PPO, or polyphenylene oxide, is a thermoplastic in high demand due to its excellent mechanical, thermal, and electrical properties. It is most commonly used in industries such as automotive and electronics. Whether you’re a materials engineer or an inquisitive individual seeking to expand your knowledge of advanced plastics, this guide offers informative insights into polyphenylene oxide and its contributions to modern manufacturing.

What is PPO in the Context of Plastic?

PPO is known for its high performance as a thermoplastic due to its exceptional strength, thermal resistance, and chemical stability. Moreover, it absorbs very little water, is flame-resistant, and is consistently sized, which adds to its industrial acclaim. Along with styrene, PPO can also be combined with many other materials, which boosts its processing versatility. This makes it a top choice for industries such as electronics, automotive, and healthcare, which require consistent performance and durability.

Definition of Polyphenylene Oxide

Polyphenylene Oxide (PPO), also known as polyphenylene ether, belongs to a class of high-performance engineering thermoplastics due to its remarkable mechanical and thermal properties. As a thermal-stable and robust aromatic polymer, PPO’s skeleton is composed of phenylene rings linked together by ether (-O-) bonds. Moreover, it possesses an exceptionally high glass transition temperature of 210-230 °C, which allows for use in environments with extreme operating temperatures. In addition, water uptake is below 0.05%, and PPO has low moisture absorption, which enables it to maintain excellent dimensional stability in humid environments. PPO is truly unmatched in its moisture absorption characteristics, and, together with low water uptake, makes it superior at maintaining its dimensions, regardless of ambient humidity. Furthermore, having inherent resistance to a wide range of chemicals, such as acids and bases, ensures its suitability for diverse industrial applications.

Its flame-retardant features, without requiring excessive additives, and the ability to withstand extreme temperatures, combined with the above factors, establish durability and safety, which are essential in military domains. Toughness, ease of processing, and cost efficiency can be best met when blending PPO with other polymers such as polystyrene (PS) or polyamide (PA).

Characteristics of PPO Plastics

PPO plastics are easily recognized for their exceptional thermal stability, which allows them to endure temperature changes without losing structural integrity or performance. They have low moisture absorption, which reduces dimensional changes, ensuring the mechanical properties remain consistent even in humid environments. PPO plastics are also hydrolytically stable and resistant to degradation, thus suitable for harsh environments in the long term. Their exceptional dielectric properties make PPO outstanding for electrical components and insulation materials, especially at high frequencies.

PPO has good resistance to aqueous salt solutions and some other chemicals, expanding its use in industrial and consumer products. Modified or blended PPO retains its base features, allowing for customization to adapt and improve ease of processing, heat resistance, or other changing requirements. This, along with its low thermal and mechanical performance costs and readily available materials, makes PPO an essential material in the modern plastics industry.

Applications of PPO in Various Industries

Due to its remarkable thermal stability, low moisture absorption, and excellent dimensional stability, polyphenylene oxide (PPO) is used across various fields. In the automotive sector, PPO polymers are commonly used to fabricate housings, connectors, and under-the-hood components that encounter high temperatures and exposure to automotive fluids, due to PPO’s high-temperature resistance. Moreover, for electrical and electronic components, as well as insulating parts like circuit boards and critical equipment, PPO’s dielectric property, coupled with its flame-retardant properties, enables its use.

The extent of the material’s application also covers healthcare because its biocompatibility and resistance to sterilization processes, such as autoclaving, make it reliable for use in surgical instruments and medical devices. Its chemical resistance enables its use in laboratory equipment, healthcare-rated enclosures, and other devices. PPO’s versatility is not limited to industrial applications, but is also evident in consumer goods, where impact resistance, along with aesthetic customization, makes it applicable for durable household appliances. In summary, PPO’s mechanical, chemical, and thermal resilience bolsters cutting-edge industrial advancements.

How Does PPO Compare to Other Plastics?

What distinguishes PPO from other plastics is its remarkable balance of thermal, mechanical, and dimensional stability. PPO has greater heat resistance than polypropylene and is therefore more suited for high-temperature applications. Compared to ABS, PPO has superior chemical resistance and absorbs moisture at a lower rate, making it more durable in corrosive and humid environments. While polycarbonate has exceptional transparency, polyphenylene oxide is better suited for situations that require high structural strength under various types of strain. The combination of all these traits makes PPO reliable across industries that require high-performance materials, proving it to be highly versatile.

PPO vs. Polyphenylene Ether (PPE)

In industry, these terms are often referred to as polyphenylene oxide and polyphenylene ether due to their similarity in base polymer. The difference can be identified in the composite forms and specific uses. Generally speaking, PPO is viewed as the base polymer in its pure or slightly modified state. Its high-dimensional stability, thermal resistance, and electrical insulating qualities make it ideal for such purposes. On the other hand, PPE tends to indicate formulations or blends where the base polymer is mixed with materials such as polystyrene or nylon to boost impact resistance, processability, or even lower cost.

Thermal and mechanical properties remain key features for automotive parts and electronic components, while manufacturing and affordability improve for PPE blends with polystyrene. Nylon addition improves toughness and chemical resistance, thus expanding suitability in industrial machinery and fluid management systems. Knowing the structure tailoring of PPE and PPO is crucial to making choices for use cases. Specialized use cases, especially those that involve extreme thermal or mechanical stress, require careful selection of materials.

PPO and Its Dimensional Stability

Exceptional dimensional stability is why Polyphenylene Oxide (PPO) stands out. Because of this, people choose PPO when seeking a material for parts that need to withstand variable conditions. When it comes to moisture absorption and heat resistance, PPO performs better than others. This means there will be less expansion or contraction with changes in temperature or humidity. Reinforced grades have an HDT of over 200°C, meaning the thermal performance of PPO is much higher than most engineering plastics. The construction of Polyphenylene Oxide also ensures better thermal performance compared to many engineering plastics. Low creep under mechanical stress improves dependability in load-bearing situations. Components where engineering plastics are relied on include, but are not limited to, the automotive and electronics industries, for their precision, tolerances, and durability, thus marking the importance of PPO as a high-performance thermoplastic polymer.

Heat Resistance of PPO Compared to Other Thermoplastics

Polyphenylene Oxide (PPO) is known for its distinctive quality of unparalleled heat resistance, exceeding 200°C, due to its heat deflection temperature (HDT). PPO has greater thermal stability compared to widely used thermoplastics, such as Acrylonitrile-Butadiene-Styrene (ABS), Polycarbonate (PC), and Polyamide (PA, also known as Nylon). For example, while ABS has an HDT of 85 – 100°C, undemanding PC has a lackluster HDT of 130 – 140°C, PC’s reinforced counterparts outperform PC. As for Nylon, its thermal performance depends heavily on the grade of nylon used and peaks at 190°C for high-temperature varieties.

The unique attribute of PPO stems from its rigid polymer backbone along with aromatic groups, which limit chain movement during heating. Its mechanical properties help PPO perform exceptionally well under high temperatures, outperforming other materials in parts for automotive, electronics, and industrial machinery that experience significant thermal stresses during operation. Reinforcement with glass fibers significantly enhances the thermal stability of PPO, providing reliable solutions for components that require thermal expansion under stress.

What are the Benefits of Using PPO in Manufacturing?

PPO (Polyphenylene Oxide) offers several key benefits in manufacturing:

- Thermal Resistance: PPO maintains structural integrity and performance in high-temperature environments, making it ideal for applications exposed to heat.

- Dimensional Stability: Its low thermal expansion ensures components retain their shape even under varying thermal loads.

- Durability: PPO exhibits high resistance to wear, chemicals, and moisture, contributing to extended product lifespans.

- Lightweight Properties: Its low density reduces the overall weight of manufactured products, which is crucial for sectors like automotive and electronics.

- Enhanced Strength with Reinforcements: When combined with materials like glass fibers, PPO achieves superior mechanical strength, making it suitable for demanding applications.

These benefits make PPO a versatile and reliable choice in diverse manufacturing environments.

High Strength and Impact Resistance of PPO

Due to its strength, impact resistance, and other unique features, Polyphenylene Oxide (PPO) is widely used in high-performance applications. It boasts incredible mechanical properties. The molecular structure of PPO gives it intrinsic rigidity, ensuring it remains durable even under intense mechanical stress. Moreover, PPO demonstrates high energy absorption, which minimizes the risk of deformation or fracturing. Material Engineering has advanced a lot, and now, with the help of new fillers and reinforcements, the performance of PPO has been enhanced. Blending Glass fibers with PPO enhances its tensile strength, making it capable of withstanding extreme conditions in demanding industries, such as aerospace, automotive, and industrial manufacturing. These features ensure that components made with PPO will deliver outstanding performance when handling a large load and repeated mechanical impacts.

Flame Retardant Properties of PPO Plastics

Polyphenylene oxide (PPO) is known for its self-contained flame retarding capabilities due to its underlying chemical structure. The polymer’s thermal stability and combustibility make it suitable for uses that require rigorous fire safety regulations. Studies show that PPO provides superb resistance to ignition with low flame spread at elevated temperatures. PPO often suffers from unenhanced thermal flame retarding characteristics. To improve them, it is frequently blended with synergistic additives such as phosphorus flame retardants or brominated ones, where flammability is preserved while mechanical strength is maintained.

Also regarded as a PPO asset for harsh integrated circuit applications is its low smoke volume when burned. For electronics and electrical applications, smoke generation is crucial in areas such as circuit boards and enclosures. Comparative testing, such as UL-94, shows that with PPO, a high flame rating is possible, which increases the scope of its application in spaces with elevated fire hazards. Elevating PPO’s ranking classifies it in the best grade for trusting security, strength, and reliability rendered from minimal unplanned combustion out of enduring materials devoid of flames. Thus, it is a preferred choice for industries that consider these factors.

Electrical Insulating Properties of Polyphenylene Oxide

PPO, or Polyphenylene oxide, is an essential polymer due to its remarkable dielectric insulator properties, which are attributed to its distinct structural features and molecular electric stress. This grade of PPO is suitable for applications with minimal electricity flow and excellent thermal resistance, as well as endurance against environmental conditions. PPO usually yields dielectric constants between 2.5 and 3.0 at a given frequency, which means that electricity is not wasted and is insulated efficiently.

It is also known that PPO shows great surface resistivity in the order of ohms 10¹³ to 10¹⁵, which assists in preventing the emission of electricity or the collection of static charge. Its other unmatched features also include good thermal stability, along with these electrical insulation properties, which together allow it to function correctly under very high temperatures of 100 degrees Celsius and above. In addition, low moisture absorption results in reduced humidity-induced deterioration, protecting while also improving insulation. These features help enhance the strength, durability, and stability of polymers globally used in persistent frequency circuit boards, transformers, and connectors, making them reliable in dealing with the risks of destruction in complex electrical systems.

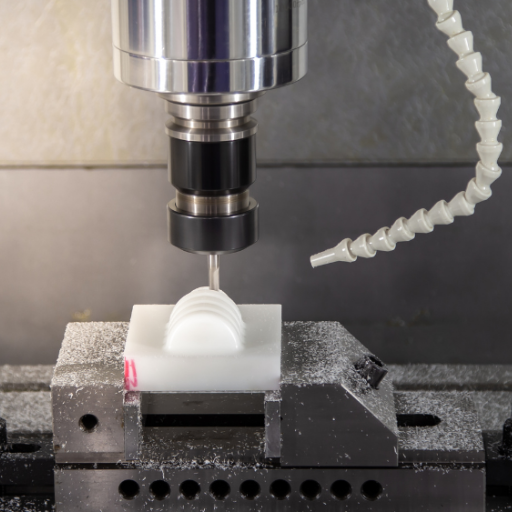

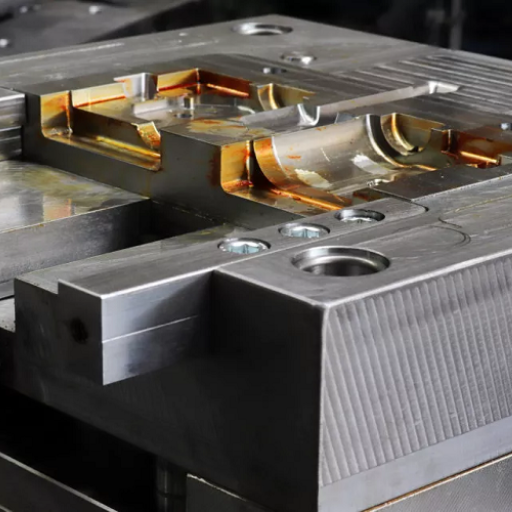

How is the PPO Processed in Manufacturing?

Generally, PPO is processed using extrusion and injection molding techniques. Often, the resin is combined with glass fibers or impact modifiers, which enhance its mechanical and thermal properties. The material is dried to eliminate moisture, which can negatively impact the performance during the manufacturing process. During extrusion, PPO is heated to a melting point where it is then formed into sheets, films, or pellets for later use. Precise and intricately detailed parts are made by first heating the material until it is pliable, then injecting it into a mold using the injection molding technique. These processes help achieve dimensional accuracy alongside maintaining a high standard of quality.

Injection Molding Techniques for PPO

In response to the Ultrasound Therapy question on injection molding techniques for PPO, I would say that injection molding for PPO begins by heating it to its melting point, which allows for more effortless flow. After it has been melted, the material is injected into a mold with a cavity of specific dimensions, under certain pressure and temperature conditions. This helps form the components intricately and accurately to size. Some of the vital points PPO molding attention includes mold temperature, high-heat-bearing materials for thermal loads, steady cycles of cooling to prevent warping of the item, and other favorable operating conditions to avoid defects. These methods are essential to the processes performed on PPO molding and improving the quality of the result.

Polymerization Process of PPO

Oxidative coupling of phenolic derivatives is admitted as the assumptive procedure, which is used for the synthesis of polyphenylene oxide (PPO). In this case, meta and para forms of phenol are used together with specific organic ligands, like 2,2’-bipyridyl. In this process, phenolic derivatives undergo oxidation to produce a more complex structure known as quinone methide. This more complex structure, also known as ‘blend’ joins to form ether bonds which makes up PPO rigid polymer backbone. The polymerization reactions change the strength of the active agent added, the reaction temperature, and finally, a decrease in the pH factor, resulting in changes to the thermal capacity and molecular weight of the polymer, which lead to measurable changes in thermal stability.

New developments in polymerization methods have included continuous processes and more sophisticated catalyst systems to improve reaction efficiency and scalability. For example, better control of oxidation-reduction cycles and the use of more sophisticated ligands enhance a polymer’s uniformity while minimizing the effects of competing secondary reactions, such as chain termination or branching. The PPO products are well-known for their remarkable thermal stability, chemical resistance, and dielectric properties, which make them suitable for long-term use under severe conditions.

Use of Additives in PPO Manufacturing

Additives significantly improve the performance and manufacturability of materials used in PPO production. Some of the most common additives are stabilizers, flame retardants, plasticizers, and reinforcing fillers. Stabilizers containing hindered phenols and phosphites are added to PPO to inhibit oxidative degradation during processing, thereby extending the polymer’s life. Flame retardants, consisting primarily of bromine compounds or phosphorus substitutes, increase the material’s ability to resist flame and fire, all while maintaining essential fire safety requirements.

To augment flexibility and reduce the glass transition temperature of PPO, making molding and extrusion easier, plasticizers are added. Meanwhile, glass fibers acting as reinforcing fillers improve the mechanical strength, impact resistance, and dimensional stability of the polymer, resulting in parts that can endure severe mechanical forces. These compositions are carefully tailored to be PPO matrix compliant, dielectric, and thermally stable. The careful selection and proportions of additives determine how the polymer performs, which highlights the complexity of formulating advanced PPO designs.

Can PPO be Recycled?

Despite PPO (Polyphenylene Oxide) possessing high-performance qualities and specific uses, it can be recycled, albeit it is a complex procedure. Recyclable PPO can be processed mechanically, chemically, or shredded, meaning it can be altered for reuse or broken down into simpler materials for reuse. Regardless of how it’s done, the process is only feasible if facilities are available, the level of contamination isn’t too high, and there are no economic restrictions. Effective recycling strategies for PPO are still in progress, marking a key area for sustainable development.

Recycling Methods for Polyphenylene Oxide

If I were reviewing recycling strategies for Polyphenylene Oxide (PPO), I would primarily focus on two methods— mechanical and chemical recycling. Mechanical recycling is a process where the chemical structure of a substance remains unchanged, allowing methods such as grinding or shredding to be used to reprocess PPO into usable materials. Chemical recycling is defined as breaking down polymers into their basic building blocks, known as monomers, or other constituents, which can be used to make new products. In this case, I would highlight the importance of ensuring that collected PPO is uncontaminated, as well as economically reasonable, and setting up scalable recycling systems.

Environmental Benefits of Recycling PPO

The recycling of Polyphenylene Oxide (PPO) offers substantial advantages in improving the environment through waste reduction, material extraction, and emission reduction. One advantage is the decreased dependency on primary, unrecycled materials, since the production of PPO creates its feedstock from recycled PPO materials. Moreover, it has been established that recycling PPO reduces the quantity of polymer waste in landfills, plastic decomposition hazards in the environment over time, and the degradation of ecological resources, which pose long-term risks. Chemical recycling and other advanced methods of recycling ensure that the protective properties of PPO, such as thermal stability and mechanical superiority, are preserved after multiple uses. Moreover, the carbon emissions of industrial systems is decreased significantly due to lesser energy consumption for the production of recycled polyphenylene oxide compared to new polymer materials. Efforts concerning strategic approaches to waste utilization, resource efficiency, and rearranging their components hinder the achievement of sustainable development.

Challenges in Recycling PPO Plastics

One of the main problems I face when trying to recycle PPO plastics is the high melting point of the polymer, which makes it hard to process and requires sophisticated technologies. Furthermore, additives or contaminants in PPO waste streams could create additional challenges and require adequate sorting and preprocessing. In my experience, maintaining the proper mechanical and thermal characteristics of the polymer during recycling is just as problematic, especially considering the damage that can be inflicted on the material due to its multiple life cycle stages. Often, difficulties of this nature must be dealt with using novel approaches. Material recuperation usually requires protective measures against alterations to the predetermined design and strict scrutiny before and including the finishing stage.

What Industries Utilize PPO?

Polyphenylene oxide (PPO) is utilized across several industries due to its high thermal stability, mechanical strength, and electrical insulating properties. Key industries include:

- Automotive: Used in components like instrument panels, under-hood parts, and structural elements due to its heat resistance and durability.

- Electronics: Commonly applied in insulation for wires, connectors, and printed circuit boards, thanks to its excellent electrical properties.

- Healthcare: Applied in medical devices and components such as surgical instruments, where chemical resistance and sterilization compatibility are essential.

- Industrial Equipment: Used in various machine parts and housings that require resistance to wear and high temperatures.

These properties make PPO a versatile material for demanding applications across diverse sectors.

Automotive Applications of PPO

Polyphenylene oxide (PPO) has a wide range of uses in the automotive industry due to its unique combination of thermal, mechanical, and electrical insulation properties. One of its most widely used subsets is automotive lighting products and accessories, which include headlamp housings where the polyphenylene oxide material must exhibit reliable performance during extensive and severe heating cycles that last over prolonged durations. Moreover, PPO is widely used in the manufacturing of instrument panels and the faceplates of electric motors due to its remarkable stability in terms of dimensions and resistance to high temperatures, which is vital for the reliability and accuracy of safety systems in automobiles.

The lightweight characteristic of Polyphenylene Oxide (PPO) offers additional benefits in the automotive field, as it increases fuel efficiency and reduces emissions by further reducing the vehicle’s weight. PPO’s industrial applications include power trains and fluid reservoirs due to its chemical resistance. Moreover, the ability to PPO with other materials, like HIPS, allows for meeting other design performance requirements while keeping expenses manageable. All of these traits expand the possibilities for modern automobiles in terms of efficiency, ruggedness, and eco-friendly design.

Use of PPO in Electrical Components

Electrical parts need durable materials such as dielectric, thermal, chemical, and moisture-resistant. These materials serve as prerequisites for the components and insulators, such as circuit breakers, of modern machinery and appliances. Due to its unrivaled qualities, Polyphenylene Oxide (PPO) is widely used for these applications. In addition, the low coefficient of thermal expansion (CTE) of PPO increases the durability for modern technology, serving as an asset for high-precision electrical components.

Moreover, the material shows excellent retardation of flame spread and meets the critical safety requirements for the electrical industry. PPO has also improved its mechanical strength and electrical insulation properties, with little increase in weight, when combined with reinforcing fillers or advanced polymers. Its flexibility is even applicable to miniaturized components, where space is limited. These attributes highlight the reason why PPO is crucial in engineering electrical systems and developing dependable, durable electrical devices.

PPO in Engineering Plastics and Industrial Goods

Served as a polyphenylene oxide, PPO is a high-performance engineering plastic due to its unparalleled thermal stability and dimensional accuracy, making it an invaluable asset for industrial purposes. Its mechanical integrity helps it withstand higher temperatures, which is necessary during the manufacturing of various automotive fuel system components, including pumps, housings, and any fluid containment system. Usually, prolonged use of PPO is not economical, so it’s best blended with other polymers, such as polystyrene or polyamide, that offer good processability and toughness unmatched by lower polymers.

In industrial goods, PPO is widely used for producing sophisticated components where precision, minimal weight, and strength are critical. Electrical and electronic enclosures, connectors, and insulation devices require it for their dielectric properties and low moisture absorption. New developments in materials science indicate an increased use of PPO due to advanced manufacturing processes, such as injection molding and 3D printing, which help meet strict performance requirements across various industries. These technologies establish PPO as a primary component for the construction of low-weight, dependable, and high-strength industrial solutions.

Reference Sources

-

Preparation and Properties of PA10T/PPO Blends Compatibilized with SEBS-g-MAH

- Key Findings: This study explored the blending of Polyphenylene Oxide (PPO) with PA10T using SEBS-g-MAH as a compatibilizer. The blends demonstrated improved dielectric properties, reduced water absorption, and enhanced mechanical strength. The addition of PPO significantly reduced dielectric loss and improved impact strength.

- Methodology: The research involved melt blending of PA10T and PPO with SEBS-g-MAH, followed by characterization using techniques like SEM, DSC, and TGA.

-

Effect of the Flame Retardants and Glass Fiber on the Polyamide 66/Polyphenylene Oxide Composites

- Key Findings: The study investigated the flame retardancy and mechanical properties of PA66/PPO composites. The addition of flame retardants, such as aluminum diethylphosphinate and red phosphorus, improved flame resistance but reduced mechanical properties. Glass fibers were added to counteract this reduction, enhancing both tensile and impact strength.

- Methodology: The composites were prepared using extrusion and injection molding, and their properties were analyzed using LOI, UL-94 tests, and scanning electron microscopy (SEM).

-

- Key Findings: This research focused on the biodegradation of e-waste plastics, including PPO-containing blends, using bacterial strains. The monoculture Pseudomonas aeruginosa strain PE10 showed consistent efficacy in degrading e-waste plastics, while a bacterial consortium demonstrated progressive improvement over time.

- Methodology: The study employed FTIR, SEM, and thermal analysis to evaluate the structural and thermal changes in e-waste plastics after biodegradation.

- Top PPO Plastic Pellets Suppliers in China

Frequently Asked Questions

Q: What is PPO in the context of plastics?

A: PPO stands for Polyphenylene Oxide, which is a high-performance polymer known for its excellent dimensional stability and mechanical properties.

Q: How does PPO compare to polystyrene in terms of properties?

A: Unlike polystyrene, which is more brittle, PPO exhibits better impact strength and heat resistance, making it suitable for applications requiring durability and stability.

Q: Is PPO a copolymer or a homopolymer?

A: PPO is typically used as a blend or copolymer with other materials, such as polystyrene, to enhance its properties, including chemical resistance and absorption characteristics.

Q: What are the applications of PPO in the automotive industry?

A: PPO is used in automotive parts due to its high heat resistance, low water absorption, and excellent dielectric properties, which ensure reliability under various environmental conditions.

Q: Can PPO be modified for specific uses?

A: Yes, PPO can be modified or blended with other resins, such as polyamide, to create materials with enhanced thermal and mechanical properties tailored for specific applications.

Q: What is the glass transition temperature of PPO?

A: The glass transition temperature of PPO is relatively high, which contributes to its high-temperature stability and makes it suitable for applications that experience a wide temperature range.

Q: How does PPO perform under UV exposure?

A: PPO exhibits good UV resistance, which helps maintain its properties and appearance when exposed to sunlight, making it a suitable choice for outdoor applications.

Q: What are the advantages of using PPO over other thermoplastics?

A: PPO offers several advantages, including low water absorption, excellent chemical resistance, and good dimensional stability, which are critical for high-performance applications in various industries.

Q: What role do fillers play in modifying PPO?

A: Fillers can be added to PPO to improve specific properties such as density, impact strength, and thermal stability, allowing the material to be customized for particular applications.

Q: Are there any considerations when machining PPO?

A: When machining PPO, it’s essential to consider its heat distortion characteristics and use appropriate cutting speeds and tools to prevent damage to the material.