Polypropylene (PP), a thermoplastic polymer in pellet form, is considered a forerunner in sustainable product design. This polymer, with its unique combination of strength, chemical resistance, and recyclability, serves as a sort of precious material for manufacturers willing to lessen their environmental impact. This guide offers an analysis of the polypropylene pellets, including their characteristics, advantages, and varied applications. We will look into how this material supports sustainable design, from its truly environmentally friendly attributes to their practical application in producing tough, hard-wearing products. Processing methods and recycling systems and their comparison to the common plastics will be considered as well. Understanding the breadth of capabilities of polypropylene will enable product designers and manufacturers to choose accordingly in respect of functionality and sustainability.

Understanding Polypropylene Pellets

What are Polypropylene Pellets?

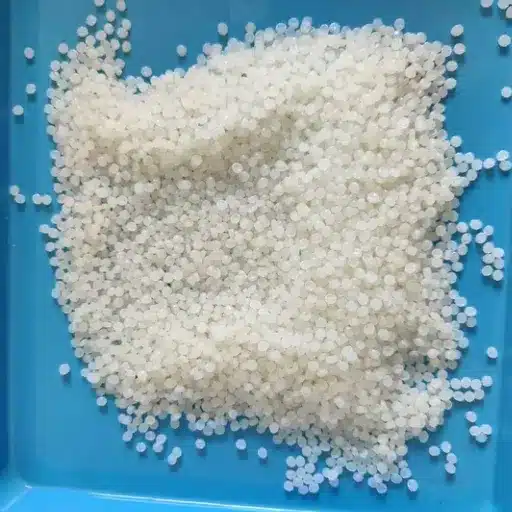

Polypropylene pellets are small thermoplastic polymer granules with cylindrical, spherical, or near-spherical geometries. Olefin resin is produced by polymerization of propylene gas, a byproduct of crude oil refinery. The resultant polymer is then melted, extruded through dies, and cut to a uniform size of pellets. It in this standard form that it is easily transported, stored, and processed, thus allowing it to be a convenient raw material for several manufacturing techniques, primarily injection molding and extrusion. These pellets are melted and molded into goods that can be re-melted again from time to time, which makes it a recyclable material.

Properties of Polypropylene

Polypropylene has its own set of properties that make it suitable for almost every application out there. These are the very features that make it useful in sustainable product design.

Chemical Resistance

It resists a wide range of chemicals, including acids, alkalis, and organic solvents, making it suitable for some containers, chemical storage tanks, and laboratory equipment.

Low Density

Polypropylene has a density of about 0.895 to 0.92 g/cm³, which puts it on the lighter side for commodity plastics. Because of its low weight, Polymer is fuel efficient in automotive applications and cost-reducing in the shipping of packaged goods.

High Melting Point

Polypropylene melting point is somewhat high at approximately 160-170°C (320-338°F), so it can be used for applications that need to resist heat, such as microwaveable containers and medical devices that undergo steam sterilization.

Fatigue Resistance

Demonstrates excellent resistance to fatigue; that is, it can sustain repeated stress and bending without cracking. This makes it ideal for living hinges found on products such as flip-top caps and storage containers.

Electrical Insulation

Polypropylene lacks a conducting ability, hence rendering it a good insulator, which is why it is considered a safe choice for the housing of electronic components and cable insulation.

Different Types of Polypropylene Pellets

One type of polypropylene is never simply called such. The term covers a variety of grades that differ on design to meet the specifications of particular performances. There are basically two varieties:

Homopolymer Polypropylene (PPH)

This is the immensely popular general-purpose grade. It is produced from propylene monomer alone and is considered to have a high strength-to-weight ratio and stiff characteristics. Packaging, textiles, and automotive parts are commonly made from PPH.

Copolymer Polypropylene (PPC)

It is manufactured by polymerizing propylene in the presence of a comonomer like ethylene. The copolymer grades are again classified into random copolymer (where ethylene is incorporated randomly) and block copolymer (where ethylene units are arranged in a regular pattern). Usually, copolymers exhibit thereby enhanced impact strength especially at low temperatures-therefore, these materials are preferred for products which need to be tougher and less brittle.

Advantages of Polypropylene in Sustainable Design

Environmental Characteristics of Polypropylene

The sustainability features of polypropylene provide some of the main reasons for its consideration for applications. It is considered one of the environmentally safer plastics because of:

♻️ Recyclability

Polypropylene is 100% recyclable. It is represented by resin identification code “5”. Recycled PP outputs can be transformed into a variety of goods including automobile parts, gardening tools, and storage bins. Recycling PP consumes less energy than producing virgin plastic, hence having a lower carbon footprint.

🌱 Lesser Carbon Footprint

The manufacture of polypropylene from propylene gas is a rather energy-efficient process compared with another polymer process such as PVC, or polystyrene. Its low density ensures that products made require lesser weight of the material, thus giving more resource-conservation.

🔥 No Toxic Releases

When burnt for energy, polypropylene releases mostly carbon dioxide and water, unlike toxic chlorine-containing compounds emitted by plastics like PVC.

Impact Resistance and Durability

Long-lasting products are naturally more sustainable, as they diminish the need for a frequent replacement. Hence, polypropylene has very high impact resistance and durability. Copolymer grades resist much impact without cracking or breaking. Due to the toughness of polypropylene, it is well suited for rough handling when making luggage, toolboxes, and children’s toys. Polypropylene by designanca prolongs a product’s working life, so waste is reduced and resources conserved.

Cross-industry Use

From the index of applicabilities, it is possible to cite the adaptability and hence use of the polymer object-a great promoter of consolidation within the matter and thus supply chains simplification. Since it is so versatile, a rare or less-lowly-recyclable material may be utilized to mankind or on a product in several ways. From sterile medical vials to rugged automotive bumpers and lightweight food packaging, PP can fine-tune and serve different technical requirements. It is commonly regarded as the foundation of modern manufacturing.

Applications of Polypropylene Pellets

Injection Molding of Polypropylene

Injection molding is considered one of the most popular ways for processing polypropylene pellets. The pellets are melted and pushed at high pressure into a mold cavity during injection molding. The material then cools and solidifies, assuming the shape of the mold. The flow properties and fatigue resistance of PP are advantageous when dealing with complex injection-molded parts, including automotive dashboards, power tool housings, and housewares.

Use Cases in Packaging and Containers

The packaging industry is one of the largest consumers of polypropylene. It finds its application in:

Food Containers

Food containers of all types, from reusable to disposable, yogurt pots, and margarine tubs require PP for its heat resistance and non-reactive nature toward food products.

Caps and Closures

Flip-top caps for bottles and jars utilize this material for its fatigue resistance.

Flexible Packaging

Polypropylene films wrapped around snacks, confectionery, and other consumer articles due to clarity, strength, and barrier properties.

Polypropylene in Toy Manufacturing

When it comes to toys, safety and durability are paramount. Polypropylene is one such toy material that is non-toxic; it is free of harmful phthalates and bisphenol A (BPA) and is able to withstand tough play. The ease of molding into difficult shapes and colorful designs creates fascinating and entertaining toy concepts.

Processing Polypropylene Pellets

Techniques for Effective Molding

Several parameters must be controlled before one can have a successful injection molding process for polypropylene:

| Parameter | Details |

|---|---|

| Melt Temperature | Generally ranging between 200°C and 250°C (392°F to 482°F), the melt temperature must be just right to provide a good flow, but if it is higher, it would degrade the polymer. |

| Mold Temperature | It is normally kept between 30°C and 80°C (86°F and 176°F). A warmer mold temperature can help the part surface finish and reduce internal stresses, while a cooler mold temperature results in shorter cycle times. |

| Injection Pressure and Velocity | The conditions should be set such that the mold is completely filled with no possible occurrence of flash or sink mark formation. |

Storage and Handling of Polypropylene Pellets

Polypropylene pellets are hygroscopic-heavier, said that they absorb moisture in vapour form from an atmosphere, but lesser than, say, nylon. These pellets should be stored in a dry, air-tight environment to avoid any processing difficulties. If the granules have suffered any exposure to humidity, pre-drying is recommended prior to molding.

Recycling and Sustainability Practices

To increase because of the sustainable feature of polypropylene, the ideal would be to set up a closed-loop recycling system. This would constitute collecting post-consumer and post-industrial PP wastes, reprocessing them into pellets, and then reusing them in the production of new articles. Several companies now have recycled grades of polypropylene that perform almost as well as virgin ones, which is a real opportunity to shift towards a circular economy.

Comparing Polypropylene with Other Plastics

Polypropylene Against HDPE

HDPE is yet another utilitarian recyclable plastic. While both have excellent chemical resistance, the level offered by the plastics is different: Polypropylene has a higher melting temperature and modulus and has greater fatigue resistance. Hence, polypropylene is used more for heat-resistant applications where mechanical integrity are of concern, such as automotive components and reusable containers. At least at very low temperatures, HDPE has better impact strength.

Cost-Effectiveness of Polypropylene Pellet

Polypropylene is the cheapest commodity resin available. With its raw material having the cheapest cost and low density, the polymer offers a high cost-efficiency to manufacturers (because more parts are needed per pound of material). This price advantage offers companies to adopt a more biological material without bearing a prohibitive cost.

Performance-as-Selling-Points Over Other Resins

Polypropylene provides the perfect trade in-between properties when set against other engineering resins such as ABS or PC, and all at a very low price. It is not that it could be higher in impact strength than a PC or higher in gloss than ABS, but often in terms of chemical resistance, durability, and processability, this is the most commercially feasible and sustainable option in many applications. Find more info now.

Reference Sources

Frequently Asked Questions (FAQs)

What are polypropylene pellets and their properties?

These small plastic granules, which exhibit highly thermoplastic properties, are called polypropylene pellets. They enjoy a reputation as incredibly polyvalent, used for packaging and automotive parts. Because of its low density (approximately 2 pounds/cubic foot), it is very light. It provides excellent impact and chemical resistance, making it suitable for applications across various industries. The melt temperatures of typical polymers allow processing by injection molding.

Injection molding uses polypropylene pellets as raw materials.

Polypropylene pellets are used in injection molding applications due to their favorable characteristics. The molten drop-in system is injected into a die, where it cools and solidifies into the desired shape. The smooth-flowing nature of polypropylene during processing helps minimize warpage in the produced articles and maintain uniformity. Manufacturers choose polypropylene largely because of its low density and weight, making it ideal for lightweight items. This thermoplastic is also environmentally friendly and can be recycled.

What is the weight of polypropylene pellets?

The weight of polypropylene pellets can vary in accordance to the particular type and formulation used. Generally, the pellets are said to have a density of about 0.9 g/cm³, or about 2 lb per cubic foot. Polypropylene is packaged in bags weighing more than 10 lbs, making it suitable for industrial applications. The lightweight nature of these pellets prevents manufacturers from incurring hefty shipping charges, thereby making handling and overall production costs more competitive. The weight of the pellets must be known to calculate the required materials for various applications.

What are some common applications of plastic pellets?

Artificial resins are marketed mainly in pellet form to the plastics industry, which uses these raw materials to manufacture various products. The industrial purposes are extraordinary. For instance, in the automotive industry, these pellets are used to produce components such as dashboards and bumpers, mainly because of their high durability and impact resistance. Packaging materials such as containers, trays, and bags, all of which maintain an excellent balance between strength and lightness, are also formed from these pellets. Other products that are called for include toys and household articles, which again demonstrate the versatility of polypropylene. By understanding the properties of thermoplastic pellets, one can study how to modify them to suit a wide range of manufacturing needs.

How do manufacturers ensure the quality of polypropylene pellets?

The quality of polypropylene pellets is ensured with testing and quality control procedures. These tests assess mechanical properties important for pellets, such as impact resistance and flow characteristics, ensuring that the pellets’ properties meet particular application requirements relative to industry standards. Further, uniformity in size and shape is essential, as irregular pellets could hamper the molding process. Another factor affecting pellet stability and performance is the use of high-quality raw materials and appropriate processing considerations. Regular audits and certifications ensure further reliability and performance of pellets produced for the given applications.

So are these polypropylene pellets green?

Polypropylene pellets are considered eco-friendly due to their recyclable nature and lower environmental impact compared to other plastics. More and more manufacturers are adopting greener operations by producing polypropylene from recycled materials, thereby reducing waste. The resistance to chemicals and low density of polypropylene make it a worthy option from the performance standpoint when it comes to its utilization so that not much material goes into its use. Also, since these are lightweight pellets, energy consumption during transportation is reduced. Being a thermoplastic polymer, it can be melted, and from that melt, it can be remolded for an application, thereby preventing any plastic from entering Earth’s environment.