional coatings and treatments, such as polyurethane coatings or plasma treatment, to enhance their wear resistance further. This advancement makes both polyamide and polyester versatile and functional across a wide range of durability-specific applications.

Moisture Control in Fabrics

Moisture management is a crucial issue in contemporary garment engineering, particularly for activewear and outdoor gear. A fabric can perform moisture management by transferring sweat or liquid through the skin either by absorption, wicking, or evaporation. For instance, hydrophilic fabrics, such as cotton, absorb moisture but can retain it within their structure for some time, thus becoming irritating when worn for extended periods. However, synthetic fabrics such as polyester and nylon are generally treated with special finishes to provide them with greater wicking properties, which draw sweat from the skin and allow it to dry quickly within the fabric.

Advanced Moisture Technologies

In recent times, microchannel fibers and nanocoatings have been introduced to promote capillary action within these fabrics, thereby increasing moisture transfer through the interface. By way of illustration, advanced wicking technologies are capable of moving moisture at rates exceeding 0.2 g per minute per square inch of fabric, thereby surpassing the transferring capacity of traditional fabrics.

Furthermore, the dual-layered fabrics have one layer that is hydrophobic and the other that is hydrophilic, ensuring that sweat is channeled outward while the wearer feels dry inside. In combination, these technologies enhance wearer comfort and thermal regulation, particularly in high-performance settings, where breathability and the shortest drying time of a fabric serve as key criteria for selection.

Environmental Impact of Polyesters and Polyamides

Polyester and polyamide fabrics rank among the most polluting synthetic fibers due to their production-based emissions and the lifestyle associated with these fabrics. The manufacturing processes are highly dependent on non-renewable resources, such as crude oil, releasing significant amounts of greenhouse gases during polymerization and processing, both of which are energy-intensive. For example, the manufacture of polyester releases an estimated 9.52 kg of CO2 for every kilogram of fiber produced.

Microplastic Pollution

Second, this also marks them as key brands contributing to microplastic pollution. Polyester and polyamide garments emit microfibers into the wastewater during washing, which then infiltrate the aquatic environment. According to the literature, hundreds of thousands of microfibers can be released from a single load of laundry. Microfibers never biodegrade but continue to accumulate in the environment, eventually entering the food chain to the detriment of both aquatic life and humans.

Polyester and polyamide are facing end-of-life problems due to their non-biodegradable nature. Garments made of such fibers can last in landfills for many decades or even centuries without degrading. Sufficient concern has led to innovations such as increased recycling of polyester, including rPET and polyamide from post-consumer waste, thereby reducing the use of virgin petrochemicals and lowering carbon emissions. These solutions, however, resolve only one part of the issue, as the recycling process can be energy-intensive and cannot yet fully prevent the shedding of microfibers.

The environmental effect of these fibers thus calls for the development of sustainable alternatives, recycling technologies, and responsible consumption to lessen their ecological footprint.

Sustainable Choices: Recycled Polyester and Polyamide

Advantages of Using Recycled Polyester

Post-consumer PET bottles and discarded textiles are recycled into polyester, which can be a more sustainable alternative to virgin polyester for reasons including reduced fossil fuel dependency. Manufacturing recycled polyester consumes 59% less energy compared to its virgin counterpart and reduces greenhouse gas emissions by approximately 32%. It also reduces waste accumulation altogether, diverting thousands of tons of plastic materials from landfills and waterways year after year.

The material offers high durability and maintains the performance attributes of virgin polyester, such as tensile strength, wetting ability, resistance to wrinkles, and shrinkage. This makes it a highly flexible product with applications from apparel and outdoor gear to interior furnishings.

With the incorporation of recycled polyester, industries can thus advance the circular economy; materials are cycled through reuse, further repurposing, rather than being sent to landfills. However, there are some challenges: energy use in recycling, which is yet another aspect of environmental release, and microfiber release. Textile production and waste-management processes are constantly evolving and thus have significant prospects for further reducing ecological burdens. Up-scaling the use of recycled polyester is therefore a significant step toward sustainable production and consumption.

Researching Recycled Polyamide Options

Recycled polyamide is typically manufactured from pre-consumer or post-consumer synthetic waste materials, including fishing nets, carpets, and industrial scraps. It can be used as an alternative to virgin polyamide in sustainable material solutions that promote environmental improvement. First, these waste materials are collected and cleaned; then they are thermally depolymerized into monomers, and finally, they are repolymerized into high-quality polyamide fibers. Therefore, this closed-loop cycle significantly reduces the consumption of fossil-based raw materials and lowers the emission of greenhouse gases during its production.

It is interesting to note that recycled polyamide yields a 50% energy savings compared to virgin polyamide, accompanied by a reduction in water usage and waste generation. Advances in recycling technology have now made it possible to manufacture recycled polyamide with properties that are almost equivalent to those of virgin polyamide, including wrinkle resistance, durability, elasticity, and moisture-wicking capabilities, which are critical for various uses in the apparel, automotive, and industrial sectors.

The challenge now lies in maintaining feedstock quality without being priced out of viability due to contamination and poor sorting with subsequent effects on recycling rates. Establishing large-scale, practical tools for recovery and processing, as well as effective schemes to increase industrial uptake, will go a long way in realizing the potential of recycled polyamide as a sustainable option in the circular economy.

Instruction for Selecting Sustainable Fabrics

Sustainable fabrics should be evaluated for their environmental impact throughout all stages of the material’s lifecycle, from production to use and disposal. Priority should be given to fabrics produced from renewable resources, such as organic cotton, hemp, or bamboo. These are grown with less pesticide and water use. Materials like Tencel (a fabric made from sustainably harvested wood pulp) and recycled polyester minimize the further extraction of resources and reduce waste. LCAs provide essential data, including carbon emissions, water usage, and energy efficiency, associated with fabric production.

- 📋 The processing stage must also be considered, because specific, reasonably renewable materials might require such heavy chemical treatments as to annul any environmental benefit.

- 🏆 A certification, such as the Global Organic Textile Standard (GOTS), OEKO-TEX, or bluesign, is regarded as an authoritative sign of compliance with sustainability and toxicity standards.

- 💪 Use and consumer durability are important: fabrics designed to last and be reused require less frequent replacement, resulting in a lower environmental impact.

- ♻️ Finally, ensure that end-of-life scenarios for the fabrics—either biodegradability or recyclability —are compatible with sustainable waste management systems, so that the cycle becomes fully closed in the circular economy.

Applications and Uses of Polyester and Polyamide

Textile Applications for Polyester

Being endowed with properties such as strength, amenability, and economy, polyester is considered one of the most versatile and widely used synthetic fibers in the textile industry. In clothing production, especially in activewear, polyester plays a crucial role, as activewear fabrics are designed with sweat and moisture management in mind, being lightweight and resistant to wrinkling and shrinking. Its hydrophobic quality makes it an engineering choice where evaporation and quick drying of sweat are concerned.

Polyester is widely used in home textiles, including upholstery, curtains, and bedding. Its tensile strength and weather resistance make it suitable for long-term applications. It is used industrially in the production of ropes, conveyor belts, and geotextiles due to its high tensile strength and resistance to abrasion.

The newer polyester blends, made with natural fibers such as cotton, bring comfort and breathability to complement the looks, while retaining the strength from the synthetic side. It is a testament to the flexibility of polyester, which can meet consumer demands in all functional areas.

Applications of Polyamide in Textiles

Polyamide, commonly referred to as nylon due to its alpine nature, finds wide application in textile production owing to its high strength, elongation, and wear resistance. These very attributes, accompanied by low moisture absorption and resistance to chemical and physical wear, make it an attractive material for applications where high-performance materials are required. A characteristic example is activewear and sports apparel made from polyamide fabrics, where moisture-wicking properties combine with stretch and tensile strength to ensure the fabrics retain their properties even under strenuous wear.

Intrinsically lightweight and resistant to abrasion, polyamide finds numerous applications in technical textiles, such as parachutes, tents, and industrial nets. The high-end generation of polyamide fibers has also led to the formation of very fine microfibers, which impart an enhanced feel and breathability to various fabrics, providing flexibility for luxurious textile fabrication in the fashion sub-industry.

Combined with environmentally conscious aspects, such as recycled polyamide, these developments demonstrate that the textile industry has adopted polyamide as a functional and ecological solution.

Selecting the Right Fabric for Your Project

Choosing the right fabric for a project depends on the application and specific characteristics of the material. Resistance, stretch, permeability to air, and resistance to external factors should be the primary considerations. For high-performance applications, such as making outdoor equipment and activewear, polyester or polyamide fabrics are considered best because of their tensile strength, moisture absorption, and wear resistance properties. Cotton remains a popular choice for informal and everyday use, favored for its softness and breathable feel that mimics the natural feel of the outdoors.

Technical considerations reach into fabric weight and weave. Lightweight woven fabrics may be favorable for projects that emphasize flexibility and comfort, especially when aiming to achieve a good drape. A heavier weave or fabric may be more suitable for applications where insulation or structural integrity against the elements is required, such as winter apparel or industrial covers. The sustainable options, such as organic cotton, bamboo fabric, or recycled polyamide, will bring ecological consciousness to the forefront for projects that consider environmental impact.

A fabric selection is made after considering additional criteria through testing; GSM (grams per square meter), thread count, and finish properties such as water repellency or flame resistance will all be taken into account for a fabric. By matching the qualities of the fabric to the functional and aesthetic needs of the setting, you achieve a project that is best designed to meet both performance and design considerations.

Conclusion: Which Fabric is Right for You?

Summary of Key Takeaways

When deciding which fabric best suits my needs, I must first consider the functional requirements of the project. This involves factors such as the GSM of a fabric, which relates to weight and durability; the thread count, which affects texture and strength; and any special finishing treatments that may be applied to enhance features like water repellency or flame resistance. These criteria ensure that a particular fabric meets the structural and practical requirements for its intended application, whether for interior design, apparel, or industrial use. Considering these technicalities, I will be empowered to make informed decisions that promote both capital performance and longevity.

As sustainability and environmental impact become increasingly important, the fabric selection process shifts accordingly. Next to technical parameters, she should consider the production process of certain fabrics, scrutinizing their environmental impact and adherence to recognized ecologically responsible practices. This would include using recycled materials or dyeing with a low environmental impact. Suppliers who offer full disclosure on their sourcing and manufacturing practices help in making ethical, sustainable decisions. The fabric selection is not about compromise—it is about finding the right balance between technical perfection and environmentally conscious manufacturing for an object worthy of both technical excellence and forward thinking.

Final Words on Polyester versus Polyamide

Polyester Advantages

A comprehensive study of polyester and polyamide reveals that both materials have distinct advantages and considerations, depending on their intended applications. Polyester will excel in durability and usefulness in outdoor applications, activewear, and other items exposed to sunlight and water, thanks to its improved resistance to UV rays and moisture. It is said to be the lightest, fastest-drying, and most cost-effective to manufacture; hence, polyester garners considerable consideration in multiple industries.

Polyamide Strengths

On the other hand, polyamide (more popularly known as nylon) excels in strength and elasticity. Being more abrasion-resistant and having a smoother texture, it suits products that are subject to wear and tear for many years, such as hosiery, backpacks, and technical textiles. Additionally, its impact resistance is of interest for functional applications, while its soft feel is favored for comfort applications.

However, polyamide is more susceptible to UV degradation and tends to absorb moisture, which can compromise its performance. Additionally, the production costs are high and should be considered before deciding on polyester.

Ultimately, polyester or polyamide may not be considered the better option; rather, the determination depends on their applicability to the project’s or product’s requirements. A slight understanding of the differences in performance between the two would enable me to assess more accurately which of the two fits better with the functional goals and the sustainability aspect of any application.

Fabric Technology: Wonder Trends!

Looking to the future, the fabric industry is undergoing a rapid evolution driven by innovations in materials science, sustainability initiatives, and the emergence of innovative technologies. The primary trend is the development of biodegradable and bio-based fabrics, replacing conventional synthetic materials that pollute the environment. Innovations in fabrics from algae, pineapple leaves, and mycelium, among others, are increasingly gaining ground as genuine contenders to petroleum-based textiles. Such materials are conceived with the end of life in mind, so they perform well but also biodegrade into nature, fulfilling the ever-increasing demands of the textile industry for circularity.

Smart Fabrics Revolution

Another significant trend is the rise of innovative fabrics, which merge textiles with technology to achieve greater functionality. Increasingly, garments are being made from conductive fibers and equipped with sensors to monitor health parameters, regulate thermal insulation, or provide haptic feedback. Industries in healthcare, sportswear, and military applications are ripe for such innovation. Real-time change fabrics capable of recording someone’s heart rate or body temperature could perhaps revolutionize preventive healthcare and performance optimization.

With the rise of sustainability, I am noticing developing trends of energy-efficient manufacturing and waterless dyeing techniques. They conserve dwindling natural resources and reduce the flow of harmful chemicals into the environment. Advances in nanotechnology and material engineering are enabling the production of more durable, lightweight, and efficient fabrics. In my opinion, these trends are inspiring and are crucial for reshaping the concept of textiles in a world that is increasingly aware of resources.

Reference Sources

- Polyamide vs polyester: differences and applications – Fulgar

- Nylon vs Polyester: Which Fabric is Best for Your Needs? – Arca Official

- Polyester vs Polyamide: Expert-Level Guide – Szoneier Fabrics

- Polyamide or Polyester: What is the Difference and Which – The Oversized Hoodie

- Recycled and Biodegradable Polyester and Polyamide – Fabric Sight

- Find more info now.

Frequently Asked Questions (FAQs)

What are the main discrepancies between polyamide and polyester?

Polyamide and polyester are both synthetic fibers, but they have distinct characteristics. The polyamide fibers, commonly referred to as nylon, offer high elasticity and abrasion resistance, making them suitable for use in activewear and outdoor gear. Polyester is typically more hydrophobic, repelling water and drying faster; hence, it has a broader range of applications, including athletic and casual clothing. Polyester also tends to be more economical compared to polyamide, which in turn affects consumer decisions. Choosing between these two fabrics depends on the purpose and properties wanted.

Environmental comparison: Polyester versus polyamide?

The environmental repercussions vary greatly between polyester and polyamide. Polyester is primarily formed from polyethylene terephthalate (PET), which can be recycled into rPET, thus contributing to waste reduction and diminishing the need for virgin materials. Polyamide production, on the other hand, usually entails more strenuous chemical processes and is hardly ever recycled, though recycled polyamide is now coming into the picture. Both textiles have a carbon footprint due to their synthetic nature; however, the increasing availability of so-called sustainable options should help offset this. The environmentally conscious consumer will undoubtedly opt for recycled polyester over the standard alternatives.

And now, is one better than the other for moisture management?

When it comes to moisture management, polyester outperforms polyamide. Being a hydrophobic fiber, polyester can draw moisture away from the skin, allowing individuals to stay dry and comfortable during physical activities; hence, polyester is primarily associated with sports and activewear. Polyamide, by absorbing more moisture, can still offer some breathable comfort, but it may remain wet for a longer period. Thus, in any activity where moisture is present, alcohol and polyester will be the first choices.

Are polyamide fibers more durable than polyester fabrics?

Due to their exceptional strength and resistance to abrasion, polyamide fibers are utilized in outdoor gear and heavy-duty apparel. Polyester, which provides its own strength and wear resistance, can lie lower in tensile strength when compared with polyamide, imparting further durability to any polyamide garment. Polyester offers better dimensional stability, as it resists shrinkage more effectively than polyamide, thereby maintaining its shape over time. Hence, the durability question between polyamide and polyester will largely depend on the application and wearing conditions.

Is polyester clothing recyclable?

Yes, indeed, polyester fabric can be recycled very well, especially if it has already been manufactured using recycled polyester. The process of recycling involves breaking the polyester fabric back into its polymer form, which can then be melted or spun into new fibers. This process reduces waste and the need for new raw materials, paving the way for sustainable production methods. However, despite all this good, polyester clothes are not equally polite in terms of fiber: when blended with other fibers, their recycling gets quite complicated. Customers aiming to reduce their environmental footprint should prefer purchasing garments carrying the logo 100% recycled polyester.

What advantages does recycled nylon bear over virgin polyamide?

In contrast to virgin polyamide, recycled nylon has many benefits. Firstly, the production of new synthetic fibers using recycled nylon will reduce environmental impact, as it utilizes materials already available, such as discarded fishing nets. It will not only reduce the amount of discarded waste but also conserve resources. Secondly, recycled nylon performs as well as its virgin counterpart in terms of elasticity and durability, making it suitable for high-performance applications. Thirdly and lastly, using recycled nylon is among those small changes that could help the eco-conscious textile industry, with the growing demand in sustainable textiles.