Polytetrafluoroethylene (PFA) Resin has already been identified as a critical material for the manufacture of high-performance components that are currently being used in fields such as aerospace, automotive, chemical processing, and medical. As it represents the front rank of all the other plastics in terms of thermal stability, chemical resistance, and the ability to release deposits, PFA resin is a crucial factor in the overall course of the modern engineering and production processes to the brink of the latest technological advancements. The article here is going to focus on the essential 10 PFA resin manufacturers who are the leaders in not only the development of this advanced material but also in deciding the future of high-performance material manufacturing as a whole. These manufacturers will be shown through their respective breakthroughs, market dominance, and contributions to the material science field in this article. Therefore, this material will not only provide a guide to those who want to be more informed about the PFA resin market in general but will also show that the only way to succeed in this narrow market is to make a comparison between the best players globally. Thus, if you are engaged in manufacturing, engineering, or any other field interested in the material being discussed, this guide will be of great help in your understanding of who is in the lead and how they are influencing the engineering of the future.

Introduction to PFA Resins and Their Importance

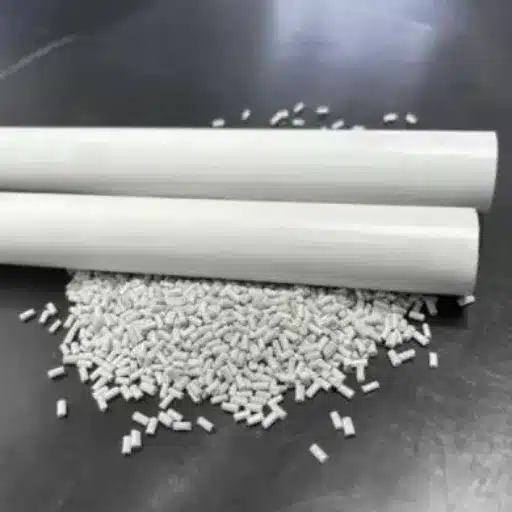

Perfluoroalkoxy (PFA) resins have the well-known reputation of being high-performance fluoropolymers having incredible chemical resistance, thermal stability, and non-stick features. Designed to merge the benefits of polytetrafluoroethylene (PTFE) and at the same time making the material more easily processed, PFA resins are found to be used in a lot of stringent industrial applications. They have excellent performance in scenarios that include the use of harsh chemicals, the presence of very high or low temperatures and the occurrence of tough mechanical stresses, hence they are vital in industries like chemical processing, semiconductor manufacturing, and aerospace engineering businesses.

PFA resins have a distinct advantage in the retention of material quality at continuous high-temperature exposure, as their melting points approach 580°F (304°C). Besides, the higher often than not 7 melting point is much higher. They also feature outstanding chemical resistance, as reactivity and subsequent attack of acids, alkalis, and organic solvents are almost nil. Their applications, thus, are among those of material storage and material transport through corrodible environments where their presence will significantly extend component life.

Apart from materials’ properties, the processing of PFA by very special methods such as injection, extrusion, and blow molding is what allows for it to be used in very complicated shapes and micro engineering designing with high precision. The wide range of possible applications, from the electronics industry to the chemical storage with these high-performance tanks, is a sign of the material’s versatility and the function that it brings with it in all the different processes and sectors.

PFA resins, in addition to being these technical properties, are also very compatible with the continually emerging processing methods, which is a strong reason for their consistent innovation in the industrial areas accommodating harsh conditions and requiring very good service.

Top 10 PFA Resin Manufacturers

1. YiFuHui

Year Founded: 2002

Introduction: At Yifuhui Plastic, we offer a comprehensive range of high-quality plastic pellets to meet diverse industrial needs. Our extensive selection includes polycarbonate (PC), PA66, POM, PMMA, HDPE, ABS, PFA resin, PPS, PEI, TPE, TPV, PP, and PTFE, Whether you require durable engineering plastics, versatile resins, or high-performance materials, Yifuhui Plastic delivers exceptional quality and reliability.

Main Products: PA66, POM, PMMA, HDPE, ABS, PFA resin, PPS, PEI, TPE, TPV, PP, and PTFE

Key Advantages: High purity, excellent chemical resistance, and a commitment to quality and customization.

Key Disadvantages: Limited global distribution networks compared to Western competitors.

Website: YiFuHui Official Website

2. Chemours

Year Founded: 2015 (spin-off from DuPont)

Introduction: Chemours is a major global leader in advanced materials and high-performance fluoropolymers. Their focus on innovation and sustainability positions them as a top PFA resin producer.

Main Products: Teflon™ PFA resins, FEP resins, and PTFE products

Key Advantages: Globally recognized brand with extensive distribution and exceptional product quality.

Key Disadvantages: Higher costs compared to emerging manufacturers.

Website: Chemours Official Website

3. Daikin Industries, Ltd.

Year Founded: 1924

Introduction: Daikin, a Japan-based multinational corporation, is renowned for producing premium-grade fluoropolymer materials, including PFA resins, with applications across various high-tech industries.

Main Products: Neoflon™ PFA, PTFE, and FEP resins

Key Advantages: Superior durability and consistently high product performance.

Key Disadvantages: Complex procurement processes for smaller businesses.

Website: Daikin Official Website

4. 3M

Year Founded: 1902

Introduction: 3M is a globally recognized innovation leader that produces a wide range of advanced materials, including PFA resins, for industrial and technological applications.

Main Products: Dyneon™ PFA and PTFE resins

Key Advantages: Robust R&D investment and a diverse product portfolio.

Key Disadvantages: Products may be priced higher than competitors.

Website: 3M Official Website

5. Arkema

Year Founded: 2006

Introduction: A global specialty chemicals company based in France, Arkema manufactures high-performance fluoropolymers, including cutting-edge PFA resins under the Kynar® brand.

Main Products: Kynar® PFA and PVDF resins

Key Advantages: Strong emphasis on sustainability and innovative product development.

Key Disadvantages: Limited product range focused primarily on specific applications.

Website: Arkema Official Website

6. Solvay

Year Founded: 1863

Introduction: Solvay is a multinational leader in chemicals and advanced materials, offering premium PFA resins for demanding industries like aerospace and electronics.

Main Products: Hyflon® PFA and other fluoropolymer products

Key Advantages: High-performance products with excellent thermal stability.

Key Disadvantages: Availability can be constrained in certain regions.

Website: Solvay Official Website

7. Gujarat Fluorochemicals Limited (GFL)

Year Founded: 1988

Introduction: GFL is a leading player in the fluoropolymer industry, providing high-quality PFA resins to markets globally.

Main Products: INOFLON® PFA, PTFE, and FEP resins

Key Advantages: Competitive pricing and strong focus on emerging markets.

Key Disadvantages: Market presence is weaker outside Asia.

Website: GFL Official Website

8. AGC Inc.

Year Founded: 1907

Introduction: AGC is a prominent Japanese company specializing in glass, chemicals, and high-performance materials, including advanced fluoropolymer resins.

Main Products: Fluon® PFA, ETFE, and PTFE resins

Key Advantages: High-quality products tailored to stringent industrial requirements.

Key Disadvantages: Higher lead times for customized solutions.

Website: AGC Official Website

9. Dongyue Group

Year Founded: 1987

Introduction: A leading Chinese manufacturer, Dongyue produces a broad range of fluorochemicals and fluoropolymers, with a growing presence in the global PFA resin market.

Main Products: PFA resins, PTFE, and FEP materials

Key Advantages: Cost-effective solutions with a growing international footprint.

Key Disadvantages: Brand recognition is still developing outside China.

Website: Dongyue Group Official Website

10. HaloPolymer

Year Founded: 1953

Introduction: HaloPolymer is a Russian manufacturer with expertise in fluoropolymer materials, offering PFA resins for industrial applications.

Main Products: PFA, PTFE, and FEP resins

Key Advantages: Value-for-money pricing.

Key Disadvantages: Regional political and economic factors may limit accessibility.

Website: HaloPolymer Official Website

Quality and Purity Standards in PFA Resin Production

The manufacturing of perfluoroalkoxy (PFA) resin is one of the most crucial and demanding processes for the production of high-performance product for critical applications, a must to be followed strictly with no compromise in terms of quality and purity. For example, high-purity PFA resins need to show also superior lifetime, implied by very low ionic contamination and high thermal endurance, which is one of the basic requirements of high-tech industries, such as semiconductor manufacturing, chemical processing, and medical technologies.

Such results are achieved through expertise in highly controlled polymerization processes and advanced purification techniques on the part of the manufacturers. Analytical testing, e.g., inductively coupled plasma mass spectrometry (ICP-MS), is being employed to the task of trace metal contamination monitoring, thus, hindering impurities to go beyond the accepted limits. Furthermore, not only through strong quality control protocols, keeping the lot-to-lot variations at arm’s length is another way of maintaining the consistent quality of the resin, with important tests being molecular weight analysis and mechanical property evaluation, among others.

Material conformity is the result of International Organization of Standardization’s standardization in the case of quality management systems (ISO 9001) and specific application standards in the case of SEMI F57 for semiconductor-grade materials, which are dictated by global regulatory standards. These reference points guarantee that PFA resins are able to adequately deliver the reliability and performance that is needed in harsh environments. The very aspects of precision and purity both indicate the importance of strict production practices and the materials’ integrity maintenance.

The Future of Fluoropolymer Resins in Technology

There has been a rapid change in the role that fluoropolymer resins play within the scope of new technologies and PFA has been a good example. They are considered the best materials due to the properties of having no chemical resistance, thermal stability and non-reactivity, for the most part. Now they are used in the very expensive business of making semiconductors, but also in renewable energy systems and all kinds of medical devices, etc. It can be easily noticed that the requirement of the purity of the materials going up to higher and higher levels in the semiconductor industry will bring about researches in, as well as the development of, the resin formulation, thus allowing better performance in the severe industrial conditions somewhere in the future.

Similarly, the focus of scientific research has changed to making reusable and green-friendly fluoropolymers because of the sustainability factor becoming so important for the industry. The industry wanting to push for environmental-friendly production has resulted in the increased number of studies in alternative products that could compete with PTFE in properties and processing while also being biodegradable. The separation of fluoropolymer resins as one of the compatible raw materials for new technologies like hydrogen fuel cell systems, cutting-edge battery solutions, and 5G communication networks, further shows their capability and part in the rapid technological development. Thus, these innovations drive the future where the demand for highly-performance oriented devices can only be met through the use of such special materials as fluoropolymer resins, the crucial engine of the world technology.

Frequently Asked Questions (FAQs)

Who are the major Fluoropolymer Resin and PFA Global Resin suppliers?

Global leaders in the Fluoropolymer mixture industry and resin material suppliers are among the major players that supply ultra-pure resin mixes and ultra-pure PFA grades which go to the market of semiconductor and automotive industries. They usually have an integrated supply chain and very strict quality control to make sure that the medical devices and data cables they make meet the specifications. The competition study of this area reveals that the major actors in the market are the 3M Company and the Chemours Company and that suppliers of the resin are working very hard on R&D. Manufacturing companies are very careful about procuring raw materials and managing them so as to always participate in the market with the same share size and in the resin market. There are many players in the market, manufacturer, buyer, etc. who have to take part in the resin market, and buyers should, therefore, be very cautious and become very careful of the general business being done by the resin suppliers, chemical-processing experience of the suppliers as well as the possibility of providing full satisfaction in their high resistance to chemicals and dielectric properties.

What is the relation between market size and market analysis in the forecast of the fluoropolymer market and market for PFA?

Market size and market analysis play a significant role in predicting the forecast as well as the estimated CAGR for the fluoropolymer market and the market of PFA. The trend of market sizes continuouly increasing across applications such as semiconductor, automotive, and medical device indicates that demand is growing. Analysts often refer to these two markets as combined as they develop their market study around pfa grades, application, and region with the purpose of providing a highly detailed market analysis and thus being able to forecast market trends and changing competitive landscape. The forecast reports issue consideration of constraints in the supply chain, the cost of raw materials, and the producers’ abilities to uptake material, which are the factors that affect the size of the resin market and projections of market share. One of the common points of mention in a global market report is advancement in technology in the field of high purity fluoropolymer formulations and making it possible to use one and the same injection molding and extrusion process for both. Strategic buyers follow these forecasts closely to plan their procurement, as well as they will be more inclined towards the usage of raw materials as collateral, for future demand satisfaction.

What are the factors that should be taken into consideration for a fluoropolymer resin manufacturer or resin supplier when selecting it?

Selecting a supplier or a fluoropolymer resin manufacturer requires evaluation of quality control, raw material consistency, and the capability to deliver high purity fluoropolymers and high purity PFA on time. Some significant supplier factors include having certifications for electrical insulation and dielectric properties, having a good R&D setup, and having enough experience with the chemical processing equipment and processes. How the supplier has been applying his track record in the wire and cable insulation and the wire and cable applications, and his capability to support such major sectors as semiconductors and automotive, should also be considered. The supply chain is affected by resilience, lead times, and the availability of the primary plastic materials. These three key factors directly influence procurement decisions, thereby resulting in the retention of market share. Last but not least, the supplier who can provide the best innovation in pfa materials and pfa grades can always be in a better position as the products will be differentiated in the market and thus be able to compete.

Why is PFA preferred for wire and cable insulation and data cable applications compared to PTFE?

Perfluoroalkoxy (PFA) is a material which can be easily processed, is produced in higher purity than PTFE, and has a better melt flow, all of which makes it the best choice for applications such as wire and cable insulation and data cables with respect to PTFE. Its being non-reactive and very much resistant to chemicals, in addition to its ion non-exchangeability, that it can operate in a very rough surrounding (among other things, in the production of semiconductors and specific types of chemical processes) and still be reliable, are really the main advantages of this material that can also be considered as the perfect match, the most suitable one. Besides their mechanical strength and flexibility, the dielectric and electrical insulation properties of the PFA materials are also excellent hence, they are indispensable for high-speed data cable and wire applications. Sometimes it is required to use only the highest purity grade of PFA in the medical devices and the semiconductor industry again to keep the area free of contamination and to have high polymer purity. Manufacturers and resin suppliers, who could provide no bigger choice, call PFA a winner on the counts of having molding that could be as simple as any part made by injection molded parts, along with consistency in its performance even under the most severe conditions.

How can the resin market size and global PFA supply be affected by raw materials, chemical processing, and supply chain issues?

The availability and cost of raw materials have a significant impact on the market size of resins as well as the ability of resin suppliers to cater to the rising demand, thereby causing ups and downs in not only the global PFA supply but also the total fluoropolymer market. Limitation of chemical processing equipment & methods including the equipment capacities and the need for specialized production for PFAs, may hinder the output and result in supply chain bottlenecks. Interruptions in the supply chain of plastic raw materials or feedstock can not only extend lead times but also force companies to seek different suppliers or make long-term contracts to stabilize the supply. The above-mentioned difficulties affect the market forecasts, and they can even cause the redistribution of the market share among the top-tier companies depending on which one is capable of reliable deliveries. The companies that are engaged in the development of new technologies and expansion of production facilities usually reduce the risks and take over the larger market proportion for pfa.

Can you indicate the main factors for which R&D and high-purity fluoropolymer development are essential in applications such as semiconductors and medical devices?

Important R&D factors for high-purity fluoropolymer and PFA include the strict quality of the product and the purification technology advancement. Moreover, the optimization in production processes is also crucial to achieve the chemical inertness and dielectric properties needed for Semiconductors and Medical Devices. Resin production comprises the development of PFA grades with certain properties according to the demand of different markets. These properties are not only dependent on the resin characteristics but also on the processes used for the specific market needs. Such collaborations between the resin supplier and the end-users in the market have been reported in the automotive, semiconductor and electrical industries, and the key areas of these collaborations are non-destructive testing and supply of new materials. R&D is another way of enhancing the competitive position of the resin supplier by introducing a new product line and providing materials for new applications. R&D expense could be high but the returns could be enormous.

How might buyers assess market trends, the competitive landscape, and the selection of leading companies from among the global PFA resin producers?

For the buyers to fully understand the competitive landscape, it is advisable that they perform market trend analysis and check the market for PFA reports to discover the CAGR, regional demand drivers, and segmentation by PFA grades and applications. The top companies can be rated by going into detail of capacities, client references in the wire and cable and semiconductor sectors and openness and quality of supply chain and raw material sourcing. The prospective buyer of PFA should see and compare the different suppliers in the market such as the availability of high-quality chemical-resistant materials, good dielectric properties, and good process ability engineering resins and verify the certifications for electrical insulation and healthcare device suitability if that is suitable. Fluoropolymer resin manufacturers are among the producers to consider partnering with especially those that are very much into R&D and have very good quality control records; stable and on-time resin deliveries are a must. At the same time, do not forget to take into account the market shares, world-class companies’ presence, and the capability to produce on a large scale as well as the capacity to expand when choosing a supplier for the long term.