Widely known as acetal or Delrin, Polyoxymethylene (POM) is one of the most commonly used thermoplastics due to its strength, rigidity, and low friction. As a result, POM is an essential material in the automotive and consumer electronics industries. What makes POM such a versatile and functional material? This guide aims to answer questions regarding its properties, the processes involved in manufacturing it, and the wide range of uses it supports. It does not matter whether you’re an engineer looking for reliable materials for precision pieces or a designer looking for sturdy plastic; this guide is dedicated to everything ‘POM’. Get ready to learn more about how the high-performance polymers revolutionize modern innovations.

What is POM and why is it Important in Plastics?

Also, Polyoxymethylene (POM) or acetal is a highly sought-after engineering material due to its high-performance characteristics. Polyoxymethylene has low friction, good strength, and high resistance to bending, making it essential in fabricating precise components. Furthermore, acetal has exceptional resistance against moisture and temperature, making it a crucial material for producing gears, bearings, and fasteners. In addition, its ability to endure continual pressure makes it an integral part of the automotive, electronics, and other consumer goods industries.

Definition and Overview of POM

Polyacetal or acetal is one of the most widely used polymers, and Polyoxymethylene (POM). This type of engineering thermoplastic can easily blend with other types of plastic. It is known for its mechanical strength, excellent stiffness, and superior dimensional stability. Moreover, polymers are highly resistant to absorbing chemicals, hydrating, or even fatigue. This makes them ideal for dynamic use in high-friction zones.

Some other industries where POM can be utilized are medical, aerospace, consumer goods, and automotive. Self-locking POM is used for levers and snap fits in furniture. This is because of its superior strength and light weight. In addition, POM polymers have low friction and strong insulating features, allowing them to be used in switches and connectors. The material is also used for medical-grade components and food-grade utensils. That enhances the durability and reduces the strict needs of patients and food. This broad range showcases POM’s functionality in current and advanced manufacturing designs. It can also be used for multifunctional parts in automotive construction aid.

Key Advantages of POM Plastic

- High Strength and Durability: I value POM plastic for its exceptional strength-to-weight ratio, which provides reliable performance in demanding applications.

- Low Friction and Excellent Wear Resistance: I rely on POM for components where friction and wear are critical concerns, such as gears and bearings.

- Dimensional Stability: Its ability to maintain precision under varying temperatures and loads makes POM indispensable for high-tolerance parts.

- Chemical Resistance: I appreciate that POM resists solvents and chemicals, enabling its use in harsh environments.

- Regulatory Compliance: The material meets industry standards for food and medical applications, ensuring safety and versatility across different sectors.

Comparison with Other Engineering Plastics

When comparing POM to other engineering plastics such as Nylon (Polyamide) and Polyethylene Terephthalate (PET), notable distinctions emerge regarding mechanical properties, environmental adaptability, and application scope.

- Mechanical Properties: POM exhibits higher stiffness and superior dimensional stability than Nylon, making it more suitable for precision components like gears and valves. Nylon offers better toughness and impact resistance, which is ideal for shock-absorbing parts.

- Moisture Absorption: Unlike Nylon, which tends to absorb moisture and swell, POM boasts negligible hygroscopicity. This characteristic ensures consistent performance in high-humidity environments without compromising dimensional accuracy.

- Thermal Performance: While PET surpasses POM in heat resistance, with a higher continuous-use temperature threshold, POM’s thermal stability is more than sufficient for most engineering applications, striking a balance between performance and cost.

- Chemical Resistance: POM and PET demonstrate excellent resistance to solvents, fuels, and oils, yet Nylon may be prone to degradation from certain chemicals, particularly acids and alkalis.

- Wear and Friction: POM leads in low-friction applications due to its self-lubricating properties, outperforming Nylon and PET in scenarios requiring smooth, low-noise motion.

Overall, POM’s unique combination of properties makes it a versatile option. It excels in specific environments where precision, low moisture absorption, and wear resistance are critical while balancing cost-effectiveness compared to higher-end engineering plastics.

What are the Mechanical Properties of POM?

Polyoxymethylene (POM) exhibits excellent mechanical properties, making it ideal for various engineering applications. Key properties include:

- High Tensile Strength: POM demonstrates strong resistance to pulling forces, enabling it to endure significant mechanical stress without deformation.

- Good Stiffness: It provides rigidity, allowing components to retain their shape under load.

- Low Friction and High Wear Resistance: POM reduces surface wear in moving parts, making it efficient for smooth-motion applications.

- Impact Resistance: It can absorb mechanical shocks, improving durability in demanding conditions.

- Dimensional Stability: POM maintains its structural integrity even under varying temperatures and environmental conditions.

These mechanical properties ensure POM’s suitability for precision parts, particularly in automotive, electrical, and industrial sectors.

Strength and Durability of POM

Polyoxymethylene (POM) ‘s durability and mechanical performance are unrivaled. POM maintains its structural integrity under mechanical load without deformation thanks to its fatigue-resistant tensile strength. For example, POM possesses a breakage elongation of twenty to forty percent, varying by grade, showcasing exceptional endurance and fatigue resistance.

Due to its aided crystalline molecular structure, POM exhibits resistance to deformation under continuous loads, giving it superior stability over prolonged periods. Additionally, POM does not deteriorate easily in harsh or extreme conditions, as it is resistant to many chemicals, oils, solvents, and fuels. This makes it the ideal candidate for automotive appliances, including but not limited to gears, bushings, fuel system components, and consumer electronic devices, which require sustained reliability and precision during diverse operational workloads.

Dimensional Stability of POM Plastic

Polyoxymethylene (POM) plastic maintains its dimensional stability due to its low moisture absorption rate, which is usually less than 0.2% at saturation and standard conditions. This ensures no significant swelling or distortion, even in highly humid or submerged conditions. POM also demonstrates a low coefficient of thermal expansion (CTE), which minimizes the risk of size alteration within the range of -40°C to 120°C. For these reasons, POM is preferred for precision-engineered components that require tight tolerances.

It is also unrivaled among other thermoplastics in long-term creep resistance. This, combined with its excellent thermal stability, allows POM to maintain its dimensional consistency when subjected to constant mechanical load at different temperatures. All these reasons make POM exceptionally reliable in demanding applications like automotive, aerospace, and industrial manufacturing, where stable and precise dimensions are crucial for safety and usability.

Low Friction Properties and Their Benefits

One of the most essential attributes of polyoxymethylene (POM) is its naturally self-diminishing low coefficient of friction because of the molecular structure. That enables less resistance between two surfaces in relative movement, thus minimizing damage and energy loss. Such characteristics are essential in dynamic applications like conveyor systems, bushings, or gears, where efficiency and durability significantly matter. This is further enhanced by POM’s self-lubricating ability, which improves performance in sealed mechanical systems or food-grade applications where external lubrication is difficult. Unlike materials such as nylon and polyethylene, POM performs better in dry and lubricated conditions, guaranteeing maximum operational output and longevity of the system’s components. Due to these characteristics, POM is widely adopted in application fields that need precision and sustained reliability.

What are the Applications of POM in Various Industries?

Polyoxymethylene (POM) is utilized across numerous industries due to its strength, stiffness, and excellent dimensional stability.

- Automotive Industry: POM is commonly used in fuel system components, gears, and interior mechanisms where durability and precision are critical.

- Electronics: Due to its insulating properties and resistance to heat, it is used in high-performance connectors, switches, and housings.

- Consumer Goods: POM is found in household appliances’ zippers, fasteners, and small precision parts because of its long lifespan and wear resistance.

- Medical Applications: Its biocompatibility and ease of sterilization make it suitable for insulin pens, dental instruments, and surgical components.

- Industrial Machinery: POM produces bushings, bearings, and conveyor components, ensuring smooth operation and reduced maintenance needs.

These applications highlight POM’s versatility and role in enhancing product performance across diverse sectors.

Use of POM in the Automotive Industry

Polyoxymethylene (POM) is very important in the automotive industry due to its remarkable mechanical attributes and resistance to mechanical wear, which gives it an advantage in precision engineering tasks. It is extensively used in POM to manufacture fuel system components, gears, electrical connectors, and handles for the interior of the vehicles. Furthermore, its low frictional coefficient and high stability lessen the degree of wear and tear even in high-stress or high-temperature situations, which enhances the vehicle’s lifespan while reducing the expenses related to vehicle maintenance.

Moreover, the material’s ability to resist harsh chemicals makes it impervious to fuels, oils, and other automobile fluids, which is important for the functionality of the engines and fuel delivery systems. POM is a growing usage trend due to its strength-over-weight advantage compared to other materials. This results in increased fuel efficiency and reduced adverse environmental impact, which illustrates the role of POM in innovation and sustainability in the automotive industry.

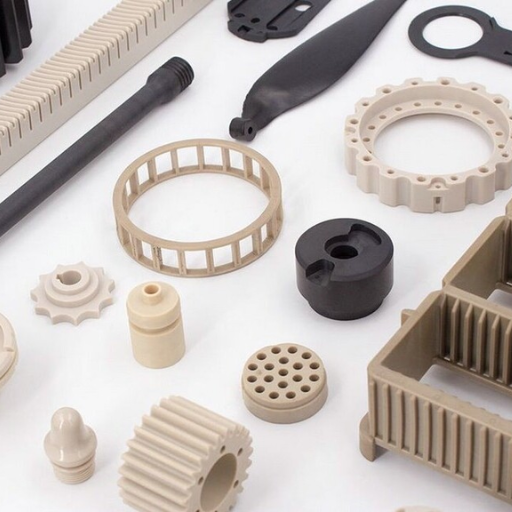

Applications in Precision Parts Manufacturing

Polyoxymethylene (POM) is widely used in manufacturing precision parts due to its exceptional dimensional stability, low friction coefficient, and high resistance to wear. These properties make it suitable for applications that require high precision and reliability over extended operational lifespans. Below is a detailed list of specific applications where POM demonstrates its superior performance in precision parts manufacturing:

- Gears and Cogs

POM’s low friction and high wear resistance make it ideal for producing gears and cogs in the automotive and consumer electronics industries. Its ability to maintain tight tolerances ensures smooth operation and reduced mechanical noise.

- Bearings

The self-lubricating properties of POM reduce the need for external lubrication, which is critical for bearings in mechanical systems. This feature extends the product’s lifecycle while lowering maintenance costs.

- Electrical Connectors

POM’s excellent dielectric properties allow it to perform effectively in high-precision electrical components, such as connectors and sockets, where durability and safety are paramount.

- Snap-Fit Assemblies

Superior tensile strength and resistance to creep make POM a preferred material for snap-fit components, particularly in applications where repetitive assembly and disassembly are expected.

- Valve Components

POM’s chemical resistance and dimensional accuracy are crucial for valve components in applications such as fluid control systems, ensuring leak-proof operation and longevity.

- Automotive Clip Fasteners

Lightweight clip fasteners manufactured with POM contribute to reducing overall vehicle weight, improving fuel efficiency while offering excellent retention strength under variable temperatures.

- Medical Device Components

POM meets regulatory requirements for specific medical-grade applications, making it suitable for precision medical device components such as inhaler mechanisms or surgical instrument handles.

- Escapement Mechanisms in Watches

The combination of POM’s hardness and wear resistance ensures durability in escapement mechanisms, a critical part of watch timekeeping.

- Consumer Goods

High-precision consumer goods like zippers, buttons, and fittings often rely on POM for its strength, lightweight nature, and resistance to wear and chemicals.

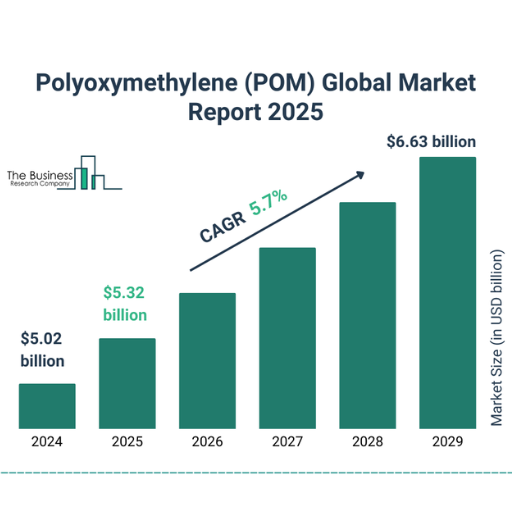

The consistent performance of POM across these diverse applications is supported by its underlying material properties, which enable manufacturers to achieve production efficiency and meet stringent quality standards. According to market studies, the global market for POM in precision component manufacturing is expected to grow by approximately 5.3% annually, driven by the increasing demand for high-performance engineering plastics. This trend underscores POM’s critical role in advancing industrial precision and sustainability.

Other Industries Utilizing POM Products

Polyoxymethylene (POM) is adaptable in other areas besides electronics, medical devices, and automotive engineering. For example, the aerospace industry uses the material’s excellent strength-to-weight ratio and dimensional stability to construct parts like gears, bushings, and fuel system components, which require high precision alongside low weight. Moreover, the consumer goods industry applies POM in manufacturing zippers, latches, and high-performance appliance parts because of its fatigue resistance and low friction.

Due to its chemical resistance and superb mechanical properties, the construction industry uses POM in plumbing fixtures, valves, and precision fittings. In industrial machinery, POM is commonly used in conveyor belts, bearings, and chain links, where harsh operating conditions require exceptional durability and smooth motion for optimal system efficiency. POM’s great versatility makes it a high-performing polymer that meets the demanding requirements across various industrial sectors.

What Makes POM a Preferred Material in Engineering?

POM is often used in engineering because it offers a unique combination of strength, rigidity, and low friction that facilitates the use of high-precision components. Furthermore, POM has remarkable resistance to dimensional changes and wear, providing successful operation in demanding applications. It is also highly resistant to chemicals and moisture, which increases its lifespan in different environments. Because of these attributes, POM stands out as a reliable material in many engineering fields.

Properties of POM that Benefit Engineering Applications

- High Mechanical Strength and Stiffness

POM’s mechanical properties include a tensile strength typically ranging from 60 to 70 MPa and a flexural modulus of approximately 2,500 MPa. These characteristics make it suitable for applications requiring components that can withstand substantial mechanical loads without deformation or failure.

- Low Friction and Excellent Wear Resistance

Due to its low coefficient of friction (approximately 0.1-0.3 depending on the counterpart material), POM is ideal for moving parts such as gears, bearings, and sliders. Its wear resistance ensures long-lasting performance even in high-friction environments.

- Exceptional Dimensional Stability

POM exhibits minimal thermal expansion with a coefficient of linear thermal expansion of around 100 x 10⁻⁶/°C. This property allows it to maintain precise dimensions over a wide temperature range, typically from -40°C to 100°C, enabling usage in high-precision engineering applications.

- Chemical and Moisture Resistance

POM is highly resistant to most chemicals, including fuels, solvents, and oils, while absorbing minimal moisture (approximately 0.2-0.35% in standard conditions). This makes it highly durable in harsh environments, such as industrial machinery or automotive components exposed to corrosive substances.

- Excellent Creep Resistance

Due to outstanding creep resistance, the material responds well to prolonged stress without significant deformation, particularly at room temperature and under moderate loads. This is especially critical in load-bearing parts that require long-term dimensional accuracy.

- Good Electrical Insulation

With a high electrical resistance and a dielectric constant of 3.7-3.9 (at 1 MHz), POM is an effective insulator in electrical and electronic components, ensuring safe and reliable functionality.

- Thermal Resistance

POM retains mechanical integrity under moderate heat conditions, with a melting point of approximately 175°C. It can operate efficiently within its temperature range and is suitable for applications exposed to occasional high temperatures.

- Lightweight Composition

With a density of about 1.41–1.43 g/cm³, POM offers a high strength-to-weight ratio, making it an effective alternative to metals in various lightweight engineering designs without compromising structural performance.

These detailed properties demonstrate why POM remains a critical material in automotive, aerospace, electronics, and consumer goods industries. It provides robust performance and reliability across diverse applications.

Understanding POM as an Engineering Thermoplastic

Polyoxymethylene, or POM, an engineering thermoplastic, has been found to exhibit remarkable mechanical characteristics, making it suitable for precision parts. It has high tensile strength, which on average is from 60 up to 70 MPa, accompanied by high strains at failure, meaning that it can take up considerable stresses without failing. This material stiffness is also described as having a modulus of elasticity of about 2600 – 3100 MPa and dominates under mechanical stress.

Also, POM has low friction coefficients between 0.1 and 0.3, significantly reducing wear in gears, bearings, and other sliding parts. The material also has remarkable resilience over a wide temperature range, from -40°C to 120°C, providing stability and operational effectiveness in harsh conditions. These precision features enable POM to outperform applications needing sustained structural integrity and mechanical reliability, especially in dynamic or high-performance environments.

How is POM Manufactured and Processed?

Polyoxymethylene is produced primarily through the polymerization of formaldehyde, including trioxane. It begins with the manufacturing of formaldehyde, which is then further chemically transformed into a polymer. After creating polymer chains, they undergo a stabilization phase to improve their chemical and thermal resistance.

POM can be processed using two methods: initial extrusion or injection molding. Both methods allow precision part fabrication and ensure appropriate size scaling. The material is heated to a specific melting point in both processes, where it is further shaped and solidified while controlling several environmental parameters.

Different Grades of POM: Homopolymer vs Copolymer

Polyoxymethylene (POM) is obtainable in two primary grades, each differing in molecular configuration and performance traits: copolymers and homopolymers. Delrin®, for example, is a homopolymer POM that consists of a crystalline structure made solely of monomer units. This means that it possesses exceptional mechanical strength and stiffness and improved resistance to fatigue. This makes it suitable for extreme stress state demands, such as gears and bearings. However, this type of polymer does possess lower resistance towards thermal and chemical degradation when compared to copolymer POM.

Copolymer POM is made by adding comonomers, which improve its thermal stability and resistance to chemicals, powerful bases, and oxidizing agents. Because of its low tendency for porosity or degradation during processing, copolymer POM is ideal for harsher environments like automotive fuel systems and industrial chemical storage.

Two categories of POM are copolymer and homopolymer. Their use will depend on the application’s requirements. Homopolymers better serve higher strength and rigidity areas than copolymers. It is also the other way around for more chemically aggressive or thermally intense environments, as copolymers perform better there.

Standard Methods of Processing POM Plastic

POM offers extreme versatility as a plastic and can be worked with multiple techniques, with injection and extrusion molding being the most popular. Injection molding is the dominant method because it allows for creating complex, detailed parts. First, heating POM accomplishes this past its melting point, then injecting it into a pre-prepared mold. Cooling it afterwards creates a solid in the shape of the mold. This method is the best for producing medium and small parts with complicated shapes, like automotive components and fasteners.

Extrusion is preferred when producing rods and tubes since they are continuous profiles. During the extrusion process, POM’s molten state allows it to be forced through a die, producing geometrically complex shapes with desired mechanical properties. This guarantees maximum production effectiveness and meets applications needing strict tolerances.

New developments in the CNC machining of POM materials have improved the machining process for low-volume and prototyping runs. Machining targets specific areas defined by the design, thus giving POM parts a high accuracy level and a fine surface finish when treatment is needed.

Thermal degradation of the polymer can severely limit the polymer’s scope of application, which makes controlling process temperatures critical. Regarded as not very eco-friendly or safe, breaking down POM leads to the release of formaldehyde. However, proper ventilation and following set processing conditions minimize the risk while ensuring efficiency, control, and workplace safety.

What are the environmental considerations for using POM?

Polyoxymethylene (POM) is used mainly for manufacturing, processing, and disposal, contributing to environmental concerns. During manufacturing and thermal processing, POM has the potential to emit formaldehyde, a dangerous substance that leads to air pollution and poses health dangers. Measures such as proper ventilation, emission control during processing, and adherence to regulatory standards capture these emissions.

POM’s inability to be broken down biologically renders it detrimental to the environment; however, if not adequately managed, it can persist in the environment for an extended period. While recycling is limited, it is possible depending on the level of contamination and impurity present in the material. Emphasis should be directed towards achievable controlled recycling for risk mitigation while ensuring stringent waste control policy compliance to reduce environmental risks cleverly.

Recyclability of POM Plastic

The concern of Polyoxymethylene (POM) recyclability is vital for those industries focused on lessening their environmental footprint and adopting sustainable policies. The technical possibilities of POM recycling exist; however, contamination, thermal degradation during reprocessing, and a lack of proper recycling facilities pose significant challenges. Research suggests that POM mechanical recycling retains essential properties of the polymer provided that contamination levels are maintained under strict controls. As a result, post-industrial POM waste, which tends to be less contaminated than post-consumer waste, often emerges as a strong contender for recycling.

New methods, such as chemical recycling, are promising to break down polyoxymethylene (POM) for remanufacturing into new materials, potentially increasing recycling rates significantly. These approaches, however, are not widely applied because of financial and technical difficulties. Recent reports from industry indicate that international efforts towards circular polymers and strict policies in critical industrial zones are accelerating innovation for better recycling methods of POM. To enhance its recyclability, manufacturers are considering closed-loop systems and material reduction strategies that simplify separation and processing at the product’s end-of-life.

Environmental Impact of POM Production

The synthesis of polyoxymethylene (POM) has considerable ecological effects due to POM’s consumption of energy from non-renewable sources for the synthesis of methanol-formaldehyde, one of the principal precursors. The production of formaldehyde involves the oxidation of methanol, which requires very high energy from fossil fuels and leads to emissions of greenhouse gases. The polymerization process can also lead to the emission of volatile organic compounds (VOCs), which pose environmental and health hazards.

Producing one metric ton of POM consumables can create anywhere from 2.5 to 3 metric tons of carbon dioxide equivalents (CO2e), depending on the energy mix used and the technological efficiency of the manufacturing facility’s processes during the clawback period. This is indeed a worrying trend. Water usage is also essential in this context as the process includes various cooling systems and chemical reaction systems, which, if poorly managed, can result in the thermal pollution of water.

These impacts continue to be addressed with improvements in renewable energy sources for power manufacturing facilities and clean production technology. Moreover, in critical industrial areas, governments and environmental authorities are starting to impose more stringent limits on emissions, thus forcing manufacturers to adopt more advanced sustainable approaches. Although initiatives are evolving sustainable production paradigms, pursuing sustainable POM production without contemplating radical re-designs of material chemistry, energy efficiency, and waste strategies remains challenging.

What are the Future Trends for POM in the Plastics Industry?

The advancements in polyoxymethylene, or POM, suggest its future in the plastics industry will be influenced by a bio-based emphasis that seeks to lower net carbon emissions and advances in renewable resource-derived POM. Circular economies will result from improved recycling technologies capable of recovering and reusing POM, while additive innovations will enhance the material’s performance and endurance in electronics and automotive applications. Furthermore, focus on low-emission production enables regulators to enforce environmental standards without sacrificing quality. These changes reflect a shift in focus from plain sustainability towards enhanced POM functionalities.

Innovations in POM Materials

As an expert in this sector, I can corroborate these trends as I’ve observed significant changes in sustainability strategies for production alongside expanding POM select formulations. New developments include the application of advanced supplements to improve wear resistance and shape retention, especially in focused industries like automotive and consumer electronics. Bio-based sources are also being integrated into manufacturing processes to offset eco-destructive emissions. These innovations in policy are essential for POM to maintain its stable standing across multiple industries.

Emerging Applications and Markets for POM Plastic

The electric vehicle industry is poised to be one of the most significant emerging markets for electric motors due to the lightweight and highly durable components that POM (polyoxymethylene) can offer. Due to its remarkably low friction levels, high wear resistance, and mechanical properties, the use of POM plastic in battery housings, precision gears, and electrical connectors that require heat resistance and dimensional stability is growing.

In addition, the medical devices sector is now utilizing POM due to its biocompatibility and excellent machinability for inhalers, insulin pens, and surgical instruments requiring high precision and dependability. Furthermore, in the water treatment industry, POM’s chemical resistance is coming into play for valves, fittings, and flow meters exposed to harsh conditions.

The development of IoT-based smart home devices has increased the demand for POM in actuators, sensors, and other intricate devices because low friction and increased durability are essential. Coupled with the trends toward miniaturization in electronic components, POM’s unique properties make it a preferred material.

Since industries worldwide focus on improving performance, sustainability, and cost-cutting, POM plastic is becoming an important engineering and design material.

Reference Sources

-

- Published: 2017

- Key Findings: This study examined the impact of material geometries and processing methods on POM’s thermal and mechanical properties. Higher tonnage injection molding improved thermal stability and mechanical properties compared to lower tonnage or resin geometries. The study highlighted the importance of processing conditions in optimizing POM’s performance for applications like plastic gears.

- Methodology: Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC) were used to evaluate thermal stability and behavior. Samples were prepared under different injection molding conditions, and their decomposition temperatures and mechanical properties were analyzed.

-

- Published: 2012

- Key Findings: This research investigated the effect of ground material percentage on the shrinkage of injection-molded POM pieces. It found that higher ground material percentages reduced shrinkage in longitudinal and transverse directions, with transverse shrinkage being more significant. The study emphasized the role of material composition in controlling shrinkage during molding.

- Methodology: Injection molding experiments were conducted with varying percentages of ground POM material. Shrinkage was measured in longitudinal and transverse directions, and results were analyzed according to ISO 294-4 standards.

- Top POM Plastic Pellets Suppliers in China

Frequently Asked Questions (FAQs)

Q: What is POM plastic and what are its main types?

A: POM plastic, known as acetal or polyoxymethylene, is a thermoplastic material widely used for engineering applications. The two main types are homopolymer POM and copolymer POM, each having unique properties suitable for different uses.

Q: What are the key material properties of POM plastic?

A: The properties of POM plastic include excellent mechanical properties, high tensile strength, low coefficient of friction, and resistance to wear and chemicals. These properties make it an ideal plastic material for various applications.

Q: In what applications is POM acetal commonly used?

A: POM acetal is commonly used in applications that require high-performance engineering, such as automotive parts, industrial machinery, and precision components. Its durability and strength make it suitable for a wide range of applications.

Q: How is POM plastic beneficial in medical applications?

A: POM plastic material offers excellent electrical insulation properties and is resistant to sterilization, making it suitable for medical applications. Its strength and durability are crucial for components used in medical devices.

Q: Can you explain the processing of POM and how it affects its performance?

A: Processing molten POM involves techniques such as injection molding and extrusion. The way POM is processed affects its final properties, including strength, flexibility, and surface finish, which are critical for the performance of plastic parts.

Q: What are the advantages of using POM sheets in manufacturing?

A: POM sheets are versatile plastic materials that can be machined into various components. They offer excellent strength and stability, making them ideal for creating custom plastic parts for engineering projects.

Q: How does the resistance of POM compare to other plastics?

A: POM’s resistance to chemicals and wear is superior to many other plastics, contributing to its widespread use in demanding environments. This durability distinguishes POM from other common plastic materials.

Q: What should be considered when selecting POM parts for a project?

A: When selecting POM parts, consider the specific material properties required for the application, including tensile strength, temperature resistance, and the intended environment. Understanding POM plastic is essential to make an informed choice.

Q: Are there any limitations to using POM in specific applications?

A: While POM is widely used, it may not be suitable for high-temperature applications above its thermal limits or in environments with strong acids. Evaluating the specific requirements of the application is crucial to avoid potential limitations.