One of the most widely manufactured synthetic polymers in the world, polyvinyl chloride finds application across many industries due to its exceptional versatility and cost-efficiency. This thermoplastic has made it big in plumbing systems and on into medical devices, while several industry professionals are unconsciously unaware of the intense science that explains its performance characteristics. To understand PVC thermoplastics, one would need to go into molecular structure, then manufacturing processes, and finally into a wide range of applications across industrial and consumer markets. Some discuss the properties of PVC and examine how its unique characteristics render it indispensable to modern manufacturing, while also examining its environmental implications for future development.

Introduction to PVC and Its Properties

What Is PVC, and How Is It Made?

Polyvinyl chloride is a synthetic thermoplastic polymer derived from the polymerization of vinyl chloride monomer (VCM). Production starts with chlorinating ethylene, in which ethylene dichloride is generated by oxychlorination. The intermediate compound is then thermally cracked at temperatures above 500°C, yielding vinyl chloride monomer as a by-product.

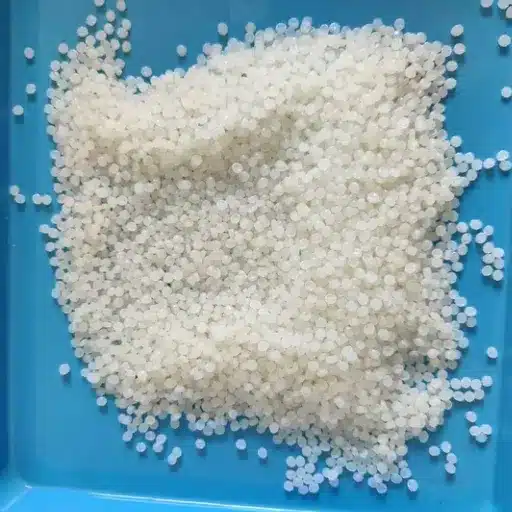

During polymerization, vinyl chloride monomer is converted into PVC using suspension or emulsion polymerization methods. Suspension polymerization accounts for 80 percent of PVC worldwide, producing coarse particles suitable for processing into rigid applications. Emulsion polymerization creates finer particles designed for flexible applications and specialty coatings.

If the polymerization temperature is not properly controlled, it will significantly affect the final molecular weight and degree of polymerization. Higher temperatures speed up the chemical reaction but result in lower molecular weights and, consequently, lower mechanical properties. Sophisticated reactor designs are found in modern manufacturing plants to impose desired temperature-time profiles on the process.

Physical Properties of PVC Thermoplastics

PVC stands out for its chemical inertness to acids, alkalis, and most organic solvents. The resistance is due to the strong carbon-chlorine bonds in the polymer backbone, which keep the molecule stable under various environmental conditions. The material provides excellent electrical insulation, dielectric strength registering between 15-40 kV/mm, depending on the formulation.

Mechanical properties depend considerably on the plasticizer content and processing conditions. Rigid PVC typically shows tensile strengths of 50-80 MPa, whereas flexible PVC shows values of 10-25 MPa. At ambient pressure, the unplasticized PVC has a transition temperature of about 80-85°C, which is convenient for cases where good dimensional stability at elevated temperatures is required.

Thermal properties decide the processing and end application of any polymer. At temperatures higher than 200°C, PVC begins to decompose, releasing HCl gas. This calls for careful temperature control during processing and also does not allow for its application at high temperatures bez an appropriate formulation.

Comparison with other Thermoplastic Polymers

PVC exhibits applications where it is advantageous over other commodity thermoplastics. Owing to its chlorine content, PVC exhibits enhanced resistance to chemicals and flame; hence, it is inherently flame-retardant, dispensing with additional flame-retardant additives in many applications.

Polystyrene, on the other hand, outperforms PVC in impact resistance and weatherability. Thus, a material is chosen based on very specific performance criteria and cost. More specifically, unlike engineering thermoplastics such as polycarbonates or ABS, PVC offers equal chemical resistance at a much lower cost. Thus, considering this, engineering thermoplastics generally outperform PVC in impact strength and high-temperature performance; hence, an assessment of the material’s suitability rests on the application.

Applications of PVC in Industry

Uses of PVC in Construction and Infrastructure

Approximately 60% of global PVC production is used in construction, underscoring the industrial significance of PVC in modern infrastructure. In water distribution systems, rigid PVC pipe stands supreme, corrosion resistance being the key: the low maintenance involved coupled with an expected service life of 50-100 years. They resist and inhibit bacterial growth, keeping water quality more or less intact compared to many metallic pipes.

Window and door profiles are yet another important construction application. PVC profiles offer good thermal insulation, weathering resistance, and dimensional stability. The multi-chamber design further enhances the insulation, while co-extrusions allow for color choices without compromising on performance.

Flexible PVC formulations are in use as roofing membranes to create waterproof barriers with superb UV resistance. These systems weld better than other membrane systems, thereby facilitating seamless installation with leakage resistance. Heat-welded seams exhibit strength higher than the base membrane material.

PVC in Automotive and Transportation

PVC finds use in the automotive industry in both interior and exterior parts. PVC used as dashboard skins includes flexible formulations that prevent cracking or fading under extreme temperature conditions. These materials must comply with rigorous flammability requirements and provide the needed aesthetic appeal and durability.

Wire and cable insulation is a critical automotive application where PVC’s electrical properties come to play. From an automotive perspective, PVC formulations are resistant to oil, fuel, and hydraulic fluids and remain flexible over a temperature range of -40 °C to 105 °C. Some of the other compounds have stabilizers incorporated to meet the specifications of automotive OEMs.

Applications under the hood require PVC compounds with much higher heat stability and chemical resistance. Air intake ducts, coolant reservoirs, and a whole bunch of different covers are rigid PVC formulations that offer resistance to automotive fluids and provide a cost-effective manufacturing solution.

Consumer Goods and PVC Plastic Products

Consumer applications attest to PVC’s versatility across various product categories. Medical devices comprising PVC formulations employ an array of medical-grade requirements for biocompatibility, such as blood bags, tubing, and disposable medical devices. These materials undergo thorough testing to guarantee patient safety and regulatory enforcement.

Packaging applications use PVC’s barrier properties coupled with their formability. Blister packs provide excellent moisture control yet allow a clear view of the product. PVC food package grades are subject to strict migration limits to ensure food safety while on the shelf.

Inflatable toys and sporting goods constitute PVC recreational products, while outdoor furniture is another end use for PVC. Those applications demand UV stabilization, low-temperature flexibility, and resistance to cleaning chemicals. Bio-based plasticizers are incorporated in advanced formulations to mitigate environmental concerns.

Types of PVC and Their Characteristics

| PVC Type | Plasticizer Content | Key Characteristics | Common Applications |

|---|---|---|---|

| Rigid PVC | Less than 5 phr | Hard, high strength, dimensional stability | Pipes, profiles, structural components |

| Flexible PVC | 15-100 phr | Semi-rigid to highly flexible | Medical devices, wire insulation, flooring |

| Chlorinated PVC (CPVC) | Variable | High-temperature resistance (up to 95°C), enhanced chemical resistance | Hot water systems, fire sprinklers, industrial piping |

Flexible PVC vs. Rigid PVC

Rigid PVC has little plasticizer, generally less than five parts per hundred resin (phr), making it hard with greater strength and stiffness. When the application requires dimensional stability, it is often used for pipes, profiles, and structural components.

Flexible PVC is made with 15-100 phr of plasticizer, producing polymers that range from semi-rigid to highly flexible. Historically, phthalate plasticizers were the primary choices, but nowadays, they are being substituted by non-phthalate ones because of regulatory restrictions and concerns on environmental issues. The selection of plasticizer affects flexibility, low-temperature properties, and migration.

Different processing techniques require different manufacturing approaches for flexible and rigid PVC. Rigid PVC processing requires higher temperatures and shear rates to achieve proper fusion and plasticizer interference. Flexible PVC processing utilizes lower temperatures to prevent plasticizer degradation while ensuring sufficient fusion.

Properties and Applications of Chlorinated PVC

Chlorinated PVC results from post-chlorination treatment of PVC resin, raising the chlorine content from 57% to 67%. This treatment raises the glass transition temperature to about 110°C, allowing higher-temperature applications whilst retaining chemical resistance.

CPVC has better high-temperature performance than ordinary PVC and can be used continuously up to 95°C. This makes CPVC suitable for hot-water systems, industrial process piping, and fire sprinkler apparatus. The material maintains dimensional stability and pressure ratings at elevated temperatures.

With chlorination, its chemical resistance to oxidizing agents and corrosive environments is increased. CPVC and other materials resist degradation by chlorine dioxide, sodium hypochlorite, and acids that would attack standard PVC. Such properties are put to good use in water treatment and chemical processing plants.

PVC Blends and Their Uses

PVC blends refer to the process of combining PVC with other polymers to improve specific properties or reduce costs. These blends provide enhanced impact resistance to ABS while maintaining flame-retardant properties. They are used in applications for electrical housings and automotive components, where toughness and fire resistance are required.

Acrylic/PVC blends offer improved weathering and optical properties for outdoor use. For window profiles, this application means more UV resistance and less yellowing. Processing-wise, it is just like processing pure PVC, but the performance enhancements set it apart.

Influenced by engineering thermoplastics, blends with PVC produce materials obtaining particular performance attributes. PC/PVC blends combine polycarbonate’s impact strength with PVC’s chemical resistance and flame-retardant properties. Thus, these specialty blends fetch higher prices, promising to marry properties uncommon in the market.

Additives and Modifications in PVC Production

Common Additives Used in PVC Manufacture

Heat stabilizers are vital for PVC processing and long-term performance. Lead-based stabilizers were once dominating the market, but now they are slowly being phased out due to environmental and health-related concerns. Calcium-zinc stabilizers now exhibit good stabilization for many applications, while organotin compounds are used where excellent clarity is required.

Plasticizers determine the flexibility of flexible PVC applications. Diisononyl phthalate (DINP) and diisodecyl phthalate (DIDP) are the primary plasticizers, with the best performance and regulatory acceptance. Bio-based plasticizers including citrates and adipates provide environmentally preferable alternatives with comparable performance.

The impact modifiers provide toughness while at low temperatures where the polymer would otherwise be brittle. Acrylic impact modifiers have been used when superior optical properties were required for clear solutions; rubber-based modifiers have been preferred when better impact resistance was needed. Chlorinated polyethylene can act both as an impact modifier and a processing aid.

Effect of Additives on PVC Properties

Additive choice directly affects the properties and processing characteristics of the final material. Lubricant packages affect the rate of fusion and the surface finish of the product during processing. External lubricants prevent the product from sticking to the equipment and include metallic stearates like calcium stearate, while internal lubricants aid wtv in particle fusion and include paraffin wax.

Colorants applied must be compatible with PVC’s processing temperature and withstand thermal conditions. Titanium dioxide provides opacity and brightness to white compounds, while organic pigments provide vivid colors. Carbon black provides UV protection and black coloration.

The biocidal additives hinder microbial growth in applications where moisture and other organic nutrients are present. Silver-based biocides provide long-term antimicrobial protection, while zinc pyrithione stands out as a simple, cost-effective alternative for certain applications. Different regions have different regulations governing the approval of biocides for certain modes of use.

Innovations in PVC Material Design

More recently, the emphasis on manufacturing PVC compounds with enhanced sustainability has been the focus of interest. Bio-based additives replace petroleum-derived components without compromising on the performance parameters of the final product. Recycled content incorporation is therefore considered in the PVC formulation within the circular economy objectives, without compromising material properties.

Nanotechnology applications could improve PVC performance by adding nanoparticles. Nano-clays improve barrier and flame-resistant properties, whereas nano-silver adds antimicrobial functionality. These technologies open new applications while simultaneously providing a means to reduce additive loading.

Simultaneously with a response to environmental stimuli through thermochromic or photochromic additives, innovative PVC formulations transform. Shape-memory PVC compounds, in the hands of an engineer, can be restored to their original configuration after deformation, thereby facilitating medical devices and aerospace components. These materials are Boston Premium at an unusual price for their specialized application.

Environmental Impact and Recycling of PVC

PVC Recycling Processes and Challenges

PVC recycling undergoes special challenges with respect to other thermoplastics, mainly due to the’ complexity of additives and contamination sensitivity. Mechanical recycling appears to be the most practical recycling process, especially for single-source waste streams with known additive packages. Post-consumer PVC usually contains a mixture of additives that only make recycling procedures even more difficult.

Feedstock recycling methods involving chemical depolymerization also become an option for mixed PVC waste streams. This conversion process works by breaking down PVC into constituent monomers and repolymerizing them into high-quality virgin materials. However, the economic viability of feedstock recycling remains difficult when put side-by-side with the cost of producing new materials.

These contamination factors, then, become critical to the success of PVC recycling. Contaminants, such as heavy metals present in legacy stabilizers, must be carefully monitored and, in some cases, rejected when stringent assessments of the waste stream are not applied. Through advanced sorting, metals and contaminants can now be separated and appropriately screened, thereby improving the quality of recycled materials.

Life Cycle Assessment of PVC Products

Life cycle assessments depict PVC’s environmental profile across its production, use, and end-of-life phases. Manufacturing energy requirements are comparable to those of other commodity thermoplastics, but the co-production of chlorine does yield economic credits. Transportation impacts remain minimal as PVC is lightweight.

Use phase environmental impacts considerably differ with the application. Applications with long service life, such as pipes and profiles, are excellent performers from an ecological standpoint, basically due to their durability. Single-use applications introduce different environmental trade-offs that need to be weighed on a case-by-case basis.

End-of-life scenarios considerably affect the overall environmental impact rating. The calorific value of PVC can be recovered in waste-to-energy plants, where emissions must be well controlled. Landfilling poses almost no ecological threat due to PVC’s chemical inertness.

Prospects for PVC in Sustainability Practices

This development targets renewable raw materials and enhanced recycling infrastructure for sustainable PVC. The bio-based ethylene derived from sugarcane or other renewable resources reduces dependence on fossil fuels while maintaining material properties. In this way, these developments reduce the carbon footprint, yet still give away to the performance advantages of PVC.

Circular economy measures promote closed-loop recycling systems for some PVC applications. Take-back schemes for flooring, pipes, and profiles generate an end stream of pure waste that can be recycled, such that quality is preserved. Such are further supported by the industry that collaborates on infrastructure development.

Green building ratings now increasingly acknowledge that PVC has a role to play in sustainable construction. The energy-efficiency benefits of PVC windows and insulation systems outweigh any negative environmental impacts during production when considering the building’s lifetime. Third-party certification specifies environmental claims and builds market confidence.

Reference Sources

- Polyvinyl Chloride – an overview | ScienceDirect

This source provides an in-depth look at the properties and chemical resistance of PVC thermoplastics. - Polyvinyl chloride | Wikipedia

A comprehensive overview of PVC, including its thermoplastic properties and various applications. - A Brief Review of Poly(Vinyl Chloride) (PVC) Recycling | PMC

This article discusses the recycling challenges and environmental considerations of PVC thermoplastics. - List of PVC Plastic Types and Their Applications | PolyPVC

A detailed guide on the different types of PVC and their specific industrial and consumer uses. - Exploring PVC: Applications and Essential Considerations | Americorp

This source highlights the diverse applications of PVC in industries like healthcare, construction, and more.

Frequently Asked Questions (FAQs)

PVC thermoplastics exhibit various properties, physically capable of maintaining service life in the production and installation of products. High tensile strength of PVC guarantees high-strength PVC pipes and electrical insulation. By adding plasticizers, one can produce plasticized PVC, which is flexible; unplasticized PVC, however, is rigid and is mainly used for building and construction purposes. PVC’s flame resistance is due to its high chlorine content, which makes it safe to use. In general, its mechanical properties can be greatly varied by altering the PVC formulation, suggesting applications across various uses.

PVC is widely used in construction, thanks to its durability and adaptability. PVC pipes are a widespread solution used in plumbing and drainage systems that do not degrade by corrosion. The sheets and films serve as waterproofing membranes and insulations. PVC has wide applications in window frames, siding, and flooring, where affordability and aesthetics are significant. Rigid and flexible PVCs can be used in any application, serving the specific intent of different construction projects. PVC compounds can also be used in construction materials for better performance characteristics.

Plasticized materials, especially PVC, are widely used in the medical devices industry due to their biocompatibility and ease of sterilization. PVC medical devices include items such as IV bags and tubing, blood bags, where flexibility and durability are of utmost importance. The polymerization of vinyl chloride enables the preparation of PVC with properties suitable for various medical applications. Also, the material’s chemical resistance offers application possibilities under highly stringent hygiene conditions. The PVC trade, furthermore, ensures that the safety of its products is monitored and that its products comply with regulations for medical use. All in all, PVC is widely used because it is so versatile and is therefore considered the first choice in many healthcare applications.

PVC recycling is a critical aspect of plastic waste management, and it also contributes to reducing environmental degradation in PVC production. Recycled PVC will be further used for construction materials and new PVC products. Collection of PVC waste, cleaning of PVC waste, and processing goes into making new raw materials in the recycling process. It is quite difficult to recycle chlorinated PVC because of its high chlorine content which, on being processed, may generate toxic byproduct. However, the recycling technologies are rapidly advancing, rendering PVC recycling more efficient and safer to review. Promoting PVC recycling shall be a relevant, agreed-upon sustainable effort in which industries can also contribute and reduce the use of virgin PVC resin.

PVC comes in two varieties: rigid and flexible. Due to its strength and durability, rigid PVC is used in construction, including pipes, siding, and window frames. Flexible PVC is plasticized and used in insulation and medical devices, where flexibility is indispensable. In addition, where a more robust material is desired, unplasticized PVC is used. PVC can thereby impart different properties when blended with other polymers or additives, producing PVC compounds for numerous applications. PVC is therefore versatile and can be synthesized in various forms depending on the application.

Owing to its low cost, versatility, and durability, PVC is the third-most widely produced synthetic plastic in the world. Given the abundance of raw materials, the production of PVC is considered economically beneficial during the polymerization of vinyl chloride, PVC particles form, which are then converted into various products. PVC is in high demand due to its many applications, from construction materials to medical devices. The presence of additives gives an opportunity to modify the PVC, imparting with properties of choice, which is great for the industries working with those particular modifications. Essentially, these factors combined place PVC at the forefront on the thermoplastic sector worldwide.