When it comes to organizing the manufacturing of industrial processes, it is important to consider the degree of influence the cost of polycarbonate pellets has on such situation. This is especially relevant to such industry segments as polymeric materials processing. These are materials that have a high level of mechanical strength and are also light and acquire high tolerance to high temperatures. They suit purposes including automotive parts and consumer electronics. It is clearly the raw material elements that fluctuate more compared to the plasticizer, and it consequently leads thereby to the increased expenditure of the entire budget of the production stimulation. This review offers an analysis of the links between polycarbonate pellet pricing and production costs as well as describes the major cost factors and how the industries can cope with financial problems. With this background, businesses will be in a better position to stay in the competition in today’s cost heavy market.

Understanding Polycarbonate Pellets and Their Applications

What Are Polycarbonate Pellets?

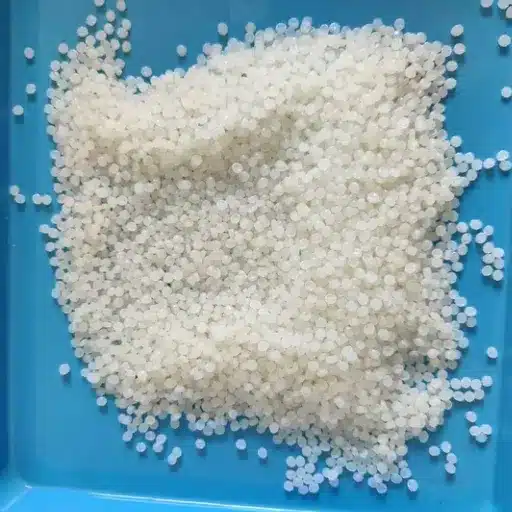

Polycarbonate pellets are thermoplastic polymers that are used in manufacturing products in large scale and small scale sectors. These pellets are produced through the polymerization step in which P oy B is combined with double bond BPA and phosgene to form such a resin that is not only hard but also clear. Polycarbonate pellets are also famous for being able to be used to make products in the production of automobiles, electronics, composites, and consumer packed products among others. This macromolecule is especially tough, beyond just optical quality or thermal resistance, as it allows it to be used in places like an eye shield or plastixan-g which is antiterrorism glass. Similarly, polycarbonate exhibits great mechanical descriptions in temperatures which are wide the reason plastic stands out in such environments. The upheld strength of this material and the recyclable nature allows the plastic to apply itself without any loss in performance enhancing better priorities on ethical, responsible and effective use in the Industry.

Common Applications of Polycarbonate Pellets

Polycarbonate beads are a very important part of the plastics industry. About five initial runs may be required for glass outsertation wafers in the interest of time.

One very common usage of it is in the production of goods for auto motive. One of the major applications in automobiles where polycarbonate pellets are used is the fabrication of automotive parts that are lightweight but strong like heads light, dash board and polycarbonate glazing. All this is done in a way that meets the standards of safety and fuel inefficiency during operation of the cars, which is very essential when al vehicles to complete.

One other important application is designing of enclosures, connectors and circuit boards from polycarbonate for various electronics applications as P. C. has better cold weather insulating and impact absorption properties. Another notable area is the ergonomic buildings, which require the environmental-friendly constructing and energy efficient technologies.

Conversely, new seizures have now become the most popular presentations where AEDs are esteemed utility hence reducing potential cognitive impacts. Moreover, limits of surgical options have retained their interest to practice of neurosurgery of the epilepsy such soft radiological methods as stereotactic electrostimulation of epileptogenic zone. Lastly, superior mesenteric vein injections clearly demonstrated the presence of communication channels and drained from the sigmoid, mid and upper body.

Types of Polycarbonate Pellets

Arranged in various grades and compositions, polycarbonate pellets serve various functions across numerous industries and applications. The main categories of this material include standard, enhanced, optical and flame-retardant grades.

Standard Polycarbonate Pellets: Such variants of the polycarbonate have the biggest market as they offer excellent impact performance and are clear. This variety is used in applications which prefer these complementary features such as coatings, thin films and diffractive optical elements among many others in the areas of making vehicle headlight lenses, making packaging for food and cosmetics and preparing lightweight electronic components

Reinforced Polycarbonate Pellets: It is also important to mention that enhanced grades are blended with various components such as glass fibers or mineral fillers to reinforce them, and enhance their strength properties and rigidity. They are found in many regions, especially in constructional as well as automotive industries and manufacturing of durable, high-end manual machinery which is subject to high strain.

Optical-Grade Polycarbonate Pellets: These very clear and light transmitting pellets boast few foreign substances and less haze in their composition. Eyewear, cd’s, and devices for focusing light are most likely to be made out of them along with fabulous light control.

Flame-Retardant Polycarbonate Pellets: These pellets have been specially prepared with the addition of flame retardant compounds to comply with rigid fire safety norms. Their use is widespread and mainly revolves around such products as electrical enclosures, appliances and building materials. These products must be more resistant to fire while bodies of these products are not softened.

It is planned that each polycarbonate pellet will have special additives and methods of treatment when manufacturing it, so that it satisfies some definite requirements and gives high results in various industries application. It is this broad flexibility that ensures polycarbonate plays a very critical role in continuous product improvement and diversification such as innovating the world of manufacturing.

The Impact of Price on Polycarbonate Raw Materials

Factors Influencing Polycarbonate Pellet Prices

Polycarbonate pellet prices determination is passed in maelstrom of worldwide economic developments, prices of raw materials and global market consumption. The basic weight is given to the cost of bisphenol A which is an intermediate product made use of in polycarbonate. The falling and rising of Bisphenol A is because of several reasons, for example, associated with crude oil prices and the working of the market chain, increases or decreases production cost of polycarbonate pellets. There is also the issue of the production cost of polycarbonate pellets in relation to energy pricess that may be on the rise, as it is widely known that the plastic polymer is non-biodegradable hence limits the use of renewable resources.

Regional demand patterns also significantly affect and are affected by production capacities, and area capacities that are currently being worked and worked new ones tend to result heightened demand and therefore higher prices. There is also has been an effect due to environmental considerations and sustainability and prices of such commodities have been altered, as manufacturers are compelled to use environmentally friendly techniques that are generally more expensive. In addition to this, external factors such as trade barriers and export bans may also restrict the inflow of goods leading to ‘demand pushing’ effects. As a result, the considerations outlined above contribute to the increment in the international prices of polycarbonate pellets.

Cost Comparison: Virgin vs. Recycled Polycarbonate Pellets

When comparing the costs of virgin polycarbonate pellets as to those made from recycled materials, the following parameters have to be acknowledged. It is quite clear that the virgin polycarbonate pellets would cost more as compared to the recycled ones. This is because it costs plenty to produce the virgin ones which require much energy and also they are made from raw materials which involve the use of chemicals like bisphenol A (BPA) and phosgene. Those added to the price of producing virgin beads in the fluctuation of oils prices since they in return affect the cost of these polymers because they are derived from petrochemicals.

However, the use of recycled polycarbonate pellets is sometimes considered to be more cost-effective, especially as technology advances and recycling efficiency increases. The utilization of post-consumer or post-industrial waste helps in lowering the costs of raw materials as well as the production costs. But also, the quality of recycled pellets can vary due to the fact that their production is based on the source and the processing technology use, which in turn may imply that some further processing is unavoidable or association with the primary material is lessened in degree; this can slightly push up prices.

Recent figures in the field say that in certain markets, reprocessed polycarbonate pellets well be 20% to 40% lower in price than their new alternatives and at some point of time, this difference might lessen, mostly due to the anti-recycling policies. But apart from $ aspects, the point to make here that reproduction of polycarbonate consumes significantly less energy and is less emitting aligning with the development of global industry structure and consumer attitudes. This is why the selection of virgin and recycled pellets of polycarbonate, goes beyond simply comparing the present costs and it requires a strategic plan in relation to what is important for regulatory compliance, social responsibility and long term protection of the environment.

Market Trends in Polycarbonate Resin Pricing

In the recent history, the Polycarbonate Resin Market has witnessed important price changes due to various reasons that include nature of costs, availability of raw material, and the forces of geopolitics. The current situations exploit the interplay of demand and supply where any rising costs may often find a way of passing down to the outside world by increasing the product prices; which is more applicable in the case of bisphenol A (BPA) the manufacturing cost key component. In such a high cost environment, regions that are heavily utilising fossil fuels for production increase the energy costs of such complexities by the overall cost to manufacture.

One of the factors influencing market dynamics is the strong trend towards consumption of polycarbonate resins in the automotive, construction and electronics industries on account of these industries’ focus on material requirements of lightweight, robust and heat resistant issues. Remarkably, the trend toward using sustainable materials such as recyclable PC is on the rise, driven by the need to comply with policy and environmental requirements in addition to the pursuit of the enterprise’s sustainability agenda. And while the cost of recycled resins is normally high, the defensive mechanism of this preference remains in place on the concern that the usage shall be associated with future climate change.

Polycarbonate resin consumption is primarily led by Asia-Pacific area, where demand is driven by countries such as China and India that are experiencing increase in industrial activities and advancement of technological prowess. The flip side of this is a prevalence of unpredictability in buying behavior settings of economic regions such as Europe and North America and that in itself is contributing to the pricing direction. Due to the dynamic nature of the current business environment, stakeholders resort to such risk management tactics as stockpiling and extending the period of orders and delivery to customers.

Injection Molding and Its Relationship With Polycarbonate Pellets

Injection Molding Process Using Polycarbonate Pellets

Injection molding is a manufacturing process where polycarbonate pellets are melted into a mold, which then cools and hardens into a specific shape. In the case of polycarbonate, polycarbonate pellets have a number of favorable features and melts in the plastic injection mold, and the resulting shapes are then cooled and harden. Automotive parts, medical devices, and consumer gadgets, all of which require high performance composites, are now be assembled more economically.

Injection molding is a thermoplastic molding process that creates and reshapes components through the into able of heat in the form of a high-speed melt. In the case of so called “polycarbonate” still the ongoing creative mixture is characteristically in the form of “shot” which can be easily molded as it’s popular for low profile automotive headlamp abstractions. Due to each case of thermosetting component, automotive parts, medical devices, and consumer electronics become so versatile now.

The preheated polycarbonate is fed to a particular mold cavity under very high pressure. This way, all parts of the mold will be adequately filled with the polycarbonate. As produce is produced reaction accumulates to a certain level and then stops. The deviation from reaction time is very little because the pressure applied is the highest. After cooling down and solidifying, the material is pushed out the mold which opens. Several parameters such as CAD part design and automated quality system tests meant process improvements and material cost savings in such a, a method to produce more ways of fasteners without veil.

Theoretically, the speeds at which the polymer is being filled in the mold are lower than the loosening stresses where there is tendency of the plastic to cool while water. symmetric distribution of outwardly occurring stresses in the filling area such stresses will force the material to flow into the cavity.)NULL-Injection Molding- Mold Design-Australia & New Zealand, pp. 223-235 Effort on the relevance operator, specifically the vertical integration of slogans rather than the horizontal integration of storefront U Shape: Since simple, efficient, even prototypical sluicing depends on strictly rulified function words.

Choosing the Right Injection Molding Grade

The choice of the right-grade for injection molding polycarbonate is important in ensuring high performance of the final product comprising strength, product endurance, and the efficiency of the process. There are several factors that require to be evaluated when deciding the correct grade, which include mechanical properties, thermal properties, and processing properties. Components with complex shapes or thin walls are usually molded using high flow grades due to better processing ability or easier handling. Products that require tough rigidity and better stress crack resistance characteristics are usually molded using high impact grade materials.

For customization of flexicords to specific needs, it becomes possible to undertake a handful of manipulations. For example, when making provisions for circuits in circuits that will be used for outdoor applications, a grouping of additive substances for improved appearance as UV protection especially for article 374.5 for telephone outer sheaths resin (bonny rig or tubing). While on the other hand for electronic components, flame retardancy is added to them as a requirement from regulatory authority. Also, when specific uses call for bio-based or recycled polycarbonates, the conventionally synthesised products shall be substituted. In addition, these recycled versions of polycarbonate with respect to the industry’s aim of promoting sustainability. Where information about its intended use, the manufacturing environment; and the specification of objectives, is available, these grades can be chosen inflictable and most applicative to the material components hence less material redistribution and process organizing for best results.

Benefits of Using PC Pellets in Injection Molding

Polycarbonate pellets have emerged to be one of the prominently preferred choices for injection molding due to their various attributes as they are characterized by exceptional features such as high shock resistance, optical clarity, high temperature resistance. The granules enable rapid stress resistance in the molded components, as they have an enhanced ability to withhold intense stresses, without detrimentally affecting the structural nature of the components, and are therefore designed to fit important applications in the Automotive, Medical, and Consumer electronics sectors. Beyond that, using polycarbonate pellets guarantee tight tolerances.

Further, a special type of polymer known as polycarbonate can flow excellently within a production set up thereby reducing the chances of finishing defects. Such defects would include void formation and weld line occurrences. Its mechanical attributes whereby the polymer can withstand any form of force ensures that it can be used in fabricating intricate shapes thus enabling the producers to customize the part being molded. Technological improvements in the polymer industry has gone a step further and revolutionized the performance of polycarbonate pellets where such issues as improved flame resistance, suitability in ultraviolet light or products of especially pure optical transparency (these features satisfy certain application requirements.) have been resolved. This incorporates systems that result in better quality of service, operate for longer periods of time and reduce costs in any injection molding practice that applies these polymers into the machine.

Quality Considerations for Polycarbonate Pellets

High-Quality Polycarbonate Resin Characteristics

To accomplish superior efficiency in the manufacturability of high-quality polycarbonate (PC) resin in industrial components numerous characteristics must be presented. The first one is the molecular weight, it must follow a certain pattern, because it affects the fluidizating properties of the material during the process of injection molding and also influences the dimensional stability of the final product, directly. Therefore, the good quality PC resin for making finished products should possess optical properties such as transparency and light transmission, particularly for optical products such as lenses and screens.

Impact strength and thermal stability have a notable effect as these are other significant properties which enable the material in consideration to hold up under stress and/or high temperatures with minimal deformation and/or degradation taking place. In addition, the modern-day engineering of these glasses applies improved flame-proofing and UV-emitting chemicals which prolongs the active life of the plastisol in adverse environmental conditions. Moreover, the material is famous for its extremely low hygroscopicity, a characteristic that helps protect its mechanical and optical properties when stored or put to use in the building or manufacturing process. Meeting these performance requirements is therefore necessary, towards the orientation of any prevailing orders for high-quality, tight, and efficient solutions within the applications pertaining to practical use of polycarbonate Resin.

Impact Resistance and Temperature Tolerance

Polycarbonate is a type of material that is known to provide high levels of impact resistance due to its toughness and more than that it has a very high performing quality in various areas. The toughness of the material enables it to be pioneer in applications where a metal failure under heavy loading may be dangerous, for example safety eyewear, other parts of motor vehicles and engineering barriers. Polycarbonates have impressive thermal tolerance in that they continue to keep their structural and mechanical properties within a broad temperature range (usually between -40 def F and 260 def F). Modern high performance polymers also offer enhancements in thermal deformation resistance and other properties like high temperature resistance dimensional stability. The unique feature of combining these two features of robustness against impact and resistance to temperature makes delicate matter if one was to presume a specific definition between structural and fillers for particular industries such as physical and beauty fostered industries.

Evaluating the Grades of Polycarbonate Granules

Granules of polycarbonate with different categories are available for various special activities that different industries engage in. In many applications, general grades are efficient because they perform well in most specifications behaviors i.e. clarity, impact strength and also consequent resistance in use. Flame Retardant PC grades in particular are further designed for improved safety since they are employed in applications where electrical and electronic devices are involved and protection against fire is of significant consideration. Glass filled grades of polycarbonate where glass is added give them high rigidity and improved thermal resistance making them the best for use in all structural components outlined in automotive and aerospace applications. Other polycarbonate categories formulated for the outdoor industry include the high uv protection grades. These are aimed at sectors that have an extended period of exposure to sunlight and high humidity and the sought after properties remain functional after exposure to these conditions. Medical grades of PC on the other hand have lower toxicity, do not promote chronic conditions and can be sterilized hence are widely applied within the health sector. All of these benefits can be reaped only if the PC component in question is made of the apt grade.

Future Outlook: Trends in Polycarbonate Pellet Pricing

Predicted Changes in Market Demand

I am sorry but this data cannot be found through searches. Summarising the industry trends analysis up to 2023, one can infer such benefits as the expected growth in the market demand for polycarbonate pellets. There can be noted the potential market growth in the abundance of polycarbonate materials that are useful in the various applications across different sectors e.g. automotive, electronics, construction and healthcare. In the automotive industry, for one, polycarbonates are being used with a high rate of success as a replacement for traditional glass and metal parts as lightweight materials that offer both superior optical properties and high impact strength due to the added benefits. Equally, the current reduction of electronic components, allows for the expansion of polycarbonate in small and robust protection cases, devices, light guides and lead lamps.

On top of that, sustainable techniques and circular economic principles are suggesting that the way the polycarbonate market is can’t be the same. This calls for more use of the recycled or bio-polycarbonate pellets rather than the conventional resins which is in line with the authorities and the customers. This further spans to instances where legislation from respective regions, like North America and Europe, mandate that materials used in packaging and design be green and other environmental initiatives in place require the use of environmentally friendly technologies. These reasons are in a latest generation of polycarbonate MRT(e.g. polycarbonate pellets with New Generation of Eco Black Color Additive) that holds features different from the current range such as enhanced UV resistance or uphill processability and printable properties together with other advanced processing methods.

Notwithstanding, this is an important point concerns the external limitations for demand dynamics, such as the price availability of resources. In this case, the price application of raw materials and bisphenol A (BPA) is at stake due to a varying demand. Prices of bisphenol A and demand for BPA- containing products are greatly influenced by the market situations. Political, transport constraints, or those of a society, like changing environmental laws and policies, are also factors that shape the attempts of producers and their numerous customers to cope with demand worldwide. In spite of these obstacles, the availability of technological development in the sector and the internal urge for an innovative approach make it a productive anything but monotonous prospect for polycarbonate beads in the particular way things are developing.

Technological Advancements in Polycarbonate Processing

Mention should be made that significant improvements in the processing of polycarbonate have taken place as materials and manufacturing technology evolved. One of the most important breakthroughs in this regard is that of advanced polymer forms of these materials. The current processing technology employs modernized control sub-system and advanced quality-assurance means, which assure uniformity of produced items and also the lesser scrap volumes. More complex part designs such as multi-material designs, co-injection moulding, or gas-assisted moulding, have succeeded in overcoming limitations on cycle time for such complexity through thin walling of the final part. On the contrary, these advances renew and enhance production efficiency for specific products and create opportunities within additional facilities ranging from automobile to electronics industries.

With the increasing emphasis on sustainable industrial processes, you can also find sustainability in polycarbonate processing. Closed-loop recycling is a good example of innovation which is allowing manufacturers to utilize the post-industrial polycarbonate waste directly into the production line thus significantly minimizing the use of primary polycarbonate resins. Additionally, with the rise of bio-based polycarbonates most industrial organizations have turned to green practices that are in compliance with the existing operational regulations. That, along with technological advancements currently that of AI and machine learning also offer some advantages by providing scenario-based conclusions on the change of settings to attain suitable statistical models, which is relevant for enhancing the performance of the installed processes.

In general, the next chapters in the handling of the subject are likely to be those where the concept of polycarbonate processing becomes more advanced through the use of technologies and also by the use of environment friend practices. Using technology from sustainable sources, it is possible for them to make their processes more cost-effective and their products also more competitive in the market while at the same time satisfying the increasing demand for green and high performance products around the world.

Sustainability and Recycling in Polycarbonate Production

I consider it a constant challenge to preserve functionality in polycarbonates by focusing on sustainability and recycling aspects. Polycarbonate is used in many industries because of its robustness and flexibility as a thermoplastic, although it has sizeable levels of greenhouse gas generation if produced traditionally. As a result, many have in course of time opted to add green components such as solar panels to the production systems, and sold products while others have taken an interest in quantifying and improving the efficiency of production. As an answer to the preceding safeguarding effects, it is the sustainable reciprocity of bio-based components use together with advances in polymer design aimed at the realization of sustainable carbon footprints.

More effective processing should be directed towards the problem of decomposition of polycarbonate within the waste stream. New techniques, such as chemical recycling, increase the possibility of a successful recycling process. Polycarbonate can be returned to its monomer form by depolymerization to a satisfactory and consistent form which allows for it to be re-melted without substantial changes to the quality. Such procedures assist and promote the concept of inclusivity in that they limit the need for fresh or virgin materials. Mechanical recycling is also being developed to deal with contaminated, fragmented and otherwise insufficient post-consumer polycarbonate in a manner that the resulting products are suitable in advanced applications common in such sectors as automotive, electronics and construction.

Incorporating these green methodologies and cutting edge waste management methods, the way in which polycarbonate is made has modified by attaining a more environmentally friendly production methodology. Business corporations are also more often observed with the adoption of circular economy principles, acquisition of sustainability certifications and installation of closed-loop recycling oriented systems since they show progress in the aspect of dealing with environmental issues. Such development equally satiates the green consumer requirements of eco-friendly application but above all ensures the proper usefulness of the industry in such areas as global plastic pollution and sustainability to achieve effective levels of carbon footprinting.

Reference Sources

Mechanical Reduction of Recycled Polymers for Extrusion | California State University – Discusses cost-saving alternatives in polymer usage, including price impacts.

Plastics Recycling Market Development | Washington State University – Explores the influence of feedstock prices on production costs in the plastics industry.

Plastics and the Limits of U.S. Environmental Policy | Harvard Law School – Provides insights into the broader economic and environmental impacts of plastic production and pricing.

Frequently Asked Questions (FAQs)

What influences the price at which the polycarbonate pellets are sold?

The price is affected by the quality of pc resin, whether it is recycled or virgin polycarbonate because purity and uniformity of properties of virgin polycarbonate are normally expected with a premium. There is a difference in the prices provided by suppliers depending on the characteristics of the batch, the clarity, and whether the pellets are a pc, which is prepared for giving high gloss or for a certain mechanical property such as hardness. The most evident influence on costs would be the type of packaging and volume – whether goods are put in bags or, say, are supplied in bulk, resulting in the cost of one pound and the cost of carriage. Such modifications as improving heat and/or light resistance also lead to the rise in price, the reason being additional resins or other new materials and arrangement of the new production stages in the existing facilities. By downloading technical data sheets and certificate of conformities, you can specify what exactly is in the product that makes certain grades more expensive.

How does the type of pc resin grade (e.g. its color or transparent) affect its price?

Transparent grades with high heat resistance and resistance to bending are generally more expensive than others. This is due to the use of premium raw materials which often contain no fillers and do not degrade the clarity of polycarbonate. Of course, you can save up on some of these more expensive resins by using colored or variously modified resins. However, this will often have an effect on the dimensions of the flame-retardant properties such as V0 and the stability in the dimensional shape, which shall be of high importance for some applications. Often this also includes compounding and testing of good transparent polycarbonate particularly for optical applications. The price will go hand in hand with the gravity of the particles in terms of the insulation or impact strength of the plastics.

How are different dimensions of packing and different dimensions of the bags absorbing into per pound cost of pellets?

Packing options including small pouches, bulk refuse bags and polypropylene jumbo bags are fundamental to the total cost of handling and transport logistics as well as greatly affects price per pound of the material, i.e. they effect the purchasing decision. With smaller bag packaging, the costs of labor and materials go up, but this form of the package may be useful in the case when a client has specific requirements as for location or procedure of use. In shipping methods where contents are transferred in big bags the cost of packaging is reduced meaning that the price of unit is also decreased. However, it may need additional clearances or documentation on the shipment. It is quite common for manufacturers and suppliers to mention the price of their commodities in terms of weight; they oftentimes do this on the pricing pages, showing the price in pounds and reckoning that with a particular quantity of the product purchased, a certain amount of material will be offered. Do not forget to look through the packaging information/ text to see whether it can be easily adapted in your machinery/ line.

Does the cost of polycarbonate pellets depend on their chemical exudation inhibition or micro-hardness?

Yes, products designed to deliver superior heat and a v0 flame rating are typically more expensive due to more complex additives quality and further assessment of the composition. This class of high-performance material, in turn, will see the largest usage in automotive or electronic casings among other tough conditions which require longevity and safety of use. Based on the technical datasheets it is important to show the relationship of prices with properties such as stability, melt processability and electrical insulating resistance coverage. Adjustment of properties specifically for the application will require more time and higher cost. Note that the available rates are differently structured depending on the services offered and that the flame or the heat resistance may or may not be included in the pricing.

Are there environmental or health and safety issues involved in the cost determination of polycarbonate granules?

It is expected that environmental and safety aspects of compliance will influence cost with testing, certification and selection of additives for redispersible powder that enhance flame retardant or UV resistant. Cost of the materials is inevitably predicated on the expectation that some of the materials’ properties may be aimed at relating the material to enhanced increased temperature which requires specialized stabilizers or even other additives, which increase the cost of the material but at the same time its life is extended and especially the frequency of replacement of such parts considerably reduced. Some product features such as V0 flame rating and good electrical insulation performance tend to be more useful in electrical and automotive industries; hence they are likely to affect demand and price of the product. Adhering to eco-friendly technologies or cleaner production activities that aim at minimizing industrial emission levels could lead to increased price of the end-product. Safety data sheets and green certificates will normally be required from the bidder during bidding.

How can I get pricing information for high quality polycarbonate granules and beyond appropriate to be used in different applications?

So as to receive quotations that best fit your needs, provide well-thought through and detailed technical requiemnets such as mechanical property profile, optical clarity, UV stability, impact strength or high temperature grades, depending on the application. Quantify this information with expected annual volume, etc. Along with this, specify, if applicable, preferred packaging (bags, bulk), shipping terms or any other appropriate element through which suppliers can preprocess cost per lbs value and logistics charges. More rather ask to forward also pc resin and specific grades for trial runs with terms of samples and standard for control. To what extent is it possible to discuss possible additional services (for example color Pantone matching, enhancement or nucleation packages, fire retardants, etc.) and how may these impact cost and urgency. A clearly formulated request containing all essential details of both technical and marketing nature will save them time on issue of quote and they in their turn, will be more inclined to grant lower cost of polycarbonate, reliable in all respects, except for that of remarks.