The comparison of the materials to be employed in the industries from medical applications to consumer goods is often reduced to the choice between Thermoplastic Elastomers (TPE) and silicones. Both groups possess properties that are to a certain extent unique and therefore make them useful for different purposes. This work intends to explain the differences between TPE and silicones and also looks at the issue of whether both can be classified as materials that are silicone-like, or not. Further, it is aimed to show that the question of whether TPE is silicone has a definite and the answer has serious consequences depending on the application area for which the materials will be used.

Introduction to Silicone and TPE

What is Silicone?

Silicone is a versatile synthetic polymer constructed from silicon, oxygen, carbon, and hydrogen. The material is very stable and has the ability to withstand very high or low temperatures, it is a very common material in industries such as medical and consumer electronics. The backbone of silicone is composed of flexible siloxane, so it is the material of choice for its combination of durability and softness. It is a material that has a very high resistance to environmental factors like UV radiation, moisture, and chemical reactions, it also has a great temperature range. Silicone as a material is also biocompatible, and this makes it a top choice for medical and food packaging applications. Due to all these features, silicone has become one of the most sought-after materials for applications demanding high reliability and performance.

Understanding TPE (Thermoplastic Elastomer)

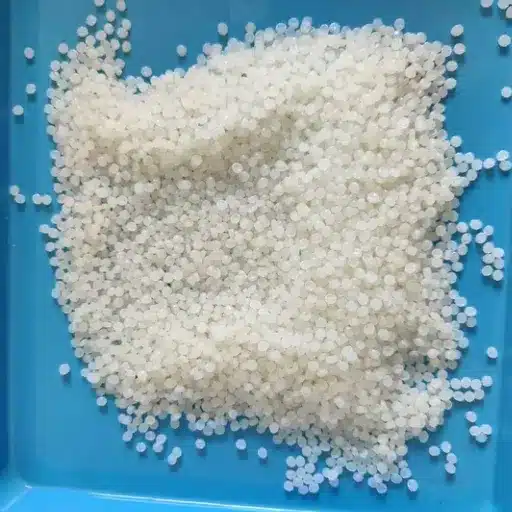

Thermoplastic Elastomers (TPEs) are a type of polymers that have the elastic properties of rubber and the processability of thermoplastics combined. These materials stand out from their melting and re-shaping ability without a significant decrease in quality, thus being excellent for several industrial fields with various usage options. The formation of TPEs involves hard thermoplastic segments and soft elastomeric domains that result in the composite getting a distinct mix of the two above-mentioned qualities, that is, tough and ductile.

TPEs (Thermoplastic Elastomers) have undergone a large scale acceptance in various industries and show certain, very important properties like more water resistance, more chemical resistance, and flexibility in an intricate configuration. These properties make them attractive for use in automotive, consumer, medical, and insulation made of electronics and this is due to their very good performance when they are in situations where they undergo heavy pressure and environmental conditions. Also, very significant the TPE formulations are now far more advanced since they have been able to be improved the recycling of these materials and hence they are now in the category of the thermoset materials that have been traditionally used.

The TPEs are the materials which applications requiring heat resistance in a harsh, very hot environment or those asking to fulfill very strict standards regarding the use of the materials in the medical and food sectors. The materials are flexible to be molded with other materials and also have a very wide range for the tensile strength of the product, which altogether gives them the advantage to be used in engineering and manufacturing of highly precise products.

Common Uses of Silicone and TPE

Silicone and Thermoplastic Elastomers (TPE) are materials that have great application in a wide spectrum of industries owing to their excellent mechanical properties. Silicon is a frequently used material in the case of applications demanding very high thermal stability and at the same time being very resistant to chemicals and more … This very characteristic makes it very suitable for applications such as sealants, medicine implants, kitchen utensils, or electrical insulation. Besides that, its capability to survive high and low temperatures and its good resistance to degradation also make it a top material in the production of automotive and aerospace parts.

TPE, however, is still a demanded commodity by some industrial sectors for its ease of processing, its elasticity, recyclability. TPE is a common material used in everyday goods like the soft-padded handles of tools and electronics, as well as in the mechanical area such as gaskets and seals for the automobile industry. The fact that it meets the safety and health standards of the industry makes it a first choice for the medical field tubing besides the syringe components and food-grade materials. Moreover, the merging of TPE with silicone in co-molded pieces enables to draw on the positive sides of both materials and to develop new approaches to solve more and more complex technological challenges manufacturer’s are facing.

Exploring the Differences Between TPE and Silicone

Material Composition and Properties

Thermoplastic Elastomer (TPE) and silicone belong to elastomer categories, yet they differ widely in chemical compositions and the properties. TPE stood as a kind of polymer that introduced the elastic features of rubber on the one side and the thermoplastic processing of plastics on the other side. TPEs consist of hard and soft segments’ blend which makes them capable of being melted and reformed without considerable degradation. So they are suitable for using in various business fields where recyclable raw materials or materials with different properties are needed.

On the contrary, Silicone is an inorganic polymer that is primarily made up of silicon, oxygen, and other elements like carbon and hydrogen. The main drawbacks of silicone are its poor thermal, chemical, and biological resistance. However, silicone is still the preferred choice in situations where high-temperature, and excellent biocompatibility are required, and is highly rated in the medical grade applications. Among Vs, silicone is the home of the highest heat- and chemical-resistant characteristics, and due to environmental issues, it has been a target for much medical research. In addition, one more advantage is that silicone’s cross-linked molecular structure makes it almost impossible to remold once it is cured, but it is still the best choice in terms of elasticity and resistance to age in comparison with TPE.

The above-mentioned discrepancies, in fact, affect their performance qualities. Typically, the use of TPE can be noticed in the fields requiring flexibility, cost-effectiveness, and easy processing. In contrast, silicone finds an ideal application in the situations of rigorous setting requirements through sterilization or heavy exposure to UV radiation. Knowing the separate attributes of TPE and silicone gives a possibility of for the choice of the most proper material for the particular application.

Manufacturing Processes: Injection Molding vs. Other Methods

Numerous applications across various industries, such as the automotive, electronics, and medical sectors, leverage the cost-effective and versatile nature of the injection molding process in combination with thermoplastic elastomers (TPEs) and sil and silicone as well. During this method, the material is brought to its molten state and then forced into a highly sophisticated mold cavity at a high pressure. The very quick production of components, the possibility of producing the exact features on each part, and the capability of manufact very intricate shapes that are kept within very strict dimensions are the advantages of the process. Further, by the reason of the very exact control of all injection parameters, injection molding significantly reduces left-over material – hence this technology goes well with large-scale production, too.

On the other hand, the choice of the method lies between injection molding and alternative methods based on such requirements as part complexity, production volume, material properties, and cost constraints. One of the most integrative methods used recently involves the combination of the best of both worlds namely the precision of injection molding on the one hand and the flexibility found in all other processes on the other. The result being these manufacturing operations fully optimized in terms of performance and lower actually.

Alternative Manufacturing Methods: Compression molding, and extrusion can be used, in case the requirements are more specific for the application. Compression molding is used to create larger, simpler items where fine detail is not important. This method offers less costly production (tools) and flexibility with batch sizes, as compared to extrusion. On the other hand, extrusion implies uniform and continuous production of cross-sectional area products like tubing and profiles, and it becomes difficult to imagine a scenario where applications requiring the use of a linear component that is not only uniform but also continuous, would not benefit from it.

Performance Characteristics: Strength and Flexibility

Strength and flexibility are main characteristics for performance of the product material which have a big effect on its useful life. Strength, that is the material’s capability to carry forces without breaking, is critical for building things that will not fall apart even with pulsating and stationary loads. Flexibility, on the other hand, means the ability of the material to bend or stretch and come back to behavior without permanent deformation. These traits are many a time required to be in an equilibrium so that, for example, high strength materials such as carbon-reinforced plastics are more likely to be used in the field of aerospace, whereas elastomers are the best choice for making seals and gaskets. Thanks to the new methods involving the hybrid materials, both tensile strength and elasticity were increased and therefore the production of more and more complexly designed products was made possible. The interrelation of these qualities is usually assessed with the aid of such parameters as Young’s modulus, tensile strength, and the ratio of elongation at the point of rupture, as they allow to predict the performance of the product under operational conditions with the highest accuracy.

Applications of TPE and Silicone in Various Industries

Medical Devices and Healthcare Products

Medical devices and healthcare products are made of thermoplastic elastomers (TPEs) and silicone to huge extent. These two are such popular materials owing to biocompatibility, adaptability, and high performance under the most challenging medical conditions. TPEs are practically unbreakable, resistant to high temperatures, and very elastic, thus, they are commonly utilized in many products including the plungers of syringes, IV bags, and the seals of respirators. But, when it comes to silicone, the material is superior to all the others because of its tough nature, long service life, and resistance to high temperatures which are critical in the cases of catheters, implantable devices, and medica

Moreover, these constituents comply with the strict norms of FDA and ISO, that is why they are so well established when it comes to safe and effective medical use. There were a few changes in the materials as the material science was progressing rapidly in the past years. These changes brought about interesting applications of TPEs and silicones making them antimicrobial and at the same time, very fit for the wearable medical sensors with advanced technologies. Yet another was that they could be processed by using the conventional machines such as injection molding or extrusion, and it was never a hassle. The result was, the very cost-effective and highly accurate manufacturing of even the most complex products. One such exemplary application is to upgrade conventional hospital beds to smart ones, which will not only save time and speed up the recovery process but also provide the user with more comfort and less stress; the product that ultimately meets the patient’s functional and psychological needs. The medical device design that completely depends on the production of the materials that could make it possible with avoiding the conventional problems linked to that, has an urgent role in the new health care systems.

Consumer Products: Toys and Home Furnishings

Advanced polymers and composite materials’ application in making consumer products, especially toys and home furnishings, was made the industry’s leading frontier by their provision of the increased durability, safety, and design adaptability. Quite often, the materials are designed to be lightweight, impact-resistant, and non-toxic, which guarantees safe product manufacturing using the different safety standards. Technologies such as compostable plastics and recyclable materials are being progressively implemented to follow sustainable environmental practices, thus catering to the rising consumer preference for green products. Also, the enhancement in the area of precision manufacturing, for instance, in the case of 3D printing and injection molding, has made the production of complicated designs and even special solutions possible, and consequently, extended the industrial sector amplified the range of use to a significant degree. The integration of these materials and processes is a continuous but quite complex journey, with benefits in terms of product quality and suitability for everyday use at the same time.

Automotive and Industrial Applications

The use of advanced materials and the availability of precision manufacturing technology have brought significant change to the automotive and industrial sectors. Specifically, lightweight composite materials like carbon fiber reinforced polymers are becoming more common. They are the times when there were no longer any worries if the weight of the vehicle could be lowered at the expense of its structural strength.

We thus have a composite material thanks to which we have gained less weight of our vehicle. This also means that the load a truck has to carry will not be lighter. This, in turn, will lead to saving money with the now lighter vehicle in comparison to reducing the trading area of a truck due to necessary overloading regulations.

Additive manufacturing technologies are also being adopted by companies in different sectors to make their supply chains more efficient and reduce production times at the same time. One of the metal 3D printing enables engineers to produce parts that have been one to some extent with very little scrap which in turn also increases the profit margin of the machine shop. Response to environmental conditions such as temperature or pressure is among the key features of some of the smart materials. This trend is seen even in the industrial machinery functioning. The industry is in love with the use of smart materials as they not only are less costly but also reduce the use of natural resources that still have a finite supply. In the end, the new materials and their related technologies will have a dominant role in the sectors’ ability to continuously improve efficiency and innovate.

Advantages and Disadvantages of TPE and Silicone

✓ Benefits of Using Silicone Rubber

There are a variety of ways to make use of silicone rubber, and it shows great versatility and flexibility because of its special chemistry. It has a name for itself because of its stability in the presence of high temperatures and that it works within a wide range of temperatures from -75 F to 500 F (-59 C to 260 C), hence it’s good for use in tough places as well. At the same time, silicone rubber is very strong against the bad effects of UV rays, ozone, and weather conditions, which means it can be used for a long and safe time outdoors. Its neither-poisonous nor biocompatible property makes it a very good candidate for the production of medical devices ad for other applications in the food industry that follow the strictest rules and regulations. Lastly, the outstanding features of silicone rubber like flexibility and electrical insulation along with the exceptional quality of coming up with a possible breakthrough in its end-uses outweigh the fact that the industries that benefit the most are those of automotive, space and electronics where the reliability and precision stand as the most prominent features. The above-mentioned three major things have led to a high rate of adoption of silicone rubber in different industrial and commercial sector

⚖ Pros and Cons of Thermoplastic Elastomers

Pros:

Thermoplastic elastomers (TPEs) offer unique properties and combinations that are very effective and beneficial in many different applications. It is not wrong to say that the biggest advantage of TPEs is the ability to process them using the same traditional thermoplastic methods like: injecting the molten material into the mold, blowing or squeezing out a continuously shaped product. This in turn, reduces production time and increases the industry’s SIL throughually plus intelligently. The common myth that the plastic industry is not eco-friendly has been proven dead wrong as the TPEs can be re-melted and formed without any change in their nature. Although the TPEs trials are in progress, the end product is not at all the same as the beginning one at all. They are in fact much more vigorous, much more capable, and much more powerful. Not to mention, TPEs are also used for toys, cables, and automotive and medical devices; they are the most specialized products in the industry. For the highest quality parts TPE can be further enhanced by adding appropriate additives or fillers or coatings among other things to what would otherwise be just a small part.

Cons:

Even though thermoplastic elastomers are acknowledged to be very advantageous, they also have drawbacks which have to be taken into account. By and large, TPEs are inferior to the traditional thermoset rubbers in terms of temperature resistance, hence they are not appropriate for places with higher temperature conditions. However, the main advantage of their recycle-ability comes with a downside part that is the decrease in the mechanical properties of TPEs, which can limit the reuse of them in high-performance applications. Moreover, another disadvantage of TPEs is that they may have a higher price than usual plastics thus increasing the overall production cost in some cases. It is apparent that TPEs sometimes do not have the same performance and toughness as thermoset rubber, which can restrict their applications to some industries. The demerits of TPEs should thus be critically evaluated against some of their positive aspects when choosing materials for certain industrial or commercial targets.

Environmental Impact of Silicone vs. TPE

In assessing the environmental effect of silicone and thermoplastic elastomers (TPEs), the efficiency of the production process, the possibility of reusing materials, and the methods for disposing of the product after the end of its life are all important factors. Silicone, a human-made material obtained from natural sources, needs large amounts of energy in order to be manufactured. Nonetheless, its capacity as being almost eternal and its resistance to most decay processes make it be a good option for reducing the environmental load even if it is often the case that the material is replacing use-and-throw products rather than in-demand and durable materials. However, the former is not an easily recyclable material and the latter’s disposal methods are generally either incineration or slow degradation in the environment, posing the issue of its potential environmental persistence.

In contrast, TPEs are easily recyclable as they are soft plastics that transform into a molten state and then can be remolded again becoming a new shape that further results in decreased material wastage. Production of TPEs is not as energy-heavy as that of silicone although the process involves the use of petroleum-based raw materials. This fact makes them a part of the greater challenge which is the fossil fuel pandemic. In some cases, TPE formulations may even degrade quickly in nature, thus, might be a source of microplastic pollution if their responsible disposal or recycling processes are not set up. Although either of the materials is equally sustainable, it still largely depends on the application area, service life, and waste management policies whichever will perform best environmentally.

Conclusion: Choosing Between TPE and Silicone

Factors to Consider for Your Application

If you are to make a choice between TPE (Thermoplastic Elastomer) or silicon, then there are various technical parameters that one has to deal with while considering the use of the applied jackets. The major ones are mechanical properties, thermal stability, chemical resistance, and cost.

| Factor | TPE | Silicone |

|---|---|---|

| Mechanical Properties | Ideal for applications with dynamic loading and movement due to extraordinary flexibility and elasticity | Maintains physical integrity over wide temperature ranges, perfect for extreme environments |

| Thermal Stability | Limited temperature range, restricted to mild thermo-mechanical stress environments | Excellent stability from -60°C to 230°C, preferred for high and low-temperature exposure |

| Chemical Resistance | Suitable for low physic-chemical stress environments, less durable under solvent or oil attacks over time | Very strong resistance to UV radiation, ozone, and wide spectrum of chemicals |

| Cost & Processing | Cheaper, easier to manufacture with thermoplastic nature and recycling options (injection molding) | More expensive initially, but may justify cost for high-performance applications with longer lifetime |

| Compliance | Can be redesigned to fulfill standards, requires consideration of microplastics impact | Meets medical grade and food safety standards, ideal for stringent regulatory requirements |

In the end, the selecting procedure must be in line with the material needs of your project, the legal bindings, and the environmental goals you have set for the future. The comprehensive assessment of these three aspects will assure that the chosen material will possess the ability to answer technical and operational requirements adequately.

Future Trends in Silicone and TPE Usage

According to my investigation, there are several trends that can be seen through the use of silicone and thermoplastic elastomers (TPE) that are bringing about their applications in various sectors. One of the most remarkable trends is the requirement of eco-friendly and sustainable materials in the auto industry. The pressure for the green attitude and environmental concerns are making the vast majority of the customers to go for the bio-based and/or the recyclable TPEs, as the solution to reducing the environmental impact taken by the manufacturers. On the other hand, silicone materials are the next target for all the closed-loop production processes and the minimum waste production through the development of 100% recyclable silicone materials.

The use of not only silicone, but also thermoplastic elastomers in more sophisticated technical and medical applications is yet another remarkable step forward in the science of materials. Plastic TPEs that are specifically made for the medical field are now being used in a range of avenues, from smart wearable devices to artificial limbs and to the delivery of medicines. In addition, Silicone keeps its role as the compound of choice for high temperatures and non-reactive environments, and that is how it stays relevant in such performing-industry branches as electronics, electric cars, and renewable energy. I’ve noticed that these materials are key supporters in the production of sustainable and rugged parts for the marketplace of clean energy particularly.

Moreover, the development of 3D printing and additive manufacturing technology leads to new directions where silicone and TPEs can be used. Different companies are researching on production of customized highly-engineered parts using these materials and as a result, the rapid prototyping is being promoted. On the other hand, these tendencies reveal a future where these materials will not only be the main part of the technical progress but also the key to wide-scale sustainable development in the field of materials.

Concluding Remarks on the Material Selection

To me, the selection of materials has turned into a more flexible and key component of the process in today’s technological world. Due to the development of materials and the ways of producing them such as additive manufacturing, more and more possibilities of the availability of the desired high-performance materials as silicones and the thermo-plastic elastomers (TPEs). These materials now have no match in terms of their customizability, durability, and adaptability. For example, the thermal stability and chemical resistance of the silicone make it an ideal option for applications where the devices are medical or automotive components, while TPEs, on the other hand, offer the right attributes that consumer products and green projects desire. The pick of the material is literally all about matching the basic properties of the material with the specific requirements of the application, taking into consideration the mechanical performance, environmental exposure, and functionality of the end product.

What’s more, the importance of sustainability in the selection of materials has been recognized. Firms are currently choosing materials that have the least impact on the environment like recyclable or bio-based TPEs. A lot of companies are making use of additive manufacturing to avoid waste and make more use of resources. Also, silicone adds to this transformation by providing longevity and reusability thus decreasing the consumption of resources in general. And material,selections nowadays do not simply focus on the goods’ performance, they are part of the firm’s evolving in conformity with the regulations and consumer expectations.

Final Summary: In summary, the selection of the material can be regarded as a very challenging, yet at the same time, the most important part of innovation and sustainability. It is by examining the advanced materials’ unique properties very cautiously along with the manufacturing technologies and environmental considerations that one can conceive of the optimized solutions with a mix of technological advancement and sustainable practices. In my case, the way to go is to be guided by data and applications to get the right material not only for briskest performance but also for lower environmental impact.

Reference Sources

- 📄Determination of Adhesion Between Thermoplastic and Silicone – Harvard ADS

Discusses the adhesion properties between thermoplastic elastomers (TPE) and liquid silicone rubber (LSR). - 📄Thermoplastic Elastomeric (TPE) Materials and Their Use – Academia.edu

Explores the properties and applications of TPE in various industries. - 📄Thermoplastic Elastomers in Biomedical Industry – ResearchGate

Highlights the benefits and applications of TPE in the biomedical field compared to other materials. - 📄TPE vs. Silicone | Comparing Elastomers for Medical Parts – Protolabs

Provides a detailed comparison of TPE and silicone, focusing on their pros, cons, and applications in medical device development. - 📄Realsex Dolls Tools – UCSB OE Wiki

Briefly mentions the differences between silicone and TPE in manufacturing applications.

Frequently Asked Questions (FAQs)

❓ Are the characteristics of the silicone the same as silicone rubber performance?

Both silicone and silicone rubber are highly elastic and include many of the same features of the elastomer such as excellent resistance to extreme temperatures and shape recovery after compression. Silicone is a polymer that is usually a cap for heat resistant characteristics. The elasticity of the silicone is practically the same as that of the natural rubber; the former, however, does not deteriorate much through use or time. Silicone rubber, on the other hand, will be used for decades around windows, and so will be the car. Bio-compatibility and a very long resistance to UV and ozone are the main characteristics of elastomers based on silicone. This is the GE Test report for silicone rubber products` breakdown tests. Moreover, it is mostly low cost to use the material in its final applications. The total processing cost is much higher than other materials, and is not usually due to the high raw material cost, but is rather the result of high tooling. Proper selection of the material for specific applications can be influenced by factors other than price alone. For example, it can be a company`s policy to avoid phthalates or lead in food contact products.

❓ How does Performance of TPE compare to thermoplastic elastomer materials?

TPE is the abbreviation for thermoplastic elastomer; it is a material known for combining both plastic and rubber-like characteristics, so it’s as soft as rubber but yet still processable like plastic when it is heated. TPE is always the cost-effective choice due to the possibility of being transformed by injection molding and extrusion, thus limiting waste compared to vulcanized elastomers. TPE has thus a large group of possible polymers with the resulting elastomer grades showing various differences in heat resistance, chemical, and elasticity, as well as melting points. It might be that TPE is the right material for your project if you need quicker delivery and recycling can be done, at least in part, in your plant. Service conditions are definitely to be taken into account when one opts for either thermoplastic or elastomeric characteristics.

❓ Can the use of TPE and LSR for the same medical device be applied?

Some TPE grades and Liquid Silicone Rubber (LSR) are the two materials that are commonly used in medical devices with different processing and performance properties which can significantly affect the biocompatibility and sterilization aspects. LSR is in the form of a liquid in an injection mold and then cured in the process that results in the production of consistency in the silicone products and that these products possess outstanding heat and chemical attack resistance so that they are often a solution for obtaining by meeting international standards. On the other hand, TPE can be injected molded without curing process and might be more cost-efficient and relevant for high-volume disposable article applications, but not all tpes are capable of the same biocompatibility. For instance tubing, seals, or utensil-like components, these principal technologies in material selection may also be a better fit when taking into account the differences in sterilization methods, regulation being followed, and the specific application. Also, it is necessary to check the material compatibility with drugs, fluids, or cleaning agents before the medical devices\’ use.

❓ What are the differences between tpe and silicone for gasket and rubber parts?

One of the main and distinct differences between TPE and silicone is in the behavior of gaskets. Silicone is usually considered to be the more temperature-resistance capable and long-term-life-resilient gasket material, while TPE can be up for the challenge of better compression set in certain low-temperature seals. the TPE material, on the other hand, is that it is a mix of materials and can be low-costly produced, and injected molded and, or compounded to enhance chemical resistance or elasticity. The medical, electrical, automotive, and other industries often use Silicone as their material of choice because of its high-temperature stability, and it is also widely used in laboratories for the same reason. Silicone is often seen as the most reliable raw material choice when it comes to gaskets or seals and indeed, any temperature or chemical environment beyond average limits. While the properties of the product play a major role in determining the type of material to be selected, the melting point & compression retention, or the candidate material should have exposures to oils or solvents, and in some instances, requirements for FDA approval may be applicable. It is recommended to test the prototypes for results at the site in controlled conditions directly.

❓ How do the materials’ properties and production behavior compare if thermoplastic is used for injection molding instead of silicone?

Thermoplastic injection molding and silicone injection molding (including silicone injection molding of LSR) use different processing windows and curing behavior: thermoplastics are melted and later become solid upon cooling, whereas silicone is a cured elastomer that might need crosslinking after mold filling. High heat thermoforming and silicone are completely opposite in process cycle time and curing behavior. Resin esters with fast cure cycle, extrusion and blow molding, but high-per-part costs are well-known for high-volume plastic and rubber hybrid parts. Silicone rubber injection molding provides the best parts with heat resistance, biocompatibility, and chemical resistance for a very long period but in most cases, a curing cycle and expensive equipment are required. Every placement of gate, presence/absence of vents, and the state of the rubber in the meantime are the details that are detectable by the chosen material for the ruling concerning the question of the additional process.

❓ Does a selection of TPE over silicone depend strictly on the process for single applications or are there other pros and cons?

TPE and silicone both offer various advantages and disadvantages for specific use; TPE have the options of quick manufacturing, recycle, and cheap development, while silicone has the qualities of being the best option for being highly resistant to heat, a preference for biocompatibility, and giving long service life. The better material, in this case, is to opt for TPE in the mid-range that implies heat resistance up to around 100 but no more. On the other hand, if the same material is to be used in a medical environment, there should be no further question as to what material to choose-tpe or silicone. Silicone wins because of its properties that make it ideal for the medical industry ie biocompatibility and sterilization procedure and characteristics/profile required in a medical instrument such as suctions, which call for the use of the least reactive material. The majority of catalysts in the medical device industry like implantable devices and instruments made with the materials have to be compatible with the requirements of ISO 10993 for the biocompatibility, so the advantage is with silicone. The cost savings due to the use of silicone in a device are when the elastomer has to be used where the conditions call for biocompatibility, and the device can be sterilized by steam autoclaving in consideration of economic and regulatory aspects.