The development of plastic products has radically changed from its initial stand point due to developments in material science and manufacturing processes . As such polymers are the primary chemicals studied in this sense as it is covered in this paper. Fundamental polymers are grounded functional materials and there is no counting the numbers of innovations they have spawned starting from unforgettable progress in electronics and portable artefacts for transport. The article shows how polymers let designers and builders create different objects in at least three dimensions and how they enable to achieve sustainability in industry. An understanding of the properties and uses of such fundamental substances enables us to see how diverse and important they are to product development in the future.

Understanding Raw Plastic Granules

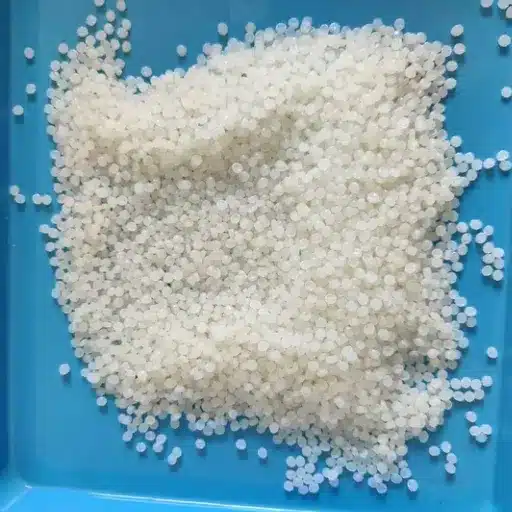

What are Raw Plastic Granules?

Plastic raw materials such as polymer pellets or plastic resins are used as the raw materials for various types of plastic products. Plastic polymers which are otherwise called the bead or sphere like plastic substances come in size granules and can be manufactured and processed by various methods using tools like the injection molding, extrusion or blow molds. They are developed from basic chemical processes of coal tar distillation, natural gas cracking, polymerization and modification to grow chemical networks constituted by different polymer families such as polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC). Raw starch granules of each such polymer are quite unique in terms of their chemical composition, mechanical properties, thermal behavior, and other characteristics, and are known to be used in the preparation of a number of products, from high-tensile structural parts to thin packaging. Them being of opted size and shape make them highly essential for enhancing process control and thus generally high qualities and purposes of the products in which they form part of.

Types of Raw Plastic Granules: PP, PE, and More

Many believe that plastic granules in their raw form are most often separated by polymer structure or (and) functional qualities these contain, being among the most used ones in practice, polyethylene and especially polypropylene (PP). Famously, polypropylene is noted for its high resistance to chemicals, its light weight, and its superiority in terms of mechanical properties which are judged by many to be the most useful, particularly when making parts for motor vehicles, articles for the common man, and upholstering instruments in the medicine. Polyethylene on the other hand, which is sometimes referred to as low density polyethylene (LDPE) or high density polyethylene (HDPE), is considered very tough as well as relatively light weight. Also, it is characterized by the ability to resist moisture or in other words, it does not allow water to pass through and this is usually very useful when the materials are used in piping, wrapping of bags, and the production of clean empty bags among many other cares.

Beside PP or PE some other notably popular granules include polystyrene that has hard structure and good heat resistivity as well as polyvinyl chloride that is known for its high chemical and fire retardancy properties. Thermoplastic granules can also be modified through incorporating various additives for example UV additives, impact modifiers or even coloring agents in order to cater the needs of other industries. It must be noted that new technologies of polymer science are aimed to create more sustainable and recyclable granules. They are to satisfy the existing requirements of the environmentalists which demand materials which are simultaneously high performing as well as environmental-friendly, or green materials.

The Importance of Density in Plastic Granules

The value of the density of the plastic pellets is an important consideration in designing and using the material as it [the density] is related to the mass, aside from the structural and processing features. It is usually conceptualized that high-density pellets will perform better in terms of strength, stiffness, and abrasion resistance and are well suited for industrial applications within the automotive, construction, and packaging sectors. On the other hand, low density pellet is lightweight, and soft which is very appropriate for form of consumer usage or composites where easy of use, heat or air retention, or weight saving in certain parts is the most important consideration.

From a manufacturing view, the density of a substance that may have an effect on the processing within the extrusion or injection molding procedures is important. Material of higher density when applied under stress will always tend to be in good flow whereas material that has low density when in form of granules may lead to shorter cycle times as they require less energy. Density further affects cost calculations; depending on the volume and ease of material handling.

Recent progress in science and technology allows it possible to affect a polymer basic density, adding fillers, foaming agents or introducing structural changes at the molecular level. In another case, microcellular foamed plastics are produced by thinning the solid polymeric material with gas and recovering about the same strength in a much lower density material. Those modifications allow producers not only to meet high performance requirements but also optimize costs for their products within the framework of current industrial challenges.

Plastic Recycling and Its Impact on Granule Supply

The Process of Recycling Plastic into Granules

There are several measures taken to recycle plastic fast food packaging into granules in a way that the end-products are produced using the least amount of resources and equipment possible. In simple terms, the process of recycling plastic into raw material like granules is broken down into several phases which makes it much easier to explain. At first, after obtaining the proper permissions, the plastic waste is collected and sorted. This is important as it aids in the classification of the different types of plastics, resin codes as well as colors and ensures a good quality of the end granules is preserved. Extensive mechanical or optical systems are often put in place during this stage to help in minimizing any errors.

After the recyclables undergo a thorough cleaning process in which all the contaminants such as dust, adhesives and residues are completely removed, they are distilled in this regard to very high purity of granules. The next step after cleaning is reducing the materials size into small and uniform pieces also known as flakes which will aid in the next cycle referred to as regrinding or densification.

The polyester laminate is left to cool and it is cut in form. At this stage the polyester laminate is placed in an oven, heated to its melting temperature and pressed out through molds to produce strands of desired widths. The retrieved strands are then cooled off, blow off and chopped in small pellets. These pellets may further undergo some procedures depending on where the granules will be used, for example, unhealthy additives may be compounded for instance stabilizers or some of them may be used in combination with reborn plastics to fulfill particular performance needs.

This process disrupts the supply of pellets as it allows for the production of recycled materials of high quality which are necessary in various industrial or consumer applications. Also, by incorporating these recycled spheres in the production process, businesses are able to decrease their reliance on traditional polymers, decrease the cost of production, and also environmentally friendly. This is why different technologies and software, such as predictive analytics and quality control systems, are slowly being incorporated to the recycling areas so as to allow these operations to generate an even more stable output while becoming more financially beneficial in the process of recycling.

Benefits of Using Recycled Plastic Granules

There are so many benefits brought by the use of recycled plastic granulates, these benefits have a direct impact economically and environmentally. For instance, the partial replacement of virgin polymer with recycled materials decreases the amount of money spent on the purchase of prime material. From the economy position, this benefit is offset by the fact that less waste is produced thus less pollution and green house gas emissions are released as a result of the production of virgin material.

In terms of industry, it should be noted that the advancement of recycling technologies has enabled the separation of the industrial filaments within an appended aspect for glue instead of any other bonding agent hence improves their quality through formatting the granule stream. Reasonably, these procedures engage the component plastics in polymeric packaging help to recover the component plastics in automotive components and plastics and other materials the same without destroying the structures. Also, production costs have been low considering that industries and countries are producing goods faster compared to two decades ago. That has to do more with recycling processes and using recycled material than other processes of traversing the markets. Long live the king of recycled material.

Challenges in the Plastic Recycling Industry

Challenges that hinder the effectiveness of the plastic recycling industry include those that stem from the sectors of technology, transport and any economical issues that increase its scaling. One such main challenge, when dealing with the recycling of plastics, is that, in many countries, plastic waste is not collected separately, is left unidentified, contains mixed polymers with other substances, and contains contaminants. The problems of excess composition allow the consumption of complex and high solvents in sorting, separation and recovery of plastic materials, which may cause them to be lengthy and costly. Finally, the practice of recycling low-cost plastic products which then become raw materials for other inferior products is a factor which continues to expose a material strain with recycling facilities as a whole.

The lack of global means for the efficient processing and disposal of waste is also among the main reasons. As a matter of fact, or even many countries do not have the technical capability to conduct effectively either the collection, transportation, and recycling of plastic waste that is why the majority of recycling associated garbage is burned or takes its final disposal in the landfills. Moreover, virgin plastic price fluctuations prove to make it harder to sell the already recycled material since, in most cases, it is more expensive. The presence of such elements as colorants or fire retardants without which many products cannot be processed in some cases enhances the negative impact towards this issue greatly as these chemicals are also considered hazardous to human health and the environment.

The current issue encompasses the general lack of awareness and involvement of the public in recycling activities which is efficient. Little knowledge of the useful programs and schemes for segregation and disposal of products causes damage to the output due to the presence of foreign substances in the recycles. All efforts to tackle these challenges demands proper policy development, promotion of technology and community sensitization to restore a sustainable plastic recycling industry.

Granule Suppliers and Market Trends

Identifying Reliable Plastic Granule Suppliers

When it comes to evaluating potential plastic granule suppliers, conformity could be classified into various parameters which will help ensure that the quality is served, that the deliveries are dependable and that the products are eco-friendly. In such an evaluation, the production capability of the supplier is the starting point. A supplier must indicate the capability of producing granules that meet a certain level of technical requirements such as the melt flow index (MFI), density strength and impact strengths for a particular application.

In addition, it is of great importance to pay attention to quality assurance. Suppliers, as part of their mandatory requirements, should establish a quality system based on standards such as ISO9001; ISO14001. These already show in practical respect a drive towards best manufacturing and best environmental practices. Such certifications though may not be that enough and for which the granules itself should be subjected to further tests in order to confirm the mechanical characteristics and durability of the granules.

There is the aspect of logistics and supply chain which is equally of utmost importance [18]. Suppliers are required to make deliveries within stipulated timelines and have inventory supporting the ability for the production to be constant. It helps in cutting costs and delivery times if a company has its own manufacturing plant or has the benefit of simple transport systems of supplying goods.

On top of the above, sustainability has become a more historical factor to be considered in the process. Since most companies now care about the environment, the focus has shifted to searching for green suppliers, who make utilization of bio or recycled things as well as material, which suits the circular economy. Sourcing or production practices that are not shrouded in mystery are said to increase customer trust and improve long-term relationships.

Lastly, the prevailing dynamism of these market changes is the shift towards the supremacy of digitalization in the process of supplier performance assessment. Business intelligence and similar corporate information systems as well as advanced technology that enables improved ERP (enterprise resource planning) but offers the possibility to provide real-time performance reporting are modern tools that assist in this decision-making process. It must be noted that such data-driven decision making is very appropriate for achieving favorable outcomes as regards the nature of work with a particular supplier, thereby serving the operational requirements and the corresponding strategic objectives.

Understanding Wholesale Prices for Plastic Granules

Plastic granules wholesale pricing relies heavily on certain essential factors including raw material, market demand, energy inputs, production process and global distribution value chain. Dominant raw materials are from crude oil and gas which takes prominent roles since their prices have direct consequences on the cost of polymer manufacturing. Also, global production levels will make some changes to supply by production shifts or the capacity expansion in regions like Asia or the Middle East, thereby, affecting the availability and price of the product.

It is also important to mention that wholesale prices are largely a function of the market demand that industries as disparate as the automotive, packaging, construction and electronics sectors have complex patterned consumption associated with the changes in economic indicators or a certain technical innovation. Such needs also modify pricing frequently since they are met with the help of developments in polymer formulations. Practical aspects on a periodic basis may cause the increase or decrease of the prices. At the same time, due to the high prices of some of the raw materials in some areas, the considerations that influence on price are freight costs, that is the cost of transporting large supplies across countries and the duty on those imports.

However, it is sufficient to take a look at the cost of plastic granules to understand that it is easier said than done. The price of this commodity is again and again fluctuating and it is important to identify the elements that lead to those ups and downs so that one can be able to earn profits out of this business.

Market Trends in the Granule Industry

Granules have become a dynamic industry where sustainability practices, volatile raw material prices and systemic regulatory alterations are changing the status quo. One of the most notable changes in the industry has been the growing need to have greener granules that are both biodegradable and/ or contain recycled content. This desire for sustainability in product development has been furthered by the transformation within polymer sciences which made it possible to achieve desired sustainable properties without compromising the quality of the products.

Geopolitical peculiarities as well as supply chain disruptions have had notable impacts on the issues traced in this paper. Within this section, reference is made to the fluctuations in prices caused by supply shortages in polymer feedstock’s allocation as a result of political developments or production challenges within a particular administrative region. Furthermore, encroaching regionalization in supply chains encourages more regional production centres for the granules so as to lessen the reliance on the global feedstock centers.

With rapidly growing development of advanced spheres, such as 3D printing, automobile manufacturing stickers and niche packing industry, applied technology is where the further development of granulates is likely to be seen. Such operations always involve rather selective requirements in terms of granules and at times trigger customized material development cycles. Under the backdrop of global initiatives calling for carbon free systems, it is anticipated that the use of granules geared towards alternative energy sources and other environmentally friendly technologies will grow further. Identifying and tackling these trajectories will continue to be an important task in order to enable every market actor to be in a position of being competitive and active in business within the constant changes in demand within the market outlook.

Innovative Applications of Plastic Granules

Extrusion Techniques for Plastic Products

When it comes to consumer electronics, smartphones and tablets are currently suffering from a significant technology deficit. The last few years have seen a steady uptick in other sectors, including automotive, wearables, and other applications. This technology explosion has been driven by a perfect storm of rising market demands, quality improvements in appliances and electronics, availability of new materials, and increased consumer awareness. Telecom companies started producing smartphones and tablets in such designs that they appear futuristic with modern ordering systems and moulding.

State-of-the-art extrusion techniques also allow for incorporating recycled and bio-based plastic granules. This falls in line with efforts towards sustainability and the decrease of virgin materials. Furthermore, modernization of screw and barrel designs tailored to the characteristic of different materials enables expanding the application even more while saving energy. It is worth noting that this progress also plays an instrumental job in satisfying the needs for high-performance plastics in the present era. Plastics that are environmentally friendly are needed in hostile applications throughout the automotive, construction, and packaging industries.

Using Granules in Packaging Solutions

Packaging solutions have changed over the years, more so with the introduction of granule-based materials as they enhance product value while decreasing buttage and presenting a realm of possibilities in packaging designs. The current polymeric granule-based formulations allow a wide range of packaging machines to be lightweight without compromising on their durability properties which combines the art of saving on materials and in the meantime practicing high value of protection. Some other additional substances may be introduced during the stage of granulation and processing in order to achieve specific values for example QUVEOxy. UV which protects products or increase weightiness such as impact strength and tensile strength and even create a barrier to prevent moisture from seeping through them. Furthermore, the advanced multilayer extrusion method is able providing even better results through the use of radical solutions to strengthen the gas barrier properties in order to prolong the shelf-life of those products in which the modern packaging is used. The only way to increase the efficiency of printing and converting processes is to make use of regranulated particles. These recycled granules allow sustainable sourcing of the required raw materials by the manufacturing entity and this particularly helps in achieving zero carbon emissions by the production processes. Most of these technological

The Future of Plastic Products and Granule Use

The future of plastic materials utilization and granule modification, in particular, is undergoing rapid changes as researchers are focusing on the addition of new chemicals and the utilization of new production practices. By using recently developed methodologies and specialized raw materials, processes, and equipment, scientists continue to find new ways to improve the properties of polymers. Internationally, advanced polymer materials are in high demand for various industries and applications including aviation, space, automotive, medicine, packaging, and construction.

There is a clear progressive level amongst manufacturers, in the ongoing development of biodegradable plastic made from plant sources like polylactic acid (PLA). The increment is due to the fact that the industry is increasingly interested in coming with solutions that are environmentally friendly. It is further estimated that the global demand for bioplastics will increase by over 15% per annum up to 2030, driven by regulation and consumer changes that emphasize consumption of more natural alternatives. There is also responsibility and governance to ensure that the waste is collected, processed and transformed into granules, which can then be used again, eliminating the reliance on new resources.

Although they are beneficial not only in addressing the environmental factors but also there are also novel applications due to these changes that are being introduced and this allows for some adaptability in terms of the engineers as well as the fabricators. It is expected that the trend is set to change as a lot of money is being pumped into research in terms of granule based solutions, with granules expected to be a major component of the plastic industry balancing performance effectiveness and cost with sustainability values.

Comparative Analysis: Virgin vs. Recycled Granules

Advantages of Virgin Granules

As indicated by pure virgin granules many benefits exist, which stem from their consistency, quality, and performance attributes.

Of primary importance is the fact that virgin granules are made from the virgin, untouched material. Such granules have a spatial layout that does not differ through the entire volume and one can be sure that they will not break at the point of application as well as their properties can be predicted in such circumstances. That is why most outstanding users such as aircraft design, medical equipment, building materials specify these materials for purchase is when a product shouls adhere to very high accuracy and life cycles potential requirements. Virgin granules contain the highest contaminant levels as they are free from such unwanted impurities which are readily observed in the recycled materials and hence are most preferred since it is the least possible chance of potential failure occurring during production and a prolonged product life cycle.

Furthermore and perhaps most importantly, virgin plastic granules from different materials are entirely unaffected by any stresses like that occur from recycling or decomposition due to heating or cooling cycles and so they maintain their shape and mechanical integrity even upon replay, this makes them a great cost-effective option to tackle those types of applications where losses from failure are not acceptable; priority constructional elements as well as such as fan and bearing housings, etc.

In general, recycleable plastic granules are at the heart of concern for positiove environmmental impact. Yet, despite the initiative of plastic-free policy, it would be naive to say that 100% plastic recycling is achievable. Though, product has made sure this question has been addressed forthwith and disposed of conclusively.

Cost Analysis: Virgin vs. Recycled Granules

When it comes to cost aspects, deciding between virgin and recycled granules is determined by several leading variables such as the type inter alia of the end product that they would be applied to, use of energy in their production and prospects for further economic gains. Virgin are known for having better attributes compared to recycled granules, but the cost of making them is higher. The higher costs are due to intensive processing of raw materials and maintaining set minimum quality standards. There are also instances when the costs could go much higher due to the price trend of fluctuating raw materials standing and the processes contributing to the production of virgin granules which are not accessible without the use of non-renewable materials.

On the other hand, recycled particles will be economically advantageous because their manufacture and processing cost is much lower. Also waste after consumer or industrial will decrease the usage of raw material and the amount of the energy used. Furthermore with the rise of the efficiency of the recycling facilities better quality recycled particles can be made thus reducing the application of virgin granules. However, despite the advantages, the recycling procedures also require investments in the separate waste collection, sorting out and cleaning the feedstock, which all should play a part in the overall consideration of the recycling process.

Environmental Considerations in Granule Selection

My process of reviewing granules aims at their environmental consequences by looking at a number of aspects that encompasses such issues as resource obtaining, expending energy and getting rid of after usage. The granule which are made by recycling are good example and one that has a huge impact on the environment because it consumes less virgin raw material. The recycled granules are processed with less energy and are less polluting compared to the virgin granules, as the production steps do not include any energy-intensive cracking or ore beneficiation steps. The granules that are recycled also help in the management and application of the waste in the environment and dispose of the necessity to build more landfills.

On the other hand, while the performance of virgin pellets is particularly superior in various contexts, it also has a cost to the environment. The extraction of raw materials and energy-intensive manufacturing result in high levels of CO2 emissions, the air pollution, the loss of flora, and the energy use of the environment, among many other unhealthy aspects. Therefore, its possible that these materials will still be used in cases like this, given that there is too much importance placed on the robustness and durability of a particular product so as to ensure that product’s life spans.

It is generally suggested staying flexible on using recycled granules. It works quite well with principle of sustainable development. In addition, integrating efficient technologies such as solid wastes management at the production point and garbage disposal for waste constituents at the end of the products’ useful life will minimize environmental reasons attributable to both recycled and virgin granules. Such kinds of improvements to the environment are necessary for more reasons than a balance of environmental preservation, stretching management problems into industry development.

Reference Sources

- Plastic Injection Molding | University of Arizona – Discusses the use of raw granules in injection molding and product design considerations.

- The Design of a Small-Scale Granulate Producing Machine | Academia.edu – Explores the design and working principles of granulate-producing machines.

- Manufacturing: Casting Plastics | Open University – Highlights the role of raw polymer granules in casting and manufacturing processes.

- Introduction to Plastics Extrusion | BYU – Covers the use of plastic granules in extrusion and their integration with other materials.

- Filament Recycling | Georgia Tech – Details the use of raw thermoplastic granules in extrusion and recycling processes.

Frequently Asked Questions (FAQs)

What are components of plastic raw materials, and what are plastic granules in relation to this?

The plastic granules or plastic pallets in English are quite simply small resin grains that are used in the major part of plastic manufacturing and production of plastic products. They are granules or pellets that are commonly used for packaging or labelling purposes and dismissed or preserved for in later use for example. Chemically, They may be produced by a method known as moulding. A plastic raw material termed as a polymer is melted joined to the grooved cylindrical rotor known as the barrel, the melt is brought to high temperatures to a molten condition and dozed into a continuous stream. Typically, this type of mechanically processed material is then allowed to cool and solidify into the final desired shape for use as and when required. These granules may be fresh resin beads or broken parts or merely finely ground solid pieces of waste plastic that have been retrieved and reprocessed. The common forms of plastic granules include polyethylene (PE), polypropylene (PP), polystyrene (PS), polyamide, and PMMA, along with their particular sets of such design measures.

What types of granules are used and what types of extruders are involved in their production?

Performing the production and extrusion melting of resin can typically be done through polymerization, which usually corresponds to a section in the user guide chapter. The point of this process can also include extrusion of the resulting polymer through the extruder, as well as its subsequent cooling and granulation, where the extrudate is cut by a granulator or granules are produced by a strand pelletizer. It normalizes the stages of manufacturing during which the temperature additives and contamination are regulated to get information of high quality on the low density polyethylene melt flow and mechanical properties. Among the available options, some of the factories may operate compounding lines that supplement the base resin with color, masterbatch, UV stabilizers or other additives as per the customer’s needs. The granules to be produced are in the forms of virgin LDPE, virgin PP and custom-built products. Manufacturers diligently take actions to remove these defects using various methods of checking and surveillance.

What are Some Ways to Classify Plastic Granules and their Functionality?

Common types of virgin plastic in the form of granules include HDPE granules, LDPE/LLDPE granules, PP granules, PS and HIPS granules as well as polyamide and acrylonitrile butadiene styrene engineering polymers especially. HDPE granules are incorporated in packagings, pipes and various industrial HDPE applications, while polypropylene granules and polypropylene pellets are found in vehicles, household goods parts and medical instruments due to its light-weight and impact sear toughness. Rigid packaging, electronics case production, disposable craft that mean more application for PS and HIPS groups due to the tensile properties and spectrum tracing nature. The situation is slightly different with bio polymeric s and engineering materials with a clear focus on some of the modern green materials such as PMMA or otherwise desired resins with high_amounts of transparency. These can be obtained at almost zero capital so as to suit the intended scope of use in which every type is most suitable to the different manufacturing processes and products that are made in the various Industries.

How the Cost of Granules is Fixed and What Conditions it?

Granules price factors are the raw material costs, which are in turn the byproduct costs of ethylene and propylene feedstock prices, resin and additive costs, and the balance between plastic raw materials demand and supply. Other determinants encompass the economic efficiency of manufacturing puzzled with is it the vis virgin LDPE or recycled granules and the extent and nature of customization as color masterbatch or compounded blends as well as logistics or kg plastic shipping charges. However, contaminants and some modification to the granules could increase the cost of the pellets, while when the granules are purchased in large quantity the cheapest price can usually be found. This is further influenced by petrochemical markets, when they have their own seasonal patterns, existing environmental laws and the accessibility of materials to be recycled. With respect to the choice of supplier, it is important to take into account not only the aspect of the cost involved — quality, consistency and compliance with standards.

Can recycled granules replace virgin granules and what are the environmental impacts?

In several instances, regenerated granules have the capacity of replacing the new ones. This has great advantages like lack of pressure on use of unconsumed raw materials from fresh sources and non-use of plastic waste in the process. Nevertheless, for the afore-mentioned reasons this modification may not be accepted. Requirements have to be met and contaminant sterilised granules are used to render their use for the processing of precision-engineered very costly applications even more complicated. Additional processing such as granulation, crushing, recovery and addition of substances or compatibilizers with normal manufacture can bring the properties of the compounds closer to those obtained when virgin material is used. This implies that the use of recycled plastic raw materials will reduce the excessive use of new polymerisation raw materials such as ethylene and propylene and their use in the right way will go a long way in reducing the amount of greenhouse gases that are produced. It is when criteria of cost-benefit analysis and legal requirements of the recycling of granules are complied with that several sectors, i.e. packaging, construction, some components of the automobile sector, etc. have their attention caught by the use of recycled materials.

What steps do resin granule plastic producers take in order to ensure its uniformity and which kind of tests are performed on it?

Manufacturers maintain quality thanks to the established methods of accurate production, control instruments such as predictability of extrusion processes, extruder control systems, and the quality control of pellet-like modifiable polymer, granules, through measurement of melt-flow index, density, and tensile strength, and level of inorganic contamination in the finished pellets. Three-dimensional analysis of size distribution is often desired; a good control of moisture and impurities is generally obtained while specific properties, viz., the impact strength for HIPS and the grade for HDPE or LDPE is applied will call for other, more particular, tests, Specially filled polyethylene is probed for, e.g., the polymer gives a high testing temperature and the ability of high density fillers concentrate into the blend. The problem of distribution of additive fillers also testing programs for consistent color, degradation tendency, and adding, for example, masterbatches or custom formulated compounds. Baseline and reference grade performance, relying eligibility of services provision, is achieved after specific customer requirements have been taken care of within the transportation, neuro, or food container markets. Consistent variation generates operation problems in the production process of downstream facilities and diminishes the utilization of better products.