This plastic has been a life changer in countless aspects of modern life-from carrying purposes such as water bottles and food containers, to being an essential material in electronics and automotive parts. Due to its durability, high versatility, and lightweight nature, industries have evolved, and the convenience level has grown substantially for the end user. But as health and environmental concerns take center stage, safety considerations of polycarbonate plastic for regular consumer use are gaining notoriety. Is it truly safe for us to use it in our daily lives, or are there risks we should be aware of? This article presents a comprehensive overview of research findings, regulatory developments, and opinions from 2025, providing a balanced and thorough analysis. Whether you are a consumer with food safety concerns or a business operator seeking compliance information, this guide will equip you with all the information you need to make informed decisions about polycarbonate plastic.

Understanding Polycarbonate Plastic

What is Polycarbonate Plastic?

Polycarbonate plastic is a rigid, lightweight, and durable polymer compared to many others, with numerous industries utilizing it. It is a versatile thermoplastic material formed by the reaction of bisphenol A (BPA) and phosgene, possessing excellent qualities of impact resistance, heat resistance, and wear resistance over time. Due to its clarity and relatively good impact resistance, polycarbonate is often used for water bottles, food containers, spectacle lenses, certain automotive parts, and electronic casings.

Recent advancements have revealed additional applications for polycarbonate in sustainable contexts, including energy-efficient construction materials and recyclable consumer products. Concerns have been raised, however, regarding health hazards from BPA leaching in polycarbonate, particularly at high temperatures or under prolonged ultraviolet exposure. Regulatory activities and developments in BPA-free polycarbonate production are ongoing, aiming to create safer options for food-contact applications while retaining the strength and other technical features of this ubiquitous plastic, as recent studies in 2025 assert.

Most Common Uses of Polycarbonate Plastic

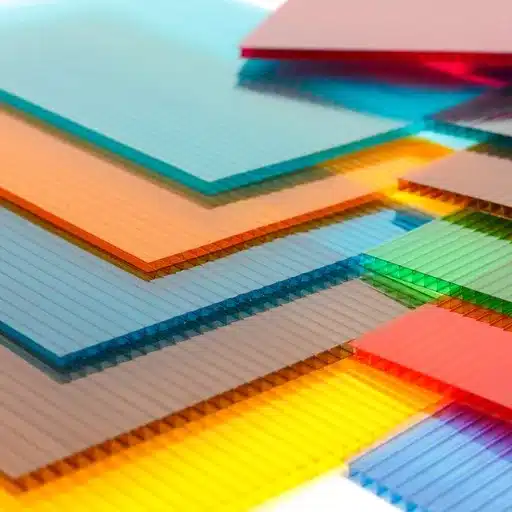

Polycarbonate plastics stand out for their unique combination of toughness, lightness, and optical clarity, making them well-suited for diverse industrial uses. It is widely used in high-end eyewear, providing impact resistance and ultraviolet protection to consumers for enhanced safety and comfort. It is used mainly in the automotive industry to manufacture headlights, window panels, and interior components, thereby enhancing vehicle safety and reducing weight, which in turn improves fuel efficiency.

The other renowned use is roofing, glazing, and sound barriers with polycarbonate sheets. The material is resistant to all forms of weathering, without yellowing or cracking, making it ideal for this application. Polycarbonate’s fire-resistant and shatterproof characteristics are utilized in safety gear, including riot shields, helmets, and protective barriers.

In the technology, electronics, and machinery sectors, polycarbonate is used to create rugged housings for smartphones, laptops, and other gadgets. Its insulating properties and resistance to heat help make it ideal for electrical use on items like circuit boards and lighting conduit. It is also being increasingly used in medical devices, as it allows sterilization with high impact strength without compromising performance.

Furthermore, with the current advances in BPA-free polycarbonate production, the material has seen increasing usage in the food-contact area. Polycarbonate products, including reusable water bottles, salad containers, and baby bottles, are now made with BPA-free variants for consumer safety. With all these uses, the material very well exemplifies versatility and, therefore, significantly contributes to the advancement and technology of design, safety across grades.

Characteristics of Polycarbonate Materials

Impact Resistance

The extraordinary polycarbonate is a unique amalgamation of properties that pique the interest of both industrial and consumer applications. Its most highlighted feature is resistance to impact with such force that it will bend, crack, or break, a defense it enjoys against any undue pressure.

Transparency & Weight

This strength is belied by its comparatively light weight, and it is more flexible than many heavier materials that may be used in its place. High transparency is perhaps yet another key trait of polycarbonate with light transmission comparable to that of glass.

Otherwise, the thermal properties of polycarbonate are outstanding; it can withstand deformation and breakage in extreme temperatures, whether high or low. Such strong thermos-resistant behavior is applicable for circumstances where temperatures fluctuate or are extreme.

There are BPA-free formulations of polycarbonates available, which, from a safety and sustainability standpoint, allay health concerns and promote green developments. Then there’s recyclability, on the other hand, a property that makes the material more attractive with rising environmental consciousness. Because of this, polycarbonate remains the preferred material in various industries that drive innovation and deliver effective solutions.

BPA: A Key Concern in Polycarbonate Products

What Is BPA and Where Can One Find It?

Bisphenol A, commonly referred to as BPA, is a chemical compound used in the manufacturing of some plastics and resins. It exists in polycarbonate plastics and epoxy resins, which are materials widely used in containers for food and beverages, such as water bottles, storage containers, and coatings inside metal cans. BPA is a blessing for making plastics sturdy, lightweight, and heat-resistant. From these attributes, its usage in various fields can be traced back for decades.

While this substance may not pose many primary health risks at the moment of contact with foodstuffs under high temperatures or extended storage times, health experts have become apprehensive due to the leaching effects of BPA. It is an endocrine disruptor: the chemical mimics estrogen in the body, leading to studies on exposure to it and addressing any potential health considerations concerning hormonal imbalance, reproductive problems, and development. To mitigate these risks, some manufacturers have switched to BPA-free alternatives, creating safer products without compromising the performance qualities required.

How Does BPA Affect Human Health?

Health studies concerning the possible damage to human health due to exposure to BPA have been numerous. It has been said that if BPA enters through food or beverage ingestion stored in BPA-containing materials, it may hamper the endocrine functions of the human body. This interruption occurs because the BPA is capable of either imitating or interfering with the action of natural hormones, especially regarding its estrogenic effects. And the disruption has been linked with a variety of health concerns, which include increased risks for breast and prostate cancers, metabolic disorders, and fertility issues.

⚠️ Special Concern: Vulnerable Populations

Children and infants are considered more susceptible to the effects of BPA due to their developing systems. Studies have even pointed out other potential associations of prenatal BPA exposure with developmental issues, such as attention-related behaviors and cognitive functions in children. Increasing BPA levels have also been linked to an increased risk of obesity and insulin resistance, thereby raising concerns about long-term metabolic health.

From a statistical viewpoint, many international regulatory agencies have established an acceptable maximum threshold of BPA in products to mitigate the risk. The FDA and EFSA, for example, continue assessing safe exposure levels to BPA as a means of protecting public health. The efforts of these bodies are aimed at reducing BPA in commonly used materials and encouraging personal awareness to avoid exposure whenever possible.

BPA Alternatives in Plastic Manufacturing

Safety concerns have triggered research and development into safer plastics, with alternatives engineered to consumer and regulatory specifications. Among them, Bisphenol S (BPS) remains the primary candidate, as other options have consistently been evaluated from the perspective of their similarity to BPA in chemical structure and manufacturing capabilities. Different options have become feasible due to the extensive questioning of BPS and its potential for endocrine activity; of these, polyether sulfone (PES) stands out as one with higher thermal and chemical resistance and is free from endocrine-disruptor risks.

| Alternative Material | Properties | Applications |

|---|---|---|

| Polyether Sulfone (PES) | High thermal & chemical resistance, endocrine-disruptor free | High-performance applications |

| Acrylic & Polyethylene | Durable, non-toxic | Food containers, water bottles |

| Polylactic Acid (PLA) | Bio-based, renewable resource derived | Sustainable packaging |

| Silicon & Glass Composites | Safety, durability | Reusable articles |

Science is rapidly developing in silicon and glass-based composites for reusable articles that offer safety and durability. The implementation of regulations and corporate initiatives encourages investors to invest in safer monomer and polymer blend production, which has a lower environmental impact. These alternatives further broaden the realm of choices available, thereby strengthening the commitment to consumer safety and environmental responsibility, rather than selling one side at the expense of the other’s product performance.

Polycarbonate in Food Contact Applications

Standards for the Safety of Food Contact Materials

A critical priority in food contact materials, such as polycarbonate, is ensuring the safety of these materials, which is governed by stringent regulations almost everywhere. Regulatory agencies, such as the U.S. Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA), ensure that these materials undergo a detailed evaluation regarding their composition, migration limits, and potential health effects. These regulations exist to ensure that no substances that could be detrimental to human health leach into food or beverages, thus protecting consumer health.

🔬 Regulatory Overview

A notable example is bisphenol A, which has been extensively studied because it is a key building block in polycarbonate production. Safety standards in the form of a specific migration limit (SML) have been set for BPA intended for food contact to reduce exposure. While the FDA maintains its position that BPA is safe at current exposure levels, EFSA is actively updating its guidance to incorporate new scientific data.

Likewise, many other regulations worldwide require compliance tests to be conducted under more realistic conditions, such as food type, temperature, and duration commensurate with actual use.

Alternatively, manufacturers may need to provide documentation, such as declarations of conformity, to meet safety requirements. Advanced analytical methods, such as chromatographic and mass spectrometric techniques, are used for trace chemical detection to determine if materials conform to prescribed limits. Such issues underscore the importance of maintaining transparency, scientific integrity, and alignment with international safety standards in polycarbonate applications.

Do Polycarbonate Products Contain BPA?

Polycarbonate is considered a rugged and lightweight material, widely used in various consumer products, including food containers, water bottles, and eyewear lenses. BPA is a chemical building block that has been questioned for potential health effects, particularly when large quantities are involved. In minor amounts, BPA can migrate from polycarbonate products in certain conditions, such as high temperature or prolonged exposure to acidic or basic substances.

According to current data, numerous industries have attempted to reduce or eliminate their use of BPA due to consumer demand and regulatory directives. The BPA-free alternatives are now widely available, allowing customers to select a product that aligns with their own principles and concerns. Scientific studies and regulatory assessments are consistent in questioning the risk potential of exposure in terms of limits to BPA, with safety measures aimed at limiting any possible detrimental effects. The improvement in BPA-free technology and conscious decision-making remain the two aspects in response to the consumer’s concern.

Leaching and Food Safety

For leaching to occur, chemicals from packaging materials or storage containers can enter food and drinks. This can occur under specific conditions, such as intermittent exposure to high temperatures, prolonged storage, or when the food is acidic or high in fat content. The leaching of BPA from polycarbonate plastic and epoxy resins into food products has been a topic of discussion for a considerable time. Research demonstrates that while regulatory agencies set very stringent safety limits for BPA exposure, cases of leaching highlight the importance of proper use and storage of these materials to minimize potential risks.

🔥 Heat Factor

In particular, studies have revealed that exposure to heat from microwaves or sunlight for extended periods can accelerate the release of chemicals such as BPA. This has amplified consumer demand for BPA-free products, which are now in the mass market.

Additionally, material science advancements have introduced an array of alternative packaging options that include the use of glass, stainless steel, or plant-based plastics, where the chance of migration is extremely low.

Keeping food safe involves manufacturers collaborating with policymakers to develop guidelines for the composition of materials, labels, and storage methods. Consumer education campaigns also help emphasize the dangers of exposing certain containers to high temperatures or using aged containers for extended periods, which compounds the risks of leaching. Higher technology, regulatory control, and better-informed consumers stand to avert such hazards arising from leaching.

Environmental Impact of Polycarbonate Plastic

Is It Possible to Recycle Polycarbonate?

♻️ Recycling Potential

The recycling of polycarbonate plastic presents both opportunities and challenges due to its durability and complex chemical structure. Polycarbonate is a thermoplastic, meaning it can be reheated and remolded, thus giving it some recycling potential.

🚧 Challenges

Successful recycling requires sophisticated sorting equipment that can separate polycarbonate from different materials; contamination from other plastics can significantly reduce the value of recycled products.

The contemporary process of mechanical recycling involves shredding polycarbonate into chips after thorough cleaning, followed by extrusion into pellets, which can be used for manufacturing again. Chemical recycling is another type of advanced process that is gaining favor because it removes polycarbonate back into its monomers, allowing for the production of near-virgin-quality material. A significant portion of the world’s polycarbonate remains unrecycled due to inadequate disposal mechanisms, a lack of recycling infrastructure, and economic barriers.

To promote the wider adoption of polycarbonate recycling, it is necessary to increase collection efficiency, raise public awareness, and invest in the research and development of technologies that make recycling processes more economically viable. That way, the industries with improvements on these fronts can drastically reduce their dependence on virgin plastics while also working toward minimizing the environmental footprint.

Lifecycle of Polycarbonate Products

The lifecycle of polycarbonate products is a complex process, encompassing multiple stages, from raw material extraction through manufacturing, usage, and end-of-life phases. Starting with the synthesis of bisphenol A (BPA) and phosgene, a polycarbonate resin is formed that is durable and versatile. These resins are then molded into various applications, including automotive parts, electronic components, construction materials, and consumer goods.

They are really favored for their impact resistance, being lightweight, and having transparency during the active use phase. Depending on the chosen attributes, industries consider them a preferred candidate for a wide range of applications, from high-performance engineering components to everyday objects like eyewear and food containers. As polycarbonate products reach an end-of-life stage, their disposal and recycling issues also come into view.

📊 Current Recycling Statistics

It is currently estimated that most regions have less than 20% polycarbonate recycling, primarily due to inefficient collection systems and high recycling costs. Chemical recycling and more advanced sorting systems are among the new technologies aiming to solve such problems by producing higher-quality and more acceptable recycled polycarbonate materials.

For example, newer mechanical recycling technologies ensure that important material qualities are retained, allowing the recycled polycarbonate to be used again for high-value applications.

By shifting towards a circular lifecycle model and scaling up the recycling infrastructure, the industry can ensure better resource efficiency and, at the same time, reduce its dependency on raw materials and greenhouse gas emissions. Encouraging lifecycle sustainability must go hand in hand with promoting a balanced approach that combines innovation, environmental considerations, and economic gain.

Comparing Polycarbonate with Other Plastics

Polycarbonate is characterized by its strength, versatility, and transparency. Among plastics like PVC and PET, it is considered one of the hardest materials, making it suitable for applications that require strength and durability, such as electronic housings, automotive parts, and protective gear. The significant difference between acrylic and polycarbonate is that acrylic tends to crack under stress, whereas polycarbonate does not.

| Property | Polycarbonate | Acrylic | PVC | PET |

|---|---|---|---|---|

| Impact Resistance | High | Low | Medium | Medium |

| Temperature Resistance | High | Medium | Low | Medium |

| Optical Clarity | High | High | Medium | High |

| Recyclability | Good | Limited | Limited | Good |

With high-temperature stability, polycarbonate can withstand temperatures higher than most plastics, such as polypropylene or polyethylene, without losing its shape. Therefore, this allows the industrial applications where heat resistance is a key factor to come into play. Polycarbonate offers an optical clarity higher than ABS and is lightweight as compared to glass, which helps it be used for lens making, medical devices, and architectural designs.

Polycarbonate, when used within circular recycling systems, holds a reduced environmental footprint in contrast. In other words, unlike some single-use plastics that are difficult to recycle, polycarbonate is amenable to reprocessing due to its advanced recycling capabilities. These advantages ensure that it can be considered a high-performance material in many industries; hence, it promotes innovation while keeping sustainability challenges in perspective.

Consumer Concerns and Recommendations

Choosing Safe Plastic Bottles and Products

When selecting safe plastic bottles and products, I always give the utmost importance to materials that are free of potentially harmful chemicals, such as BPA and phthalates. These chemicals may leach into food or beverages, especially when plastics are heated or used over an extended period, and thus may pose health concerns later on. To avoid this, I mostly opt for high-quality BPA-free materials, such as food-grade polycarbonate or other safe alternatives, like Tritan. Labels and certifications can often clarify the standards a product adheres to, and so I meticulously check these indicators before making a purchase.

Additionally, I consider the article’s longevity and reusability. Choosing a material that can withstand repeated use, like polycarbonate, is beneficial for both safety and sustainability considerations. Reusable bottles and goods reduce environmental waste and avoid temporary plastics that can deteriorate quickly and release harmful substances. Paying attention to care instructions, such as avoiding extremes in temperature and regular cleaning, ensures the safe and long-term use of these articles.

I also prefer brands and manufacturers willing to disclose all specifics about their materials and production practices. In my mind, supporting a company that thoroughly tests its products and strictly adheres to safety regulations allows me to have confidence in what I buy. In the end, choosing safe, high-quality plastics will safeguard my health and help to promote an eco-responsible way of living.

How to Reduce BPA Exposure

🛡️ Practical Steps to Minimize BPA Exposure

- Choose BPA-free products: To minimize exposure to BPA, I prefer to be educated on the choices I make in the products I use in my everyday life. Primarily, I try to buy BPA-free products, especially when it comes to food storage containers, water bottles, and kitchenware.

- Use alternative materials: Wherever possible, I prefer glass, stainless steel, or high-quality BPA-free plastics, as these materials tend to be the best for human health and the environment.

- Avoid heating plastic containers: Heating food in plastic containers is something else I try to avoid, as heat can induce the leaching of BPA and other chemicals into the food. I transfer food into glass or ceramic containers before placing it in the microwave.

- Be selective with canned foods: I also avoid canned foods unless they come from companies that use cans with BPA-free linings. Among other things, I read product labels and research manufacturers’ practices to ascertain the safety of what I buy.

- Proper maintenance: Washing plastic containers occasionally by hand with mild soap and warm water is my habit: a procedure that is often avoided in the dishwasher to prevent degradation, which in turn may lead to the release of harmful compounds.

As a confident measure for personal reduction in exposure and an involved healthy lifestyle for me and my family, I consider all such activities and continue to stay informed about possible BPA sources.

Future Trends in Polycarbonate Plastic Use

In the future, issues related to the environment and health will be rapidly shaping the industrial landscape and consumer interfaces with polycarbonates and their plastics. Concerned about the rising concerns associated with BPA, more manufacturers may be focusing on BPA-free technologies and sustainable production methods. In the same vein, I have witnessed the rise of biodegradable plastics and other innovative ways of utilizing recycled materials, which align with the global movement to reduce plastic waste and preserve the environment. This trend inspires me to believe that such products will soon be recognized as the safer and greener option rather than as exceptions.

🚀 Emerging Applications

With developments in materials science and technology, more potential applications seem to be emerging for polycarbonate plastics in fields such as automotive, construction, and renewable energy. For example, I’ve read that their use is increasing in lightweight yet durable components for electric vehicles and construction materials used in energy-efficient buildings. Such developments demonstrate the versatility of polycarbonate plastics and their potential for sustainability, provided they are used responsibly.

I, for one, remain hopeful about the new trends, but I am always cautious about what I purchase. I believe that supporting companies that demonstrate transparency in their operations and are committed to sustainability will, in a small way, encourage the wider adoption of safer and greener practices in polycarbonate plastic usage.

Reference Sources

-

Is Polycarbonate Plastic Toxic? Understanding Its Impact – Explores the health toxicity of polycarbonate plastic with insights from scientific evidence.

-

What is BPA? Should I be worried about it? – Discusses BPA in polycarbonate plastics and its implications for food and beverage storage.

-

A Common Plastic Comes Under Scrutiny: Examining the Use of Polycarbonate in Bottles and Food Containers, Along with Its Safety Concerns.

-

Polycarbonate Plastics and Human BPA Exposure: Urinary Study – A study showing the impact of BPA exposure from polycarbonate drinking containers.

-

Bisphenol A Leaching from Polycarbonate Baby Bottles – Highlights the endocrine-disrupting effects of BPA leaching from polycarbonate materials.

Frequently Asked Questions (FAQs)

Q1Is polycarbonate plastic safe for food applications?

Polycarbonate is a good material for food contact applications because it can endure physical abuse and high temperatures. However, concerns exist regarding BPA exposure from polycarbonate containers. According to some studies, BPA can leach into food, especially when containers are exposed to high temperatures or come into contact with certain types of liquids. The Food and Drug Administration (FDA) has reviewed the safety of polycarbonate and established guidelines for its use; however, consumers would rather opt for less risky options. It is essential to verify that the products are labeled as BPA-free when used for food storage, such as baby bottles.

Q2What may be the health hazards from exposure to BPA?

BPA exposure has been associated with health effects, especially in vulnerable populations such as infants and pregnant women. It has been purported in the research literature that BPA acts as an endocrine disruptor, bringing about potential reproductive health problems. Prolonged exposure to higher levels of BPA may lead to health problems through increased risk of prostate disorders and other types of hormonal disruptions. Studies conducted by the National Institute of Environmental Health Sciences have demonstrated BPA’s capacity to mimic estrogen, increasing concerns about BPA’s effects on developmental processes. Hence, it is essential to minimize exposure by choosing plastics labelled as BPA-free.

Q3Do polycarbonate products contain BPA?

Much of the traditional polycarbonate is made with polycarbonate resins containing BPA. This raised concerns about BPA leaching into food and beverages, particularly in consumer products like drinking bottles and food containers. The market has seen an increase in BPA-free alternatives, which are gaining more attention from the health-conscious population. Manufacturers now produce polycarbonate plastics free from BPA, addressing safety concerns while retaining valuable properties such as impact resistance and fire resistance. Always check the label before purchasing.

Q4Is BPA harmful to human health?

Yes, BPA exposure has been linked to some potential health effects. Studies have implicated BPA as an endocrine disruptor, causing hormonal imbalances that may impact human health. These considerations are especially critical in sensitive populations such as children and pregnant women, where exposure during critical developmental periods leads to long-term health consequences. BPA has been found to leach into food and beverages; thus, cumulative exposure becomes a concern. Selecting BPA-free products and minimizing the use of conventional polycarbonate containers helps reduce these risks.

Q5What alternatives are available to people besides polycarbonate plastics?

Instead of polycarbonate plastics, there are alternative, safer choices. Nowadays, many manufacturers offer BPA-free options, including plastics made of alternative polymers that do not leach harmful chemicals. Glass and stainless steel are also used for storing food and drinks in BPA-free and high-durability variations. Finally, some bioplastics are being developed from natural sources to promote ecological balance. Consumers who want to opt for safe alternatives should always read the labels on products to confirm the presence of BPA-free markings.

Q6What environmental impacts does polycarbonate plastic have?

The environmental consequences of polycarbonate plastics are increasingly concerning. While polycarbonate is a durable material, its constituents could be hazardous if the process is not handled correctly. Being polycarbonate, the production itself can be a source of pollution if the waste materials produced are disposed of irresponsibly. Waste disposal also poses a risk that these polycarbonate products will become part of plastic waste in landfills or the ocean. Researchers are now advocating for improved recycling methods and alternatives that are biodegradable, which would reduce the environmental footprint of plastic materials.